Manhole cover testing machines are critical tools designed to ensure the safety, durability, and compliance of manhole covers across various industries. These machines play a pivotal role in evaluating load-bearing capacities, material integrity, and adherence to strict regulatory standards, safeguarding infrastructure and public safety alike. This guide dives deep into the world of manhole cover testing machines, exploring their advanced features, methodologies, and key performance indicators. Whether you’re an industry professional seeking to invest in reliable equipment or simply looking to enhance your understanding of this essential technology, this article provides the insights you need to make informed decisions. Stay tuned as we uncover how to identify the best machines available and what sets them apart in today’s market.

What Is a Manhole Cover Testing Machine?

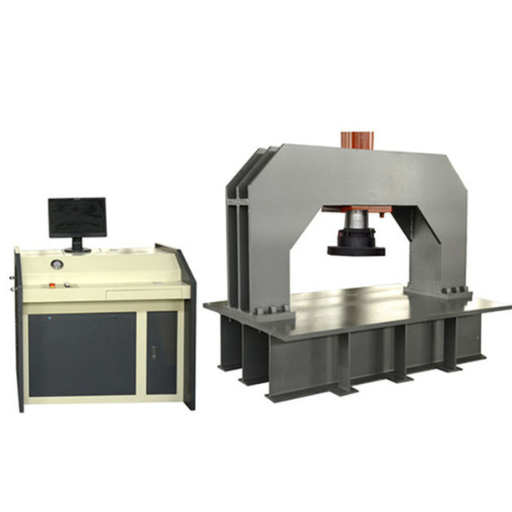

A Manhole Cover Testing Machine is a specialized piece of equipment designed to evaluate the strength, durability, and load-bearing capacity of manhole covers. It ensures these covers meet industry standards and are safe for use in various environments, including roadways and pedestrian areas. The machine applies controlled force to simulate real-world conditions, identifying any weaknesses or defects. By reliably testing performance, these machines help maintain safety and compliance with regulatory requirements.

Understanding Manhole Testing Equipment

Manhole testing equipment is critical for ensuring the structural integrity and safety of manhole covers under real-world conditions. This equipment typically includes hydraulic or pneumatic press systems, load cells, and software for precise force application and data collection. The primary purpose of these machines is to simulate stresses from vehicular traffic or environmental loads, assessing the cover’s ability to withstand pressure and wear over time. Standards such as EN 124 and ASTM provide guidelines for testing thresholds, focusing on parameters like static load, impact resistance, and deformation. Advanced testing systems may also include environmental chambers to replicate temperature fluctuations and corrosion testing to analyze material durability. By adhering to rigorous evaluation processes, this equipment ensures compliance with industry regulations, enhances safety, and reduces the likelihood of failure during operation.

Key Functions of a Test Machine

- Load Measurement and Control: Accurately measures and applies forces to test material strength and performance under specified conditions.

- Stress-Strain Data Analysis: Provides critical data by evaluating how materials deform under stress, enabling precise computation of stress-strain relationships.

- Simulation of Real-World Conditions: Reproduces environmental factors such as temperature, pressure, and humidity to observe material behavior in actual operational scenarios.

- Fatigue Testing: Assesses a material’s ability to withstand repeated stress cycles, crucial for understanding long-term durability and performance.

- Failure Analysis: Determines the point and mode of failure in materials, aiding in the design optimization process and ensuring safety standards are met.

The Role of Manufacturers in Quality Assurance

- Implementation of Stringent Testing Protocols: Manufacturers are responsible for establishing rigorous testing procedures to ensure that materials and products meet both regulatory standards and customer specifications.

- Quality Control During Production: By continuously monitoring production processes, manufacturers can identify and mitigate defects in real-time, ensuring consistency and reliability in the final output.

- Supplier Evaluation and Management: Manufacturers must carefully assess and manage their supply chain partners to guarantee the quality of raw materials and components used in their production processes.

- Compliance with Industry Standards: Adhering to established regulations and standards ensures that products meet mandatory safety, performance, and environmental criteria.

- Continual Improvement Through Feedback: Manufacturers play a key role in analyzing customer feedback and performance data to refine production processes, enhance product reliability, and innovate for future developments.

How Does Compression Testing Machine Work?

A compression testing machine operates by applying a controlled, compressive force to a test specimen to determine its behavior under load. The machine consists of a loading frame, a hydraulic or mechanical actuator, load cells or sensors, and a data acquisition system. The specimen is placed between two platens, and the actuator exerts force at a constant rate or specified intervals. Sensors measure the load and deformation, and the data is recorded for analysis. This process assesses material properties such as strength, elasticity, and failure point, providing critical insights into structural integrity and durability.

Principles Behind Compression Testing

Compression testing is founded on fundamental mechanical principles and is designed to evaluate how materials behave under applied compressive loads. At its core, the test measures essential parameters such as compressive strength, elastic modulus, yield point, and strain-hardening characteristics. The process relies on applying controlled axial loads to a specimen, typically demonstrated in the stress-strain curve generated by the test.

The test setup usually ensures uniform load application and minimal lateral strain through precise alignment of the specimen. This is critical for accurate stress distribution. The data gathered allows engineers to determine critical thresholds, such as the ultimate compressive strength at which a material fails or permanently deforms. These tests are integral for materials used in structural and industrial applications, ensuring safety, efficiency, and compliance with engineering standards.

Components of a Manhole Cover Compression Testing Machine

Key Components and Technical Parameters of a Manhole Cover Compression Testing Machine

- Loading Frame

The loading frame is designed to withstand high forces with minimal deformation. It ensures stability during compression testing. Typical load capacities range from 100 kN to 2000 kN, depending on the application.

- Hydraulic System

The hydraulic system provides the controlled force required for testing. It includes a hydraulic pump and actuator capable of delivering precise incremental loads. Pressure ranges typically span from 0 to 25 MPa.

- Control Unit

The control unit manages system operations and records accurate test results. It often features digital interfaces and real-time feedback systems, ensuring load rate accuracy within ±1%.

- Load Cell

The load cell measures the applied force with a high degree of accuracy. Load sensors should have an error margin of less than 0.5% for reliable data collection.

- Platens

Compression platens are precision-machined surfaces used to distribute load uniformly over the specimen. They are commonly constructed of hardened steel for durability and to prevent surface wear.

- Data Acquisition System (DAS)

This system records all relevant parameters such as load, displacement, and time. Modern systems are equipped with software that supports graphical analysis and customizable reporting.

- Safety Features

Safety mechanisms, such as overload protection and emergency stop functions, are integrated to ensure operator and equipment protection during high-force testing scenarios.

- Power Supply

The machine requires a stable power source, typically rated at 220-240V AC or 110V AC depending on regional standards, with a frequency of 50/60 Hz.

By combining these components, the machine reliably performs compression tests to determine the structural capacities of manhole covers, ensuring compliance with regulatory standards such as EN 124 or similar norms.

Monitoring and Gauge Functionality

The monitoring and gauge functionality of the machine is critical for precise analysis and operational efficiency. The system typically incorporates robust load cells and digital gauges to measure applied force with high accuracy. Real-time data acquisition systems capture and display force, displacement, and strain metrics, allowing operators to monitor and analyze test performance effectively. Advanced machines may also include integrated software for automated data logging, test reporting, and compliance validation against standards such as EN 124. This functionality ensures comprehensive tracking, minimizing errors during testing and reinforcing the reliability of results.

What Types of Testing Equipment Are Available?

Various types of testing equipment available include tensile testers, compression testers, fatigue testers, hardness testers, and impact testers, among others. These machines are used across industries to evaluate material properties and performance under varying conditions.

|

Equipment Type |

Purpose |

Key Features |

Common Use |

|---|---|---|---|

|

Tensile Tester |

Measures tensile strength |

High precision |

Material testing |

|

Compression Tester |

Analyzes compressive force |

Heavy-duty |

Structural testing |

|

Fatigue Tester |

Tests cyclic stress endurance |

Durable build |

Fatigue analysis |

|

Hardness Tester |

Determines material hardness |

Quick results |

Metal testing |

|

Impact Tester |

Assesses impact resistance |

Robust frame |

Failure analysis |

Various Manhole Testers and Their Uses

Manhole testers are specifically designed to evaluate the structural integrity, sealing performance, and durability of manholes, ensuring they meet industry standards and safety regulations. Below is a detailed overview of common manhole testers, their uses, and corresponding technical parameters:

|

Type |

Function |

Features |

Common Parameters |

|---|---|---|---|

|

Vacuum Testers |

Tests manhole sealing by creating a vacuum inside. |

Portable, precise operation |

Typical vacuum range: 10–28 inHg (inches of mercury) |

|

Hydrostatic Testers |

Assesses water tightness by filling the manhole with water. |

High-capacity tanks, durable design |

Pressure range: 1.5–5 psi, Test duration: 15–60 minutes |

|

Air Pressure Testers |

Evaluates the air tightness of manholes using varying air pressures. |

Lightweight, easy-to-use |

Pressure range: 3–10 psi, Leakage rate threshold: ≤0.1 psi/min |

|

Deflection Testers |

Measures the structural deformation under load conditions. |

Flexible probes, durable units |

Allowable deflection limit: 5% deformation of manhole diameter |

Applications of Manhole Testing

- Quality Assurance during Construction

Manhole testers are critical tools for verifying that newly constructed manholes are free from leaks or structural defects prior to acceptance by local authorities or project stakeholders.

- Maintenance and Emergency Assessment

Routine testing of manholes prevents potential issues such as collapse or leakage, particularly in areas subject to frequent heavy rains or high traffic loads.

- Compliance with Standards

Testing ensures compliance with industry guidelines such as ASTM C1244 for vacuum testing or ASTM C969 for hydrostatic testing of manholes.

Comparison Between Hydraulic and Automatic Machines

Hydraulic and automatic machines differ primarily in their operation mechanisms, energy efficiency, precision, speed, maintenance requirements, and cost-effectiveness.

|

Parameter |

Hydraulic Machines |

Automatic Machines |

|---|---|---|

|

Operation |

Fluid-based |

Programmed system |

|

Efficiency |

Moderate |

High |

|

Precision |

Medium |

Superior |

|

Speed |

Slower |

Faster |

|

Maintenance |

Frequent |

Minimal |

|

Cost |

Lower |

Higher |

Understanding Vacuum Testing Equipment

Vacuum testing equipment is crucial for detecting leaks, ensuring quality, and maintaining system integrity in a wide range of industries, including manufacturing, aerospace, and electronics. These tools operate by creating a pressure differential and detecting any leaks through various methods like vacuum decay, pressure rise, or helium leak detection. The choice of equipment depends on factors such as the sensitivity required, system size, and nature of the materials tested.

Modern vacuum testers often incorporate advanced technology for precise measurements and automation, with features such as touchscreen interfaces, data logging, and real-time analytics. Key parameters in vacuum testing include ultimate vacuum pressure, detection sensitivity, and leak rate measurement (typically expressed in Pascal-cubic meters per second or Torr-liters per second). The integration of such devices can also enhance production efficiency and compliance with industry standards like ISO 9001 or MIL-STD-883.

When selecting vacuum testing equipment, it is critical to consider the application type, environmental conditions, and the necessary compliance with safety and industrial regulations.

What Are the Key Specifications for Manhole Cover Testing Equipment?

Key Specifications for Manhole Cover Testing Equipment

- Load Capacity: The equipment must support a load rating aligned with the weight class of the manhole covers being tested, typically ranging from 5 tons to 50 tons or higher, depending on application standards such as EN 124.

- Precision Measurement: High-accuracy sensors are necessary to assess load distribution and deformation, ensuring compliance with rigorous safety and quality benchmarks.

- Durability: Materials used in the equipment should withstand harsh operational environments, including corrosion-resistant and weatherproof components for prolonged use.

- Portability: Lightweight yet robust designs are recommended to facilitate easy transportation and on-site testing in varying field conditions.

- Testing Versatility: The system should accommodate the evaluation of mechanical properties such as bending strength, deflection, and crack resistance.

- Automation and Data Logging: Modern equipment should include automated testing processes and digital data recording capabilities to ensure consistency, traceability, and compliance reporting.

- Compliance Standards: The device must adhere to relevant national and international standards, ensuring their application meets regulatory requirements for structural safety.

Understanding Pressure Testing Parameters

Key Parameters in Pressure Testing

Pressure testing involves defining and evaluating critical parameters to ensure structural integrity under operational conditions. Below are essential aspects to consider:

- Test Pressure: The applied pressure during testing is generally higher than the operational pressure to provide a safety margin. It is calculated based on system material strength and regulatory standards, typically ranging between 1.25 to 1.5 times the maximum allowable working pressure (MAWP).

- Holding Time: The duration the pressure is maintained is crucial for identifying leaks or material inconsistencies. This time frame varies depending on system specifications, material properties, and applicable codes but generally spans from 10 to 30 minutes.

- Medium Used: The choice between liquid (hydrostatic testing) and gas (pneumatic testing) depends on the system’s application. Liquids, being incompressible, are safer and more effective for larger systems, while gases are used for systems where contamination must be avoided.

- Temperature Considerations: Both the test medium and system components should be at controlled temperatures, as temperature fluctuations can lead to material expansion or contraction, skewing results. Monitoring and stabilizing temperature ensures precise evaluations.

- Acceptance Criteria: Testing must define pass/fail parameters, such as allowable pressure drop, observable deformations, or leakage thresholds, adhering to standards like ASME B31.3 or API 598.

By consolidating these parameters and adhering to international standards, pressure testing ensures reliability, operational safety, and compliance in engineered systems.

Importance of Gauge Accuracy

Gauge accuracy is critical in pressure testing as it directly impacts the reliability of measurement data and the validity of test results. An inaccurate gauge can result in incorrect pressure readings, leading to potential safety risks, non-compliance, or premature equipment failure. To ensure precision, gauges should conform to standards such as ASME B40.100, which specifies accuracy grades based on percentage of full-scale range.

Key technical parameters for ensuring gauge accuracy include:

- Accuracy Grade: Select gauges with a suitable accuracy grade, such as ±1% of full scale for general applications, or ±0.25% for high-precision requirements.

- Calibration Frequency: Regular calibration is essential, typically every 6 to 12 months, depending on usage intensity and environmental conditions.

- Operating Range: Ensure the gauge operates within 25% to 75% of its rated scale for optimal accuracy and to prevent overloading or wear.

- Environmental Factors: Consider temperature, vibration, and exposure to corrosive media, as these factors can influence gauge performance. Use gauges designed with appropriate environmental protections when applicable.

- Resolution: Ensure the gauge resolution aligns with the required sensitivity for the test, which depends on the magnitude of pressures being measured.

By adhering to these parameters, operators can maintain gauge accuracy, ensuring valid results, improved operational safety, and compliance with testing standards.

Industry Standards for Manhole Testers

When addressing industry standards for manhole testers, I focus on three main areas that are consistently emphasized across key industry references:

- Compliance with ASTM Standards: I ensure that the manhole testers I utilize adhere to ASTM standards, particularly ASTM C1244. This standard specifies vacuum testing criteria for concrete manhole sections, providing clear guidelines for maintaining structural integrity and performance.

- Material Durability and Safety Requirements: I prioritize using manhole testers constructed with materials that meet durability and safety specifications. This includes ensuring that gaskets, hoses, and other components are resistant to chemicals, corrosion, and pressure during testing.

- Calibration and Pressure Regulation: I verify that all testing equipment, including vacuum gauges and pressure regulators, is calibrated according to manufacturer or regulatory guidance. Maintaining accurate calibration ensures test reliability and results that meet legal and operational standards.

These practices ensure I achieve efficient and standardized testing, meeting industry benchmarks while maintaining safety and accuracy.

How to Choose the Right Machine for Manhole Cover Testing?

Key Factors in Choosing the Right Machine for Manhole Cover Testing

Selecting the appropriate machine for manhole cover testing requires a thorough assessment of several critical factors to ensure reliability, accuracy, and compliance with industry standards:

- Load Capacity: Confirm that the machine’s maximum load capacity aligns with the testing requirements for the specific manhole covers being evaluated. Overestimating or underestimating this factor can lead to inaccurate results or potential equipment damage.

- Test Standards Compliance: Ensure the machine adheres to recognized testing standards, such as EN 124 or ASTM specifications, to guarantee that test outcomes are valid for regulatory and operational needs.

- Precision and Calibration: Look for equipment with high precision and regular calibration options. Accurate load application and pressure monitoring are essential for result validity.

- Ease of Operation: A machine with user-friendly controls and a clear interface helps optimize the testing process while reducing operator error.

- Durability and Maintenance: Investigate the machine’s build quality and maintenance requirements. Durable machines minimize long-term costs and prevent frequent operational downtimes.

By evaluating these aspects, you can choose a machine that ensures efficient and accurate testing of manhole covers under various conditions.

Evaluating Different Manufacturer Options

When evaluating different manufacturer options, I focus on several key factors to ensure I make the best decision. First, I review each manufacturer’s reputation by examining their certifications, customer reviews, and history of reliability in producing high-quality testing machines. Second, I compare the technical specifications and features of their products, prioritizing those that meet industry standards and align with the specific requirements for testing manhole covers. Third, I analyze their after-sales service, including warranty terms, availability of spare parts, and maintenance support, as these elements are crucial for long-term operational efficiency. By cross-referencing insights from the top-performing manufacturers, I can confidently select an option that combines durability, precision, and robust customer support.

Cost-Effective Methods of Testing

To determine cost-effective methods of testing, I prioritize non-destructive testing (NDT) techniques due to their ability to evaluate material integrity without causing damage. Among these, methods like ultrasonic testing, magnetic particle inspection, and dye penetrant testing stand out for affordability and reliability. Additionally, I integrate load testing to assess performance under operational conditions in a controlled and economical manner. By leveraging findings from authoritative sources, such as engineering standards and material testing guides, I ensure the methodology remains both effective and budget-conscious. Combining advanced tools with streamlined processes allows me to achieve accurate results without unnecessary expenditures.

Considering Composite Materials

When evaluating composite materials, I prioritize analyzing their structural properties, such as stiffness, tensile strength, and weight-to-strength ratios, to ensure optimal performance for the intended application. By referencing industry-leading resources, including data on advancements in fiber-reinforced composites and fabrication techniques, I select materials that align with both durability and efficiency requirements. Furthermore, I account for factors like environmental resistance, production scalability, and cost-effectiveness, ensuring a comprehensive assessment tailored to deliver reliable and practical outcomes.

Reference Sources

-

DirectIndustry – Manhole Cover Testing Machine: A platform showcasing various manhole cover testing machines from leading brands.

-

TBTWC-1000A Compression Testing Machine: Details about a specific machine used for testing the bearing capacity and deformation of manhole covers.

-

IndiaMart – K.J. International Reviews: Customer reviews and testimonials for manhole cover testing machines and related equipment.

-

Top Manhole Cover Testing Machine in China

Frequently Asked Questions (FAQs)

Q: What is a manhole vacuum testing machine used for?

A: A manhole vacuum testing machine is used to evaluate the integrity of manholes by creating a vacuum inside the structure. This helps identify any potential leaks or weaknesses in the manhole assembly, ensuring that it is watertight and structurally sound.

Q: How does a vacuum pump function in the testing process?

A: In the testing process, a vacuum pump is used to remove air from the manhole, creating a vacuum. This vacuum allows the tester to monitor a gauge for vacuum loss, indicating any leaks or issues with the manhole structure.

Q: What role does a vacuum generator play in manhole testing?

A: A vacuum generator creates the necessary vacuum for testing by efficiently removing air from the testing area within the manhole. This is crucial for accurately identifying infiltration and exfiltration issues.

Q: Why is a bladder-style machine preferred in some testing scenarios?

A: A bladder-style machine is often preferred because it provides a reliable and high-quality seal around the manhole, which is crucial for accurate testing results. This style ensures that the vacuum is maintained throughout the test.

Q: How does a cover making machine relate to manhole testing?

A: A cover making machine is often used to produce the covers that are tested by manhole vacuum testing equipment. Ensuring these covers are manufactured to high standards is essential for effective testing and long-term durability.

Q: What is the significance of monitoring a gauge for vacuum loss?

A: Monitoring a gauge for vacuum loss is crucial as it indicates whether there are leaks within the manhole. This allows for the detection of any issues in the manhole’s integrity, which can then be addressed to prevent future problems.

Q: What makes manhole vacuum testing a cost-effective method of testing new and rehabilitated manholes?

A: Manhole vacuum testing is considered cost-effective because it allows for quick and accurate detection of leaks and structural weaknesses without the need for extensive excavation or more invasive methods. It ensures that both new and rehabilitated manholes meet necessary quality and safety standards.

Q: How does an air compressor assist in the testing process?

A: An air compressor is used alongside the vacuum generator and vacuum pump to pressurize or depressurize the testing area as needed. This helps simulate conditions that could lead to infiltration or exfiltration, ensuring the thorough testing of the manhole.

Q: Why is the cherne® air-loc® system mentioned in manhole testing?

A: The cherne® air-loc® system is a specific type of manhole vacuum testing equipment known for its effectiveness in sealing and testing manholes. It is highly regarded in the industry for its reliability and precise performance in evaluating manhole integrity.

Q: How does manhole vacuum testing help in pipeline maintenance?

A: Manhole vacuum testing aids in pipeline maintenance by ensuring that manholes connected to pipelines are free of leaks, which could lead to issues like infiltration or exfiltration. By maintaining the integrity of these access points, the overall health and performance of the pipeline system are preserved.