Testing of materials is all about accuracy and consistency when considering durability and wear potential. The Böhme abrasion testing machine is the heart of materials testing when deciding stone, concrete, and other building materials for abrasion resistance. This article will look into how abrasion resistance is considered in different industries, the exact manner in which Böhme testing methods are done, and how the actual equipment and machine meet the standards of international test procedures.

Key Takeaway: Whether you’re a materials scientist, an industrial quality inspector, or an innovator in testing technologies, this comprehensive guide provides practical insights on applications and significance of abrasion resistance measurement.

Introduction to the Böhme Abrasion Tester

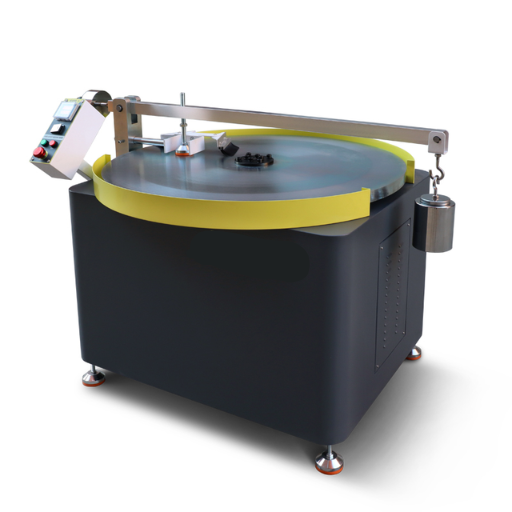

The Böhme Abrasion Tester is a standardized testing device used for determining the abrasion resistance of materials, particularly for flooring, tiles, and natural stone applications. It produces material loss through friction under controlled conditions, delivering consistent and reproducible results.

This method follows the international testing standard ISO 10545-6 for ceramic tiles, ensuring uniformity and equality in abrasion resistance tests across all industries.

What is the Böhme Abrasion Testing Machine?

The Böhme Abrasion Testing Machine is an apparatus used to test material resistance against abrasion, mainly in construction, flooring, and natural stone surface applications. The device places a standardized load onto a specimen while the specimen is rubbed against a revolving abrasive disc, and the resultant material loss is measured to assess wear resistance.

- Tests capability and life of materials exposed to heavy traffic

- Complies with international standards such as ISO 10545-6 for ceramic tiles

- Meets EN 14157 standards for natural stones

- Features automated load systems and digital measurements

- Provides computer-controlled testing parameters

History and Development of the Böhme Tester

The Böhme abrasion tester finds its origin in the early 20th century, when there was an urge to arrive at a systematic method for testing the abrasion resistance of construction and flooring materials. Originally a manual apparatus, it has evolved significantly with technological improvements:

- Early 20th Century: Manual apparatus for testing stone and concrete materials

- Mid-Century Development: Introduction of controlled conditions and standardized procedures

- Modern Era: Automated load systems, digital read-outs, and computer-controlled parameters

- Current Standards: Compliance with international testing protocols

Importance of Abrasion Testing in Material Science

Abrasion testing is a fundamental process in material science that evaluates the wear resistance and durability of materials under frictional forces. This testing is crucial for understanding the lifespan and performance of materials used in high-stress environments.

Benefits of Abrasion Testing:

- Prevents premature material failures

- Reduces maintenance costs

- Supports material selection processes

- Ensures quality control compliance

- Promotes development of safer, more sustainable products

Primary Purpose and Applications

The Böhme Abrasion Testing Machine is designed to simulate abrasion wear on materials, primarily those used for flooring, paving, and construction applications. Key applications include:

- Natural Stone Testing: Determining suitability for high-traffic areas

- Concrete Assessment: Evaluating durability for heavy-load applications

- Ceramic Testing: Ensuring compliance with international construction standards

- Quality Control: Supporting material selection and durability assessment

Key Features and Benefits of the Böhme Abrasion Tester

Precision and Reliability in Testing

Modern Böhme abrasion testing machines are engineered for maximum precision and reliability:

- Precise abrasion wheels for consistent testing

- Strong sample mounting system

- Digital controls ensuring uniform operation

- Advanced automated features compensating for component variations

- Finely calibrated surfaces and adaptive load application

Compliance with International Standards

The Böhme tester adheres to multiple international standards:

- ISO Standards: Ensuring global consistency in testing procedures

- ASTM Standards: Meeting American testing requirements

- EN Standards: Complying with European testing protocols

- Calibration Requirements: Maintaining traceability and accuracy

Advantages for Engineers and Researchers

- Precise assessment of material durability and performance

- Standardized procedures ensuring reproducibility

- International recognition and compliance

- Support for material selection and development processes

- Enhanced quality control capabilities

Comparison with Other Abrasion Testing Methods

| Method | Purpose | Sample Type | Abrasion Unit | Key Feature |

|---|---|---|---|---|

| Böhme | Surface wear | Flat surfaces | Volume loss | Rotating disc |

| Taber | Surface durability | Coated surfaces | Weight loss | Rotating wheel |

| LA | Aggregate toughness | Aggregates | Percent wear | Steel drum |

| DIN | Vulcanized rubber | Rubber, elastomers | mm³ loss/unit | Abrasive roller |

Distinct Features of the Böhme Abrasion Tester

- Uses a rotating disc to simulate natural abrasion processes on flat surface materials

- Measures volume loss precisely to determine wear resistance

- Suitable for various materials: concrete, stone, and ceramics

- Provides repeatable results in accordance with international testing standards

- Allows variable load and testing parameters according to sample requirements

Advantages Over Alternative Testing Methods

- Standardization: Well-established testing procedures guarantee reproducible results across laboratories

- Versatility: Suitable for testing heterogeneous materials with non-uniform surfaces

- Precision: Accurate measurement of volume loss beyond visual or qualitative methods

- Control: Proper evaluation under controllable and repeatable abrasion conditions

- Efficiency: Economical and time-saving compared to lengthy field testing

Applications in Various Industries

Construction Materials

Abrasion resistance testing is crucial for selecting finishing materials in high-wear applications:

- Flooring Systems: Testing durability for commercial and industrial applications

- Pavement Materials: Ensuring longevity in high-traffic areas

- Industrial Surfaces: Evaluating resistance to mechanical stress

- Warehouse Flooring: Testing concrete performance in heavy-duty environments

Ceramics and Wear-Prone Surfaces

Advanced material engineering enhances durability in ceramic applications:

- Zirconia and Alumina Inclusions: Providing structural strength and crack resistance

- Thermal Spraying: Creating hard, wear-resistant surface layers

- Chemical Vapor Deposition: Applying protective coatings

- Extended Lifespan: Maintaining functional and aesthetic value in regular usage

Role in Quality Control and Material Performance

The Böhme abrasion tester plays an essential role in determining wear resistance, providing precise data for material selection, standard compliance, and long-term performance prediction.

Ensuring Durability and Longevity of Materials

A comprehensive approach to material durability involves:

- Advanced Testing: Accelerated wear testing and weather exposure evaluation

- Design Optimization: Stress analysis and load distribution improvements

- Condition Monitoring: Real-time detection of wear indicators

- Preventive Maintenance: Proactive approaches to reduce failure risk

Data-Driven Design and Production Decisions

- Real-time data analytics for process improvement

- Predictive analytics and simulation modeling

- Material performance evaluation metrics

- Machine learning integration for accurate forecasting

- Operational efficiency and design optimization

Choosing the Right Abrasion Tester for Your Needs

When selecting an abrasion tester, consider the following factors:

- Material Type: Identify whether materials are rigid, flexible, homogeneous, or multilayered

- Industry Standards: Ensure compliance with applicable ASTM or ISO standards

- Wear Conditions: Determine appropriate abrasion media and pressure parameters

- Equipment Features: Look for easy calibration, precise data collection, and software integration

- Operational Requirements: Choose equipment that meets your specific testing needs

Frequently Asked Questions (FAQ)

What is a Böhme abrasion testing machine used for?

How does a Böhme abrasion tester operate?

What is the role of a defined test track in abrasion testing?

What abrasive materials does Böhme abrasion testing use?

What are the typical specifications of the rotating abrasive wheel?

How is the number of cycles determined in Böhme abrasion testing?

What is the function of the counter in Böhme abrasion testing?

Why is Böhme abrasion testing important for natural stone slabs?

Reference Sources

-

Controls Group – Böhme Abrasion Tester: Provides details about the Böhme Abrasion Tester, including its method and specifications.

-

Matest – C129 Abrasion Tester Böhme: Explains the use of the Böhme Abrasion Tester for various materials like paving stones and concrete slabs.

-

UTEST – Abrasion Testing Machine According to Böhme: Describes the machine’s application in determining the abrasion resistance of concrete and natural stone products.

-

YouTube – Böhme Abrasion Test Machine: A video demonstration of the Böhme Abrasion Tester and its use in testing materials like paving stones and natural rocks.