Instrument And Equipment Wholesale

2025Bending Testing Machine: High-precision Automation Solution

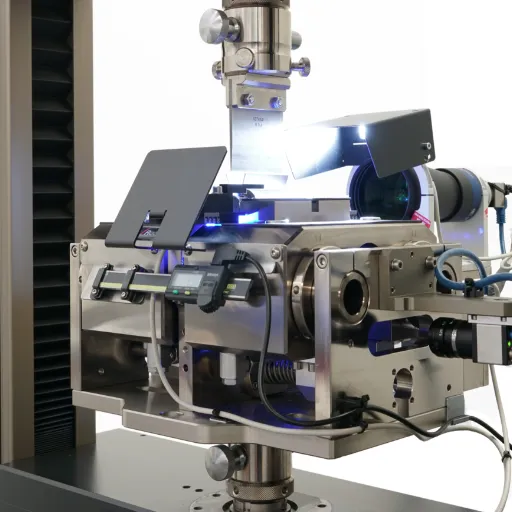

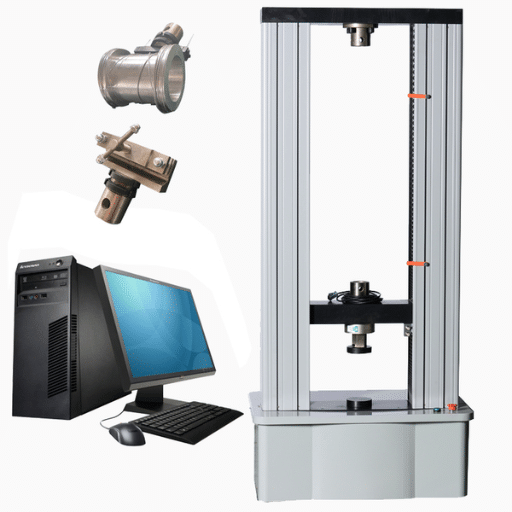

Introducing our High-Quality Bending Testing Machine, crafted by a premier factory in China renowned for precision engineering. Designed for accurate three-point and four-point bending tests, it ensures reliable material evaluation for industries. Built with eco-friendly materials and advanced controls, it offers customization for optimal performance.

What Is A CNC Bending Testing Machine

-

Applies controlled force to evaluate material bending strength and flexibility.

-

Measures properties like flexural modulus, yield strength, and deformation limits.

-

Used in industries like construction, automotive, and aerospace for quality control.

-

Features real-time data monitoring with advanced software for precise results.

-

Available in various load capacities, from 5 kN to 500 kN, for diverse applications.

How to Perform a Bend Test: A Step-by-Step Guide

Bend testing is crucial to establish strength, ductility, and resistance to stress in a material. Standard testing procedures need to be followed for accurate results. In addition, use honest bend test equipment that a bend test equipment supplier will provide you.

- Prepare the Test Specimen: Select and prepare a sample material according to the specified dimensions and standards. This ensures consistency and reliability in the test results.

- Set Up the Equipment: Position the specimen on the bend test machine, ensuring it is aligned correctly with the supports and the loading fixture. Check the equipment settings for accuracy and precision.

- Apply Force: Gradually apply force to the specimen, either in a three-point or four-point bending configuration, depending on the test requirements. Monitor how the material responds to the stress.

- Observe and Record Results: Carefully observe the specimen for signs of deformation, cracks, or fractures. Record the necessary measurements, such as the bending angle, load, and deflection, to evaluate the material’s performance.

- Analyze Data: Use the collected data to determine whether the material meets the desired criteria for its intended application. Common analysis includes assessing the yield strength and flexural modulus.

Essential Tests You Can Perform with a Bending Test Machine 2025

Explore our Bending Testing Machine, which is designed for precise material characterization. This specialized equipment enables detailed materials analysis under controlled bending conditions, delivering essential data for research, development, and quality assurance in various industries.

Freight Forwarding

Efficient global shipping ensures your Universal Testing Machine arrives on time, with secure handling and cost-effective air, ocean, or road transport options tailored to your needs.

Customs Brokerage

Expert customs brokerage simplifies international shipping, ensuring compliance with regulations and fast clearance for your Universal Testing Machine to avoid costly delays.

Warehousing Solutions

Safe, climate-controlled storage protects your Universal Testing Machine, with flexible inventory management to streamline distribution and minimize delays for your operations.

Supply Chain Management

Comprehensive supply chain oversight optimizes logistics for your Universal Testing Machine, providing real-time tracking and seamless coordination from manufacturing to delivery.

How to Choose the Right Bending Testing Machine?

- Select a machine with the appropriate load capacity and test fixtures (e.g., 3-point, 4-point) suitable for the materials and sample sizes you will test.

- Ensure the machine's test space and adjustable test span can accommodate the dimensions of your specific specimens accurately.

- Choose user-friendly software that allows for easy test setup, control, and provides essential data analysis for bending properties like flexural strength and modulus.

- Verify that the machine complies with relevant industry standards for bending tests (e.g., ASTM, ISO) and has a durable build for consistent performance.

- Consider the manufacturer's reputation, after-sales service, technical support, and available calibration/maintenance services.

What are the uses of Bending Testing Machine?

- Construction Industry: Tests the flexural strength and load-bearing capacity of concrete beams, steel rebar, wood planks.

- Automotive Manufacturing: Evaluates the bending resistance and durability of components like axles, chassis parts, suspension arms.

- Aerospace Sector: Assesses the bending strength of materials and components used in aircraft structures, such as wing spars and fuselage sections.

- Materials Science & Manufacturing: Used to characterize the flexural properties (flexural strength, flexural modulus) of various materials including plastics, composites, ceramics.

- Furniture and Wood Industry: Tests the bending strength of lumber, engineered wood products, and furniture joints and components.

Bending Test Machine Operation Tutorial

Components of Bending Testing Machine

Choose from a variety of controller packages, grips, fixtures, chambers, extensometers, and more, all designed to perform thousands of ASTM, ISO, EN, DIN, and JEDEC industry-standard test methods. When you are ready to complete your system, contact us, and an application expert will help you optimize it for your testing requirements and budget.

Bending Test Machine Price

Discover our top Bending Testing Machines, tailored for your needs. Our advanced technology ensures reliable, efficient, and professional material testing solutions.

Wire Repeated Bending Testing Machine

Our Wire Repeated Bending Testing Machine ensures precise testing of metal wires (φ0.3-φ10mm) per ISO 7801. It evaluates plastic deformation and defects with a 90° bend, auto-stopping after breakage, ideal for the steel and cable industries.

Universal Testing Machine

Universal Testing Machines (UTMs) perform tensile, compression, and bending tests on materials like metals and plastics. Equipped with high-precision load cells and advanced software, they ensure accurate, reliable results. Price depending on load capacity, automation, and features.

Bending Testing Machine Data Overview

| Parameter | Details |

|---|---|

| Load Capacity Range | Ranges from 0.0005 N for micro-testing to 2000 kN for heavy-duty bending. |

| Testing Versatility | Specializes in three-point, four-point, and cantilever bending tests. |

| Accuracy and Precision | Features high-precision load cells with ±1% accuracy and digital controls. |

| Environmental Conditions | Operates from -160°C to 1000°C and 5% to 95% RH for realistic bending simulations. |

| Software and Automation | Includes user-friendly software with AI-driven data analysis for bending tests. |

| Speed Range | Adjustable from 1 mm/min to 1000 mm/min for precise control of bending rates. |

| Crosshead Travel | Offers up to ±4500 μm displacement for versatile bending specimen testing. |

| Extensometer Integration | Supports integrated or external extensometers for accurate strain measurement during bending. |

| Power Supply Options | Compatible with 220V/50Hz or 440V/60Hz, depending on regional requirements. |

| Safety Features | Equipped with overload limits, safety valves, and emergency stop functions. |

Manual vs. Automated Bending Testing: A Comprehensive Comparison

| Aspect | Manual Bending Testing | Automated/CNC Bending Testing |

|---|---|---|

| Setup Time | 15-30 minutes per test configuration | 2-5 minutes (programmed configurations) |

| Repeatability | ±5% variation due to human factors | ±0.5% variation with servo control |

| Operator Skill Requirements | Highly skilled technicians required | Basic training sufficient |

| Test Speed | Limited by manual operations | Up to 10x faster with automated sequences |

| Data Quality | Subject to transcription errors | Direct digital capture, error-free |

| Multi-Specimen Testing | Single specimen per operator cycle | Batch processing up to 50 specimens |

| Environmental Testing | Difficult to maintain conditions | Precise environmental control |

| Cost per Test | High labor costs for complex testing | Lower per-test costs at volume |

| Compliance Documentation | Manual record-keeping prone to errors | Automatic compliance reporting |

| Safety | Higher risk of operator injury | Enclosed, automated operation |

| Fixture Accuracy | ±0.1mm positioning accuracy | ±0.01mm CNC positioning |

| Test Standardization | Varies between operators | Identical test execution every time |

| Real-Time Analysis | Post-test analysis only | AI-driven real-time insights |

| Traceability | Paper-based, limited detail | Complete digital audit trail |

| Equipment Utilization | 40-50% efficiency typical | 85-90% automated efficiency |

Why Choose Our Bend Test Equipment Supplier

We are dedicated to delivering top-tier Bending Testing Machines with unmatched precision and reliability. Whether you need advanced testing equipment for industrial applications or research purposes, we offer solutions tailored to your requirements.

We specialize as expert Bending Testing Machine manufacturers, leveraging years of experience to provide high-performance machines. Our designs ensure accurate bending test results, prioritizing durability with robust materials and advanced technology.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Expert Insights on Bending Testing Machine

What is bending testing?

Bending testing, or flexural testing, measures a material’s behavior under flexural stress. It determines properties like flexural strength, flexural modulus, and strain by applying force to bend a sample supported at two points, causing deformation or failure.

How does a bending machine work?

A bending testing machine, often a Universal Testing Machine with bending fixtures, works by applying a controlled downward force via a loading nose (indenter) onto a test specimen supported by two points. It measures the applied load and the resulting deflection of the sample as it bends, capturing data like a load-deflection curve.

What is the standard for bend test?

Bend tests are governed by various international standards depending on the material (metals, plastics, composites, ceramics) and test method (e.g., 3-point or 4-point bending). Common organizations issuing standards include ASTM (e.g., ASTM D790 for plastics, ASTM E290 for metals), ISO, JIS, and others, which specify procedures, fixtures, and sample dimensions.

What are the safety rules when using a bending machine?

Safety rules for bending machines include keeping hands and body parts clear of potential pinch points and moving parts, wearing appropriate personal protective equipment (PPE) like safety glasses (especially for brittle materials that might fracture), ensuring the test fixture and sample are properly secured, and knowing the location of the emergency stop button.

How does a bend test work?

A bend test works by placing a prepared sample onto two support points within the testing machine’s fixture. A third point, the loading nose, then descends from above, applying force at a controlled speed, typically midway between the supports. The machine records the load applied and the distance the sample deflects until it reaches a specified limit or fails.

What is manual bending machine?

A manual bending machine is typically a hand-operated tool or piece of equipment used for permanently forming or fabricating materials (like metal tubes, pipes, or sheets) into desired angles or shapes, rather than testing material properties. It utilizes mechanical leverage or a hand-pumped hydraulic system to apply force.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

In assessing strength and durability, the flexural test is very important. It is essentially a mechanical test that measures resistance […]

In materials science and engineering, the study of mechanical properties is vital for selecting an appropriate material. Flexural strength and […]

Understanding the strength and flexibility of ductile materials is crucial in industries ranging from construction to manufacturing. Amongst the tests […]

Consider the last-mentioned property: bending or flexural strength. It is among the most studied general properties in engineering, construction, and […]

When it comes to understanding material performance, flexural strength plays a crucial role in determining a material’s ability to withstand […]

Considered the metal fabrication industry to be revolutionized by CNC bending machines for precision, efficiency, and versatility in the shaping […]

2025 Trends in Bending Testing: CNC Precision and AI-Driven Insights

The evolution of bending testing in 2025 is the CNC technology and AI analytics altering forever material evaluation processes. CNC bending testing machines are at present offering the highest level of accuracy whereby a test can be carried out consistently and repeatedly with the least interference by the tester.

With advanced software, the machines can carry out an unprecedented real-time analysis of actual bending stress data using an AI methodology and on the basis of that furnish practical details about the performance of the material under study. This is of paramount significance to industries such as aerospace and automotive where requirements for materials that are light yet sturdy are very much confirmed.

Through AI-driven analysis, manufacturers can very much optimize material selection and design such that components like aircraft wing spars and automotive suspension systems conform to applicable safety and performance standards. The combined wins of CNC automation and AI in enhancing testing capacity will begin another chapter in material science innovation.

Get Your Precision Bending Testing Solution!

Ensure material integrity with a reliable, high-precision bending testing machine. Partner with us for expert solutions tailored to your flexural testing needs, whether for standards compliance or R&D. Evaluate properties like flexural strength and modulus accurately. Contact us today for a customized quote and advance your testing capabilities!

Frequently Ask Questions

Q: What is a rotating bending testing machine?

A: A rotating bending testing machine is a specific type of fatigue testing equipment used primarily for cylindrical specimens. It applies a constant bending moment while the specimen rotates, causing alternating tensile and compressive stresses to determine fatigue strength.

Q: What kind of stress is applied by a rotating bending testing machine?

A: A rotating bending testing machine subjects a specimen (usually round) to a constant bending moment while it rotates. This action creates fully reversed alternating tensile and compressive stresses on the specimen’s surface, making it ideal for studying fatigue properties of materials under cyclic bending loads.

Q: What is a universal bending testing machine?

A: A universal bending testing machine is essentially a standard Universal Testing Machine equipped with the necessary accessories (fixtures, software) to conduct flexural or bending tests according to relevant material testing standards.

Q: How does a bending test work on a bending testing machine?

A: A bending test on a bending testing machine involves placing a specimen horizontally across two support points. The machine then applies a downward force via a loading nose (indenter) at one or two points between the supports, measuring the load and resulting deflection.

Q: What makes a best bending testing machine?

A: The best bending testing machine depends on the application, considering factors like force capacity, test speed control, accuracy, compliance with industry standards (e.g., ASTM, ISO), versatility for different materials and fixture types, and the quality of the data acquisition software.

Q: What is a bending fatigue testing machine used for?

A: A bending fatigue testing machine applies cyclic bending loads to a specimen to determine its resistance to fatigue failure. It evaluates how many load cycles a material can withstand before breaking or fracturing under repeated bending stress.

Q: How does a wire bending testing machine function?

A: A wire bending testing machine is designed to repeatedly bend wire specimens through a specific angle and radius. It counts the number of bends or cycles until the wire breaks, assessing its flexibility and durability under continuous bending stress.

Q: What kind of information is gathered by a bending moment testing machine?

A: While “bending moment testing machine” isn’t a standard machine name, equipment capable of bending moment testing (like UTMs or fatigue testers) measures the applied load and deflection to calculate the bending moment acting on the specimen, which is critical for determining bending stress and material properties.