Rubber Testing Equipment: Essential Instruments for Elastomer Testing

It is rather difficult to overestimate the role of rubber testing equipment in providing the compliance,

It is rather difficult to overestimate the role of rubber testing equipment in providing the compliance,

Friction and wear act as influences upon the performance, potential for failure, and efficiency of mechanical

Key Takeaway: Friction and wear are critical factors that measure a material’s performance, durability, and reliability

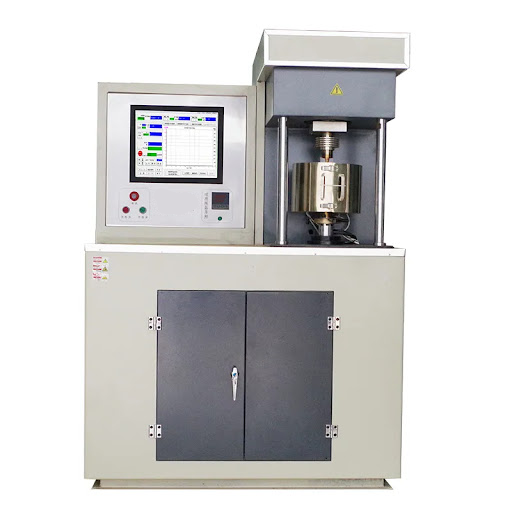

The Four Ball Wear Testing Machine is a crucial instrument in the field of tribology that

Wear testing machines are essential in all industries, from manufacturing to R&D, for checking the durability

Testing of materials is all about accuracy and consistency when considering durability and wear potential. The

Material testing is the core of design and manufacturing, where one guarantees that each component or

Adhesive strength is essential to really test the efficiencies or reliability of film tapes across various

Daily necessities require packaging to guarantee product integrity, safety, and customer satisfaction. Technology advances faster than

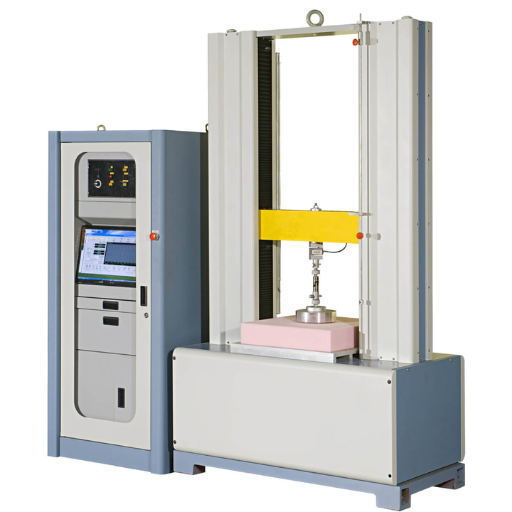

In the foam and sponge industry, precision and quality assurance call for compression and hardness testing.

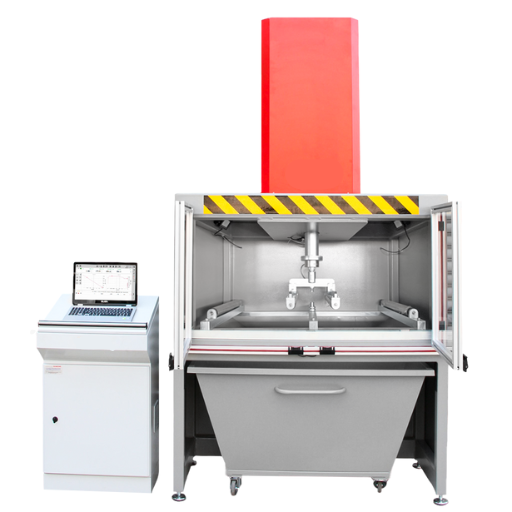

Glass and tile testing machines are essential tools for ensuring material durability, safety, and compliance with

Impact testing is one of the most crucial evaluations performed for confirming material durability and performance