Understanding how a material behaves in service under stress is vital for industries ranging from construction, manufacturing, and engineering, among others. “Tensile strength” and “break strength” are two of the many parameters that are discussed concerning materials’ capacity to carry general loads and stresses. A first impression might make one think that the concepts are interchangeable when, in fact, each serves a particular purpose when testing a material’s capacity to handle general loads and stresses. This article sets out to differentiate tensile strength from break strength, describing their particular roles and significance and how they differ in determining load limits. Whether you are working on a defining engineering project or merely trying to make an informed decision on materials for a given job, this guide will equip you with the knowledge required to make the right choice for their specific applications.

Introduction to Breaking Strength and Tensile Strength

Importance of Understanding Breaking Strength

When choosing materials for specific applications, safety, reliability, and suitability are prime factors, in which breaking strength plays a key part. Breaking strength is simply the force that a material can withstand before it fails to keep together: materials bearing this property in construction industries are subject to rigorous loads and operations. After knowing the breaking strength, the application of materials can be limited to accidents or collapse of structures.

The concept of breaking strength is also essential for improving material utilization. If the materials chosen have an appropriate breaking strength, the design should just meet the actual load requirements and should stop short of overengineering. For instance, materials that provide high breaking strength yet low weight are desirable for use in aerospace or automotive designs where efficiency must be enhanced. Therefore, understanding this property provides engineers with the tools to balance safety, utility, and costs effectively.

Finally, breaking strength is a basic yardstick for institutes in finalizing a material between two alternatives. It would help decide if that rope, cable, or structural member can stand the demands of a particular job. When combined with other attributes such as tensile strength or resilience, the breaking strength helps describe the response of the material to stress, which forms the basis of placing an informed decision in line with the requirements of the eventual application.

Overview of Tensile Strength vs. Break Strength

Tensile strength and break strength are two important parameters that are stressed into ascertain the behavior of a material under load. Both of them are interrelated yet different in nature. Tensile strength is the breaking point of the material whereupon a certain huge force is applied and the material begins to break. It is an indicative of the durability of the material and its ability to perform under high load. Break strength, in contrast, refers to the exact point where the material breaks and fails under the applied force.

So, while the two forces describe similar concepts, they are, in fact, two separate measurements. Tensile strength is a measure of the maximum force a material can resist, while break strength is the force existing at the very breaking point. For example, a very thin rope with very high tensile strength undergoes slight weaknesses and hence has a slightly lower break strength.

Consideration of the two in conjunction aids in picking the proper material for a particular application. For very demanding circumstances, both tensile strength and break strength must be taken into consideration in selecting a material that is able to meet the specified performance rating. This in turn minimizes the risk of failure while assuring safety and reliability in structural and mechanical applications.

Relevance in Material Performance and Safety

- Importance in Engineering and Construction: Material properties of performance such as tensile strength and break strength are paramount for construction and engineering safety and reliability. They will provide information on the behavior of a material when suddenly subjected to various stresses and may help engineers in selecting particular materials suitable for any form of demand. Dangerous materials, if improperly evaluated, have the potential to cause structural failure, accidents, or inefficiencies.

- Risk Assessment Through Material Selection: Choosing the right material with appropriate tensile and break strengths, thereby reducing the possibility of mechanical or structural failures, is what risk assessment through material selection means. In high-risk projects: bridges, buildings, heavy machinery- even a slight error in judgment-bear unforgiving consequences. The emphasis on exact performance of materials therefore eliminates possibilities of expensive repairs, time delays, and hazards, thereby ensuring durability and constant performance throughout operational stresses.

- Lifespan and Sustainability Enhancement: To wrap up, choosing suitable materials based on their performance properties will also promote sustainability by increasing the lifespan of the structure or equipment. Such worthy materials get fewer chances to be replaced or repaired, which in turn saves resources and exerts a lesser strain on the environment. Such an approach conforms to how much attention is being laid on sustainable practices in modern engineering, thus conserving economic as well as environmental capital.

Units of Measurement for Breaking Strength

Common Units Used: kN, MPa, and More

Breaking strength is measured in units that provide standardized values for accuracy. Internally, kilonewtons are the frequently used force units. Such units are favored for larger forces, such as those often encountered in the fields of engineering and construction.

Another reliable one can be the one that expresses breaking strength as a term of pressure called megapascals (MPa). Because MPa describes the notion of stress as force per unit area, it finds its applications in the realm of tensile testing for material such as metals, plastics, and composites. It is more accurate and scalable, therefore immensely useful in activities where detailed material analysis is paramount.

Though sometimes unusual units such as pounds-force (lbf) or kilograms-force (kgf) are employed, depending greatly on the locality or industry adhering to the non-metric system, essentially kN and MPa serve as the dominant standards due to their accepted definition worldwide and due courtesy of integration into modern scientific and engineering workflows. A clear understanding of these units and their actual application ensures that there is no discrepancy or incoherence across fields of usage.

Working Load Limit and Its Importance

The working load limit is an important safety factor defining the safest maximum specified load that any equipment, such as a rope, chain, or a lifting assembly, can be subjected to. This is based on the minimum breaking strength of the item divided by a safety factor that accounts for factors such as wear, environment, and possible uncertainties during use. The working load limit ensures safe utilization of equipment and thus protects people from accidental injury and death due to equipment failure.

Maintaining safe working practices in heavy industry, including construction, shipping, and manufacturing, largely depends upon respecting the WLL. Overburdening the equipment beyond the WLL may lead to catastrophic failure with loss of property, legal responsibilities, or even life-threatening hazards to human life. Proper training of workers about the WLL inculcates within them an appreciation for this parameter so that they may wisely choose not to misuse equipment in disregard of the working load limit regulations.

To achieve a safe working atmosphere, equipment must be inspected regularly for irregularities or damage, and the WLL markings must be legible and conform to requirements. Also, a user should always take into account dynamic forces-the shock loads-when assessing if a specified WLL can be relied upon for a particular task. Equipment with a well-defined and very carefully determined WLL is an assurance of safety during the use of the equipment; thus, it helps operators to keep the equipment for a longer time, thereby embracing a culture of responsibility and reliability during their work.

Minimum Breaking Strength Considerations

MBS serves as the breaking strength below which any given equipment or material will fail. This value is established through standardized testing at controlled environmental parameters and should be regarded as a critical measure to ensure that an item is safely and reliably used and hence subjected to further mechanisms of incidents. In other words, if an operator understands the MBS, it becomes difficult for them to overload the equipment or cause misuse of it.

From practical considerations, safety margins are typically placed on consideration of the MBS to offset variable conditions or dynamic factors, such as weathering factors. For instance, a conservative safety factor-in aspect of which expedients are selected-allows all circumstances to place even more extreme demands on the allocation capacity. Precisely with this in view, balancing these conditional factors in one’s application ensures personal safety and tool longevity.

Conversely, one distinguished difference exists between Minimum Breaking Strength and Working Load Limit, in that the latter is usually only part of the MBS depending on the safety factor to allow for a safe range to work in. MBS is the ultimate load a material can bear, and working within the WLL protects and prevents undue wear or early failure due to overloading. For operational safety, always follow the manufacturers’ specifications and industry standards for both.

Testing Methods for Measuring Strength

Tensile Test: Procedure and Significance

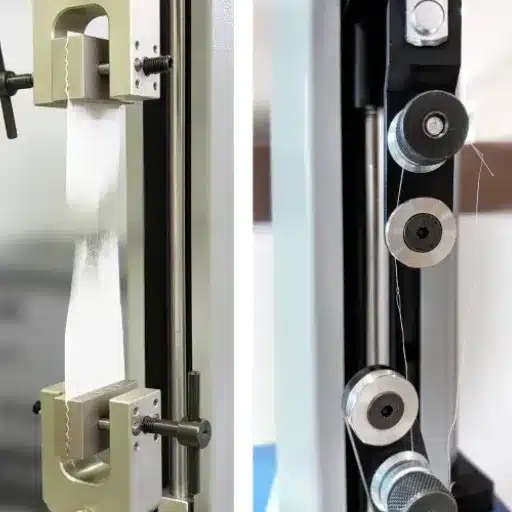

The tensile testing is considered one of the basic means of mechanical strength testing of materials while stressing them under tension. It involves placing the specimen of the material in the testing machine, holding it at both ends, and pulling it apart at a controlled rate. The intention is to obtain tensile strength and elongation parameters, as well as stress at failure parameters of the material.

In most cases, one is to prepare a test specimen that conforms to standard dimensions and is free from defects. The specimen is then clamped inside the testing machine. Next, a tensile load is applied gradually and evenly along its longitudinal axis. While the test is in progress, measurement of parameters such as force applied and elongation is recorded to plot a stress-strain curve from which vital parameters such as ultimate tensile strength (UTS), yield strength, and modulus of elasticity can be obtained.

In simpler terms, tensile testing signifies how a material behaves in real life situations. Using tensile test results, industries design components that fulfill safety and performance criteria so the material can support expected loads without failure. A good tensile testing enables a company to decide on, specify, or practically verify a material for use in a particular product design or quality control procedure.

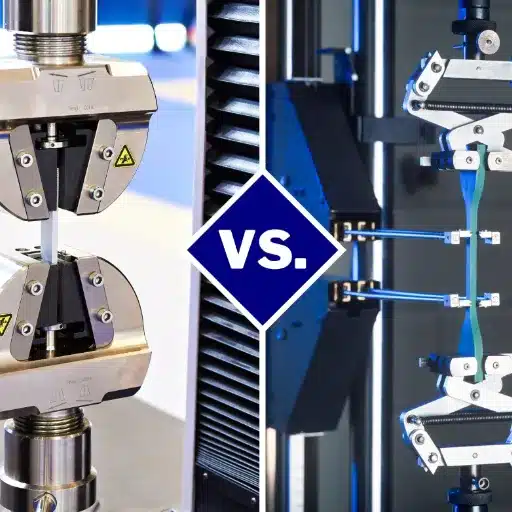

Types of Tensile Strength Testers

Tensile testers are machines designed to measure the behavior of materials under tension, thereby obtaining important data on their strength and viability. Broadly speaking, tensile strength testers fall under two categories depending on their functional aspects or working mechanisms- universal testing machines and hand-operated testers.

Universal Testing Machines

These are versatile testers performing not only tensile but also compression and bending tests. They are provided with precision controls and sensors to accurately gauge measurements. Due to their reliability and versatility, UTMs are the preferred testing machines for metals, plastics, composites, and other materials in research and industrial applications. These can be either electromechanical or hydraulic systems.

Hand-Operated Testers

These are small and inexpensive testing machines which are suitable for basic tensile tests. Such hand-operated testers find use in quick testing or in-field testing where ease of use and portability are of paramount importance. These, however, lack myriad features of UTMs and essentially find limited usage or initial testing of material properties.

This classification showcases the gamut of choices available, thus enabling users to select a tensile strength tester based on the accuracy, versatility, and scale needed in a particular application. Both types of tensile testers are vital in confirming material properties during quality assurance, product development, and material investigations.

Yield Strength vs. Breaking Strength in Testing

Yield strength and breaking strength are two major concepts in materials testing used for understanding material behavior when loaded. Yield strength indicates the stress at which a material will undergo plastic deformation and it can no longer return to its original shape after the load has been removed. A critical application of this term exists where retaining the shape of the material under a given load is necessary since it marks the transition from elastic to plastic deformation.

Breaking strength, conversely, is the greatest magnitude of stress the material can bear before it eventually fractures or breaks down. This definition is used in trying to ascertain the maximum allowable load in cases where utmost efforts should be made to prevent failure occurring due to extreme forces. Breaking strength is always higher than the yield strength since it is the maximum limit that the material attains at breaking.

Both values have been very important in the selection, design, and safety analysis of engineering and manufacturing materials. Yield strength sets material limits under everyday conditions, while breaking strength sets reliability for extreme or catastrophic load conditions. The interplay of these features provides a fair judgment in the application of materials, taking into consideration both performance and safety.

Practical Applications Across Various Industries

Construction: Load Limits and Safety Factors

Understanding load limits and applying adequate safety factors constitute essential principles in engineering to safeguard structural integrity and public life. Load limits form the ultimate force or weight exerted on a structure by any adverse load beyond which failure of the structure occurs. The ascertainment of load limits involves careful consideration of the properties of materials with respect to yield strength and breaking strength. Safety factors are, to an extent, buffers for uncertainties arising due to inconsistencies in materials, unforeseen stress conditions, and even human error. These factors, therefore, provide an added layer over the load limit design to prevent any structural failure under service and extreme conditions.

Safety factors are determined by engineers based on the kind of structure, its intended use, and even environmental considerations: In areas with earthquakes or with heavy winds, buildings will necessarily be designed with robust safety factors to provide for those dynamic forces. Such safety factors also differ with the materials over which they are applied: steel, concrete, or composites are subjected to safety factors that will make them fulfill the application demands to the utmost opportunity. Hence, the chance of the structure failing can be minimized while at the same time, allowing the materials to be used more efficiently.

Hence, the construction industry tries to strike a balance between safety and efficiency through a strict implementation of standards and scientific principles. The regulatory codes and standards serve as very important aspects both in unifying practices and placing a limit on what is acceptable for safety factors. Together with computer-aided simulation and testing, it becomes possible to accurately predict how the building will perform in reality, thus ensuring that public safety will always be rated at the top.

Manufacturing: Material Selection and Efficiency

Material selection is indeed the heart of manufacturing and contributes directly to efficiency, costs, and the actual performance of the product. In the selection process, materials are evaluated based upon various components such as strength, durability, weight, and sustainability. While prioritizing these factors, the final product must be safe, practical, and economically priced. Most manufacturers go for materials that combine performance with availability, choosing steel for strength, or composites for energy savings.

Efficiency in manufacturing also depends on how the materials are used. Efficient waste management during the manufacturing can reduce costs and promote environmental sustainability. Minimizing waste includes precision cutting, automation, and recycling of scrap wastes, all of which lead to optimum usage of resources. Further enhancement is achieved by advanced manufacturing methods such as 3D-printing, which allows materials to be used minimally without compromise of structural integrity, thus reducing waste to a minimum. The aforesaid approaches help standardize and limit the time taken to manufacture one unit as well.

Being sustainable in material selection becomes an environmental consideration most manufacturers take seriously in the present. Renewable, recyclable, and biodegradable materials have become increasingly popular. Consider that recycled metals or plant-based polymers might help reduce production-related environmental impacts. Striving for sustainability does not only position individual processes with regard to an ever-so-important global environmental agenda but also enhances their market appeal since consumers are becoming ever more conscious of ecological issues. An ideal material selection for manufacture will thus be a fine balance of performance, cost, and sustainability.

Aerospace: High Tensile Strength Requirements

High tensile strength should be often handed to materials for aerospace purposes so that they retain their structural integrity and maintain safety under conditions of extreme stress. The tensile strength of a material is considered to be its capacity to resist tension until it breaks. One could argue that the tensile strength of airframes, wings, and engines is very important since these structures must bear high mechanical stresses while maintaining extremely minimal weight. This minimal weight is important for optimizing performance and fuel efficiency.

Among some of the more frequently used materials in aerospace are titanium alloys, aluminum alloys, and carbon fiber composites. Titanium alloys are extremely valued in the aerospace field for their highest strength-to-weight ratio, excellent corrosion resistance, and resistance to high temperatures; hence they are applied in the jet engine and structures. Aluminum alloys tend to be popular in aerospace because they are lightweight, easy to manufacture, and are cost-effective, particularly in fuselage construction. Thus, carbon fiber composites stand out in tensile strength and stiffness with an even lighter weight, so much so that they are instrumental in high-performance aircraft design.

To further meet the stringent requirement of tensile strength, grinding testing and materials selection are employed. Finite element analysis, fatigue tests, and thermal tests are all performed to guarantee that the materials can withstand real test conditions. By pairing new materials with testing protocols, the aerospace industry shall continue to make new breakthroughs in design-optimization aspects such as performance, safety, and sustainability.

Advancements in Testing Technology and Standards

Emerging Technologies in Strength Testing

Technology developments have brought about new methods for testing strength in diverse industries. Among them, NDT techniques are gaining prime importance, allowing engineers to test the strength of materials without destroying them. These methods serve to gather very crisp and precise data in segregating structural integrity and are gaining developments in favor of their utility and precision.

Simulation-based testing is another essential technique that employs cutting-edge computational models. Using finite element analysis (FEA), an engineer can simulate the behavior of materials under varying stress conditions, thus reducing excessive physical testing. This strategy allows for time and cost efficiency and potential fault detection at the design level.

Another revolution brought about in the field of strength testing is by the incorporation of ML and AI. AI algorithms analyze vast amounts of data arising from the test processes, picking up trends and anomalies that traditional methods might miss. Thus, they increase decision-making and improve the reliability of material performance in vital applications. These technologies, in combination, are redefining the parameters of strength testing for safety and efficiency in engineering and design.

Standardization of Testing Methods

Cryptic testing protocols compromise the essential uniformity, reliability, and comparability of test results seen across different industries and applications. Following standardized testing procedures ensures engineers and researchers are equated with a uniform set of procedures from which to accurately evaluate the strength of materials. This simple measure is above all paramount when sharing test data with one another or collaborating on a project.

Standardized methods also lead to enhanced regulatory compliance. Several industries, such as aerospace, construction, and manufacturing, dictate testing standards that must be followed in order to comply with safety and performance regulations. Organizations such as ASTM International and ISO formulate test guidelines that are universally accepted and ensure all parties follow the same set of standards. This lessens the yet margin for error, inculcate confidence in the test results, and safeguards both end users and producers.

Testing Procedures That Have Been Standardized Become the Basis to Encourage Further Innovation-An advanced testing procedure can be developed with confidence if material properties are tested base on an existing procedure. The easy validation of results obtained through material testing will smooth the path of integrating these results into any research and development work. This will simultaneously help rapidly inculcate new discoveries and dispel any misunderstandings that thereof cause delay or inefficiencies, thereby establishing a progressive trend in engineering and material sciences.

Future Trends in Material Strength Measurement

With the integration of advanced technologies, measurement strmodulus of material strength is swiftly evolving. The major trends include the implementation of automation and AI justified testing procedures. Automated systems can substantially increase test efficiency and reproducibility while decreasing human errors. AI is being used to detect data patterns, predict material behavior under varying conditions, and optimize testing processes.

Another trend concerns non-destructive testing (NDT) methods. These techniques allow researchers to examine a material without destroying it and retain its integrity while gathering critical data for its strength. Improved NDT methods such as ultrasonic testing and laser-base ones provide a better edge for precision and reliability and thus are indispensable in industries like aerospace and civil engineering, where the safety of materials is of utmost concern.

There is also a growing focus on sustainability on material testing. Researchers are trying to lessen waste during testing by means of reusable samples, simulation techniques, and green methods. Advances in digital twins and virtual testing environments would probably tab the largest portion in reducing resource consumption while providing almost exact strength measurement. Such trends together aim at bringing forth testing methods that are efficient, sustainable, and reliable in testing the durability and resiliance of materials for any application.

Frequently Asked Questions (FAQ)

Common Questions About Breaking Strength and Tensile Strength

Q: What are breaking strength units?

A: Breaking strength units are simply the units of measurement used to indicate the maximum force applied to a sample before failure or breakage occurs. The units are generally pounds per square inch or any other units of force per unit area.

Q: Is breaking strength the same as tensile strength?

A: Breaking strength is another name for tensile strength, and thus, both concepts are related. Tensile strength measures the maximum stress a material can endure while being stretched; with breaking strength for the force used to break the material. Thus, tensile strength is the maximum stress a material can handle before rupture.

Q: Why are tensile strength values important?

A: Tensile strength values are important for the mechanical characterization of materials. It shows the maximum stress that a material can resist before failure, which is required for cases when materials are being stretched by forces. Knowing the tensile properties helps engineers design better and safer structures and products.

Q: What is the difference between breaking strength and bursting strength?

A: Breaking strength is the force required to break a material. Bursting strength is the pressure that a material can withstand prior to rupture. The breaking strength is expressed usually in psi, and the bursting strength may be expressed in units of force per square inch. It is useful to understand these distinctions when choosing materials for a particular application.

Q: How can you measure breaking strength in a material?

A: To measure breaking strength, force is applied to a material until it ruptures. That force required to tear the material apart is measured by tensile testing machines. The measurement is based on force units, often specified as pounds per square inch (psi) or Newtons.

Q: Why is knowledge of maximum stress important?

A: The knowledge of maximum stresses a material can withstand is important as a safety and reliability consideration in engineering applications. It is important in determining the amount of safe working load so that failures through excessive force could be prevented. For example, in construction, it is equally important to know the breaking strength of a material for structural integrity.

Q: What determines breaking strength?

A: There are several factors affecting breaking strength ranging from sample composition to structural physical conditions and even environmental factors. Ductile materials have a greater breaking strength than brittles because they would be able to deform before breaking. Temperature and humidity are among other factors that could change tensile properties.

Q: What is ultimate strength?

A: Ultimate strength means the maximum stress a material can withstand before it starts to fail. In material science, it is a crucial parameter for determining the load-bearing capacity of structures and components. Ultimate strength is measured together with breaking strength to provide a complete view of the performance of the material.

Q: What does tensile stress measure?

A: Tensile stress measures the internal forces that develop within a material when it is subjected to an external pulling force. Force applied per unit area, such as psi, are the kinds of tensile stress. The knowledge of tensile stress is important in predicting the behavior of materials under load and ensuring their capability to deviate the forces exerted upon them.

Q: How is breaking strength used in daily life?

A: Some of the biggest applications of breaking strength occur with construction materials, textiles, and ropes. Knowing the breaking strength will allow product manufacturers to really design a product that can sustain a certain load without failure. It is especially important for safety applications in liftings and riggings, where it is crucial to know what forces a material can withstand to prevent an accident.

References

- Breaking Strength Vs. Tensile Strength | Key Differences – Explains the differences between breaking strength and tensile strength, including their measurement units (e.g., MPa, psi, N, lbf).

- Tensile Strength vs. Break Strength: What’s the Difference? – Discusses break strength as a measure of force and its typical units like pounds per square inch.

- Break Strength Testing – Provides insights into break strength testing methods and standards.

- ASTM D638: The Definitive Guide To Plastic Tensile Testing – Covers ASTM D638, a standard for determining tensile properties, which includes breaking strength.