The box compression tester machine remains one of the most sophisticated packaging and material strength testing machines; it is a must-have tool for many industries that tolerate no compromises on durability and reliability. The machines are typically used to test the compressive strength of boxes, cartons, and packages to ensure that such items will be able to resist the forces normally experienced during shipping, storage, and handling. For any industry or organization engaged in quality management, and control as well as the maintenance of the supply chain, this article aims at exploring how box compression testers are employed within that framework. The readers would be in a position to understand the science that is at the helm of these machines, specific aspects that these machines measure, and the value in terms of how these machines are beneficial in industries that need to perform above average in packaging.

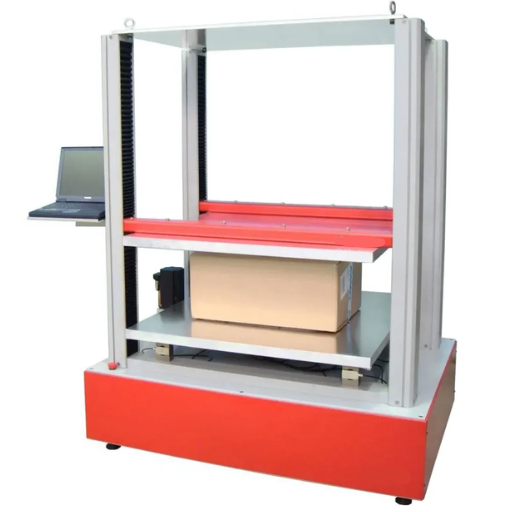

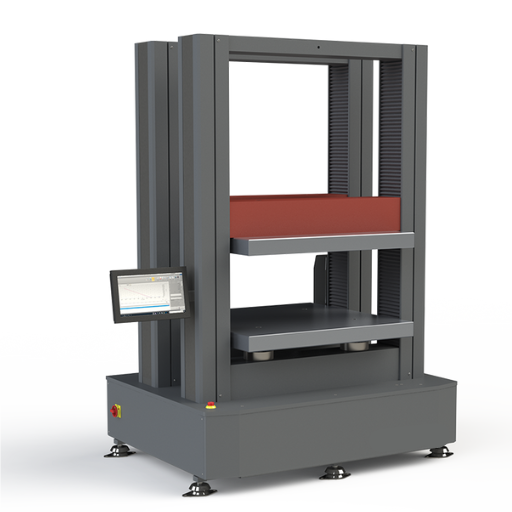

What is a Box Compression Tester?

A box compression tester machine evaluates the resistance of packages eversive of various forces which they may have to deal with during transportation. It measures the maximum weight a box can hold before distortion and destruction of its shape occurs, which to packing and handling makes it immensely useful in the development of packaging. Such testing is significant since it replicates realistic context like load piling hence transport strain which enables producers to target certain quality parameters as required.

Purpose of a Box Compression Tester

Generally, the role of a box compression tester machine is to test the stiffness of the materials used in boxes. With the help of box compression tester machine it is possible to determine the amount of loads applied on a box until it fails, hence safes gurards the shape of the packages during storage, transportation and stackability. Product design defects, meeting industry specifications upon completion and reducing the amount of materials used without compromising its performance caught in such environment are translated into practice with it. Consequently, it is safe to say that all goods are kept in their original state in the course of all supply chain operations through and through them.

Key Features of High-Quality Box Compression Testers

1. Accurate Load Sensing: Fitted with high-sensitivity load cells to measure the load during the test with great precision for consistent and reliable results.

2. Variable Testing Speeds: It enables users to adjust variables such as compression rate to reflect other scenario-demands, allowing experimentation with different configurations.

3. Sturdy Fabrication: Manufactured of strong materials, that enable the instrument to endure high load forces and repetitions without affecting the desired functional accuracy.

4. Digital Display/Recording: An enhanced digital screen coupled with a capability of logging the test results and exporting them for further processing is present.

5. Adheres to Specification: Conforms to relevant and international test methods including ASTM and ISO and TAPPI thereby assuring applicability and validity of the findings.

How the Tester is Designed for Testing

A box compression tester machine is a bio and also qualitatively optimized for the performance that includes numerous applications. The frame of such devices also uses the heavy-duty and durable materials, which allow diminishing unnecessary oscillation or obstruction during the tasks. The efficacy of the equipment is enhanced with the latest constituents of load cell and sensor technologies that provide excellent Newton/Height ratio measurements. On top of this advancement, improving and adjusting parameters and observing instantaneous figures for productivity is quite easy due to the easy-to-use and loaded interface. All these apart from other features such as conformity to organizational requirements such as ASTM and ISO standards make the tester it very effective and flexible for use in different applicationswhich may include material design, failure and strength of materials.

How Does a Box Compression Test Work?

Box Compression involves assessing the compressive strength of boxes and packages by using a controlled compressive force to determine their resistance to deformation or breakage. In this simple but effective analysis, one side of the box is placed over the other side of the box compression tester machine. The pressing plate, lower or upper, presses the box uniformly and increases the load on the box constantly till the box deforms eventually. The purpose of this test is primarily to police areas like the one which covers the maximum weight bearing capacity of the package and the type of defection that is noted when the boxes under question are loaded to the maximum capacity.

Steps Involved in a Compression Test

1.Specimen Making Arrangement

This refers to making sure that the box or packing enclosure is in the desired state for purposes of testing. The condition entails checking the dimensions, absence of any prior imperfections and conditioning the specimen in accordance to the applicable directives such as temperature and humidity.

2.Verification of the Accuracy of the Machine for Compression test

It is also important to check if the compression tester machine has been properly adjusted to correctly determine the force. The load limit of the machine needs to be set and all the relevant details need to be input for that specific testing standard.

3.Location of the Specimen On The Platform

Place the box or the package material on the lower and upper platens of the testing devices so that the force is distributed evenly within the structure.

4.Controlling Settings of the Test

Setting the instrument (testing device) to apply load at a fixed speed in accordance with the standard method of testing. For instance, there might be a need to adjust the rate at which compression or load is applied.

5.Performance of the Compression Test

Conducting a series of compression tests by engaging the box compression tester machine and submitting it to loading. During the whole process, especially when the box begins to distort or collapse from the pressure applied, observe closely how much force is created in what deformation.

6.Apparatu’s Assessments and Documenting

Take measurements such as, the maximum load, when there is a change in the load (i.e, increase in the load there is a deformation) and the failure region. Therefore, it is very important to take this picture when the test is being carried out.

7.Interpretation and Report Writing

Carry out the evaluation of the pumpkin box in view of the obtained results. Decide whether the directions for use or standards were satisfied, and the degree of conformity to descriptions briefed in the test method. Prepare and issue a comprehensive network analysis report as part of the test report writing.

8.After Test Examination

Evaluate the cut specimen and type of failure aimed at defining or at least indicating weaknesses and possible design deficiencies that might prevail.

The Role of Load Cell in Testing

1.Measuring the Applied Force

Demands on the accuracy and precision of the forces applied while conducting tests are met by load cells which can precisely measure the force being applied. This information is pivotal to the analysis of whether the test specimen will or will not achieve the performance levels predicted.

2.Adjustment and Setting of Measurement Equipment

Load cells are also important for testing machine calibration to assure the same results would be obtained even with different tests in different ‘ambiences’.

3.Recording Load Changes

In cases of dynamic testing, load cells are designed to facilitate recording of dynamic load changes. which is useful to determine any short time disturbances and/or any spurious event resulting load levels.

4.Practical Use of Load Cells

During a portrait frame specimen testing, load cells can be subsumed for providing excessive force safety which can prevent damage of equipment as well as the challenge of generating surrogate test results.

5.Confirmat each Design

It is the correct measurement of loads using load cells that helps ascertain that the construction of a material, a component or a structure sustain maintenance with regard to a certain performance specification.

The box compression tester machine is a necessary device in the manufacturing process that ensures the structural integrity of packaging materials such as cardboard boxes.

Understanding Compressive Resistance

Compressive strength is a term used to refer to the extent to which a given structure or material is able to resist forces that are axial and attempt to minimize its overall dimensions. It is an essential part of engineering and material sciences since it affects the expected load carrying capacity of a solid when subjected to crushing forces, without breaking. Testing is done by increasing the level of compression on to the specimen in a systematic manner until somehow the specimen either deforms or cracks. Concrete, metal and most frequently in composite materials contain higher compressive resistance and these are studied to assess the performance of the load-bearing materials. There are essential factors such as the shape and size, composition, as well as the surroundings when evaluating the compressive resistance. Box compression tester machine and similar pressure machines can also fall under this category in relation to folding.

The Importance of Compression Strength in the Packaging Industry

The attribute of compressive strength is an important aspect of the packaging industry because the extent of component breakdown under load is determined by this parameter. This property signifies the ability of boxes, containers of any kind, and other types of packaging to be vertically stacked during storage or transport without crumbling or bending. The probability of damage to the product is eliminated as well as improved product efficacy and reduced wastage, which translates into lower costs and, in general cases, higher productivity. Furthermore, it is also important to design the packaging with such thickness and toughness that it would still be environmentally acceptable and, therefore, would allow for a reduction of the mass of the material used. This can be achieved by tests such as the compression strength test using a box compression tester machine.

Why Compressive Strength Matters for Packaging

Compressive strength is one of the primary determinants when it comes to packaging, it implies a constituent’s capacity to bear a vertical weight without giving in. Packaging effectively also means that it is reliable in safeguarding the product throughout the processes of shipping, handling and storage. Absence of compressive strength may cause the box to deform or even collapse thus compromising the safety of the contents as well as the structural stability. Optimizing this property allows the producers to introduce packages that can incorporate different processes without damages to the goods, improves stacking and increases the dependability of supply corridors. It also aids in striking a balance between cost and environmental factors by reducing materials without any performance compromises. Therefore, compressive strength possesses a unifying solution in regard to product protection as well as the efficiency of operation in different sectors.

The Impact of Compression and Stacking on Cartons

When we talk about cartons and how to optimize performance for all packing applications, compression and stacking effects are described as expectations of preserving the form and the function of the carton. Compression strength is important for the third, it makes sure that they withstand the weight of a pyramid between themselves have and does not crush or distort, which is imperative especially in logistics and warehousing units and areas. Proper stacking techniques, as well as packaging design that has been adjusted load-wise, further, helps to avoid unnecessary damage and increases efficiency during transportation as well as storage. In reaching these goals, one has to remember the properties of the material in use, agency force and whether or not the primary purpose is allowed in this position, aspects which are fundamental in maintaining the firm’s goods in an approved or expected state from the source to the destination.

International Standards: ISO 12048 and ASTM D642

ISO 12048 presents analytically discusses resistance of an apparatus to static vertical loads. Particularly focuses on strength characteristics and deformation of the package under specified external conditions for the purposes of stacking transport packages into transport unit and storage. ASTM D 642 meanwhile describes in a certain manner, a number of test procedures for container and shipping package compression load tests. There is the question of packing strength index, which is to say, the integrity of the package, in case a transport and storage are simulated. Both aforementioned norms are aimed at improvement in the safety and economical side of handling packages.

Choosing the Right Testing Machines

Each testing machine should begin with an evaluation of the expected test objectives and the intended standards particular to the industry one operates in. Critical parameters in the selection process are the test to be conducted (i.e. compression, tensile or vibration tests) type of the specimen/ pack specification and the testing conditions area. The machines should be able to conform to the standards such as ASTM, ISO etc to safeguard the goal of accurate and repeatable results. Furthermore, more sophisticated pieces of equipment, which facilitate the collection and analysis of the data automatically, are also recommended for ones use, as they aid in efficiency and reduce routine manual duties of testing. It is also very vital that the equipment is well maintained and calibrated in order to ensure the tests carried out are reliable.

Factors to Consider When Selecting a Box Compression Tester

1.Maximum Load Capacity – Check that the tester is able to withstand the maximum load. Rate the capacity of the tester in terms of both lightweight and heavy-duty package materials.

2.Precision and Accuracy – Find testers with high precision, repeatability. Instruments with sophisticated sensors and digital load cells should be sought for precise measurement.

3.Compliance with Standards – Ensure to check if the machine complies with testing procedures, such as ASTM D642, ISO 12048, or other applicable industry standards, for results which are reliable and comparable.

4.Testing Modes and Versatility – Invest in equipment which allows different test modes, for instance, stack testing, crush testing, and top load testing, for more extended range of applications.

5.Automation and User-Friendly Interface – Look for testers featuring automatic operation, navigation software or touch screen interfaces to make them easier to use and avoid any operator mistake.

6.Data Collection and Connectivity – Choose machines with built-in data collection systems, reporting and exporting facilities and connecting to outside systems via USB, Ethernet or wirelessly.

7.Durability and Build Quality – Inspect the design of the tester. Strong frames and durable materials are a must for longevity and wear resistance.

8.Size and Compatibility – Confirm that the tester measures up to the testing space and is within the range of sizes of the packages or products under test.

9.Calibration and Maintenance Requirements – Ascertain ease of calibration as well as maintenance. Preference is given to equipment that features easy calibration procedures and/or multiple replacement elements that come easily.

10.Cost-Efficiency – Consider performance characteristics in relation to cost. Detail maintenance costs for efficient and durable machines over a longer period considering likely duration of elasticity.

Comparing Different Testing Equipment

The primary types of testing equipment include tensile testers, hardness testers, impact testers, fatigue testers, and universal testing machines.

|

Key Point |

Tensile Tester |

Hardness Tester |

Impact Tester |

Fatigue Tester |

Universal Testing Machine |

|---|---|---|---|---|---|

|

Primary Use |

Tension test |

Hardness test |

Impact force |

Fatigue test |

Multi-purpose |

|

Material Types |

Metals, Polymers |

Metals, Alloys |

Metals, Polymers |

Metals, Composites |

Broad range |

|

Load Capacity |

Moderate |

Low to High |

High |

Variable |

High |

|

Accuracy |

High |

High |

Moderate |

High |

High |

|

Calibration Ease |

Moderate |

Easy |

Easy |

Moderate |

Moderate |

|

Maintenance |

Moderate |

Low |

Low |

High |

Moderate |

|

Cost |

Mid-range |

Budget to High |

Mid-range |

High |

High |

Applications of Box Compression Tests

A box compression tester machine provides testing options for quality control in a variety of industries by analysing the strength of packaging materials subjected to load. Examples of such usages include determining how much load a cardboard box can hold or how safe the contents inside will be, following packaging rules and regulations and stretching the use of materials. Such examinations are in fact serious in many sectors- food and drinks, chemicals, medicine, general use goods among others since some of these products have to be repacked in suitable levels to stop them from getting damaged while being moved or transported.

How Compression Test Can Be Used in Various Scenarios

There are many instances when compression testing is handy to assess the capacity and performance of various materials. In many cases, what interests me most is the maximum weight that can be applied to the given object or box before they start deforming or collapse. This falls directly in the drawing of cost-effective but structurally sound packaging that passes the set standards. An example in this respect is the logistics industry where the box compression tester machine employed ensures that the cartons or container may not be destroyed by pressure when they are stocked or rather transported. To be more precise, in construction, these types of tests are used to establish the strength of the concrete or metals and composites used to produce the proposed constructions.

Determining the Stacking Capability of Cartons

To estimate the stacking capability of cartons, first I would check the compressive properties of that material in ideal and controlled conditions by conducting compression tests and evaluating the maximum load. This is done by applying force following a uniform time or rate until the carton fails so as to understand its stacking strength. Apart from this, I shall also examine the carton’s design, size, and the quality of materials as such factors are interrelated in giving any product its stacking characteristic. Finally, I would like to support my analysis with numbers of empirical experiences, industry standards, or some guidelines, in particular ISTA (International Safe Transit Association) norms, to finalize the conclusion about the assessment in order to make it valid in the light of common practice or precautions.

Utilizing Compression Strength Tester for Packaging Testing

The procedure to consider for this question is simple. I would start off with the box compression tester machine and determine the box/carton strength before failing. This is done by putting the box/carton into the box compression tester and applying a continuous vertical force until the box/carton buckles. This checklist also includes using ASTM D642 or any other relevant guidelines to standardize the test and greatly reduce the variance of the external compression forces.

Also to be considered are the other parameters such as carton shape, geometry, flute direction, and material as they influence the strength of the containers. Notably, such packaging can be verified to be able to fulfill its safety and functional purpose such as transport, storage, or display when employing industry data and materials provided by credible organizations such as ISTA and ASTM. Each datum will then be used to enhance a packaging unit’s strength while still reducing costs and enhancing logistical efficiency.

Reference Sources

- Lansmont – Compression Testers: Provides details on how compression testers work and their applications.

- Rycolab – Box Compression Tester: Focuses on testing compressive strength of corrugated boxes according to international standards.

- Presto Testing Instruments – Box Compression Tester: Offers insights into lab testing instruments for measuring box compression resistance.

- Qualitest – Flexible Packaging & Film Testing Equipment: Covers a range of packaging and film testing equipment compliant with international standards.

- PMMI ProSource – Package & Material Testing Equipment: Features a variety of package and material testing equipment from global brands.

Frequently Asked Questions (FAQs)

Q: What is a Box Compression Tester Machine?

A: A Box Compression Tester Machine, often referred to as a BCT, is a testing instrument designed to measure the compressive resistance of corrugated boxes and other packaging. It helps assess the strength of packaging materials and ensures they can resist compression during transportation and storage.

Q: How does a Box Compression Tester Machine work?

A: A Box Compression Tester Machine works by applying a compressive force to a corrugated box or packaging material. The machine measures the force required to deform or crush the box, providing data on its deformation and stacking capability. This helps manufacturers determine the stacking load that packaging can withstand.

Q: What is the significance of the stacking test in packaging?

A: The stacking test is crucial in packaging as it evaluates a box’s ability to withstand vertical stacking pressure. By simulating real-life conditions, packaging engineers can ensure that the boxes maintain their integrity during storage and transport, preventing damage to the contents.

Q: What standards are used in Box Compression Testing?

A: Box Compression Testing often adheres to standards like ASTM D4169, which provide guidelines for assessing the performance of filled transport packages. These standards ensure consistent and reliable testing results, helping manufacturers and suppliers maintain quality control.

Q: What devices do packing and testing departments tend to have?

A: The use of Box Compression Tester Machines is primarily among key personnel such as packaging engineers, and maufacturing and supply engineers responsible for production and testing of packing materials. The machines’ purpose is to ensure the structural fitness of any packagings made with cardboard or paper tanks.

Q: What are some of the elements that affect the prices of box compression tester machines?

A: The specifications, brand (e.g. Rycolab Box Compression Tester), model (e.g. computerized variant), the testing capacity and certain optional additions such as data analysis software are some of the factors that will contribute to the price of a Box Compression Tester. Usually, the most effective measuring tools are costly, but they are precise and dependable.

Q: Can Box Compression Tester Machines test different box sizes?

A: Yes, Box Compression Tester Machines are designed to accommodate various box sizes. They are adjustable and can be calibrated to test different dimensions and types of packages, including finished packages and cardboard boxes, ensuring comprehensive testing for all packaging needs.

Q: How does a Box Compression Tester contribute to packaging quality?

A: By measuring the compressive resistance of packaging, a Box Compression Tester helps manufacturers and suppliers assess the strength and durability of their products. This ensures that the packaging can withstand the rigors of transport and storage, reducing the risk of damage to the contents and enhancing overall product quality.

Q: Are there computerized models of Box Compression Tester Machines?

A: Yes, there are computerized models of Box Compression Tester Machines that offer advanced features such as automated testing processes, digital data recording, and detailed analysis. These models provide more precise and efficient testing, making them ideal for high-volume testing environments.