Consider the last-mentioned property: bending or flexural strength. It is among the most studied general properties in engineering, construction, and material science. It determines the magnitude of bending force-to-stress the material can stand against, producing a load on it. For making a bridge that lasts forever, for ensuring the construction of buildings against adverse load-bearing circumstances, or for choosing materials in an advanced manufacturing setup, flexural strength comes handy in assuring performance and safety. This guide will walk you through the basics of flexural strength, its significance in various industries, and the measurement procedure. At the conclusion of this guide, you will be clear on why a material’s flexural strength matters and how it affects the selection of a material and structural integrity.

Introduction to Flexural Strength

Definition of Flexural Strength

Flexural strength or bending strength indicates the capability of a material to resist bending or flexing forces upon it, i.e., the ability to resist distortion under applied bending. It is a measure of the stress at the surface of the material at the instant of yielding or fracture when subjected to a bending load. This property is employed mainly to evaluate the material’s performance under actual circumstances when forces act on it to bend it.

The importance of flexural strength lies in its ability to predict a material’s behavior under existing conditions. Industries such as construction, aerospace, and automobile require materials with the required flexural strength to maintain the structural components safe and durable under loads. High flexural strength is considered essential in the case of beams, panels, and other load-bearing members so that they do not bend with time and eventually fail.

Flexural strength is usually determined by standardized tests such as the three- or four-point-bending tests, which involved the application of force to a material sample until specified bending or fracture occurred, and these values observed were then used to calculate the flexural strength of the material. This flexural strength value assists the engineer and other designers in choosing appropriate materials that satisfy safety and performance criteria for the particular application.

Importance of Flexural Strength in Various Industries

Flexural strength is significant in various industries because it contributes to the durability, safety, and performance of materials used in structural applications. In the construction industry, for instance, materials are concrete, steel, and composites, and these materials are selected by considering their flexural strength so that they can bear loads with minimal risk of cracking or failing in beams, slabs, or bridges. It is a parameter that helps engineers in designing structures that may survive both static and dynamic stresses though time.

Design in the automotive industry also considerably depends on flexural strength, from frames to panels, chassis, among others. These must resist intense forces and vibrations during operation without deformation or fracture. Thus, with high flexural strength, materials used in the automobile can resist such stresses and result in safer and dependable products offered to the consumers. It also gives manufacturers the resources to experiment with lightweight designs that do not compromise the integrity of a vehicle.

Likewise, aerospace and electronics industries are dependent on materials that have an adequate flexural strength. Aircraft components need to have steadfast performance under severe aerodynamic forces, whereas electronic enclosures need flexural strength to shield the delicate equipment from mechanical distress. Taking everything into perspective, the knowledge and employment of flexural strength bring about improvements in performance, safety, and efficiency in different modern-day industries.

Applications in Engineering Design

In Engineering design, and thus in guaranteeing structural integrity and functionality, flexural forces assume a very important role. Structures such as beams, panels, or frames are subjected to the application of bending forces. Hence, their ability to resist bending is very critical. Assuming a priori knowledge of the flexural strength of members, engineers go ahead to design structures that comply with safety requirements while being able to sustain different lift.

Where civil engineering design is concerned, flexural strength is an important factor in the design of bridges and buildings. For instance, pure concrete beams and slabs are absolutely incapable of resisting bending forces; hence, reinforcement with steel or some other material is necessary. It is in the exact measurement of these flexural properties that the assurance is given that these structures will withstand practically all conceivable dead and live loads without being destroyed.

Likewise, for mechanical engineering, flexural strength is needed to provide for machine parts under cyclic stresses. Gears, shafts, turbine blades are just a few applications where the material should stand to repeated bending stresses without failure by cracking or breaking. The use of materials of proper flexural properties will ensure that these components perform reliably during extended periods of operation, thus further reducing the risk of failure and the associated costs of maintenance.

Theoretical Background of Flexural Strength

Factors Influencing Flexural Strength

Material Composition

The presence of a uniform and dense microstructure in a material would indicate it bears excellent flexural strength that resists deformation and cracking under a given stress. Parametric presence of impurities, voids, and inconsistent bonding in a material causes weak integrity, which in turn reduces its flexural strength.

Environmental Conditions

Areas of temperature fluctuations, moisture, corrosive environment would expose the material to degradation and loss of flexural strength. Higher temperature may cause thermal softening and thermal expansion, or an increase in temperature, may lead to moisture absorption and resultant swelling out from the moisture in case of some metamaterials like composites or wood.

Physical Geometry

The physical dimension and geometry of a component are other factors that play crucial roles. Since a structure having thick or uniform cross-sections is generally very much capable of resisting bending stresses, sharp corners, or notches, or other stress concentrations are usually the culprits in weakening the structures.

Relation to Modulus of Elasticity

The modulus of elasticity or Young’s modulus is a fundamental property of matter that designates the ability of a material to resist deformation under stress. It provides the stress-strain relation in the elastic region, where the material regains its original shape when the stress is removed. Stiff and less deformable materials exhibit a higher modulus of elasticity.

This property is approximately related to the flexural strength of a component, enabling it to perform under applied force with no permanent deformation. The higher modulus materials, like steels, soften better, while the low modulus materials, such as rubber, are stiff and capable of withstanding considerable mechanical stress.

Material selection with respect to their modulus of elasticity is an important part of engineering design to ensure that a product meets its structural or functional requirements in a safe, durable, and efficient manner. An understanding of the modulus of elasticity allows an engineer to predict how much deformation will occur in a component subjected to given loads and to use this information for accurate calculations in design optimization.

Understanding Flexural Moduli

The flexural modulus or modulus of elasticity refers to a measurement that describes the bending stiffness of any material. It represents the amount of flexural stress that the material will undergo before the bending is relieved by the forces acting upon it. Being an SI unit of pressure, the pascal (Pa) gives an idea of the material’s capabilities to resist bending or acting under loads due to structural considerations.

The higher the flexural modulus a material has, the stronger the structural requirements for it to maintain its shape under load. To this effect, there are several industries where the knowledge of the flexural properties determines material selection. Ideally, low flexural modulus materials are very flexible for absorbing energy or acting dynamically.

The testing procedures have been standardized; for instance, in a three-point bending test, the sample is loaded at its midpoint while resting on supports at either end. The test provides data essential for estimating operational performance under actual service conditions. By studying the flexural modulus of a material, informed decisions may be made in selecting, manufacturing, and applying materials so that the structural integrity of the materials applied may be guaranteed in a given structure and function during service in whatever field.

Calculation of Flexural Strength

Step-by-Step Guide to Calculate Flexural Strength

- 1

Prepare the Test Specimen

Obtain a rectangular or cylindrical test specimen made of the material to be analyzed. Ensure it meets the prescribed dimensions and standards for testing as outlined by relevant guidelines such as ASTM or ISO. Proper preparation ensures reliable and reproducible results.

- 2

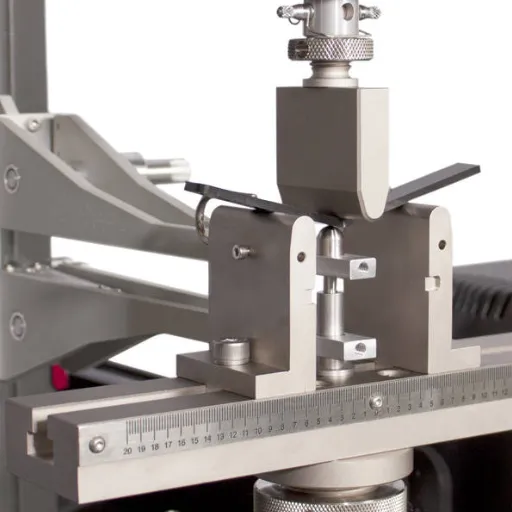

Set Up the Testing Equipment

Place the specimen on the supports of the flexural strength testing apparatus, typically configured as a three-point or four-point bending setup. Adjust the apparatus to ensure it is aligned properly and the load will be applied directly in the center of the specimen.

- 3

Apply the Load to the Specimen

Gradually apply force to the specimen at a constant rate while measuring the load and displacement. Continue increasing the load until the specimen fails or fractures. Record the maximum force applied, as this will be used for calculations.

- 4

Calculate Flexural Strength

Use the following formula to calculate the flexural strength of the material:

Flexural Strength, σ = (3 × F × L) / (2 × b × d²)

| Variable | Description | Unit |

|---|---|---|

| F | Maximum load applied | N |

| L | Length between supports | mm |

| b | Width of the specimen | mm |

| d | Depth of the specimen | mm |

Important Note: The flexural strength obtained from this calculation represents the stress a material can withstand before it fractures when subjected to bending. This value is critical for applications involving structural components, as it indicates the material’s capability under various loading conditions.

Practical Considerations in Calculation

Calculating flexural strength demands careful measurement of certain parameters, namely, dimensions of the specimen and the applied load. A discrepancy in any of these: the width (b), depth (d), load data, can greatly affect the results. Accurate values of dimensions and applied loads ensure a reliable basis for material characterization under bending stresses.

Further consideration is to calculate flexural strength.Drawing linest An additional consideration also makes a difference, namely the environment. Temperature and humidity affect material properties, particularly those of polymer or composite. Testing at stipulated conditions, in accordance, for instance, with ASTM or ISO guidelines, will aid in making results repeatable relative to any possible environmental variations.

The last one is the condition of the specimen. Surface irregularities exist with all types of specimens and could affect the material’s behavior under testing if taken seriously. Make sure your specimen adheres closely to the prescribed specifications of preparation, and inspect those specimens before testing so as not to falsely interpret the calculated flexural strength in terms of structural capabilities of the material.

Examples of Calculation for Different Materials

Example 1: Calculating Flexural Strength for Concrete

To calculate the flexural strength of concrete, the formula commonly used is:

Given Parameters:

- Span length (L) = 400 mm

- Width (b) = 100 mm

- Depth (d) = 150 mm

- Maximum load (P) = 15,000 N

Calculation:

Example 2: Calculating Flexural Strength for Steel

Steel is often tested using a three-point bending test. The flexural strength can be calculated as:

Given Parameters:

- Maximum load (P) = 20,000 N

- Span length (L) = 300 mm

- Width (b) = 50 mm

- Depth (d) = 25 mm

Calculation:

Example 3: Calculating Flexural Strength for Plastic

Flexural strength in plastics is vital for evaluating structural performance. Using the same formula for three-point testing:

Given Parameters:

- Maximum load (P) = 500 N

- Span length (L) = 200 mm

- Width (b) = 20 mm

- Depth (d) = 10 mm

Calculation:

Key Insight: These calculations demonstrate how material type and dimensions influence flexural strength, aiding in structural assessments and material selection for specific applications. Always ensure proper specimen preparation to guarantee accurate results.

Testing Methods for Flexural Strength

Overview of Common Testing Methods

Flexural strength is commonly measured by two main tests: the three-point and four-point flexure tests. These tests work by exerting a load on a specimen supported at specific points until it fails, thus giving insight into the bending performance of the material. Both testing procedures are commonplace due to their simplicity and reliability.

In the case of the three-point bending test, the sample is placed on two supports, whilst a centered load is applied at a single point. This method is quite convenient when dealing with smaller specimens, and it produces accurate results when considering the location of maximum stress and actual point of failure. It is aimed at testing specimens having uniform properties and dimensions.

The four-point bending test loads the specimen at two points while it is supported on two others. This method allows the load to be somewhat evenly distributed across the span of the specimen and hence, is more suited for large or elastic specimens. It reduces the stress concentration that the specimen endures at a single point, thereby providing a better assessment of the flexural strength of a material over a considerable length. Both techniques are of equal importance whilst selecting materials based on structural integrity and performance.

The Three-Point Bending Test

Advantages

- Simple setup and operation

- Requires minimal material preparation

- Suitable for smaller specimens

- Provides clear maximum stress location

Limitations

- Stress concentration at loading point

- May not reflect real-world conditions

- Limited to detecting localized defects

- Single point loading limitation

The term three-point bending test refers to the determination of flexural strength and modulus of a material. A specimen is placed on two points of support so that load is applied concentrically at the midpoint of the span. The force is gradually increased until the specimen breaks or gets deformed. It is a common test done for metals, polymers, and composites that are practically subjected to bending forces.

This test arrangement sets a condition of pure bending stress at the center of the specimen; thus, it is most suited for investigating the behavior of materials under bending loads. Three-point bending test results give insight about how well the material withstands deformation, resists failure, and maintains structural integrity. The test is invaluable and commonly used since it is simple to set up and requires almost no material preparation.

Still, the three-point bending test has its drawbacks: the stress concentration at the point where the load is applied may not mirror a real situation in which stresses are distributed more uniformly; in addition, using a single point of loading might fail to pick up on defects or inconsistencies that might be found present in much larger specimens. Nevertheless, the reliability and simplicity of the three-point bending test render it an important means in industrial and research applications for material evaluation.

The Four-Point Bending Test

Advantages

- Uniform stress distribution

- Better for brittle materials

- Represents real-world conditions

- Detects defects over larger area

Considerations

- More complex setup required

- Higher equipment costs

- Requires precise alignment

- Longer testing time

The full title for a four-point bending test is any modification of a three-point bending test that wants to achieve more uniform stress distribution in the material being tested. Unlike in a three-point bending test, the applied load in a four-point bending test is shared between two points that lie equally spaced along the length of the beam between the supports. As a result, a constant bending moment exists in this region with no point load, which removes the stress concentrations found at a single load point and allows for a more comprehensive evaluation of material properties, especially concerning defects and inconsistencies over a larger area.

One of the many advantages of the four-point bending test is the assessment of material behavior under constant bending moments useful specifically for the testing of brittle materials like ceramics and composites. This constant moment in the central part of the beam enables researchers to analyze the resistance of a material against deformation or failure under sustained loads. From another perspective, the test also represents actual scenarios for application in which stress distributions are more or less uniform.

Meanwhile, the setup is pretty straightforward in comparison with the three-point bending test and, in return, offers more precise information on the flexural strength and stiffness of a material. By avoiding the disturbing influence of local load concentrations, the four-point bending test has gradually, and rightfully so, gained popularity in research and industry for developing products that satisfy strict performance and safety requirements in structural and mechanical contexts. This thus makes it an indispensable tool for quality assurance and material development.

Interpreting and Utilizing Flexural Strength Results

How to Measure Flexural Strength Effectively

For effective measurement of flexural strength, it is commonly tested under controlled conditions of an established procedure. The sample undergoes three-point or four-point bending, where a load is applied until the material bends or fractures. These methods give precise data about the material’s resistance to deformation with applied stress.

Critical for accuracy are proper sample preparations and testing equipment calibration; the sample should be a uniformly sized piece free from any surface defects that could influence the results. Also, equipment capable of applying a precisely measured and consistent load within the required range for the material should be used.

Once on this, there ought to be procedures for the interpretation of test results. Flexural strength is generally expressed in terms of stress taking into the dimensions of the sample and applied load as relates to time during testing. Should one want to pertinently compare the results, it has to be related to results derived from similar tests following the same procedure. This establishes steady data capable of being used in material selection and product design. Application of this principle yields dependable data ready to be interpreted for practical application.

Interpreting Test Results

First, when interpreting test results, it is vital to verify that the conditions and methodologies used during testing are truly in line with accepted-standard procedures. When the parameters of the test, from how load is applied, through environment control, to even sample preparation, consist of standard procedures, it ensures that the data produced is reliable and comparable. If there is some deviation from the consistent procedures, then the results cease to have any value; their interpretations may become incorrect.

After the data have been verified for any consistencies, the analyst can immediately switch to identifying apparent patterns and correlations in the results. Focus on noticing trends-trends that show variations in the technological performances of the material at various stresses or time intervals. Comparison of these observed signs with some of the benchmarks set in the past or literature regarding the subject is often preferable in qualifying the outcomes. Where the results are not in line with the known reference, one could suspect either a unique material property or an experiment error that requires investigation.

In concluding, base decisions about the suitability of the material for the intended application on findings gathered from the tests. While communicating, ensure that any implication of the data is made explicit, such as margins of safety, limits of service, or means of performance, while actually noting any observed constraints resulting from the testing. This will necessarily make it possible to utilize the interpretation of test results for material selection or product development from which they will have meaningful value.

Real-World Applications and Implications

Flexural strength is crucial for industries focusing on materials that must resist bending stress without fracturing. For instance, in construction, the measurement of flexural strength gives engineers the basis on which to select materials for beams, bridges, and floors to support structural integrity upon loading. Knowledge of material responses to tension and compression is thus essential so that designers can avoid hazards of structural collapse and enhance safety in edifices and infrastructures.

Flexural strength is also hugely tested in the manufacturing of composite materials and polymers. These materials are usually incorporated into situations of aerospace, automotive, and sporting goods, where the ability for bending is essential. Flexural testing of materials, therefore, permits the manufacturer to adjust material compositions to meet the precise performance requirements of a lightweight yet tough product-a process that fuels material engineering and product design innovations.

Frequently Asked Questions (FAQ)

Flexural strength calculation is the process used to determine the resistance of materials to bending forces. A load is applied to a specimen until it fails during the test, usually in a flexural testing machine. The flexural strength is expressed in pounds per square inch (psi) and is crucial for evaluating materials’ performances under bending loads.

Flexural strength often tends to increase with tensile strength and compressive strength. While tensile strength describes the ability of a material to resist pulling forces, compressive strength is its ability to resist pushing forces. These relationships become significant during the design of reinforced concrete structures where loads should be in appropriate balance to ensure safety and optimum performance.

The flexural strength is important in construction to ensure structural integrity since it helps them determine the bending resistance of a material used in a beam, slab, or any other member. Higher flexural strength implies that it can resist bigger loads without failure, which becomes paramount in feigning structures that are surely safe.

The four-point bending test is a conventional technique for determining the flexural strength of materials. During the test, the specimen is supported by two points while the load is applied on two other points, thus producing bending moments. Such method helps measure the flexural resistance of material accurately and is really useful in testing flexural resistance of concrete and other materials.

Flexural strength improvements can be brought about by employing high-quality aggregates, optimizing the mix design for concrete, and providing reinforcements such as steel rods. Treatments that increase tensile modulus while decreasing flexural modulus may also enhance overall performance against bending loads.

There is a correlation between the compressive strength and flexural strength of concrete. Generally speaking, concrete having higher compressive strength can resist greater forces of bending and provides a good base to resist tensile stresses applied on it in bending. In other words, compressive strength is taken into consideration while calculating the flexural strength of concrete.

The modulus of rupture refers to a material’s flexural strength, i.e., the stress at which it fails to bend. It is important to give the engineer a measure of bending capacity of a member and is generally employed alongside the strength reduction factor for safety design.

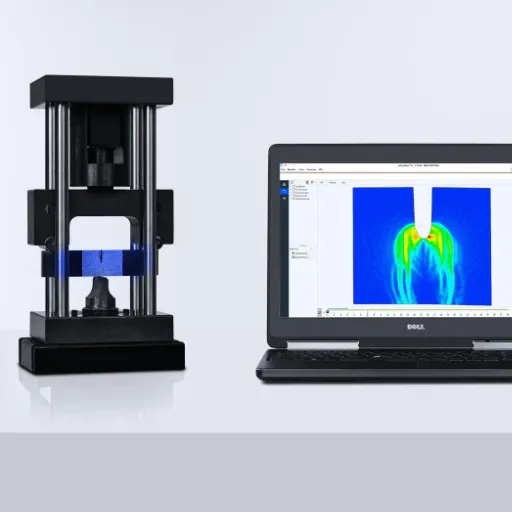

A flexural test machine is of paramount importance in measuring the flexural strength as it puts up the controlled force on the specimen till it is fractured and keeps a record of both the force and the deflection, thereby permitting an accurate computation of flexural strength of the tested material as a function of the stress and strain it undergoes during testing.

Flexural strength calculation can vary drastically across materials on account of their differing physical properties. For instance, the bending modulus and capacity to resist bending of a material such as concrete may yield different results when subjected to the same phenomenon vis-à-vis metals. Each material may require specific methods of testing, such as ASTM D790 for plastics, in order to properly assess its respective flexural strength characteristics.

References

- Guide to Flexural Strength in Materials – Explains how to measure flexural strength using specific beam dimensions and span lengths.

- Flexural strength – Wikipedia – Provides the formula for calculating flexural strength and explains the parameters involved, such as load, span length, width, and thickness.

- The Definitive Guide to ASTM D790 Flexure Testing – Covers ASTM D790 standards for measuring flexural properties under bending strain or deflection.

- CIP 16 – Flexural Strength of Concrete – Details the determination of flexural strength as Modulus of Rupture (MR) using ASTM C78 standard test methods.