A Charpy impact test machine is vital in the field of material testing, without a doubt, towards the measurement of impact energy which is then converted to toughness and resistance of those materials under appropriate conditions. In fact, it is like a medium of communication, to explain how this very important device works its applications and the reasons behind it all. Even if you happen to be affiliated to materials science or engineering or may be just interested in how the structural aptitude of an object is maintained, this information draws one’s attention to the working mechanism of the charpy impact test machine. The main parts are also explained. Moreover, the basic principles of this system are presented. In addition, their use in the real world will be mentioned in this paper, to help you understand what makes this type of testing so vital in many ambiance types from building to aviation. Get ready to know why even centuries of existence cannot really stop the art of preserving the strength of many materials used in different aspects.

What is an Impact Test and Why is it Important?

While impact tests are an essential means of evaluating the resilience of a material, i.e., its ability to deform or resist a sudden or instantaneous load without failure, they are also used in the evaluation of the toughness of the material which the material refers to and its response to extreme operating conditions such as crash or heavy materials. The aforementioned test provides the characteristics of the material strength and specificity, which is useful in the selection of materials to be used in dangerous or performance demanding areas by engineers and manufacturers. It shows how materials will withstand forces in demanding conditions by creating a real-life situation, thus minimizing the occurrence of defects.

Defining the Charpy Impact Test

Also known as the charpy v-notch test, the charpy impact test, measures the ability of a material to absorb energy during a fracture under high strain-rate. This property is important because it characterizes the material notch toughness and is thus a measure of its resistance to impact. In modern Charpy tests, a sample of material is broken by a fixed amount of force using a pendulum in order to produce fracture. In this case the values given may be the energy absorbed in joules while the material was tested for its performance under tension. In recent past the room for enhancement and manipulation of these results, through modeling and enhanced materials databases, has been greatly filled, thus providing engineering with better accuracy of such tests and giving a uption to provide the materials suitable to the conditions such as in the aerospace, automotive and construction industries. When material is moved up and mounted in charpy impact test machine then it is not able to maintain its performance standards and breakage of materials occur.

The Role of Impact Testing Machines in Material Evaluation

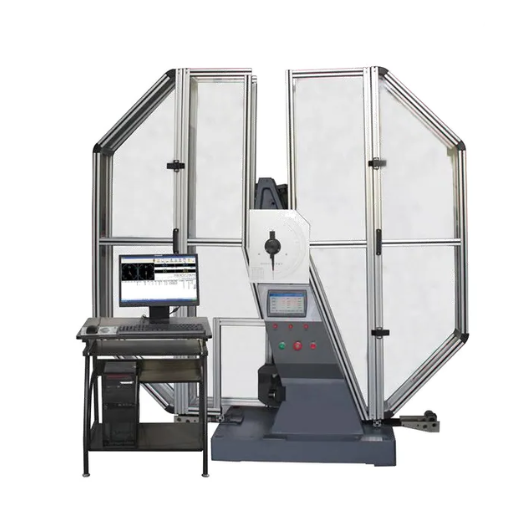

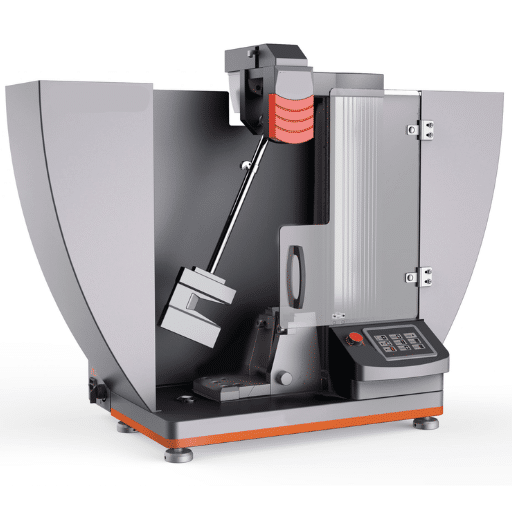

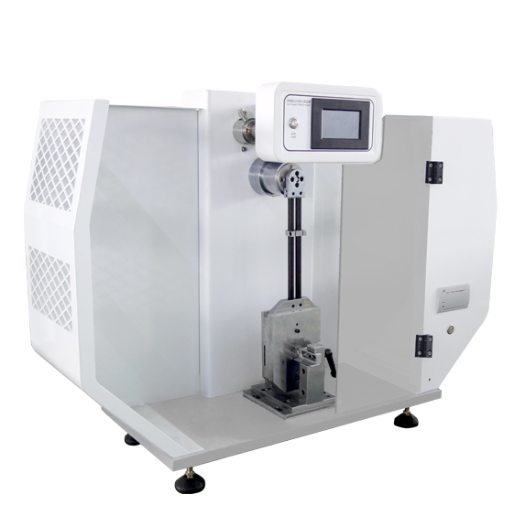

Materials interfaces have always been marveled upon due to its achievements, especially in the area of structural testing, thanks to the charpy impact test machine that enables evaluation on how tough and resistant a specific material is to shock loads and/or dynamic loads in terms of compression. Such testers in general entail hitting a particular material something otherwise known as test sample with the so called hammer as in Charpy and processus izod testers. And those impact testing studies are done in order to learn the behaviour of material or structure under impact scenarios and other forms of mechanical loading ways namely vibration, crash and so forth.

Prominent acts of improvement are seen to be culminating in impact testing machines. For instance, advanced detectors and data collecting systems that function to measure high ranges of energy, even up to these characteristics of crack faces openings and shapes, makes this process even more reliable. Also, impact testing machines are computerized and include software that can analyze impacts in real time and in most cases, results can be easily compared to these standards or limits since they are interpreted in automated mode.

Such areas include for instance those in aerospace, automotive and construction industries tha6t are very specific in nature in terms of ensuring safety within particular material properties. An example is found in the crash tests for vehicles which provide information on the material that has a high level of energy absorbed that consequently protects the users of the motor vehicle. By the same token, certain materials usage in aircraft construction is subject to taking or counteracting impact forces when arguing detonation activities at massive fluid bombs that causes a lot of reaction due to Gang bang events. Hence, impact testing machines are useful not only in the materials selection but have application involving system safety and the safety of individuals.

The Importance of Impact Test in Metal and Plastic Industries

Material Testing Assessment finds its relevance in metallurgic and polymer industries wherein the capacity of a given material towards absorption of sudden forces or shock loadings, and toughness or ductility is quantified. When it comes to metal materials, it offers performance attributes that include its definition as one of the brittle materials along with the possibility of cracking or breaking, as well its behavioral changes when exposed to a certain temperature for which it is designed for civil engineering or automotive parts. In the case of plastics, the impact tests focus on properties such as flexing, swelling and breaking point, deploying for packages, fast moving consumables and industrial materials. The results of such testing are necessary for manufacturers who wish to select the most appropriate materials for the production, improve the safety of their goods and meet the standards determined by the industry. Such tests do not only minimize the chances of breaking the structure but also help manufactures designs that are new, stronger and environmentally friendly materials. A common method is the Charpy impact test machine. Now applied to animatronic contents for skateboards, for instance.

How Does the Charpy Impact Tester Work?

A charpy impact test machine consists of a specific pendulum, which aims to break through samples having an engineered notch. The effort required for the fracture to occur is determined and indicates how tough the material is and its ability to resist shock loads. This experiment finds out how much force a structure can take before it breaks; the other importance of this test is providing answers to whether the material is brittle or ductile.

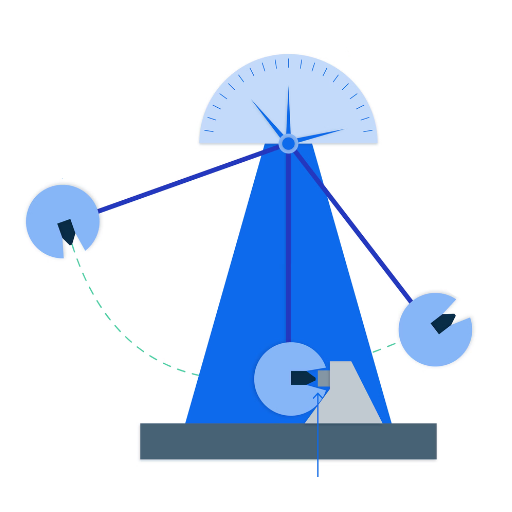

Components of a Pendulum Impact Testing Machine

Impact testing machines, especially Charpy impact test machine, have different vital components responsible for the accurate and precise material impact resistance measurements. These components are as follows:

1.Pendulum Arm: Used to hit the specimen. This is the arm which can be referred to as the hammer and is usually of great mass and modernistic calibration that strikes the specimen with limited energy.

2.Specimen Holder/Fixture: The frame where the test specimen is mounted is such that the test conditions are not altered.

3.Notched Specimen: It is a pre-cut specimen whereby; the notch, being rather specific, acts as an inter-stress level surface at which the initiating crack will develop.

4.Scale or Energy Indicator: A device such as a simple dial or digital readout (monitor) that gauges or informs the amount of energyzoid absorbed by a breakage.

5.Base Frame: Form a solid standing support structure, in ropes a guidance type staggered components which allow the charpy potential.

6.Adjustable Support Anvils: Hold the targeted specimen still in position but leave room for the coming force to reach the targeted point on the specimen.

All the above-mentionable parts working together will sustain the stability of direction of Charpy or Izod test with adequate and important information regarding the structural behavior of the material when it is subjected to impact loading.

The Mechanics Behind the Pendulum and Notch Interaction

It is essential when testing Impact to consider interaction between pendulum and notch because it is a key entity in fracture of material and energy release characteristics. In a Charpy or Izod test, the notch is the area of the sample that is impacted by the pendulum from a given height, as designated? And the most important part is the notch. The notch is used to localise the attention on a particular area so that failure is at the same location of the piece and is the same. After the strike, the kinetic energy of the pendulum is converted into the kinetic energy of the specimen, making it deformed and broken. One could measure how much of the energy is dissipated – this is the essence of this experiment, the fracture toughness of the material. This is designed in such a way that finished system checks out as intended making it feasible for engineers to analyze impact characteristics of materials, quantitatively.

Understanding the Energy Absorbed During Testing

The energy handling capability of a material in response to sudden loading is calculated by the energy absorbed in the course of an impact test and it directly reflects the toughness of this material. Such energy is calculated as the difference in tangeancial energy of the pendulum before and after the specimen is fractured. Generally, materials with more ductility will withstand higher loads and take up more energy before fracturing thus demonstrating enhanced toughness to dynamic load. Energy absorption also depends on various factors, which include specimen shape, test temperature and material structure, and thus must be performed in controlled environments for both accuracy and repeatability.

What Materials Can Be Tested with a Pendulum Impact Tester?

A charpy impact test machine can test many materials like metals, polymers, composites, and ceramics. Metals like a steel or an aluminum are hard because, in order to predict the impact load, they have to be taken down. Polymers are tested in order to determine how easy or difficult it would be to break them, in different situations like thermoplastics and thermosetting plastics. Composite materials which are in demand for the manufacturing of airplanes, cars, etc are tested to see the behaviour of the matrix material and the reinforcement under the impact loads. Although ceramics are very brittle, they can also be tested to measure their fracture energy. Still, accurate and reliable results can be achieved only when such preparation is done intentionally and exactly, following the requirements of such materials categories.

Testing Metals with Charpy Machines

The Charpy test is a standard method of evaluating mechanical properties of a material namely how much energy it can absorb upon a fracture, which is equivalent to its toughness. Among the tests, a metal sample with notches is put into a testing device and hit with a hammer in the form of a pendulum. The most workable characteristics determined over such specifications include the ductility of the material, the fracture energy, and the temperature of those transitions, which are essential in determining the behavior of the material in view of the different conditions. This procedure is of utmost importance for metals that are used in situations where the temperatures are extremely low, causing the toughness of the material to lessen significantly.

Evaluating Plastic Materials with Charpy and Izod Methods

While analyzing plastic substances for charpy impact test machine, izod along with charpy test method, the extent of damage for all impacts is determined by the energy absorbed before fracture. Both the tests as well cause the notched portion of the specimen, suspended on a pendulum, to be hit under specific conditions, with some variation in orientation and sample positioning that in some cases may cause small deviations. They are necessary to quantify the toughness of each plastic and whether it can be used for impact bearing purposes. The knowledge of the energy of fracture available as a characteristic value helps in selection of materials, particularly for details prone to mechanical forces or under conditioned loads.

Comparing Impact Resistance Across Different Specimens

When comparing impact resistance across different specimens, the common types include notched and unnotched specimens, thin and thick sections, and specimens with varying orientations.

|

Specimen Type |

Key Feature |

Impact Behavior |

Application |

|---|---|---|---|

|

Notched Specimen |

Pre-cut notch |

Measures fracture |

Structural testing |

|

Unnotched Specimen |

No notch |

Measures toughness |

General durability |

|

Thin Section |

Reduced thickness |

Sensitive to loads |

Lightweight parts |

|

Thick Section |

Greater thickness |

Handles heavy loads |

Structural support |

|

Varying Orientation |

Aligned/grain |

Affects strength |

Specific designs |

Why is Calibration Important for Impact Testing Equipment?

It is important to properly calibrate the impact testing equipment to obtain the accurate, reliable and repeatable results. The caliiration adjustment performed on the equipment is essential because this ensures that the measurements of the equipment are in line with the available standards so that the toughness, behavior and any such property of the material is obtained accurately. This procedure helps in eliminating the errors that are associated with inaccurate measuring equipment due to mechanical wear and tear, changes in the environment or even an improper machine set up thus, also ensuring that the industry practices and the quality control specifications are met at all times. Finally regular calibrations help in improving how useful the test data is in as far as crucial applications of engineering and design is concerned.

Ensuring Accuracy with Standard Test Procedures

When conducting material tests, obtaining accurate measurement results is made possible by following standard procedures of tests, which ensure that the methods referred to when conducting measurements such as tensile strength, brinell hardness etc., are markedly consistent. Such backs are provided in different institutions including standardizing bodies like ASTM, ISO, and DIN which avoid errors through operator errors or even change in environmental conditions. Select controls include the careful assembly and adjustment of the fixture and testing machine, routine calibration of the testing machine and workpiece, and testing under the desired conditions of temperature, loading rate among others. Detailed information should also be maintained for traceability and validation purposes to ensure data consistency. Following adherence to the experiential approaches already existent, the industries in context will easily meet the set standards of quality as well as improve the effectiveness of main design goals of the system.

The Role of Calibration in Reliable Test Results

The primary goal of performing calibration on an instrument is to make sure the instrument performs its intended functional activities as dictated by the user with reference to limited parameters of instrument performance. However, not any instruction device by itself is always able to make the user 100% certain about the result of the test and how the equipment will perform over a certain period of time. In as much as compliance is not by itself mean accomplishment of the set objectives, improvements occur to avoid wastes and errors that affect the ability of the product to save the intended purpose. Of great importance is performing checks and realignment of instruments involving calibration procedures in compliance with certain standards and procedures from time to time especially in these kinds of applications (scientific and/ or industrial applications), to make sure the results remain credible. In these cases, furthermore, the charpy impact test machine meets all these requirements with lack of frequent re-calibration.

What are the Differences Between Charpy and Izod Impact Tests?

The primary differences between Charpy and Izod impact tests lie in the orientation of the specimen, notch positioning, and method of testing.

|

Parameter |

Charpy |

Izod |

|---|---|---|

|

Specimen Position |

Horizontal |

Vertical |

|

Notch Facing |

Away from hammer |

Toward hammer |

|

Support Type |

Both ends |

One end |

|

Hammer Swing |

Hits center |

Hits top |

|

Test Setup |

Simple beam |

Cantilever |

|

Energy Measured |

Absorption |

Absorption |

|

Notch Orientation |

Centered |

Offset |

|

Application Area |

Structural |

Materials |

Comparing Charpy and Izod Test Methods

Charpy and Izod test methods differ in specimen position, notch facing, support type, hammer swing, test setup, energy measurement, notch orientation, and application area.

|

Key Point |

Charpy |

Izod |

|---|---|---|

|

Specimen Pos. |

Horizontal |

Vertical |

|

Notch Face |

Away |

Toward |

|

Support Type |

Both ends |

One end |

|

Hammer Swing |

Center hit |

Top hit |

|

Test Setup |

Beam |

Cantilever |

|

Energy Meas. |

Absorp. |

Absorp. |

|

Notch Orient. |

Centered |

Offset |

|

Application |

Structural |

Materials |

Choosing Between Charpy and Izod Impact Testing for Specific Applications

It is not rare for someone like me to choose either the Charpy or Izod impact test depending on the application of the material in question. I have observed that when I have to conduct a strength test to determine the R-curve behavior of a given material considering the fracture resistance to be a structural fracture, charpy tends to be more applicable as it involves horizontal orientation of the tested-hammer hits at the center of the specimen, thus reflecting/Universal loading which is structural in nature. However, when a material exhibits resistance to its fracture toughness in a limited space, testing becomes necessary and in such a case, Izod test is done. This is because the specimen is set in a vertical and cantilever configuration which allows to study the material under such localized loads and this is useful especially for shock transfer ability of the material. Thus, when doing Gordons construction of comparison, my ability to appreciate the adaptation of the given structure/material will determine which of the tests to use.

Reference Sources

-

Step-by-Step Guide: Conducting the Charpy Impact Test (ASTM E23) – A detailed guide on conducting the test, including sample preparation and procedures.

-

Installing, Maintaining, and Verifying Your Charpy Impact Machine (NIST) – A comprehensive document from NIST covering installation, maintenance, and verification of Charpy machines.

-

Instron 8200 Impact Tester Operating Instructions – Operating instructions for a specific impact tester, useful for understanding machine setup and operation.

-

NIST Sharpens the ‘Charpy’ Test to Make a More Precise Impact – Insights into NIST’s efforts to enhance the precision of Charpy testing.

-

Charpy Impact Testing – Metal and Metallurgy Engineering – A discussion forum with expert insights on the standard test method and its applications.

Frequently Asked Questions (FAQs)

Q: What does a Charpy Impact Test Machine purpose serve ?

A: Charpy Impact Test Machine is designed for the characterization of mechanical properties of materials. It is particularly useful in assessing the energy absorption capacity of the fracture prone metal in order to characterize its ability in terms of real situation based stress engineering.

Q: What is the procedure of testing the metal in the Charpy impact test ?

A: The Charpy impact test involves the use of a pendulum where an instrumented equally pitched V-notch orupoek is inserted into the specimen holder. The test is based on a pendulum that is released in the swinging state and hits the specimen. The amount of energy absorbed by the specimen during the breakage is determined which simply indicates the impact strength of the concerned material.

Q: What is a 750J Machine in the Charpy Impact Testing?

A: The 750J Charpy Impact Test Machines is designed to be used when the maximum energy level is K90J and can be increased up to transferred energy 750 Joules. This is particularly useful for examining those materials which need to be tested against impact strength over a wide range of impact energies.

Q: Why is there a notch requirement for the specimen for Impact test?

A: Notches in Charpy Impact Test play an important role because they are introduced to the specimen with a purpose of enhancing the complete fracture of the specimen at a specific location, which makes toughness testing more feasible. It helps to evaluate the performance of that material when subjected to impact and is a very important factor when evaluating metals for their impact strength.

Q: In the Charpy Impact Test, what provides the basis for writing the test report?

A: Test sequences have to be carried out before Charpy Impact Test reports are prepared. These reports contain information about testing like absorbed energies and material response to testing in specific contexts together with adherence to the relevant standardized regulations governing the testing of metals.

Q: What is the distinction between Charpy pendulum impact test and drop weight test in principle?

A: In Charpy pendulum impact test, the pendulum is used to hit the specimen and since the pendulum helps in the fracture testing. In contrast, in a drop weight test, a weight is made to fall from a certain height to the specimen to impose the impact load and is mostly used for big samples and constructions.

Q: In the course of testing metals, why do we need to use certain metallic impact testers fitted with measuring devices?

A: Metallic specimens must be tested using impact machines mounted on devices. This provides temporal information of force, energy and displacement in the making of the impact. This renders a clearer understanding of the metallic structure during impact including notions of ductility and toughness.

Q: How is the range of the impact determinant to the choice of the testing equipment ?

A: The impact range is the amount of energy that the test equipment can apply. It is therefore important to choose the one that assures performance for a specific case and enables the examination of the material for each of the impact energies in question.