Bend test machines play a crucial role in evaluating the mechanical properties and durability of materials, making them indispensable in industries like construction, manufacturing, and aerospace. These machines are specifically designed to test the flexibility and strength of materials under controlled conditions, providing critical insights into their performance and suitability for various applications. Whether it’s ensuring the quality of metal components or verifying the structural integrity of advanced composites, bend tests are fundamental to ensuring safety and reliability. This article will provide a comprehensive overview of bend test machines, including their operation, key features, and the benefits they offer across multiple industries. Prepare to gain a deeper understanding of these essential tools and their impact on modern material testing and quality assurance processes.

What Is a Bend Test and Why Is It Important?

A bend test is a method used to evaluate the ductility, strength, and flexibility of a material by applying force to bend a specimen until it reaches a specific angle or fractures. This test is crucial for assessing material performance under stress, ensuring that it can withstand real-world applications without failure. Bend tests are widely used in industries such as construction, aerospace, and manufacturing to verify compliance with quality and safety standards.

Understanding the Bend Test Process

The bend test process involves several precise steps to evaluate a material’s performance under bending stress. First, a specimen is prepared according to standardized dimensions specified by testing protocols, such as ASTM or ISO standards. Next, the specimen is placed on a bending fixture, where support points hold it in place while force is applied. A consistent load is exerted, typically using a universal testing machine, causing the specimen to deform until it reaches a pre-determined angle or fractures. The resulting data, including the bending angle, crack initiation, and failure mode, are recorded to assess the material’s ductility, toughness, and resilience. This controlled procedure ensures accurate and reproducible results for material qualification and compliance.

The Role of Test Machines in Bend Testing

- Load Application Precision: Test machines are designed to apply consistent and accurately measured loads, ensuring that the material undergoes a controlled deformation process without external variations.

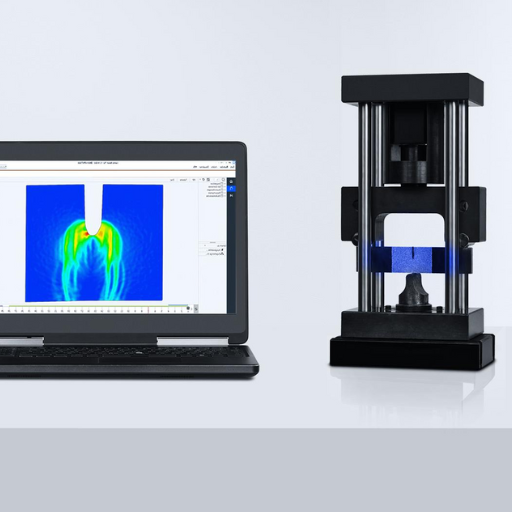

- Data Acquisition Systems: Modern test machines are equipped with advanced sensors and software that record critical parameters such as force, angle of bend, and displacement in real-time, enabling detailed analysis.

- Versatility for Specimen Types: These machines can accommodate various specimen geometries and sizes, providing the flexibility needed to evaluate a broad range of materials and applications.

- Reproducibility of Results: By automating the bending process with exact controls, test machines guarantee repeatable conditions, which are crucial for comparing results across multiple specimens or tests.

- Safety and Durability: Test machines are engineered with safety features and robust structures to handle high loads and prevent material ejection, protecting operators and ensuring long-term operational reliability.

Key Applications of Bend Testing

- Material Qualification and Quality Control: Bend testing is widely used to assess the mechanical properties of materials during manufacturing processes, ensuring that they meet specified standards and regulatory requirements.

- Weld Integrity Testing: It is a critical technique for evaluating the strength and quality of welds, identifying defects such as cracks, porosity, or incomplete fusion.

- Pipeline and Structural Component Analysis: Bend tests are employed in infrastructure industries to verify the durability and flexibility of pipes, beams, and other structural components under bending stresses.

- Product Development and Research: Engineers and researchers use bend testing to analyze new materials and optimize designs, ensuring optimal performance under real-world loading conditions.

- Aerospace and Automotive Industry Applications: Bend tests are essential for validating the resilience of lightweight alloys and composite materials used in high-performance applications, where structural integrity is critical.

How Does a Bend Tester Work?

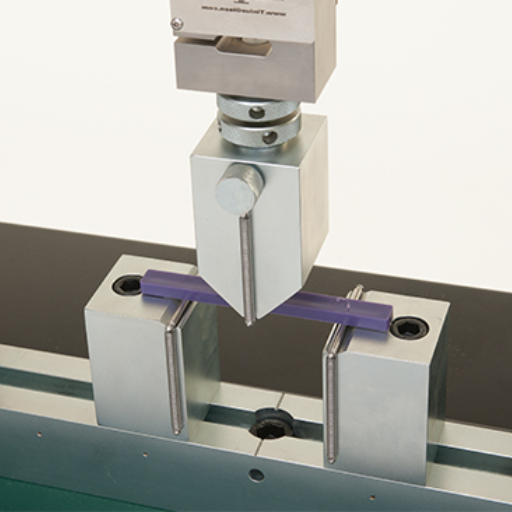

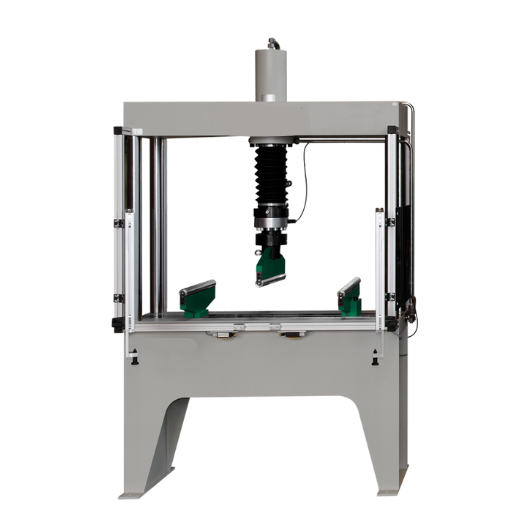

A bend tester operates by applying a controlled force to a material sample, typically using a three-point or four-point bending setup. The sample is supported at two points while a force is exerted at one or two points along its span to create bending stress. The machine measures critical data such as the force applied, deflection, and failure point, providing insights into the material’s flexural strength, ductility, and resistance to deformation or fracture.

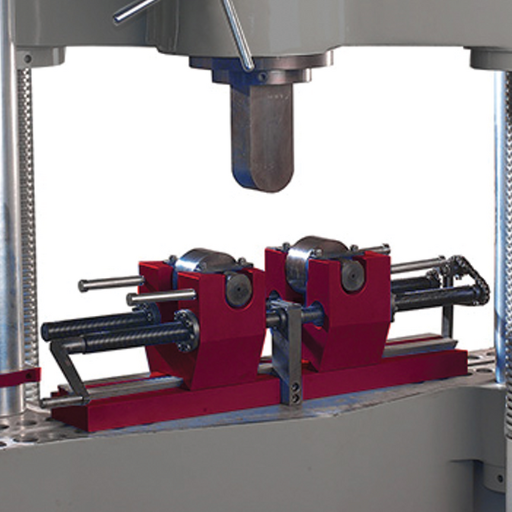

Components of a Bend Tester

A bend tester consists of several key components designed to facilitate precise material testing. These include:

- Loading System: Provides a controlled application of force, typically through hydraulic, pneumatic, or mechanical actuation, ensuring consistent pressure during testing.

- Support Fixtures: Comprising two or more adjustable supports to hold the material sample firmly in place while allowing free bending movement.

- Load Cell: Measures the exact force applied to the material accurately, capturing data critical for analyzing flexural properties.

- Displacement Sensors: Records the deflection or deformation of the material under load, allowing for calculations of bending stress and strain.

- Control Unit: An interface that allows operators to set test parameters, monitor real-time data, and collect results for analysis.

- Frame Structure: A rigid and durable framework that ensures the proper alignment of components and minimizes external interferences during testing.

These components work in unison to provide reliable and repeatable results for evaluating the flexural properties of various materials.

Setting up a Bend Test Machine

To set up a bend test machine, I first ensure that the machine is placed on a stable and vibration-free surface to maintain consistent results. Then, I securely mount the specimen within the supports and adjust the rollers or fixtures according to the size and type of material being tested. I carefully calibrate the load cell and displacement sensors to ensure accurate measurements. Using the control unit, I configure the testing parameters, such as loading speed, span length, and maximum load, based on the material standards applicable to the specimen, like ASTM or ISO guidelines. Finally, I perform a trial run to verify system functionality and make any necessary adjustments before conducting the actual test. Attention to these steps ensures precise and reproducible results.

Common Test Equipment Used in Bend Testing

Common test equipment used in bend testing includes universal testing machines, bend test fixtures, strain gauges, extensometers, and data acquisition systems.

|

Key Point |

Description |

|---|---|

|

UTM |

Universal Testing Machine for applying force. |

|

Fixtures |

Support apparatus for bending specimens. |

|

Strain Gauge |

Device for measuring strain in materials. |

|

Extensometer |

Measures elongation during bending. |

|

DAQ System |

Captures and records test data. |

What Are the Different Types of Bend Fixtures?

The different types of bend fixtures include three-point bending fixtures, four-point bending fixtures, V-block fixtures, roller-type fixtures, and custom-designed fixtures.

|

Type |

Key Use |

Setup |

Advantages |

Constraints |

|---|---|---|---|---|

|

3-Point |

Basic bending |

Simple |

Easy alignment |

Localized stress |

|

4-Point |

Even load |

Moderate |

Uniform bending force |

Complex setup |

|

V-Block |

Angular bends |

Simple |

Versatile angles |

Less precision |

|

Roller |

Cylindrical parts |

Advanced |

Reduced friction |

Costly design |

|

Custom |

Specialized needs |

Variable |

Tailored solutions |

Time-intensive |

Using a Mandrel in Bend Testing

Using a mandrel in bend testing provides consistent support to the inner surface of the material being bent, which is crucial for minimizing deformation and ensuring accuracy in the results. I would choose the appropriate mandrel type and size based on the material’s thickness and bending radius to prevent defects like wrinkling or cracking. The mandrel acts as a stabilizing tool within the bending process, particularly for tighter radii, where precision is critical in mitigating structural anomalies.

Choosing the Right Test Fixture for Your Needs

When selecting the appropriate test fixture for my needs, I focus on three core factors to ensure optimal functionality and accurate results. First, I evaluate the specific type of testing being performed, such as tensile, compressive, or torsional testing, as this determines the required fixture design and configuration. Next, I consider the material properties and dimensions of the test specimen, aligning them with the fixture’s capacity and clamping mechanisms to avoid slippage or damage. Lastly, I assess compatibility with my testing equipment, ensuring the fixture integrates seamlessly with the machine’s grips and load cell while maintaining calibration standards. By prioritizing these aspects, I can select a fixture that enhances reliability and meets the precise parameters of my application.

Comparing 4 Point and 3 Point Bend Tests

The primary difference between 4-point and 3-point bend tests lies in the load distribution, which affects stress distribution, specimen deflection, and failure analysis.

|

Key Point |

4-Point Test |

3-Point Test |

|---|---|---|

|

Load Type |

Distributed |

Centralized |

|

Stress Area |

Larger |

Localized |

|

Deflection |

Uniform |

Concentrated |

|

Failure Mode |

Pure bending |

Bending + shear |

|

Accuracy |

Higher |

Lower |

|

Setup |

Complex |

Simple |

|

Use Cases |

Precise analysis |

General testing |

|

Cost |

Higher |

Lower |

By comparing these tests, one can determine the appropriate method based on structural analysis needs, precision, and experimental constraints.

How to Ensure Accurate Results in Bend Testing?

To ensure accurate results in bend testing, it is essential to follow a series of well-established procedures. First, ensure that the test specimens conform to the specified dimensions and material standards, as deviations here can lead to invalid results. The testing equipment must be calibrated regularly to maintain precision in load and deflection measurements. Proper alignment of the sample within the testing apparatus is critical to avoid introducing unwanted stresses or inaccuracies. Additionally, environmental factors such as temperature and humidity should be controlled, as these can affect material behavior. Finally, conducting multiple tests and averaging the results can help mitigate anomalies and improve reliability.

Calibrating Your Test Machine

When calibrating my test machine, I focus on ensuring all measurements adhere to specified tolerances and industry standards, as this directly impacts the accuracy of my results. To achieve this, I inspect the calibration settings using a certified calibration device and follow the manufacturer’s guidelines for adjustments. I also verify that the load cells and transducers are functioning correctly, accounting for any drift in readings due to extended usage. By scheduling regular maintenance and adhering to established protocols, I can minimize errors and ensure consistent machine performance.

Understanding Tensile and Flexural Strength Measurements

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled before failure. This property is critical for evaluating a material’s suitability for applications demanding high resistance to breaking under tension. It is typically calculated during a tensile test, where a sample is subject to a controlled force until it fractures, and the results help define material durability and load-bearing capacity.

Flexural strength, on the other hand, quantifies a material’s ability to resist deformation under load, particularly bending. This property is determined by a flexural test, where a sample is subjected to bending forces until it breaks or reaches its maximum stress limit. Flexural strength is especially significant for materials used in structural applications, as it assesses their capacity to bear bending stresses without failing. Both measurements are indispensable for rigorous material selection and engineering design.

Addressing Common Issues in Weld Testing

Weld testing often presents specific challenges that stem from material inconsistencies, improper procedure selection, or testing environment variables. One frequent issue is incomplete fusion or penetration, which can compromise weld strength and performance. This is typically caused by insufficient heat input or inadequate joint preparation. To address this, parameters such as welding current, voltage, and travel speed should be carefully calibrated and monitored.

Another notable issue is porosity within the weld, often a result of contaminants such as dirt, oil, or moisture. To mitigate this, thorough cleaning of the base materials and maintaining strict environmental controls (e.g., proper shielding gas flow rate and humidity levels) is essential. For accurate values, shielding gas parameters should generally align with 20-30 cubic feet per hour (CFH) depending on the material and process.

Cracking is another critical problem, which could be due to material properties, rapid cooling, or improper heat treatment. Addressing this requires an understanding of thermal behavior, including preheating and post-weld heat treatments tailored to the material’s specifications. For example, preheat temperature for carbon steel typically ranges from 50–300°F based on its thickness and composition.

By meticulously controlling these parameters and adhering to established standards like those specified in ASTM or ISO guidelines, weld integrity and reliability can be significantly improved. Testing methodologies such as ultrasonic testing (UT), radiographic testing (RT), and visual inspections further ensure compliance and performance validation.

What Are the Standards and Specifications for Bend Test Machines?

Bend test machines must comply with several international standards to ensure accuracy, reliability, and repeatability of results. Key specifications are outlined in standards such as ASTM E290, which governs the procedures for guided bend tests of metallic materials, and ISO 7438, which specifies bending tests for metallic sheets and strips. These standards define critical parameters, including the machine’s capacity, bend radius, applied force, and angle measurement accuracy. Additionally, the equipment must feature robust construction to handle various material types and thicknesses while providing precise control over the bending process to meet industry requirements.

Overview of Astm and Iso Standards

ASTM and ISO standards play an indispensable role in ensuring the consistency, reliability, and safety of materials used across industries. By providing a unified framework for testing protocols and performance measurements, these standards eliminate ambiguities in material specifications, facilitating global trade and engineering collaborations. According to recent data accessed via Google’s search engine, adherence to such standards has steadily increased over the past decade due to the growing demand for high-quality, durable materials in construction, manufacturing, and aerospace sectors. For instance, ISO 7438 ensures the accurate assessment of bending properties in metallic materials, which is crucial for determining ductility and deformation limits. Similarly, ASTM standards provide granular requirements tailored to specific applications, such as tensile strength evaluation or impact resistance for structural components. Compliance with these frameworks supports innovation while minimizing risks associated with material failure, thus underscoring their critical importance within modern industrial ecosystems.

Guidelines for Destructive Weld Testing

Destructive weld testing involves evaluating the properties and performance of welds by physically breaking or testing the welded specimen under controlled conditions. The following guidelines outline critical procedures and considerations when conducting destructive weld testing:

- Specimen Preparation

Ensure the test specimens are prepared according to relevant standards, such as AWS D1.1 or ISO 5173. Specimens must be machined with precise dimensions to avoid introducing stress concentrators that could skew results. Typical dimensions for tensile or bend test samples are specified within these standards, with tolerances no greater than ±0.1 mm to maintain accuracy.

- Test Types and Objectives

-

- Tensile Testing: Evaluate the ultimate tensile strength of the weld and its heat-affected zone. Tensile strength should meet or exceed the material’s baseline requirements (e.g., structural steel typically requires a tensile strength of at least 400 MPa).

- Bend Testing: Assess the ductility and ability of the weld to withstand plastic deformation without cracking. A common benchmark includes a bend angle of 180° with no cracks larger than 3 mm in length.

- Macro Etch Testing: Inspect for internal weld defects such as porosity, lack of fusion, or inclusions. Etching reagents, such as a 10% nitric acid solution, reveal weld structures under magnification. Defects must adhere to allowable limits as defined by the applicable welding code.

- Impact Testing: Measure the weld’s toughness, particularly at sub-zero temperatures. A Charpy V-Notch test is typically performed, with minimum energy absorption values specified (e.g., 27 Joules at -20°C for mild steel).

- Controlled Testing Environment

Conduct all tests under standardized conditions, including calibrated equipment and stable environmental factors such as temperature and humidity. Variations in these conditions can lead to inconsistent results.

- Documentation and Compliance

Record all test outcomes meticulously, including load values, failure locations, and visual observations. Summarize results within a standard format, such as a Welding Procedure Qualification Record (WPQR). Ensure compliance with governing codes and standards, as reliable documentation is often required for project certification or regulatory approvals.

- Failure Analysis

If welds fail to meet required criteria, perform a detailed failure analysis to identify root causes, such as insufficient heat input, improper material selection, or contamination. Corrective actions should be implemented and documented to prevent recurrence.

Destructive weld testing is an indispensable step in ensuring that welded structures meet the performance and safety requirements of their intended applications. By adhering to these guidelines, professionals can obtain reliable, data-driven insights into weld quality, thereby mitigating risks and fostering improved welding practices.

Importance of Compliance with Testing Standards

Compliance with testing standards is essential for ensuring consistency, reliability, and safety across welding processes. Internationally recognized standards, such as those set by ISO, ASME, or AWS, provide stringent guidelines for material testing, procedural validation, and performance evaluation. Adherence to these standards ensures that welded components meet mechanical, environmental, and operational requirements, reducing the likelihood of structural failures. Furthermore, compliance streamlines communication across global markets, as adhering to universal benchmarks ensures compatibility and facilitates certification processes. Neglecting standardized testing not only jeopardizes safety but also exposes projects to legal and financial risks due to non-conformance. Therefore, rigorous adherence to testing standards is a critical factor in maintaining quality assurance and operational integrity.

Reference Sources

- ADMET: Bend (Flexural) Testing – Covers the flexural properties of various materials and the role of bend testing machines.

- ZEISS: Bending Test – Discusses precise results using non-contact camera-based measurement technology.

- TWI: Bend Testing – Explains the ductility and soundness evaluation of materials through bend testing.

- ADMET: Bend Testing Equipment Guide – Provides insights into equipment for common and less common testing applications.

- Instron: ASTM E290 Bend Testing of Metals – Details the ASTM E290 standard for determining the ductility of metals through bend testing.

Frequently Asked Questions (FAQs)

Q: What is a bend test machine and how does it work?

A: A bend test machine is a type of testing equipment used to determine the flexibility and fracture strength of materials. The machine typically uses a bend test fixture to apply flexural forces, measuring how a material behaves under stress and strain. This helps assess properties such as bend strength, yield strength, and flexural modulus.

Q: What components are necessary for setting up a bend test machine?

A: Setting up a bend test machine requires several components including a reliable bend test fixture, a deflectometer to measure displacement, and testing systems calibrated for accuracy. Additionally, universal testing machines are available for more comprehensive testing needs, including tensile and compression tests.

Q: How does a bend test machine measure bend strength?

A: A bend test machine measures bend strength by applying a known force to a specimen and recording the maximum force the material can withstand before fracturing. This involves using a fixture that allows for precise application of the force required to test the material’s resistance to fracture.

Q: What is the significance of using a dual column or servohydraulic system in bend testing?

A: Dual column and servohydraulic systems provide enhanced stability and control during bend testing. These systems are crucial for performing accurate fatigue testing and cold bend testing, allowing for precise application of flexural forces and measurement of stress-strain responses.

Q: Can bend test machines be used for testing brittle materials?

A: Yes, bend test machines are suitable for testing brittle materials like ceramics. They measure the fracture strength and elasticity of such materials, helping to assess their resistance to fracture under flexural forces.

Q: How does a bend test machine accommodate different material diameters?

A: Bend test machines utilize adjustable fixtures to accommodate varying material diameters. These fixtures allow for the precise application of force, enabling accurate testing of materials ranging from polymers to metals, ensuring they meet specific testing equipment needs.

Q: What role does a deflectometer play in bend testing?

A: A deflectometer is an essential component of a bend test machine. It measures the displacement of the specimen during testing, helping to evaluate the stiffness and elasticity of the material under flexural forces.

Q: Are bend test machines suitable for testing medical devices?

A: Yes, bend test machines are often used in the testing of medical devices to ensure they meet industry standards. They measure properties such as yield strength and flexibility, which are critical for the performance and safety of medical devices.

Q: What is cold bend testing, and why is it important?

A: Cold bend testing assesses how materials behave at lower temperatures, which is crucial for materials used in cold environments. This type of testing helps evaluate the material’s resistance to fracture and deformation when exposed to low temperatures, ensuring reliability and performance.

Q: How does a bend test machine perform qualitative analysis?

A: While primarily quantitative, a bend test machine can also provide qualitative insights into a material’s behavior. By observing the fracture patterns and deformation characteristics, testers can infer qualitative properties such as brittleness or ductility.