The charpy impact testing machine is still one of the most widely used machines for assessing the behavior of materials subjected to impact loads. Every practicing material engineer, industrial expert, and developer should appreciate the purpose, applicable environment, and the relevance of such equipment in any material development and the assurance for the use of the developed materials. This article will give an in- depth understanding of the charpy impact testing machine’s conventional use, starting from its capabilities and ending with the fields using it, including automotive, construction, and aerospace industries. Should you keep reading this write-up, you will comprehend the usefulness of the said test in predicting the sturdiness of materials in different areas of engineering. Let me take you on a journey to explore the charpy impact testing machine and its significance in the modern day engineering material science practices.

What is a Charpy Impact Testing Machine?

We make use of a charpy impact testing machine to know the extent of energy that would be taken up by the material when it fractures. This is to check the tenacity – how strong the material is before it breaks. Several tons meter weight is made into a huge pendulum and when released the pendulum strikes the notch on the specimen that is mounted in the apparatus. The absorbed energy when the material break occurs is measured and shown to know or assess how a material is resistive to impact failure. This is one of the most common methods used in material testing and engineering to verify with simulative practices the safety and efficiency of materials.

Understanding the Charpy Impact Test

The Charpy Impact Test is a type of test that one can use to assess how much energy a given sample can withstand before breaking, and consequently how tough and impact resistant the specimen is. In this test the sample is notched, placed in position, and a pendulum is then swung and made to strike the specimen; the energy is already measured at the fracture of the specimen. The main aspects which affect the results are the temperature, the condition of the notch, and the speed at which the materials are made to undergo loading. This is necessary for materials that are to be used in areas where impact or shock absorbers are vital. Such areas are for example construction, has multiple applications in design, drive line or power train and aeroplane design. In this article you will see the proper way of using a charpy impact testing machine in real application, why do we need it and how do we especially prepare the materials for this testing.

Key Differences Between Charpy and Izod

The key differences between the Charpy and Izod impact tests lie in the sample positioning, notch orientation, hammer strike location, and testing setup.

|

Parameter |

Charpy |

Izod |

|---|---|---|

|

Sample Position |

Horizontal |

Vertical |

|

Notch Orientation |

Away from hammer |

Facing hammer |

|

Strike Location |

Opposite notch |

At the notch |

|

Support |

Both ends |

One end |

|

Testing Plane |

Edgewise |

Flatwise |

|

Energy Measured |

Absorbed to break |

Absorbed to fracture |

Components of an Impact Testing Machine

Impact testing involves the use of a machine, known in layman terms as toughness testing machine, which requires a wide range of tests which involves fracture energy measurement. The major parts of such machines are explained below:

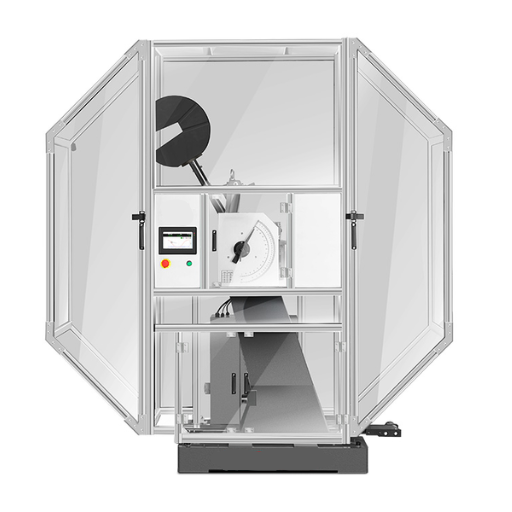

1.Pendulum Impact Hammer

The impact hammer pendulum, which is commonly manufactured out of a hardened steel, comes in a pendulum configuration so as to exert a controlled force on the specimen. This tool permits adjustment of the height and the mass of the pendulum for the different levels of impact energy.

2.Specimen Holder

This jig is used to clamp the specimen during the test. It is built based on the type of the test, such as Charpy test, Izod or Drop weight test so that there is no misalignment or absence of support.

3.Supports and Anvil

These elements hold the specimen in the resting position. For a charpy impact testing machine all the ends of the specimen rests on the supports. In an izod test one end of the specimen rests on the support while the other end is clamped vertically.

4.Notching Device

A notching device makes a preset notch on the specimen. The size of the notch and the angle it is made are important for the result to be repeatable and comparable.

5.Measuring Scale or Electronic Digital Display

The pendulum motion is converted into quantifiable data by the measuring scale or the electronic digital display, and it is this amount of energy that is converted into the scale or the electronic digital display monitors.

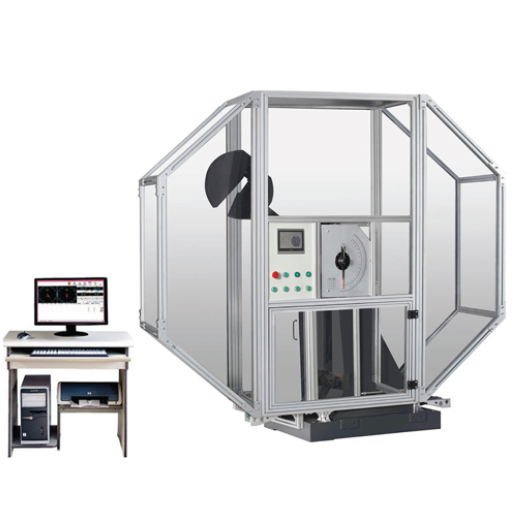

6.Test Chamber Enclosure

Sliding doors cover the test enclosure walls for safety reasons, preventing the participants from any dangerous issues that might occur during the test performance.

These mechanisms are aimed at enabling robust and consistent impact testing results- functions that are very crucial in the study of material behavior especially when subjected to sudden forces.

How Does a Pendulum Impact Testing Machine Work?

The charpy impact testing machine is used for testing a given material’s potential strength. In the hour of executing the given test, by elevating the pendulum to a certain height, hence, energy is conserved in the form of potential energy. As the pendulum is released it comes downward hitting the sample which breaks the membrane. The absorbed energy needs to be calculated by determining how high the pendulum has gone after the impact. The resistance of materials determined through the impact energy functional is used to perform impact tests on materials using standardized methods whose results are in general high speed and are, most importantly, to evaluate the performance of materials even during sudden dynamic loads.

Components of a Pendulum Impact Tester

In general terms, several components can be delineated in a typical pendulum impact test equipment, crucial for correct functioning and evaluation.

1.Pendulum rigid arm: Usually rigid, usually with a striking face or hammer, the pendulum arm provides energy circulation to the object under test with the help of gravity. Its bolt, weight as well as shape are configured based on the pertinent testing directives.

2.Test sample stage (anvil): This fixed assembly holds the sample firmly during testing. It is thus structured in such a way that either sample movement occurs during the test or more significant distribution desirability is achieved.

3.Scale or any measurement device: Scale or any measurement device provided in the pendulum impact tester evaluates lost energy by the use of height transducers measuring the actuation line before and after impact. It gives the overall energy needed to break the material.

4.Support or Base structure: This robust base supports the test assembly to isolate it from vibrations/external factors which may cause defects in the experiment.

5.Hammer Latch: This releases the pendulum arm in a controlled and consistent manner such that the same amount of energy impacts the specimens every time.

6.Shelter: Because of the potential for impact test, safety shields and/or enclosures are provided to ensure operator safety as well as to prevent any damage from debris moving at a high velocity.

7.Data Collection System (if present): More sophisticated designs be provied with analyses sensors and recording system containing information on the impact testing procedure.

All parts serve different purposes for testing the materials resistance to sudden, external, and heavy forces so that they help engineers evaluate the durability of materials and realization of design in practice more safely. All these components are uniformized according to international testing standards such as ASTM or ISO for clear and fair results.

The Role of the Test Machine Frame

The frame of this testing machine acts as a foundation, providing the necessary strength and rigidity during impact testing processes. Its purpose is to absorb shocks rather than transfer them to the systems, this enhances the accuracy of the tests and ensures that they can be replicated in most circumstances. Often made from heavy-duty materials such as steel or reinforced metal alloys, the frame contains all functional parts, the impactor and specimen holding devices inclusive. Upon calibration, the frame allows for easy injections of energy during test performance in accordance with strict guiding principles by ASTM and ISO Amongst other requirements, it is an important factor in the material testing equipment that you will find.

Understanding the Pendulum Impact Mechanism

The operation of charpy impact testing machine works based on two physical laws – kinetic energy and momentum, in order to characterize the specimen’s behavior under rapid rates of loading. When the pendulum is released from an initial height, it acts as a weight falling and gaining speed so as to gain kinetic energy until a specimen is approached. Upon the impact of this kinetic energy, some portion of the energy is destroyed by the material and deformation or fracture occurs in the material. The rest of the energy is carried away by the pendulum which further continues its arc. The presence of advanced sensors and encoders that measure the extent of pendulum’s motion after the impact and in the end, they allow for a clear determination of the energy dissipated.

How to Prepare a Specimen for the Charpy Impact Tester?

The preparation of the test specimen to be tested in the Charpy impact testing machine involves several steps:

1. Determining the material of the test specimen: The appropriate test specimen is one which conforms to the testing standards be it ASTM E23 or ISO 148. With that said, the material in use must be uniform and devoid of any flaws.

2. Good working knowledge of machines: The specimen has to be worked to specific dimensions according to the standards, which may differ. For this purpose, 10 mm x 10 mm x 55 mm is used mostly, but some variations may occur due to the kind of test it is.

3. Notch Making: The specimen should contain a notch at the middle. The specification on the type of notch, i.e., whether V-notch or U-notch, with all accurate depth, width, and angles are specified by the standards. This accuracy can only be achieved with the help of specific tools.

4. Changing the cross-section of the section members: The cross-section of the members of the tested samples is extended and smooth, no Saint-Ichel steps or Polish durations. Otherwise, the test results will be impacted and polishing will be done.

5. Examination: Ensure that the machined specimen inside satisfies all dimension and proper shape tolerances by utilization of accurate measuring devices such as a Caliper or a Micrometer. Any specimen which does not satisfy the tolerance conditions should be eliminated.

Stepping through these steps in detail will produce results that can be relied upon from one test to another on a charpy impact testing machine.

Importance of Specimen Notch and Broaching Machine

The Charpy V or U notch utilized in the charpy impact testing machine acts as a stress magnifier encouraging fracture propagation within the sample under controlled circumstances, which is vital for impact testing. This allows us to have comparable and controlled parameters while evaluating the material for impact resistance. This is attributable to the broaching machine that faithfully reproduces an internal V-Notch or U-Notch, which is a crucial element that helps eliminate the corresponding errors. Furthermore, the broach patterns the notch so as to conform to ASTM E23 standards or any other applicable standard thus ensuring reliable test results.

Using an Automatic Specimen Broach

In dealing with the function of the automatic specimen broach, operations must be carried out only when the machines are present in the calibrated and aligned position with the machine specified in the designed by the manufacturer. In my way of thinking, fastening the test specimen so that it will not move when broaching is the first step. Afterwards, adjustments of the machine follow to cut a certain type of notch such as a Charpy’ V or U notch which is defined by ASTM E23 or any other related standard. The method is very effective as it provides unparalleled results of notching with minimum operator interference. It is also important to ensure that the broach is serviced frequently – from sharpening blades to inspecting the components of the broach – as this does not allow the notches to misalign and is within the protocol of tests performance.

Common Impact Specimen Standards: ASTM and ISO

ASTM and ISO rules and regulations are necessary for standardizing the processes of impact testing worldwide. ASTM E-23 is a commonly drawn out practice for fabrication and testing of notched bar impact samples, with examples being the Charpy and Izod tests. It includes content, dimension specimen, notch shaped specimen, and methods for testing to be the same in each laboratory.

The same can be said for ISO 148-1 standard that describes specifications for the Charpy pendulum impact testing of metallic materials. The standard aims to achieve specificities in every aspect of received specimens, ensuring not to exceed the intolerances applied on notch dimensions and also in the application of testing adding care to the slide. In other words, both standards focus toward reproducibility and precision with: reliance on other facilities is eliminated.

Compliance with these standards enables the manufacturing companies, testing laboratories and the regulatory agencies to ensure the uniformity, assessing the performance of the material as well as assures the safety and quality of many industries of interest. Working equipment should be regularly calibrated, and samples prepared very precisely, in order to follow these tough international regulations.

What are the Test Results from a Charpy Impact Test?

The main purpose of conducting a Charpy impact testing is to evaluate the impact resistance of the steel or any other material under consideration. This is provided by assessing the strength of the piece and can be measured in Joules (J) mostly because the energy required to break is the ability measured. It means that, useful data can be gathered to evaluate the capability of a structure to resist instantaneous impacts, or forces, or to study the transition between ductile and brittle behaviors of different materials at low or high temperatures, which is also referred to as the ductile-brittle transition.

Interpreting Impact Resistance and Fracture Patterns

The resistance to impact can be measured by examining the material’s reaction in the presence of the applied forces by examining the absorbed energy from fracture as is evident during the use of the Charpy impact testing machine. Major explanations include an indication of whether the material is ductile or brittle, unlike metallurgical temperature and composition. Ductile fracture consists of a lot of deformation and fibrous-type fracture, while brittle fracture involves very little deformation and a lot of cleavage and granular fracture. Energy absorption patterns, together with different types of fractures, enable us to decide on the application of materials in various impact loading cases.

Calculating Energy Absorbed and Impact Strength

In order to approximate the absorbed energy and impact-strength of a material, I would look into the findings of established impact tests, such as Charpy and Izod tests. In a charpy impact testing machine, an notched piece is hit by the vice of a hammer, and the energy gets dissipated at the fractured points which imply the toughness of the material. The toughness is determined by dividing the energy used up by the contact area at the cut. This method allows characterization of the material in terms of its ability to resist impact forces, which means that it is possible to make a judgment of how the material will function in practice under a given force.

Assessing Material’s Notch Toughness

Standardized methods such as Charpy Petrol pen drive not available and ferraty type of impact test is considered to be among the most diagnosis methods for assessing the notch toughness of the material correctly. They are crucial when examining the defining characteristic of a material under either impact or sudden volumes. As accounts of the earliest known instances state here, Charpy is commonly used in industry as a test if and how a notched bar rings inertia after it has been cut – in this case with the charpy impact testing machine. The Izod test is similar; however, the sample and the loading conditions differ. All of these techniques are relevant to sectors where it is important to assess fracture betide in impact when choosing the features and design of materials.

Choosing the Right Impact Testing Equipment for Your Needs

When it comes to the choice of impact testing equipment, one has to put to scrutiny the type of material, its application and the requirements for testing standards. For example, in the case of brittle materials, Charpy and Izod tests are applicable to measure the energy absorption and assess the fracture control of the material. In addition, it is essential to check whether the equipment is designed in such a way that the specified size and sample orientations as the specific standards such as ASTM or ISO are achieved. Retrofitted units which have digital data acquisition and analysis features would dispense an improved accuracy and less variation due to human interference or activities which are today applicable in most if not all quality measures. Also, assess the size of testing activities involved and long term serviceability to ensure they are in line with the shelling costs and the efficiency of the equipment respectively.

Understanding the Range of Impact Testers

A variety of impact testing machines are manufactured depending on the requirements of the testing material to guarantee optimal performance. For instance, Charpy and Izod methods of impact testing are used to measure the energy required to fracture the specimen. These are techniques that use characterized pendulum boys to apply the force with great accuracy. And these industries are automotive, aircraft, building materials all of which use these methods. Drop weight testers also find a number of applications in large scale tests or for practical purposes where a particular impact condition is to be recreated.

Manual vs. Automatic Specimen Testing

Manual and automatic specimen testing differ in terms of labor intensity, precision, consistency, speed, cost, and operator expertise requirements.

|

Parameter |

Manual Testing |

Automatic Testing |

|---|---|---|

|

Labor Intensity |

High |

Low |

|

Precision |

Moderate |

High |

|

Consistency |

Variable |

Reliable |

|

Speed |

Slow |

Fast |

|

Cost |

Low upfront |

High upfront |

|

Expertise |

Required |

Minimal |

Evaluating Charpy Machines with 750j Capabilities

The 750J charpy impact testing machines are paramount in determining the toughness of materials under high impact conditions. These particular impact testing machines allow an extreme amount of energy to pass through the sample in question to allow reliable results. The main considerations when assessing such machinery include energy calibration, adherence to ASTM standards, ISO fraternity standards and protective features.

1.Energy Calibration – Allows for improved ability to measure full capacity of absorbing energy. Machines have to be calibrated on a regular basis and comparing with a traceable reference in order fourtest results to always be consistent.

2.Standards Compliance – If any charpy machine is tested make sure that it meets the ASTM E23 and ISO 148 to be precise as these are the standards that govern such acceptable charpy test parameters.

3.Safety Features – A 750j machine is a very high energy machine that requires adequate containment, a safety shutdown system with specimen auto serving features is installed for operator and occupational health safety.

Most of the newer Charpys in this range have special data acquisition systems embedded in them for impact testing which allows in-situ observation and evaluation of the results. More or less, there are some added facets like automation enhancing human fallibility and vindicating repetitive testing. Studying specifications of machines and getting them certified by established bodies is a prerequisite, amongst other factors, when making a decision.

Reference Sources

-

Conducting the Charpy Impact Test (ASTM E23) – A detailed step-by-step guide on conducting the Charpy Impact Test.

-

Izod Charpy Impact Tester Operation Guide – Provides operational guidance for Charpy and Izod impact testers.

-

Charpy Impact Test: ASTM E23 – Explains the standard Charpy Impact Test specimen and its specifications.

-

Impact Standards: Charpy V-Notch Specimens (NIST) – Offers insights into standards and requirements for Charpy V-Notch specimens.

-

Charpy Impact Tester for Metals | Qualitest – Information on Charpy Impact Testers for metals, including compliance with ASTM E23 and other standards.

Frequently Asked Questions (FAQs)

Q: What is the point of a Charpy Impact Testing Machine?

A: It is an apparatus used to determine the extent to which the material is impacted without failure, the material can be metallic or plastic. This is essential to ascertain if a certain material is ductile or brittle when exposed to high dynamic forces.

Q: How does the Charpy Impact Testing Machine function?

A: This is possible thanks to the use of an impact pendulum that hits a specimen with a notch, usually made of a metal or plastic material, and records how much energy is used in breaking the sample. These Correlation Between Two Materials tests or its results is of importance in most accurate impact resistant testing machines.

Q: Why is the Charpy V-notch test a necessary part of metal testing?

A: Charpy V-notch testing is critical in the testing of metals because such a test answers the question of how much energy of fracture is present in the design of a given metal and its toughness to allow impact in the service environment.

Q: What associates are exalted in said Charpy Impact Testing Machine?

A: Some of these features include an impact pendulum which is accompanied by specimen supports, a capacity pendulum and sometimes a digital display to keep the test records. All of these components ensure the right process of achieving the best feasible results of the tests.

Q: How do test sequence and specimen temperature affect the test process?

A: The temperature of the specimen is one of the differences due to which the affected results are significant to the cause. The test sequence and the technique of installing the specimen at the place where the impact takes place play an important role in the impact results determination.

Q: How are Charpy tests different from Izod tests?

A: Both tests are used to determine the ability of the material to withstand an impact, but in the Charpy test, the sample is held in the horizontal position, while in the Izod test the sample is held in the vertical position. The position of the sample during these tests also changes the way stress from the impact is spread, and correspondingly, the data obtained.

Q: When are impact tests said to be instrumented, and how do they vary from legacy approaches?

A: Instrumented impact testing is a more refined version that comes with sensors that collect information about force and energy at different times of the impact. In comparison to conventional ways of quantifying the energy only after fracture, it is more useful to assess all stages and the engineering materials involved.

Q: Are Charpy impact testing machine different from drop weight testers?

A: Drop weight testers are also a type of impact testing equipment where a weight lifted and then allowed to fall on the test piece to observe the specimen deformation. These kinds of tests offer an alternative impact resistance test whereas the Charpy test may not be suitable for some tests.