ASTM E8 tensile testing is fundamental to engineering materials, being the base test for metals in mechanical properties and strength. Researchers, engineers, and even students must understand this method in order to assess how materials behave when put in tension. The blog explores ASTM E8 tests, test procedures, specimen preparation, and interpretation of strength measurements. After going through this article, you would surely understand why this standardized procedure is the hallmark of reliable and consistent material performance. So stay with us as we walk you through all aspects of the test for your learning and practical application.

Overview of ASTM Standards

Introduction to ASTM Standards

ASTM International, formerly called the American Society for Testing and Materials, is a worldwide organization that develops voluntary consensus standards designed to improve product quality and safety and to facilitate market access and trade compliance. These standards provide clear and precise definitions accepted across various industries like construction, aviation, energy, and manufacturing and serve as guidelines to test, measure, and evaluate materials and products.

The essence of ASTM standards is that uniform testing results must be common, and the methods must be reliable. When the methods are standardized, materials investigators and manufacturers worldwide will obtain reliable and reproducible results that demonstrate that materials possess the specifications required for the applications for which they are used. For example, mechanical testing standards such as ASTM E8 describe the tensile testing of materials, which will reflect the strength, ductility, and behavior of materials under stress.

The ASTM standards are applied and trusted worldwide because of the rigorous process in developing them, taking into account industry representatives, academics, and other participants of the society. They are well-rounded because they describe standards that most industries would require to maintain quality and safety on a global scale. Having a fair understanding of these standards is must for any person engaged in materials testing and development.

Importance of ASTM in Material Testing

ASTM standards are of paramount importance in material testing since they provide a universal and consistent way of analyzing materials for quality, safety, and performance. These standards provide for the reliability and uniformity so that each industry can verify results and compare them with each other with a minimum amount of discrepancies. Upon following ASTM standards, professionals can confidently come to conclusions about materials to meet particular demands in applications, thereby increasing confidence in the consumer and the end product.

One of the advantages of ASTM standards is that they tend to make safety and compliance a priority. They provide a testing structure to mitigate potential hazards arising from material failure occurring in areas like construction, manufacturing, or aerospace. Through diligent compliance with ASTM standards, industry bodies can determine where the limitations lie and thus make informed decisions that will keep them clear of accidents and subsequent failures of products in their actual application.

Further, these standards provide ASTM with the platform for innovation by clearly defining the standards for the development of new materials. The researchers and developers go on to test their prototypes according to these standards so that the products are capable of meeting the said standards before they reach the market. This stimulates an orderly process of technological advancement while safeguarding the quality control. In simple terms, ASTM standards create a structure of consistency, safety, and growth within material testing across industries around the world.

Common ASTM Standards Related to Tensile Testing

Tensile testing is a crucial method utilized to determine the strength and ductility of materials. ASTM has made various standards in order to maintain uniformity and accuracy in such tests. ASTM E8/E8M is among the most commonly used standards, providing the procedures for tension testing of metallic materials. This standard gives instructions on specimen preparation, speed of testing, and recording of data so that different tests can be reliably compared.

The other major one is ASTM D638 for tensile testing of plastics. It provides the test method for determining the tensile properties of unreinforced and reinforced plastics, both rigid and semi-rigid. Usage of this standard allows manufacturers to ascertain the tensile performance of their materials and their suitability in such fields as automotive, construction, and electronics.

ASTM D3039/D3039M is the primary standard for composite materials. It describes the appropriate method of testing polymer matrix composites reinforced with high-strength fibers. This will enable the engineer to accurately ascertain tensile strength and modulus, which are primary parameters in structural applications. Compliance with these standards ensures quality assurance and sustainable pathways for the novel application of materials across industries.

Tensile Testing Methodology

Standard Test Method for Tensile Testing (ASTM E8)

ASTM E8 covers all aspects of conducting tensile tests on metallic materials. It is popularly adopted when the need arises to determine fundamental properties of materials such as tensile strength, yield strength, and elongation. In simple terms, it denotes a test conducted where forces act on a particular material or specimen, attempting to pull it apart, thereby giving clues as to the material behavior when subjected to stress.

The specimen is prepared with the dimension prepared as per the standard, so that the result would be consistent and accurate. The specimen is clamped into the testing machine under which a tensile force is steadily applied. The forces and elongation of the specimen are recorded and key values of parameters can be determined from it. These values help ascertain if the material is suitable for a particular usage.

ASTM E8, so to say, is an assurance held by the industries and laboratories that test methods and results are reproducible and comparable. It is upon following this that one can maintain sound practices and develop safe and efficient structural designs. It is an accepted method of evaluating mechanical properties of metallic materials in various engineering and manufacturing applications.

Specimen Preparation for Tensile Tests

The preparation of specimens for tensile testing assumes great significance in getting accurate results. The specimen must be machined with precise dimensions depending on the set standards, namely ASTM E8, to ensure trustworthy and repeatable results. Standard dimensions assist in bringing uniformity across selections in tests and materials. Improper machining may create irregularities that cause errors during testing.

Raw material has to be initially checked for dimensional and compositional requirements before any machining. The testing specimen should be smooth finished so as to minimize any surface imperfections that might act as sites for stress concentration thus bearing effect on the results. At all times, specimens have to be handled with care to avoid any bending, scratching, and damages that will ultimately compromise the validity of the test.

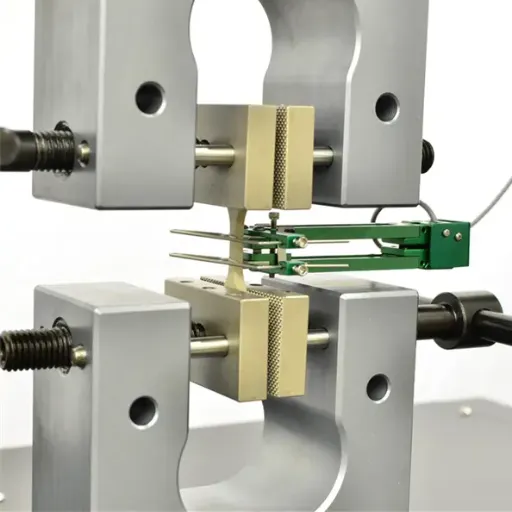

While setting up for tensile testing, the alignment is essential to make sure that no unforeseen stresses are introduced during the test. Proper holding of the specimen within the grips of the testing machine is necessary to avoid any misalignment that may give rise to incorrect readings. Full compliance to the set standards and guidelines throughout the preparation and testing procedure, will ensure the validity and consistency of the results.

Tensile Testing Systems and Equipment

Tensile testing systems dig into the material properties under uni-axial tensional load. Generally, such systems contain a testing frame with a load cell, grips, or fixtures to hold the specimen. The testing frame forms the structural part, and the load cell is an instrument to measure the force exerted on the material. Grips hold the specimen adequately during testing so that it cannot slip. The data acquisition system records critical characteristics describing the performance of the material such as stress and strain.

Tensile testing machines come in many varieties dependent on what is being testing and the nature of the materials involved. The most commonly utilized tensile testing machines are universal testing machines. They can test a wide array of materials and operate on different principles. On the other hand, these models are mostly hydraulic and electromechanical. Electromechanical systems are typically superior if fine load applications in series of smaller magnitudes are involved, while the hydraulic one can offer the required force for more heavy-duty specimens. The choice of a particular equipment lies in the nature of your material, its expected loads, and your method of application.

For the results to be reliable, proper calibration and maintenance must be ensured. Calibration is to ensure that all parts of the test machines, such as load cells and extensometers, give proper readings within the specified tolerance limits. Regular maintenance, which includes lubrication, inspection, and realignment, ensures prolonged life of the testing equipment and avoids errors during testing. Thus, by performing tensile tests in accordance with established standards and properly maintained systems, one can get crucial data on the material performance and support quality assurance in a whole swath of industrial sectors.

Tensile Properties and Strength

Understanding Tensile Strength and Modulus

The tensile strength represents the highest stress a material can bear when being stretched or pulled before failure. It is a crucial property to study to understand how a material exists under tension and to reflect its qualities and its dura-bility. Materials of a high tensile strength are generally used in applications where resistance is needed against pulling forces. Examples are cables, structural components, and fasteners.

The tensile modulus, alternatively called elastic modulus, interprets the stiffness or resistance of a material to any deformation when placed under stress. It is obtained by deriving the modulus of elasticity from the start of the stress-strain curve where it has a linear relationship, indicating how much a material will stretch given a load. The greater the tensile modulus, the stiffer the material; conversely, a low tensile modulus value connotes flexibility. It is indispensable information for those who work in fields such as construction or product design, where a certain amount of flexibility or rigidity is required.

Tensile strength and modulus, thus, combine to stand out as primary indices for material performance evaluation. They orient engineers, manufacturers, and designers toward the selection of materials that adequately fulfil the mechanical requirements of the applications they are working with. Hence, the understanding and evaluation of those properties lead to ensured safety, durability, and efficiency in products at an optimized level of material use and costs.

Factors Affecting Tensile Properties

Tensile properties are key characteristics influenced by the factors concerned with the composition of the material, the manufacturing process, and the surrounding environment. These factors together dictate how a material behaves when subjected to tensile loads, that is, to tensile forces deformations, or breaking.

Material Composition: The chemical composition and microstructure of the material are the determining factors for its tensile properties, strength, and elasticity. For instance, in metals, a higher carbon content will lead to greater strength but decreased ductility. In contrast, composite materials combine different components to maximize strength while maintaining some flexibility. The arrangement of atoms or fibers within the structural system also modifies how much stretching or stress damage the system can carry.

Manufacturing Processes: The manufacturing method used tends to vary the tensile properties. For these material processing operations such as forging, rolling, or heat treatment, the microstructure gets modified to enhance strength, and the presence of internal flaws is reduced. On the other hand, deficiencies may arise as a result of flawed processing, which may impart voids or stress concentrations that precipitate failure.

Environmental Factors: Factors such as temperature, humidity, corrosiveness, etc., contribute very much to the extent of effect due to environmental nature. Strength diminishes with the increase of temperature, while softness may set in as well. Contrarily, in the low-temperature regime, brittleness sets in. Long-term exposure to moisture, or corrosive chemical attacks, may corrode an otherwise good material, thus slowly corrodes down the tensile capability of the material itself. These considerations are crucial to keep in mind when choosing materials for a specific purpose.

Comparison of Plastic and Composite Tensile Strength

The typical comparison usually goes into how composites have generally been considered better in tensile strength than plastics. Plastics are versatile and cost-effective, yet the tensile strength is less in them depending on their simple molecular structure. So, plastics will deform or fail under much less stress than composites and, therefore, are not suitable for high-stress applications.

Putting it in layman’s terms, composites are a special material engineered to combine the strengths of each of its components. For example, fiber-reinforced composites may contain a strong reinforcing material such as carbon fibers in a polymer matrix. In this configuration, the tensile strength afforded by composites is very high allowing the composites to undergo much higher tensile stress while also maintaining their shape and integrity. In essence, the layered structure of composites increases their ability to resist force and distribute stresses better than plastics.

Therefore, choosing plastics or composites depends on the application at hand. For applications where high tensile strength is required, such as aerospace or construction, composites should be the choice given their superior performance under stress. On the other hand, plastics will remain the cheaper manufacturing alternative requiring low tensile properties wherein cost consideration, easy possible processing, and light-weighting are the prime concerns.

Applications of ASTM E8 in Industry

Tensile Testing of Metallic Materials

Tensile testing of metallic materials is essential to determining their mechanical properties such as tensile strength, yield strength, and elongation. Such testing provides the critical data on how metals behave under tensile forces so that engineers can cleverly choose the materials for particular applications. ASTM E8 provides methods for performing tests to ensure that industries get accurate and consistent results.

In the process of testing, a standardized specimen is prepared-that specimen is usually a cylindrical or rectangular sample-and is placed in a tensile testing machine. The machine increases the load on the specimen until it is fractured, at the same time measuring parameters like the maximum stress it can withstand and the maximum amount of stretch it can sustain under rupture. Measurement of these parameters plays a vital role in evaluating the quality of materials and their anticipated performance in real-time situations.

Industries such as aerospace, automobile, and construction very much depend on tensile test results for their safety and reliability aspects of metallic components. For example, during construction, the strength of steel bars is tested to meet structural requirements. ASTM E8 provides reliable guidelines for accurately assessing metallic materials so that manufacturers and engineers can design safe products with optimum performance.

ASTM D638 and its Role in Polymer Testing

ASTM D638 is a standard test method used to determine the tensile properties of reinforced or non-reinforced plastic materials. The test chiefly determines key mechanical properties such as tensile strength, elongation, and modulus of elasticity. These parameters assess a polymer’s resistance to forces and deformations during stress and help manufacturers to evaluate the performance of materials for different applications.

A standardized specimen of the polymer is prepared and subjected to tensile force under controlled conditions until failure. The material behavior in the test provides valuable data pertinent to strength, flexibility, and mechanical resilience. ASTM D638 is principally valuable for comparing mechanical properties of different plastics and to certify such materials for use in industries like packaging, automotive, and construction.

Following ASTM D638 helps engineers and manufacturers predict the performance of polymers in real-world conditions. The presence of a standard procedure assists in Repetition of testing, makes quality control easier, and guarantees safety and longevity of the plastic components in the application they are meant for.

Real-World Examples of ASTM E8 Implementation

ASTM E8, which gives the standard test methods for tension tests on metallic materials, finds wide applications in several industries. One of the most eminent examples of its application is in the aerospace industry, where it is crucial to measure the tensile strength of materials like aluminum alloys for aircraft structures. ASTM E8 ensures that materials meet the very critical standards of strength and reliability; thus, it contributes to the safety and durability of aircraft components under extreme conditions.

Another instance of real-world implementation of ASTM E8 is through the construction of steel reinforcements and structural components. Contractors and engineers determine the tensile properties of steel used in bridges, buildings, and other infrastructure through ASTM E8. Such testing ensures that the materials can bear the mechanical stresses that confront them over time, thereby preventing the eventuality of structural failure and endangering the general public.

Lastly, ASTM E8 is frequently used for quality assurance in the manufacturing industry. ASTM E8 standard test methods are employed in testing automotive parts, industrial machinery, and many other manufactured products to see that the metallic components comply with the specifications before production and deployment. This brings about standardization and helps to reduce defective parts being produced while promoting compliance to regulatory requirements in the global markets.

Evolution of ASTM Standards

Historical Development of ASTM E8

The ASTM E8 standard developed by ASTM International sets forth practices for carrying out tensile tests on metallic materials. The origin of the E8 tensile test standard dates to the early 20th century, when there was a felt need for standardization due to developments in industry. It was important to standardize tensile testing for uniformity in judging the performance of materials under stress to foster a reliable production of metals and engineering applications.

The E8 standards have been revised many times over the decades to reflect the development in engineering practice and further developments in scientific knowledge. In each of the amendments, there was an intention to make changes to the test methods, accuracy of measurement, and also to take into account new materials and new technologies. Such changes and updates are needed, and they are carried out upon the input of all stakeholders, including industry experts, researchers, and regulatory bodies so that the standard remains relevant to the industries in multiple facets.

ASTM E8 is still one of the most commonly recognized and referred standards for tensile testing. It is used in manufacturing, quality control, and legislation in several industries, including automotive, aerospace, and construction. In doing so, the E8 standard has kept itself up to date with technological advances, therefore allowing manufacturers to meet the global demand for highly reliable and well-engineered metallic components.

Recent Updates and Changes in ASTM Standards

ASTM standards had attempted to take postulate from changes concerning industries and time-dependent advancements in technology. Changes in recent years have given more attention to digital integration for smoother testing and data analysis. Among other changes considered are the use of automated systems and software tools that standardize test results with modern manufacturing and quality control methods in terms of precision, accuracy, and repeatability.

Another emphasis introduced was sustainability in ASTM standards. Most changes give instructions on the reduction of material wastage, recycle of materials, and on maximizing the life span of metallic components under consideration. Such changes were initiated under the worldwide focus on the environment and with the aim of assisting the industries to meet environmental regulations without compromising rights to quality and safety.

Lastly, ASTM has included further guidelines for accommodating recent advances in material science. For instance, these updates often cover new alloys and composites and the testing methods to be applied to make sure that these new materials meet the specified stringent criteria for performance. It follows that by updating its standards in this manner, ASTM will support manufacturers in confidently utilizing advanced materials in major engineering works so that ASTM standards would find application in several other industries.

Future Directions in Tensile Testing Standards

Tensile testing standards, as they develop, tend to be more tailor-made to match emerging industries and frontier materials. Advanced materials like nanocomposites and biomaterials are developing at a rapid pace and, thus, need to have standardized testing procedures that cater to their singular properties. There is a need for the introduction of more specified testing procedures that can be tailored to highly specialized material properties to gather reliable data for the manufacturers or researchers.

The other focal point concerns integrating automation and digital technologies into tensile testing. Automated testing might try to eliminate human error and provide consistency of results. On the other hand, digital developments will enhance data collection and analysis. In today’s test environment, real-time monitoring and thorough reports might be standard features, thereby permitting users to decide on-the-fly given the data collected about material performance and environmental suitability for application.

The last one is an increasing need for an internationally common tensile test procedure. A harmonization of standards from one country to another will help interoperate and promote trade as materials tested in one country will fulfill criteria required in any other country. This kind of approach fosters collaboration among industrial domains and builds confidence about test reliability and comparability, thereby assisting innovation and efficient manufacturing processes worldwide.

Frequently Asked Questions (FAQ)

Q: What are ASTM standards for tensile testing?

A: ASTM standards for tensile testing are guidelines developed by the American Society for Testing and Materials in order to carry out tensile tests on materials using specified methods. These standards such as ASTM D3039 and ASTM A370 deal with several aspects concerning the tensile testing of materials including how specimens are prepared, setting up the test, and how the test results are reported.

Q: What is uniaxial tensile testing?

A: Uniaxial tensile testing is a method in which a tensile force is applied to a specimen in one direction until it causes failure. This is one of the most important tests for determining the tensile properties of metallic materials and other materials under uniaxial tensile stresses for analysis of yield point, yield point elongation, and other critical measurements.

Q: How is the yield point stated in ASTM standards?

A: The yield point is described at a point on a stress-strain curve for a material at which the said material starts to deform plastically. It is important to identify the yield point in tensile testing, according to ASTM standards, because it gives information on strength and ductility of the material considered important for engineering application and construction.

Q: What are tensile test specimens, and how do you prepare them?

A: Tensile test specimens are samples of material prepared for tensile testing. The preparation of specimens involves cutting the material to standard shapes, which could be round specimens or dog-bone shapes, with uniform thickness and other dimensions as required in ASTM standards. Preparation of specimens determines the accuracy of the test results.

Q: What is the role of test speed in tensile testing?

A: Test speed is the rate at which the tensile force is applied during tensile testing. Different ASTM standards specify the test speeds to be adopted to obtain dependable results, such as ASTM E646. Test speed influences the tensile properties measured, such as tensile strength and modulus.

Q: How are ASTM standards related to tensile testing of composite materials?

A: ASTM also provides some special guidelines for testing composites for tensile strength, which may differ in their properties from metals. The standalone procedures laid out by ASTM D638 test composite specimens for their mechanical properties so that one can be confident that the result for composites can be compared with that of different materials.

Q: What is the importance of specimen thickness in tensile testing?

A: The specimen thickness is important in tensile testing since it can influence the outcomes obtained. ASTM standards give the accepted limits regarding specimen thickness values to represent the properties of the material accurately. Deviations from these values can result in irregular stress distributions and data on various failure mechanisms.

Q: How can one ensure the request complies with ASTM standards?

A: To ensure that one implements ASTM standards throughout the test, one must implement the test following the methods prescribed in the ASTM documents relevant to the test. This means that for the specimen preparation, test setup, and data interpretation, one must work in accordance with specifications set out in the standards. Anybody willing to execute ASTM-compliant testing must read the entire standard.

References

- ASTM E8: Standard & Specimens for Metals Tensile Test – ZwickRoell

Details the ASTM E8 standard for uniaxial tensile testing of metals at room temperature. - Tensile Testing Composite ASTM D3039 – Intertek

Focuses on ASTM D3039, which measures tensile properties of polymer composites. - ASTM D638: The Definitive Guide to Plastic Tensile Testing – Instron

Explains ASTM D638, the standard for tensile testing of reinforced and non-reinforced plastics. - ASTM Standards – Instron

A comprehensive resource for various ASTM standards, including those for tensile testing.