When testing malleable materials or testing materials in general, the bend test is one of the vital tests to perform if you want accurate results. Whether you are working with metals, plastics or any bending material, you must comprehend their behaviour under bending loads before you can assess the standards, resilience and applications they can be utilized in. This blog aims to further your knowledge on the bend testing process and to simplify this, it will outline the importance of the test in material assessment. No longer will you be in the dark about why manufacturers, engineers, and material test managers all across seem to understand the essence of this test. In the same way you will be asked to engage discussion pertaining to the fundamental principles of this test.

Understanding the Bend Test

What is a Bend Test?

The bend test may be classified as a mechanical test as it is used to measure the strength and resilience of a material. Consequently, it is classified as mechanical test because it also gives the attention to the resistance to material cracks and fractures. It is a psychological and simple way of checking how the material reacts under pressure and its ability to resist damage. The material sample is subjected to a specific angle during the test and is checked if it breaks, and much information is gathered about the performance of the material in a real-world environment.

The conditions for the bend test can be used for the study of metals, plastics and composites. This allows engineers to search for trace cracks or any kind of imperfections that can cause doubt about the material’s dependability and quality of the intended material. For instance, slumping of the material. Engineers and technicians need to cross-reference their data to make sure it is correct and confirms the information they are compiling.

Importance of the Bend Test in Material Testing

The bend test is extremely valuable for determining the qualities of materials and their dependability. By gradually applying bending pressure to a material or even until it breaks it is possible to evaluate its resistance to abuse, its ductility, and its resistance to abuse. Like other techniques, these are essential to all materials. It is especially useful for materials made of a combination of metals, plastics, natural fibers, or variables, as one can test them under real conditions to evaluate their performance.

Key Benefits: The advantage of the bend test is that it can detect flaws like small cracks, gas pods, or brittle areas of the material which could be a concern. The flaws, however, could make a huge difference to the material’s physical properties and its strength. This is very handy as it can help the engineers to reshape the model, allowing the use of other material that will satisfy the required properties.

Additionally, the bend test allows one to obtain comparable, normalized data, thereby it is support for making decisions in the study of production and materials engineering. Therefore, it is possible to meet specific, pre-specified industry requirements and, consequently, is support in materials engineering. The test is very important and is long in such areas as construction and aerospace engineering, where it is possible to expect serious consequences.

Types of Bend Tests

Various types of bend tests are used to test the suitability of materials for specific applications. Some of these bend tests include the three-point bend test, the four-point bend tests, and the guided bend test. The goal of these test methods is to ascertain both the flexibility and the ability to deform in the form of the material. Due to this, the tests evaluate resistance to failure.

Three-Point Bend Test

Unlike the four-point bend test or directed bend test, the three-point bend test is less complicated and is more widely used. Typically, a three-point bending test is performed by placing a sample over two support points and putting a load on the sample’s central point. Along the way to the failure of the sample, essential data on its bending and ductility properties is collected, a test that is recommended for metals, polymers, and composites.

Four-Point Bend Test

On the other hand, it is possible to have a uniform stress over the middle of any given material during the four-point bend test, as it only requires loading at two points. As one would expect, this is important in dealing with ceramics and glass, as there are minimal specific stress points present. With the minimum amount of specific loading, this test would be of maximum benefit to ceramic and glass.

Guided Bend Test

Last but not least, the guided bend test, a more useful form of testing, would be like performing the specified bending of welded samples, as it focuses on the welded joints. The industry benefits by using these two tests to check the material in different material loads.

Preparing for the Bend Test

Specimen Preparation

To get proper and consistent results, the proper preparation of components is of prime importance. Follow the standards to cut and shape the component as required in order to use in particular standards. This will help you assess mechanical properties. Also, make sure that the dimensions and the finishing is as per standard to help you with error free stress-strain relationship. Also, cut and eliminate all the unsatisfactory components such as burrs and uneven surfaces. The specified dimensions are essential in obtaining the correct stress-strain relationship, which is true for most mechanical tests, as well as the preparation of the plane strain measurements, which include compression tests, and the other requirements in the ASTM standards.

Important Note: In addition to this, the calibration and the adjustments of the properties of the test unit are essential for the material under study. The typical components of the testing device consist of a loading frame, an application plunger and support, etc. The supports by ensuring their precise location enable proper positioning of the specimen which in turn allows for proper deformation, which is crucial in the assessment of ductility, strength, and toughness of the test material. It is crucial to keep in mind the international protocols such as ISO, ASTM, etc., since they ensure the data is valid and can be considered for comparative purposes.

The outcomes based upon what the machine records like the maximum the machine records and the extent of the deflection of the specimen gives valuable inputs with respect to the mechanical properties of the materials. The tests concerning bending of the materials, when appropriately arranged with the right equipment and set up as well as well structured specimens, allow an effective and in depth material assessment to be carried out by the engineers and manufacturers for industrial implications and for structures of the materials.

Selecting the Right Test Specimen

The bending test selected, it is important to carefully choose the test specimen as it plays an important role in ensuring reliable and accurate results. The standard dimensions and shapes are set by the relevant standards, like ASTM or ISO which must be followed so that the test specimen is consistent. Flat or rectangular specimen are preferred and the format should be proportioned to the testing equipment so the equipment does not give any hindrance when in use.

- Material Considerations: There are factors such as material width, thickness and type, and these should be considered during the specimen preparation as they will affect the bending performance.

- Material Specifications: Different materials like metals and polymers have different specifications and require different preparation methods to meet the required standard.

- Surface Preparation: The removal of any impurities like deburring ensures the material surface is only focused to reveal the material properties.

It is crucial to verify that the specimen complies with the test. For an example, a certain test intends to measure flexural strength; it is important for the specimen to reflect its use. The enabling of a specific and proper preparation for the material to meet the test opens the opportunity for engineers to choose a certain MPN and also design further products.

Choosing the Appropriate Test Method

The use of a bending testing machine allows the evaluation of the bend properties including strength and stiffness of a variety of materials. The choice of an appropriate test depends on defining the testing objective. For example, in the flexural properties of a material needs to be tested, the use of three-point or four-point bending is common. Such methods require application of load on the specimen until the deformation or failure occurs, and as a result, allows an accurate measure of the mechanical properties it has.

| Material Type | Standard | Application |

|---|---|---|

| Plastics | ASTM D790 | Flexural testing guidelines |

| Metals | ASTM E290 | Metal bending procedures |

The choice for the bending method also requires consideration of the type of the material and the shape of the material. Different materials such as metals, plastics, and composites require different methods of testing to ensure the required standards are met. Following the provided guidelines improves the accuracy of the test reports and gives the test more weight.

The bending machines need to be calibrated as well as the forces applied have to be of the proper magnitude. Moreover, the conditions of the test such as humidity and temperature have to meet the proper conditions laid out in the standards. This ensures that the required test are is as little as possible and the reports on the testing are not misleading. With proper calculation, the engineers could test the performance of the materials and develop an product and quality assurance with the tests.

Types of Bend Tests for Ductile Materials

3-Point Bend Test Explained

To understand the mechanical properties of highly malleable substances, you have to test them in specific ways – a common method used to achieve this is the three-point bend test. This fairly well-known three-point bend test is designed to yield better insight into how a sample behaves when a force is applied at its center. This allows researchers to better understand how the material behaves in the real world. It is also very informative in terms of material strength and flexibility.

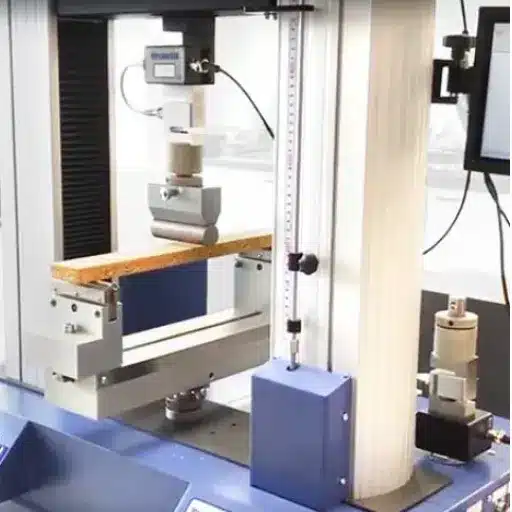

Testing Equipment: The instrument used to carry out this testing is called a bending test machine, which can be programmed to apply the desired force. This force is intentionally set to examine the material’s behavior at specific points. The points of emphasis here are the material’s flexural strength, ability to withstand a force that would not instantly break it, and its resistance to breakage while under tension or compression. The setup is both compact and simple and is very intense and therefore very reliable because it can give the same results thousands of times.

Each and every testing instrument, machine, or laboratory component in the of materials engineering and science has a system in place that is versatile. They are configured to analyze various sample configurations and materials, and have a very wide range of applications. All testing instruments are calibrated to a high level, ensuring testing to be done under the same conditions and in an efficient manner. In the case of the boundary of the materials testing instruments, precise measurement is taken that is in very detail, and these measurements result into the essential 3-point bend tests that allow compliance to be easily verified, enabling quality assurance and development of new materials.

4-Point Bend Test Overview

The 4-point bending test is a commonly employed procedure for assessing the flexural strength and elasticity of a material. As opposed to the 3-point bending technique, the 4-point method utilizes forces on the material from 2 distinct points, which ultimately generates an extended region on the material with consistent bending moment. The utilization of this configuration offers more detailed information appertaining to the response of the material to bending forces in comparison to the 3-point technique, as it allows the removal of shear stresses that are in the region under consideration.

Advanced Features: The machine used in this type of testing is known as the bending testing machine and one of its features is the high level of control offered over the actions to be taken and measurements to be made. It quite often comes with elements like adjustable supports, load cells (that measure the applied force), and displacement sensor(s), which keep an eye on the bending. These machines are useful, in that they provide consistent testing environments and can be used in the comparison of differing materials, allowing engineers and researchers the ability to improve material treatment. The technology can be used in real life also. It plays a critical role in the construction of machines, aircrafts, even the manufacturing sector.

This testing method is vital in giving the respondents of a given application information to improve the performance of a given product, as it points out the capacity of a material to resist breaking, and the 4-point bending test offered by the developed material ensures the material is durable and prevent the rapture of the material by demand and application. Moreover, innovation is enabled with the 4-point bending test, as it reveals a stronger and lighter material properties to the material engineers,reducing weight on the material components.

Comparing 3-Point and 4-Point Bend Tests

With attention towards the mechanical sciences, it is evident that break testing is the focal point for verifying the material’s mechanical features. The two basic tests are the 3-point and 4-point break tests. Both the 3-point and 4-point tests are very useful in the testing of materials, and it mostly relies on the material characteristics and the testing conditions. Testing and using unique materials usually depend on the type of material.

3-Point Bend Test

During the 3-point bend test, support is provided for the material being tested on both ends, and force is applied on a single mid point. This type of test is simple and provides valuable information on the compressive strength and modulus of a material. However, stress in the test is localized, meaning the load is concentrated in one area and therefore the test may not provide an accurate reflection on the material’s performance unless it is uniformly applied.

4-Point Bend Test

On the other hand, the 4-point bend test raises the force on to the material on two points, while the rest is supported on two ends. Here, stress is better applied and helps to allow the materials to be better applied under even stress. The exam is repeated, which makes it useful for teachers to test to see how better materials can be used even with heavy stress. The tests are very different from testing to see how better materials can be offered under pressured stress, that is to say, with better performance in real applications.

Both methods are very helpful in developing and refining the materials to attain the maximum performance and to enhance sustainability in their purpose.

Executing the Bend Test

Using a Universal Testing Machine

A bending test system is a piece of machinery that is used to determine how well a material can resist mechanical stress. This system applies a precisely-calibrated stress to a material by bending the material, and with it, we can quantify its performance, strength, and durability. Implementing this process is important since the data obtained allows us to check if materials comply with modern standards and ensure their efficiency.

Machine Operation: The way the machinery is designed allows the sample to be placed in between supports with the center or any other point getting the controlled force applied. This method allows us to record the response of the material using sensors and meters. Some of the most important properties these tools allow us to measure are, in addition to bending strength, elasticity and their break points. Such tools are invaluable in the construction, manufacturing, and aerospace industries as the need for material with a very low failure rate is crucial.

Materials science is a fast-growing field and therefore needs new inventions which can be created by comparing different materials, changing their components to ensure peak performance, and saving resources. For instance, the greater use of composite products is envisaged as a way to improve performance. With detailed studies supported by exact measurements, these devices are used to shift materials in the desired direction, solving the problems materials face.

Calibration of Test Equipment

Why Calibration Matters

Calibration is an indispensable process for ensuring the accuracy and precision of test equipment’s readings. It involves benchmarking readings from an instrument against a predetermined standard and adjusting it accordingly. This type of process boosts reliance on the data that is being generated, lowers the level of variation, and brings the equipment into line with the industry’s standards.

Calibration Importance

Maintaining sufficient precision and stability is possible through regular equipment calibration. Although devices might be accurate when first set up, over time, the settings may become less precise; this phenomenon is called drifting and results from instrument wear, prolonged use, or exposure to harsh environmental conditions. Certain equipment parameters may therefore be compromised, resulting in faulty output, thus data interpretation and conclusions as well as product generation can easily be flawed. This allows for the early identification of problems that can be corrected to prevent expensive errors if the equipment is maintained at a certain regular service interval.

Calibrating Test Equipment the Right Way

For effective calibration to work, companies need to adhere to well-defined policies and possess dependable reference standards with a clear trail of documentation. Equipment should usually be adjusted in similar condions to maintain the operating accuracy. Proper documentation of calibration procedures enables follow-up and support for audits and thus compliance to both regulations and quality control standards.

Step-by-Step Procedure to Perform a Bend Test

- 1 Prepare the Specimen: A specimen has to be prepared following the dimensions specified in a standard and must follow the standard. Despite utility, the specimen should to be free from cracks or corrosion, as these defects with influence the results.

- 2 Install the Bend Test: To set up the machine, install the test on a flat surface is not move and has to be stable. Attach the fixtures as mentioned for the specimen, such as the dimensions and type.

- 3 Clamp the Specimen: The specimen has to be inserted and clamped carefully and for each the test to be done there is a proper center and the clamp has to be aligned properly to ensure it is not moved during the clamping. Reverify the alignment in order to ensure that it will not affect the test and the system will perform accurately.

- 4 The Test System Adjustment: Set the machine in accordance with the standard, else its default settings or the configuration should be placed according to the requirements of the materials (e.g., ASTM or ISO test samples). Adjust the loading and bending speed mechanics.

- 5 Conduct the Test: Start the loading and set the system to the test. Minimize the power applied to the wings of the specimen. Expect success or failure in varying angles to the core metal of the specimen which shifted during the power.

- 6 Inspect the Test: Measure the bending properties and, more importantly, the extent of bending based on the specified regulations. After the proper tests have been completed and the consequences are obtained, they should be written and recorded.

Analyzing Bend Test Results

Interpreting Bending Behavior

Pyrolysis is the thermal decomposition of rosin that Rose Marry. FTIR spectroscopy results facilitate the chemical characterization of the evolved gas. Additionally, an optimized pyrolysis procedure guarantees quality analysis, compliant with ASTM standards, within its predetermined test duration.

Technical Analysis: The sum of the differences between the bending moments (ΔM) at deformation in the bending of curved beams shaped as channels at every measured angle of fiber orientation helps in defining the curvature prediction error (ε). From the results, it is possible to ascertain the precise value of ε. The conditions valid for Levenberg-Marquardt’s iterative curve fitting approach indicate a high degree of reliability.

Moreover, the evaluation of the photomechanical forces formed at the gas-ecoducrt junction facilitated the completion of the colormap study as it provided the necessary data.

Common Mistakes in Bend Testing

Sample Preparation Errors

An overlooked blunder in bend tests is the preparation of the samples. It is advisable to prepare the material of the test specimen to be in perfect order without any deformation as it might drastically affect the entire test process. Stains and sharp edges that can come because of scratches in the material need to be avoided as not only do they elude proper measurement, they actually add more strain to the material to cause premature failure.

Equipment Alignment Issues

The proper alignment of the equipment is another common problem. To guage the effectiveness of the test, the uneven force output needs to be avoided. Specifically, the regular schedule of calibration and maintenance for the test ensures the equipment operates effectively and reliably.

Environmental Factors

Lastly, the climate of the testing room is another common allowance. Uncontrolled bending tests is a second mistake which is a result due to the change in the climate or the test area. This is why the environmental conditions need to be kept constant. The bending tests need to be under the same conditions of the intended use of the material so that meaningful results are produced.

Best Practices for Accurate Results

Enabling the Equipment to Deliver on Its Promise

If you’re looking at bending tests, you’ll know that you need to calibrate everything beforehand. Keeping the gear in the acceptable range on the regular ensures that everything is coming out as it should and eliminates issues with your data.

Test-in-a-Box Procedures Are a Must

In bending tests – if your mind’s completely on something else – it’s tending to become a complete Trainwreck. You have to, though, to keep your test results in sight, attempt to lose your material in the background. Also, the tests are very forgiving in a range, so in a larger scale there is a little bit of a safety net.

No Skipping Corners On the Manual

If the handbook says “prep the material like this,” it actually means “prep the material like this.” That’s because the results will be immediate. tests are great for many reasons, one of them being that they’re easy to calibrate. Different equipment may be used, and the types of machinery that usually require bending tests are very forgiving (compared to machines that don’t).

Frequently Asked Questions (FAQ

What does bend testing mean and what are its purposes?

Bend testing assesses the resistance and ability of materials while learning about the effect they have on stretching and bending forces. Metals tradmet bend testing, as they show ductility and resistance to bending. Bend testing exposes the specimen to specific forces, which plays a role in the determination of the material’s yield strength and fracture toughness. Bend testing is specifically important to materials that will experience bending loads because their yield strength can be assessed using the bend test.

How can I set up a bend test fixture?

The setup is simplified with a test fixture designed for bending. For a bending test, the test fixture should be able to grip the specimen and—with the use of several adjustments—apply the needed forces. Two or more points securing the load are needed for the specimen, and the load is applied to the center to ensure uniform bending or can be using a different 3-point grip fixture to apply a more concentrated load. Pay special attention to comply with the needed standard to ensure the bend test standard is followed and to obtain accurate results.

Can You Specify The Types Of Bend Tests?

The types of bend testing can be categorized as simple bend testing, free bend testing, and semi-guided bend testing. Every type has its own unique setup and utilization which often depends on the material being experimented on along with the specific attributes that need to be gauged, such as brittleness or fracture resistance.

Can You Name The Suitable Materials For Bend Testing?

Albeit the amount of pressure being registered, bend tests are utilized on a wide array of material types such as composites, metals, and plastics. The test can be seen as a contrast where ductile materials come with a lesser of a fracture and brittle materials come with a greater chance of breaking which allows a comparison of the different mechanical properties.

In What Way Does A Bend Test Work?

Bending stresses are nothing but the internal stresses of materials when being subjected to bending forces. A material is to be investigated on how well it can be endured before giving way. The objective of this is the material’s actual behavior. The way in which it is to be utilized and such properties is something that has to be complied with in the structure, as required for its real world applications in the market.

Why is the stress-strain curve considered in the bend test?

Essentially, the stress-strain curve exposes the bending test’s response towards the applied forces, showing the yield and ultimate tensile strength points of the material. The curve’s analysis would also shed some light on the materials’ elastic and plastic deformation qualities, a factor that would aid greatly to the materials real world applications.

How can the outcomes of a bend test be properly explained?

The way the substance responds throughout the test and anyise fractures, whether they are apparent or invosible, and the appropriateness of the testing method would all have to be taken into account to properly explain the outcome of the bend test. In comparison to what one would expect, there are barely any deformations present in a ductile material that has never experienced and fractures, while severe, one expects less resistance, deformation and stres es followed by fracturing in a brittle metal.

What are some parameters that might impact a bend test outcome?

There are many things to consider: the specimen’s geometry, test speed, ductility, and tensile properties, just to name a few. Moreover, the bend radius and the test speed, along with the type of bend test that one is using, might also have a bearing on the outcome of the test.

Do fatigue tests have any correlation to bend tests?

Fatigue tests have not a direct but indirect impact on bend tests, especially in relation to long-term bending loads. They help in determining the material’s behaviour over the long term such as in the bending cycles. It provides engineers and designers’ critical equipment whilst providing important test data.

References

- Bend Test – STEP Lab – Explains the guided bend test procedure, including sample placement and force application.

- Bending Test: Suitable for Both Brittle and Ductile Materials – Details the bending test procedure using a 1-point bending device.

- Bend Testing – TWI Global – Provides an overview of the bend test as a qualitative method to evaluate material ductility and soundness.

- Essential Guide to Bend Testing: Evaluating Material Strength – Describes the process of applying a load to a sample until it flexes or fractures.