Understanding the strength and flexibility of ductile materials is crucial in industries ranging from construction to manufacturing. Amongst the tests for these properties, a bend test yields valuable information about the material in terms of its resistance to being deformed- cracking or breaking. This book provides copious information about the flexural test-all its significance and methodology, alongside examples. An engineer, a materials scientist, or a curious learner, the resource can set the study of ductile materials up to interpret performance. That is our journey to understanding how this very important test wins favor in material design and innovation.

Understanding the Bend Test

What is a Bend Test?

The bend test is an investigative means to establish the ductility and flexibility level of materials subjected to bending stresses, and consequently, it seeks to ascertain the materials’ attitudes on being bent. Usually, the testing sample is placed on two supports, and a force is applied vertically downwards at the center of the span until the test specimen attains the stipulated angle or fails. The engineers and scientists, by implication, view this test as giving an estimate of the material’s resistance to deformation and, therefore, is a vital part of quality control and material design.

! Key Applications

One good bend test is to ensure that materials will undergo strain during their manufacturing processes and will not undergo cracking or breaking when bending, forming, or welding. Here, making these bend tests highly important to industries like construction, aerospace, and automotive engineering wherein materials undergo high degrees of mechanical stress.

The tests would, in essence, declare a material unfit if it does not meet production specifications applicable to its expected use, thereby ensuring safety and reliability. Such tests are usually conducted to ascertain the material properties such as bending ability, surface cracks, and overall structure when stressed. Knowing these kinds of properties would allow manufacturers and engineers to understand if a material is suitable for a certain task or project or if there are limitations that might be solved by another process or material selection.

Importance of Flexural Testing

Flexural testing is used to study the mechanical behavior of a material subjected to bending stress, i.e., to find flexural strength, flexural modulus, or resistance to deformation, all of which are considered when evaluating the design for structural integrity. The information regarding the performance of materials under conditions of stress enables industries to assess the safety, quality, and durability during the designing and fabrication of any product.

- Construction Industry: Essential for beams, panels, and structural components

- Automotive Sector: Critical for components experiencing bending forces

- Aerospace Applications: Vital for ensuring material performance under stress

The insights that flexural testing offers go about aiding optimization of production processes. If materials are suspected to have weaknesses or inconsistencies, manufacturers will correct their methods or search for other appropriate materials depending on the performance requirements. This then attests to ensuring reliability and safety of the product, thereby instilling consumer trust.

Basic Principles of Bending Behavior

The term bending behavior describes a material or structure’s capacity to resist deformation when acted upon by an external force. Bending behavior is considered to be influenced by properties such as the elasticity of the material, geometry, and the manner in which it is loaded. These factors in a way combine to show how the material or structure goes through swelling under stresses which help engineers and scientists predict how it will perform in the field.

Stress-Strain Relationship

A very first principle in bending behavior is the stress-strain consideration. When a material is bent, the fibers along the outer curve are subjected to tension while those along the inner curve get compressed. The point in the cross-section on which there is no stress is termed the neutral axis. This makes the forces clearly opposed, indicated by which internal resistance is offered by the material against bending and the basis for the design of efficient structures with safety.

Moreover, these two properties are of paramount importance when it comes to analyzing the behavior of the material. Bending strength stresses how much load it can withstand before a fracture, whereas stiffness is the ability to retain shape under a load. The testing of these properties is flexural testing, with the results assisting an engineer to decide whether a material can fit an application or not, thereby giving assurance for ample life of a structure and foreclosing any possibility of structural failure.

Types of Bend Tests

Overview of 3-Point Bend Test

The 3-point bend test is an experimental procedure in general practice to obtain data on the flexural strength, stiffness and flexural modulus of concrete and metals. It views a test material being bent by force applied at one centrally located point while suspended across two supporting points. Here, the load is triangular, so engineers can study the behavior of the material as it is loaded and stressed in bending.

With the gradual increase of applied force, the material experiences compression on the upper surface and tension on the lower surface. It is especially useful for studying brittle materials, such as ceramics, which might not elongate much in an axial tensile test. The data from this test give the maximum force the material can withstand before breaking, and useful information regarding stiffness and elasticity.

The test is easy to conduct yet provides critical information that makes material selection and design possible. The data are used by different industries to choose appropriate materials for applications where bending and structural integrity are issues—for bridge structures, beams, and other load-bearing systems.

In-depth Analysis of 4-Point Bend Test

The 4-point bend test is the method most usually applied to determining the flexural strength and modulus of various materials. While the 3-point bend test applies load at a mid-span of the specimen, the 4-point bending develops two loading points along the length of the specimen creating an area of pure bending between the loading points. In this configuration, the shear forces are nullified in the middle portion of the specimen, whereas flexural stresses develop and allow a proper evaluation of the material’s ability to bear loads.

Key Advantages of 4-Point Testing

- Uniform stress distribution over larger area

- Better evaluation of structural requirements

- Reveals weak points across specimen length

- Provides practical insights into real-world conditions

One major advantage of the 4-point bending test lies in its capacity to measure material behavior under uniform stress over a larger area. This feature is especially valued in the analysis of materials having high structural requirements, such as bridge supports, aerospace structures, and machine elements. The test imparts information concerning maximum load sustained by the material prior to failure, along with elasticity and stiffness of the material under test. These particular quantities are very important for an engineer or a designer to consider for the sake of safety and durability in their projects.

Practical insights into potential failure points in materials exposed to real-life conditions are also provided via the procedure. Since the test subjects the material to bending stress over a fairly wide portion of the sample, it can disclose weak points that might not show under other testing procedures. In effect, this helps in the invention of more suitable materials for key applications that perform better and are less prone to failure.

Comparison of Bend Test Types

| Test Type | Load Application | Best Application | Key Feature |

|---|---|---|---|

| 3-Point Bend Test | Single point at midspan | General strength testing | Focuses on mid-span stresses |

| 4-Point Bend Test | Two points across length | Structural components | Uniform stress distribution |

| Free Bend Test | Manual application | Quality control | Quick ductility assessment |

Generally considered by some authors into three categories differing according to their purpose of testing and classification of material properties, there are bend tests: the three-point bend test, four-point bend test, and the free bend test. Each of the test types differs in design and application and thus gives different information about material behavior.

Bending Test Methods and Standards

ASTM Standards for Bend Tests

ASTM standards related to bend tests concern all established procedures for the application of testing to ensure reliability and usefulness of results in industry. The standards define key factors of the test like specimen dimension, bending angles, test procedure, evaluation of properties-failure-ductility, flexibility, elongation, and so on.

A ASTM E290

Semi-guided bend test specification for testing ductility of metallic materials. Covers fixture design, bending radius, and testing speed for reliable and repeatable results.

A ASTM A370

Comprehensive testing of mechanical properties of steel products, including various bend test types to determine steel flexibility under stress conditions.

Standard Test Methods Explained

Standard test methods are established procedures for examining materials and the mechanical, physical, or chemical properties thereof. They help ensure materials will meet the safety, quality, or performance standards before their application. Regular use of standard test methods allows manufacturers, engineers, and researchers to compare materials consistently and to predict how they will behave under particular conditions.

Common Standard Test Methods

Tensile Test

One of the simple and widely accepted standard test methods is the tensile test, which is operated to study the response of materials to forces that tend to pull them apart. These forces produce many properties like tensile strength, yield strength, and elongation. The tensile test is mainly used for cases wherein a material to be tested has to sustain some considerable stress without failure, such as construction or automotive engineering fields, depending on the strength of the material.

Impact Test

Another crucial test method is the impact test that measures a material’s ability to resist shocks or to absorb energy under sudden application of force. Tests of impact such as Charpy or Izod are essential in establishing the actual performance of a material under severe environments or unexpected conditions.

Choosing the Right Test Method

Some of the important factors to take into consideration in selecting an appropriate impact test method are the type of material to be tested, how it is going to be used, and the environmental conditions involved. For example, brittle materials like ceramics may require tests to prove their ability to resist sudden force without fracturing. Ductile materials, on the other hand, such as some metals, are tested while focusing on their ability to deform before breaking.

- Charpy Impact Test: Quantifies energy absorbed during fracture – suitable for high impact applications like automotive and construction

- Izod Test: Evaluates resistance along specific orientations – beneficial for controlled stress directions

- Industry Standards: Align with recognized standards and regulatory requirements for global validity

Testing Equipment for Bend Tests

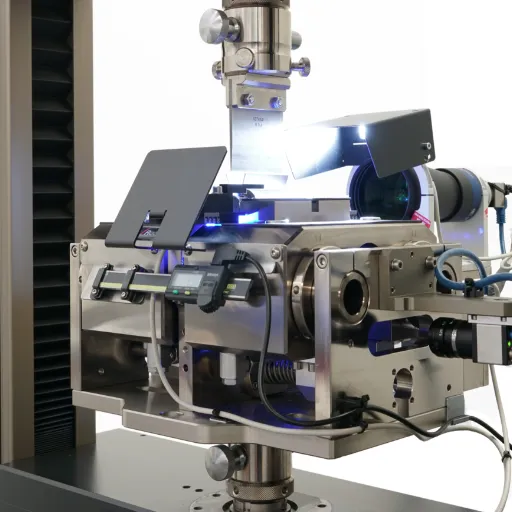

Universal Test Machines Overview

Universal Test Machines (UTMs) are considered multi-purpose instruments that determine mechanical properties of various materials under certain environments. A UTM thus tests materials under tension, compression, bending, shear, etc., and hence is known as the multipurpose material testing machine. By giving an exact force and by measuring the extent of deformation of the stone under the force, the UTM reveals the strength parameters, ductility, modulus of elasticity, etc.

Principal Components of UTMs

- Load Frame: Supports the material under test

- Load Cell: Measures the applied force

- Crosshead: Applies load onto the sample

- Control System: Controls load parameters and records data

UTMs are built in conformity with testing standards of the world-e.g., ASTM and ISO-whose parameters ensure that any data obtained are generally accepted, thus applicable to a specific situation. Apart from that, they can form the basis of quality control, product development, research, etc. Their conventional setup-sample arrangements are special in each case-and adaptability to testing for varied materials render them very important in safety, compliance, and innovations related to material science and engineering.

Types of Testing Equipment Used

| Equipment Type | Primary Function | Industry Applications | Example Models |

|---|---|---|---|

| Universal Testing Machines | Tension, compression, bending tests | Construction, automotive, aerospace | Instron 6800 Series |

| Hardness Testers | Resistance to deformation | Metal industries | Rockwell, Brinell, Vickers |

| Impact Testers | Sudden load effects | Bridges, machinery | Charpy, Izod testers |

| NDT Equipment | Non-destructive integrity testing | Aviation, energy sectors | Ultrasonic, radiography |

| Environmental Chambers | Extreme condition simulation | Electronics, automotive | Temperature/humidity chambers |

Calibration and Maintenance of Test Machines

Test machine calibration and maintenance must be properly undertaken to guarantee accuracy, reliability, and long life. Calibration is the act of adjusting and verifying that the instrument under test is within specified parameters and produces consistent and accurate results. Regular calibration reduces unsafe errors and guarantees adherence to industry standards and regulations. In critical applications, testing equipment should be calibrated by certified personnel or accredited laboratories.

Calibration Benefits

- Ensures accuracy and reliability

- Reduces measurement errors

- Maintains industry compliance

- Guarantees consistent results

Maintenance Activities

- Periodic inspections

- Component replacement

- Lubrication procedures

- Environmental monitoring

A timely calibration combined with timely maintenance of the test machine increases its working efficiency, maximizes utility life, and reduces downtime and operational cost. Organizations should document calibration and maintenance activity to maintain audit records and for-traceability. A clearly documented working procedure for these activities not only ensures enhanced performance but also saves the organization from heavy liabilities caused by unfortunate deaths due to defective equipment.

Emerging Trends in Bending Tests

Advancements in Testing Methodologies

The recent series of developments in bending test methodologies concerns achieving accuracy with reliability and efficiency. One such development allows the integration of automated testing methods. This automation limits human error and guarantees the force is applied consistently; others view this as a limitation arising from inaccuracy in measurement collection approaches of different precision. The more precise the outcome, the less is the testing time.

Key Technological Advancements

Automated Testing

Reduces human error and ensures consistent force application for improved accuracy and reduced testing time.

Digital Simulation

Enables prediction of material behavior under various conditions with reduced experimental testing.

Non-Destructive Testing

Allows property assessment without material destruction for real-time quality control.

Role of Digital Simulation Techniques

Digital simulation techniques have great importance in analyzing and optimizing bending tests. It means that engineers can model and predict material behavior under bending loads without ever having to resort to building and testing an actual prototype. Using state-of-the-art computational algorithms, simulations shed light on stress distributions, deformations, and failure points, ultimately achieving more efficient and reliable designs.

Simulation Advantages

- Reduces time-consuming and expensive physical testing

- Enables testing of varying materials and geometries

- Shortens product development cycles

- Detects early design faults for safer products

Current integration with AI and machine learning continues to improve accuracy and provides valuable predictions for material performance and lifetime evaluations.

Evaluating New Materials through Bending Tests

Bending tests are deemed necessary to establish new materials to decide on the real strength and flexibility of the material. The force is applied up to bending, and measurements yield combinations of factors, including bending strength, stiffness, modulus of elasticity, and response toward deformation. The information from bending tests is most of the time utile as it tries to reproduce conditions in the real world wherein the material will be subjected to loading.

Test results will be used to ascertain whether the materials studied are suitable for certain applications such as construction, automotive, aerospace, etc. For instance, materials characterized by high bending strength and good elasticity could be considered as candidates for structural support members subjected to high real stresses. On the other hand, those materials displayed low bendability or that would break during the test may need to be either further developed or modified.

By the means of bending tests, designers and scientists enhance designs and materials to achieve maximum performance while confronting safety and regulatory expectations. This approach ensures that newly developed materials will not only be tested for their reliability but also contribute towards better resource utilization and sustainable production practices. Fundamentally, bending tests are a vital procedure in developing innovative materials that modern industries today demand.

Frequently Asked Questions (FAQ)

Q: What is a bending test?

A: A bending test is a mechanical test to determine bending characteristics of materials. The test is performed by applying a force on the specimen so as to bend it, to see if it can oppose bending without fracturing or yielding to plastic deformation.

Q: How is the test setup for a bending test configured?

A: The test setup is usually configured in such a way that a fixture supports the specimen at two points, applying a bending moment at the middle. This configuration ensures that accurate measurements of displacement and resistance to bending can be obtained during the test.

Q: What materials are commonly subjected to bending tests?

A: Bending tests are carried out on various materials used in engineering applications, such as plastics and metals. Bending tests on steel, for instance, are extremely important from the perspective of engineering because these materials often have to bear significant bending loads.

Q: What is the difference between 3-point and 4-point bending tests?

A: The main difference between the two lies in the test set-up. A test of 3-point bending means the specimen is supported at the ends and testing load applied at the center. On the other side, a test of 4-point bending has two load application points, one on each side of the center, thereby distributing the bending stress more uniformly along the length of the specimen.

Q: How does specimen preparation affect the results from bending tests?

A: Proper specimen preparation is essential for the bending test to be accurate. Aspects such as the dimensions, surface finish, and uniformity of the specimen could alter the behaviors of materials under bending loadings and thus influence the bending observed in the test situation.

Q: What does plastic deformation mean in bending tests?

A: Plastic deformation is the permanent change in shape caused by a bending force beyond the elastic limit. During a bending test, it implies how much bending is admitted without any recovery, a crucial item to note for a practical study of the material in everyday applications.

Q: Why is testing important in the assessment of safety of a material?

A: For the safety and reliability of materials in different applications, testing is necessary. Through bending tests, engineers can see how a material resists bending forces, and from that, they evaluate its performance under actual conditions of use, thereby helping to avoid failure in structures.

Q: What bodies set standards for bending tests?

A: Organizations such as ASTM set forth standards for performing tests for flexural strength or other mechanical testing procedures. Deviations from the standards would give results that may not be comparable with those obtained from bending tests carried out under this standard in other laboratories or in the industries.

Q: How does bend testing assist in material selection?

A: Bend testing helps to assess the mechanical properties of the material to allow engineers and designers to select the best material for the application. By knowing the bending characteristics, one can select those materials that will adequately perform under bending loads anticipated.

Q: Are bending tests used to perform fatigue testing?

A: Yes, bending tests are modified to perform fatigue testing that assesses the behavior of materials under repeated bending loads through time. The testing is used to pinpoint places where materials may fail and to make sure that materials can survive cyclic bending without fracturing or losing integrity.

References

- Fundamentals of Bending Tests (BND) – Explains the basics of bending tests, including three-point and four-point bending methods.

- Bend Testing – AHSS Guidelines – Discusses standards like ASTM E290, ISO 7438, and JIS Z2248 for bend testing of metals.

- ISO 7438: Bend test on metals – Details the ISO 7438 standard for determining the bending properties of metallic materials.

- Bending Testing – Focuses on bending tests for brittle and low-plasticity materials like cast iron and tool steel.