From construction to manufacturing, impact testing is pivotal in ensuring every material’s dependability and longevity. With the right impact testing machine, a company can ensure higher accuracy and reproducibility in its results while reducing bias. In this guide, a reader will be able to learn everything there is to know about impact testing machines, from their key components and applications to their primary uses and buying considerations. Every professional or researcher will greatly benefit from understanding the role of machines in material testing and the solutions offered by the industry today.

What is an Impact Testing Machine?

An impact testing machine assesses a person’s ability to withstand sudden forces or shocks during controlled conditions. These machines evaluate energy absorbed by a material during fracture, providing crucial information regarding its toughness as well as its resistance to impact. Almost all industries and manufacturing firms, construction companies, and those in the aerospace sector make use of impact testing machines. The information provided from these testing machines ensures that the materials used in construction or manufacturing are reliable and safe for use in critical conditions where they might face unexpected stress. The two primary methods of impact testing are Charpy and Izod – both are standardized and therefore yield reliable and consistent outcomes.

Understanding the Impact Test Methodology

Impact testing is based on attempting to recreate real-world scenarios, in which materials undergo rapid loading, by analyzing the energy absorption process. Charpy and Izod methods are well-known due to their strong infrastructure focused on repeatability and accuracy because they have been standardized by institutions such as ASTM International and ISO.

- Charpy Impact Test

The energy required to break a notched specimen is measured using a Charpy pendulum which strikes the specimen. The specimen is held horizontally between anvil supports with the notch oriented away from the impact direction. Material toughness can be quantified as a specimen’s fracture loss in energy, calibrated against a scale. Some important factors to the Charpy method include temperature and notch designs due to their effect on brittleness and impact resistance.

- Izod Impact Test

In the Izod test, the main difference is the specimen position vertically and is held rigidly at one end. A pendulum hammer impacts the free end and leads to material separation along the notch. As in with the Charpy test, energy absorbed is measured and utilized along with calculated values to determine the ductility and toughness of the material under sudden load conditions.

As for material engineers, both methods assist in predicting failure, defining safety margins, and designing components prone to dynamic stresses. These methods are crucial for the described industries which operate with, high-demand, powerful materials capable of enduring extreme mechanical forces.

Importance of Impact Resistance in Material Testing

Impact resistance is a vital property for materials used in structures, automobiles, and aerospace technologies – areas which demand the highest performance. It pertains to the ability of a material to endure energy absorption and dissipation through sudden loads without breaking apart. Materials that possess high impact resistance are beneficial in the safety and reliability of the components, as they can endure unpredictable forces like collisions and mechanical shocks.

Impact resistance is critical in developing new composites and alloys, which has been a focus within material science recently. For example, fiber reinforced polymers and high-strength steel alloys are increasingly used in their engineered forms where impacts are encountered due to their increased impact resilience. Other modern techniques like instrumented impact testing enable real-time assessments of energy loss during impacts, or cracks during impact, giving engineers more than enough information about materials’ extreme condition behavior. Having this kind of data helps professionals to choose the right materials and design structures for reliable and safe operation in stringent conditions.

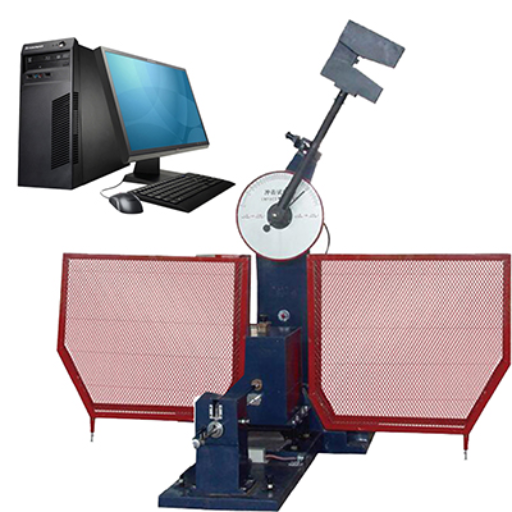

How Does a Pendulum Impact Tester Work?

Pendulum impact testers function by dropping a pendulum of known weight and height onto a specimen placed within its swing radius. The pendulum’s potential energy, governed by its height, transforms into kinetic energy as it swings. Impact with the specimen transfers some of that energy, resulting in deformation or fracture. In this case, the tester measures the energy absorbed by the material during the impact as the difference in energy the swinging pendulum possesses before striking and after striking the specimen. This information, together with other assessment actions, allows us to determine the values for its toughness and impact resistance.

Components of a Pendulum Impact Testing Machine

A pendulum impact testing machine focuses on separate, distinct components, each working towards optimal measurement and maximum accuracy of impact resistance:

- Pendulum Arm and Hammer

The systhem uses a pendulum arm which does not deform from the test within a specimen. The arm behavior is essential during the test and needs to provide some rigidity which can be attained through materials like steel The attached impact hammer, which comprises an integral part of the entire system also needs to provide enough impact energy through its geometry, mass, and energy threshold to provide appropriate standards.

- Specimen Holder (Anvil)

Holders are the specimen frames that permit specimen insertion, tightening screws and clamping arms immobilizes the test piece ascertaining no motion form the test piece. Because of the need for good alignment and clamping relative to the impact plane, most of these holders are adjustable and made in accordance to Interlarnational standards.

- Energy Scale or Digital Readout

Energy quantification may be done using a mechanical scale on analog or a digital display. Modern machines come fitted and integrate with sensors for energy quantification and computer systems to automate calculations turning systems to robotic models, hence reducing work load, the amount of human error as well increasing precision and accuracy.

- Release Mechanism

The Release Mechanism manages the first positional frame for suspended pendulum arms such that the pendulum’s angular displacement from the vertical position is zero. It controls the amount the pendulum is allowed to swing and is focused on reducing variability in the motion.

- Braking System

To avoid ancillary damages, pendulum testing machines incorporate an effective braking mechanism that stops the pendulum after the initial impact. Commonly used methods to achieve this safely and swiftly include hydraulic or friction brakes.

- Protective Enclosure

To protect operators, impact testing equipment is usually encased within a protective shield or chamber that contains all fragments resulting from specimen rupture. Such enclosures are made from visible materials like polycarbonate, which add transparency.

- Calibration and Adjustment Features

Newer models offer tools for precision calibration to align system parts and check energy values to be within required limits before the test commences. These functionalities ensure compliance to standards such as ASTM E23 or ISO 148.

All these components enable the machine to give reliable and precise measurement of impact resistance, which makes the pendulum impact testing machine indispensable in the fields of material science and engineering.

Applications of Pendulum Impact Testing

Pendulum impact testing machines are essential instruments in all industries and fields of research for evaluating the toughness and durability of materials. Hereunder follows an exhaustive list of their most important uses:

- Material Characterization

In the evaluation of impact toughness and energy absorption capacity in materials, Pendulum impact tests are routinely performed. Take Charpy impact tests for example; certain values such as impact energy (in Joules) and the corresponding fracture mode provide vital indicators about a material’s brittle or ductile behavior during severe high rate strain.

- Quality Control

For industries such as aerospace and automotive manufacturing, pendulum impact testing is incorporated into the company’s quality control procedures. Continuous testing allows them to meet compliance requirements like ASTM E23 or ISO 148 so that reliable and consistent manufacturing outcomes can be achieved.

- Failure Analysis

Pendulum impact tests are used by Engineers in post-failure analysis to identify mechanical problems in structural components to determine the cause of failure. The results of the tests performed can attribute the cause of failure to either insufficient fracture toughness, systematic material flaws, or other intervening conditions.

- Customization for Industry Standards

The Construction and oil and gas industries conduct impact testing on materials like steel to ensure that they meet certain safety factors and operational requirements. For example, in bridge construction, pendulum testing data is used to evaluate the resilience of steel beams subjected to sudden load applications.

- Educational and Research Applications

Within academic and research institutions, pendulum impact testers are often stratum used for studying the fracture mechanics of materials. Such data is crucial for devising new materials which are tougher and possess application-specific engineered properties.

All these applications emphasize the importance of pendulum impact testing in material characterization and global cross-industry technological advancement. The critical need of materials science and manufacturing industries is fully addressed by this technique for its ability to accurately quantify and evaluate material resilience through rigorous testing.

What Are the Key Features of Quality Impact Testing Equipment?

- High Accuracy and Precision

Rigorous testing and comparison of materials demand quality impact testing equipment which yield consistent and accurate measurements.

- Durability and Sturdy Construction

Data accuracy hinges on the ability to withstand harsh testing environments and result in consistent long-term operational reliability.

- Ease of Use

Test setup and execution become effortless with the use of streamlined controls and interfaces, which significantly minimize error. As such, personnel can conduct tests with greater efficiency.

- Compliance with Standards

The equipment must adhere to the set standards like ASTM or ISO to ensure cross-industry validation and relevance of test results.

- Versatility

A good system should have enough flexibility in the scope of materials and test configurations to provide value in many applications.

ASTM and ISO Standards in Impact Testing

The ASTM and ISO organizations have guidelines on how to perform and verify an impact test and ensure consistency in the evaluation of material properties. For example, ASTM E23 provides guidelines on the test methodologies for measuring the impact strength of metallic materials by Charpy and Izod pendulum tests, detailing specimen care, fixture, and machine calibration. Also, ISO 148-1 provides guidelines on the Charpy impact test for metallic materials paying attention to the notched specimen geometry, temperature, and energy values measured during the test.

Following these standards is imperative because they remove uncertainties in the execution of the tests and facilitate data comparisons across laboratories and industries. Both ASTM and ISO require exacting calibration of the testing equipment in relation to the test precision and reproducibility. In addition, revision to the standards embraces new boundaries offered by sensor and data acquisition technology concerning the testing procedures for high-performance materials and composites. With adherence to these standards, industries ensure thorough compliance with internationally accepted benchmarks while mounting compliance to safety standards, rigorous testing, and claiming performance evaluation.

Impact Energy and Impact Velocity Measurements

Making precise measurements of impact energy and impact velocity is critical for assessing the structural integrity and safety of the material during dynamic loading conditions. Impact energy is estimated using calibrated impact testers like pendulum impact testers or drop weight machines which quantify the energy absorbed by a material during fracture or deformation. This helps to estimate the toughness of the material and its sudden force resistance.

In contrast, Impact velocity is assessed using high speed impact sensors, laser velocity systems, or other optical methods. These advanced systems are capable of monitoring the contact velocity at the moment of impact which is extremely important for replicating real world scenarios. Impact energy and velocity are often quoted using computational and experimental approaches to validate the predicted behavior of the material over a wide range of stress rates.

Recent advancements in sensor precision and data acquisition has improved the fidelity in collection of detailed datasets, allowing industries to refine the selection and development of materials for use in critical applications such as automotive, aerospace, and sports protective equipment. When coupled with the appropriate methodological framework, these techniques permit evaluation aligned with international testing standards.

How to Choose the Right Impact Testing Equipment for Your Needs?

The selection of appropriate impact testing equipment is based on the following criteria:

- Application Requirements

Define the specific materials or products you intend to test. There are differences in testing equipment when evaluating aerospace metals alloys compared to testing polymers used in consumer products.

- Testing Standards

Idetifying the relevant industry standards, such as ASTM or ISO, is a given. These requirements also apply in the other way, i.e., the testing equipment must be able to meet these requirements for reliable and accurate results.

- Impact Energy Range

Assess the impact energy range capabilities of the equipment. A pendulum impact tester may be required for larger high energy impacts, while drop-weight testers may be better suited for smaller precise impacts.

- Data Collection and Analysis Features

Look for features of advanced data acquisition systems which provide better measurement and analysis. Streamlined reporting due to integrated software improves compliance with regulatory frameworks.

- Durability and Maintenance

Evaluate the frame and the equipment’s build quality along with the intended routine maintenance. This high quality frame and low maintenance coupled with high quality materials will greatly extend the equipment’s lifespan and lower long-term costs.

Following these considerations allows one to choose impact testing equipment that best matches one’s operational requirements while still utilizing the technical requirements set by the company.

Comparing Charpy and Izod Impact Testing Machines

|

Key Point |

Charpy Impact Test |

Izod Impact Test |

|---|---|---|

|

Sample Orientation |

Horizontally placed |

Vertically clamped |

|

Notch Position |

Facing away from the impact hammer |

Facing towards the impact hammer |

|

Pendulum Impact Direction |

Behind the notch |

Into the notch |

|

Test Standard |

ISO 148, ASTM E23 |

ASTM D256, ISO 180 |

|

Test Purpose |

Material toughness evaluation |

Impact resistance assessment |

|

Clamp Design |

Two supports on both sides |

Fixed at one end |

|

Specimen Size |

Larger standard specimen size |

Usually smaller specimen size |

|

Common Materials Tested |

Metals, composites |

Plastics, metals, composites |

|

Energy Measurement Method |

Energy absorbed by specimen |

Energy absorbed by specimen |

|

Typical Applications |

Structural materials analysis |

Polymers and non-metallics testing |

|

Energy Absorption Range |

Suitable for higher energy ranges |

Limited to lower energy ranges |

|

Industry Use |

Aerospace, construction materials |

Automotive, packaging industry |

|

Ease of Specimen Preparation |

Simple for standard materials |

More complex for some materials |

|

Equipment Cost |

Moderate to high |

Generally lower |

|

Resulting Data |

Impact toughness (Joules) |

Impact strength (Joules/m or lb-ft) |

Cost Considerations for Impact Testing Systems

When assessing costs for impact testing systems, several components come together to determine total costs. Capital costs related to equipment purchases tend to differ significantly based on how sophisticated the system is. For example, Charpy testers tend to comprise moderate to high cost owing to their precision engineering and robust design meant for high impact scenarios, making them favorable for aerospace and construction material testing industries. In contrast, Izod systems tend to be less expensive and are preferred in the automotive and packaging industries that require lower energy impact tests.

Different ways of spending money, such as operational expenses greatly add to the overall cost. Some relevant examples are checking maintenance, calibration, and consumable materials such as assessment test standards or pendulum tips, which need to comply with rubrics set by ASTM or ISO for their accuracy. Furthermore, more advanced systems that feature augmented interfaces of data acquisition software may need extensive training or technical help, which brings us back to the cost structure. Such industries have to consider how much precision impact testing systems offer alongside the range of impact data to ensure that the financial investment is well optimized.

What Materials Are Typically Tested with Impact Testing Machines?

Materials evaluated in impact testing machines include polymers, metals, composites, and ceramics. Commonly, metals like aluminum, steel or titanium undergo testing for dynamic load fracture resistance and toughness. Assessment of polymers and composites focus on their ability to nylon and carbon fiber, endure stresses and impacts for aerospace or automotive functionalities. Although brittle, certain ceramics undergo specialized testing to evaluate their performance when subjected to sudden stress. These materials are chosen for their prevalence across engineering, construction, and manufacturing fields, where faulty mechanical property data poses serious risks to safety, and performance.

Testing Plastics: Impact Strength and Toughness

Like any other material, plastics undergo a thorough evaluation process to assess their impact toughness, which is vital for testing usability withstanding demanding forces. Impact strength and toughness both involve a combination of physical and chemical characteristics of materials fragmentation performance under pressure. Energy absorption tests include the Charpy Test and the Izod Test, both of which deliver fracture forces or blows. Now, engineers have sophisticated computational techniques as well as a variety of scientific methods to evaluate complex situations where precise predictions are needed, without undergoing physical testing. Functionality in crashing automobiles or dismantling planes, as well as electronics, makes it essential to know this kind of information in advance when using plastics for protective and construction purposes. Advanced developments within the branch of polymer science are making progress toward increasing the durability of functional and eco-friendly materials.

Metal vs. Polymer: Differences in Impact Resistance

In relation to impact resistance, one must consider several key material properties when making comparisons between metals and polymers. The former tend to endure impact more efficiently because of their granularity and dilatancy alloyed with stainless steel or titanium. Polymers, on the other hand, have a range of molecular chains and in some cases, add-ons, so they will show impact resistance differently. As an example, engineering polymers ABS are polycarbonate and are meant to endure impact by high forces without succumbing to cracks or breaks.

One of the critical differences is the impact damage of these materials whereby a certain impact force is applied. Metals tend to suffer from deformation whereby they would bend or dent and would not snap unless the force exceeds the yield value. In contrast to that, those are temperatures and time dependent, known as viscoelastic behavior or about polymers as brittle behavior. Some forces or low temperatures would enable them to absorb that much energy but break easily under too much force.

Improvements in material science have refined the impact resistance of both categories. Alloys have stronger performance parameters, and metals gain the inclusion of reinforcements or plasticizers in polymers. There are metals that exceed in terms of rigidity, thermal stamina, or strength. It is becoming more and more common to use polymers where weight, resistance to corrosion, and low price dominate. Where these distinctions exist, engineers would integrate and combine materials optimized for such operational criteria.

How Specimen Preparation Affects Testing Results

Material testing methodologies require specimen sizing, shaping, finishing, polishing, and specimen alignment. Proper specimen preparation matters in achieving consistent and accurate testing results across various testing methods. Tessellation directly impacts the consistency of test data. For example, surface scratches and improper fixture alignment causes stress concentration, leading to data falsification through too early failure. Rough or uneven surfaces also reduce accuracy and precision during hardness testing, specifically the supply of finishing indent measurement.

Now, standardization is reinforced in advanced preparation protocols to avert such mistakes. For instance, ASTM and ISO provide specific requirements for a given standard, such as regarding the polishing, machining tolerances, and even the dimensional upkeep of the polished specimens. Moreover, the preservation of temperature and the environment of the workspace gaps during preparation are crucial in the case of polymers and some composites which are sensitive to heat. Following such stringent protocols assists laboratories in minimizing variability and improving dependability, ensuring that the mechanical and physical properties reflect actual conditions.

What is the Importance of Quality Control in Impact Testing?

Maintaining consistent quality standards during impact testing is vital to ensure test outcomes are both accurate and dependable. This safeguard helps protect against oversights in procedural steps undertaken during the testing, equipment, and sample preparation as they are all aligned to a consistent benchmark. Stringent quality control helps enhance accuracy which in turn decreases variability. This guarantees that the material properties measured are indicative of the actual values, as they would be subjected to in service conditions. It further aids in meeting compliance with industry standards, safety regulations, and preserving reputation in the outcomes of the tests.

Ensuring Accuracy with Hardness Testing and Impact Tests

In order to ensure accuracy, there requires to be a combination of sophisticated methods and instruments which integrate precision measures for conducting hardness tests and impact tests. Contemporary hardness testing procedures like Rockwell, Brinell, and Vickers have shown that they can deliver consistent results when there is accurate and consistent force application, sample surface preparation, as well as careful calibration of measurement devices. Controlled environmental factors are equally important in impact tests so as to allow proper specimen notching for characterization of material toughness and resistance to rapid loading forces such as Charpy and Izod impact tests. Data integrity is further advanced with automation, real time analysis, and acquisition when high precision automated devices are used. Compliance to ASTM or ISO standards as well as data reliability that backs vital engineering and design decisions is achieved with these practices.

Role of Impact Testing in Manufacturing and R&D

Impact testing is integral to contemporary manufacturing, as well as research and development (R&D) since it permits assessment of a given material’s properties with precise loading applications. Recent innovations in testing techniques, for instance, instrumented impact testing machines, provide the possibility of detailed evaluation of material injuries and energy dissipation processes. These innovations utilize high-speed data acquisition systems that measure the force and displacement parameters during material interactions, which increases the resolution of the data collected during testing.

Additionally, most industries now use a combination of computational modeling and experimental impact testing to evaluate materials under various conditions. This approach reduces reliance on numerous tests, thus streamlining development schedules and expenditures. The specifics of certain applications, like automotive impact test for crashworthiness or aerospace materials for robustness evaluation, highlight the growing need for advanced impact testing technologies. The safety and durability of the products are improved, and the processes of manufacture, quality control, and compliance with legal requirements become more stringent.

Reference Sources

-

Izod and Charpy Impact Testing Machines and Standards – This article discusses the Izod and Charpy impact testing machines and their standards.

-

Innovative Impact Testing Machine for Enhancing Simulations – A paper summarizing the development of a state-of-the-art impact testing machine for simulating impacts like vehicular crashes or debris.

-

High Impact-Testing Machine for Elastomers Investigation – This study introduces a high-speed testing machine concept for characterizing the impact behavior of elastomers at high velocity.

Frequently Asked Questions (FAQs)

Q: What is an impact testing machine used for?

A: An impact testing machine is used to determine the impact resistance of materials by simulating real-world conditions. It measures how materials behave under sudden force or shock, providing valuable data for product development and quality control.

Q: What are the different types of impact test methods?

A: The most common impact test methods include the Charpy V-notch test, Izod test, and Gardner impact test. Each method has its specific setup and application, helping to assess the toughness and brittleness of materials.

Q: How does the range of impact affect test results?

A: The range of impact, which refers to the energy levels applied during testing, can significantly affect the results. Different materials will respond differently to varying energy levels, making it crucial to select the appropriate range to accurately assess impact resistance.

Q: What role does sample preparation equipment play in impact testing?

A: Sample preparation equipment is essential for creating standardized impact specimens that meet specific dimensions and surface finishes. Proper preparation ensures that the results of the impact resistance testing are reliable and comparable to ISO and ASTM standards.

Q: What is the significance of the falling weight in impact testing?

A: The falling weight is a critical component of impact testing machines. It delivers a sudden force to the impact specimens, and the energy of the falling weight is measured to determine the material’s resistance to impact.

Q: Can impact testing machines conduct both tensile impact and compression tests?

A: Yes, many modern impact testing machines are versatile and can perform both tensile impact and compression tests. This capability allows for a more comprehensive understanding of a material’s mechanical properties.

Q: What are some key standards that impact testing machines must comply with?

A: Impact testing machines need to comply with various standards, including ISO 8256 and ASTM standards. These standards outline the methods and criteria for conducting impact tests, ensuring consistency and reliability in results.

Q: How do you interpret a test report from an impact testing machine?

A: A test report provides detailed information on the impact resistance of a material, including energy absorbed, type of test performed, and specific test conditions. Understanding these details is crucial for evaluating material performance and making informed decisions.

Q: What is the importance of a cooling chamber in impact testing?

A: A cooling chamber is important for testing materials at various temperatures. It allows for the assessment of impact resistance under different thermal conditions, providing insights into how materials will perform in real-world applications.

Q: How does high throughput impact testing benefit industries?

A: High-throughput impact testing allows industries to evaluate multiple samples quickly and efficiently, streamlining the testing process. This capability is particularly beneficial for manufacturers looking to optimize their materials and ensure quality control without extensive delays.