Considered the metal fabrication industry to be revolutionized by CNC bending machines for precision, efficiency, and versatility in the shaping of metal components. Therefore, be it a manufacturer or an engineer, or maybe one who is just intrigued by the mechanics of advanced industry, grasping how CNC bending is done is necessary to realize its impact on various fields. The complete guide is being laid out to take you through the CNC bending process from scratch, introducing the machine and how it works, then moving on to view the mechanical concept behind its accuracy and the advantages it offer to today’s fabrication. By the conclusion of this guide, you will understand the role CNC bending machines play in producing anything from elaborate designs to extremely rugged structural parts.

Understanding CNC Bending Machines

Definition and Core Functionality

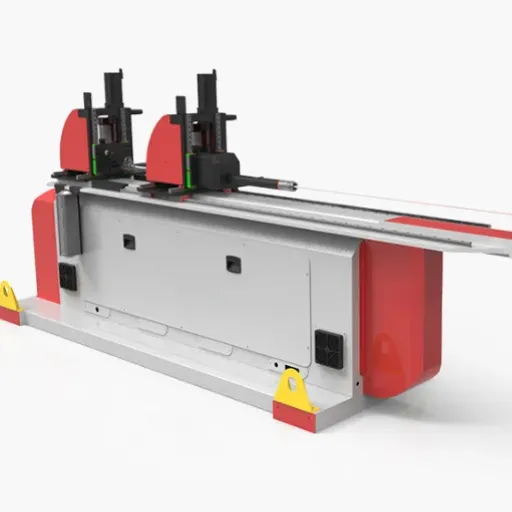

Basically, CNC bending machines are computer-controlled machines used for the bending of sheet metal and other materials. CNC stands for computer numerical control. The numerical control gives instructions to the machine by way of a computer program, so that complicated bending operations can be performed with utmost accuracy and repeatability.

The main function of CNC bending machines lies in their capability to be able to bend the material into various shapes and angles precisely. They achieve this through the punch, die, and press mechanism which exert usage of controlled force on the material. Then the software dictates the operation of the press, punch, and die concerning the bending free of all material outside the requirement of the specification in the design.

Key Advantage:

The game changer when it comes to the CNC bending machines is the efficiency of their working while maintaining uniformity during mass-scale jobs. Less of a manpower-intensive process, they have minimal chances of faults and, therefore, have a faster production cycle. This makes it a must-have for industries pertaining to automobiles, aerospace, or construction, where accuracies and quality matter most. Costs go down while product reliability goes up when a process becomes easier and faster with CNC machines.

How Computer Numerical Control (CNC) Works

A Computer Numerical Control machine works by automation of machining tools using pre-programmed software. The set of instructions dictates exactly where and how fast a tool will move along with what sort of action it must take to produce a part or product. This programming is derived from the numerical code, which is known as G-code and instructs the machine to do cutting, drilling, or milling operations with very fine and tight tolerances.

CNC Process Steps:

- Digital Design: First comes the digital design or model borne from designing software called CAD.

- Code Conversion: The second step consists of converting this digital model into a code readable by machining software called CAM, which loads the CNC machine to execute machining operations.

- Tool Pathing: Following this, the tool pathing synchronized to DIY material shaping is prepared.

- Execution: CNC machines serve different industries by working on materials such as metals, plastics, or even wood.

As far as CNC is concerned, it is efficient in constantly repeating operations accurately, hence minimizing human error. Production of complex and intricate components which would be difficult or even impossible to manufacture manually is one of its capabilities. Since the machines operate with increased speed, every finished product is made strictly in conformity with the same specifications. This characteristic is of paramount importance to industries requiring delicate precision-like aerospace, medical technology, and automotive manufacturing.

Automation in the Bending Process

Automation in the bending operation has essentially been a boon to manufacturing, rendering processes seem smoother and more consistent. An automated bending machine has a sophisticated control system that can perform tasks with very little human intervention. The good thing about this is its ability to keep human labor low. This also reduces human handling errors, where a greater degree of accuracy should be required in the manufacturing process.

Automation Benefits:

- Standard Output: One major advantage of bending automation is its ability to give a standard output even in higher volumes.

- Consistency: Manual bending is more or less subjected to some variation, thus posing inconsistency in the end product.

- Perfect Programming: In an automated system, the same bends are programmed and executed perfectly.

- Industry Applications: Essential for aerospace, automobile, and medical technology industries.

Automation is an additional factor in ensuring efficiency and safety. Automated bending machines are capable of operating for long hours, thus elevating production rates and curbing downtime. They come equipped with electronic safety features that safeguard workers from any direct interaction with the machinery. Thus, automation is not just a means of ensuring production quality but is also a safety factor for workers, making the manufacturing environment more reliable and efficient.

Applications of CNC Bending Machines

Industries Utilizing CNC Bending

Due to accuracy, efficiency, and flexibility, CNC bending machines find applications in various industries. One principal industry is automotive, where CNC machines are used in manufacturing components like exhaust systems, chassis parts, and brackets. Thus, the process of bending must produce uniformly spaced bends with complex designs to meet acceptable standards established for automotive assemblies.

Automotive Industry

Manufacturing components like exhaust systems, chassis parts, and brackets with uniformly spaced bends and complex designs.

Aerospace Industry

Precision and reliability for fabricating lightweight and strong parts for aircraft, ensuring compliance with stringent safety standards.

Construction Industry

Bending structural rigor and metal reinforcements for buildings, bridges, and other infrastructural projects.

Another prime user of the CNC bending machines is the aerospace industry. Precision and reliability are the utmost concerns; CNC technology facilitates easy fabrication of parts that need to be light and strong for aircraft. These machines can carry out cutting-edge designs on aluminum and titanium, ensuring compliance with stringent safety and performance standards.

CNC bending technology is largely helpful for the construction industry. It is employed to bend structural rigor and metal reinforcements meant for buildings, bridges, and other infrastructural projects. This application provides for structural strength and, hence, design flexibility, rendering CNC bending machine an expensive asset for utility in modern construction procedures.

Specific Examples in Automotive and Aerospace

| Industry | Applications | Key Requirements |

|---|---|---|

| Automotive | Exhaust systems, chassis, suspension components | Complex geometries, tight tolerances, structural integrity |

| Aerospace | Airframes, engine brackets, landing gears | Lightweight yet strong, exceptional strength-to-weight ratio |

The CNC bending machines found very critical application in automobile manufacture for producing precise parts involved in exhaust, chassis, or suspension. For automotive applications, CNC bending with its complex geometries and tight tolerances is preferable for function and efficiency. This allows components to meld perfectly with the overall design while still retaining their structural integrity required for safe performance.

In aerospace applications, CNC bending is needed to shape lightweight yet strong components for airframes, engine brackets, and landing gears. Materials with an exceptional strength-to-weight ratio are called for in onward applications, and the CNC bending method permits the shaping of material to a close specification without adverse effect on material properties. Such precision is critical in a field where an operational risk becomes great by the slightest of inaccuracies.

Both industries gain from the CNC bending machines being scalable and automatable. High rates of repeatability assure quality in production since they are carried out in mass, whereas customization is available to meet the singular requirements of innovative designs. Until CNC bending technology was embraced for the production of high-end passenger cars and cutting-edge aircraft, the precision and reliability to fabricate high-performance components efficiently did not exist.

Role in Construction and Furniture Manufacturing

CNC bending technology enables construction and furniture manufacturing through efficient and precise production of durable components. In construction, such technology facilitates the fabrication of structural elements, including beams, frames, and supports, with the highest precision. Steel structures require strength with careful consideration of dimensions so that buildings, bridges, and other infrastructure projects are just some applications that may be aided by CNC bending. The ability to maintain consistent quality and perform intricate bending makes CNC bending crucial for current construction activities.

Furniture manufacturing uses CNC bending technology in order to make complicated and custom designs, considering function and aesthetics. Metal and tubular components such as chair frames or table legs may be bent and formed with precision to modern design standards. This allows furniture makers to come up with designs that are more pleasing to the eye and are sturdy enough to last for a lifetime. The process also turns out to reduce wastage of material and increase production efficiency, which is especially important by way of sustainable manufacturing.

Manufacturing Benefits:

- Raises the quality of products

- Reduces errors in the production process

- Provides greater freedom to designers

- Flexible scaling for different production sizes

- Accommodates both small artisans and large industrial manufacturers

On its own, CNC bending technology can only somewhat help construction and furniture manufacture: it raises the quality of products, reduces errors in the production process, and lends greater freedom to designers. Its flexible scaling accommodates industries with different production sizes, ranging from small artisans to large industrial manufacturers. CNC bending is thus still widely used owing to the range of both classical and modern applications that it is asked to serve.

Benefits of CNC Bending Machines

Improved Accuracy and Precision

CNC bending machines offer unprecedented accuracy and precision in metal fabrication processes. The computer-controlled nature of these machines eliminates human error and ensures that every bend is executed exactly according to the programmed specifications. This level of precision is particularly crucial in industries where even the slightest deviation can result in component failure or compromised safety standards.

Faster Production Times

With CNC bending technology, entire production periods are cut short through automation and increased efficiencies. Manual bending, for example, is time-consuming and laborious, whereas CNC machinery performs operations in very little time and with a high degree of accuracy. This great speed becomes important when faced with tight deadlines or the need to rapidly churn out huge-volume productions without compromising product quality.

Production Efficiency Factors:

- Eliminates human error and standardizes procedures

- Produces same results in each single product

- Eliminates manual adjustments or corrections

- Smooth transition between product designs

- Quick programming updates for different production runs

The technology boosts manufacturing capacity by eliminating human error and standardizing procedures. A CNC machine applies experimentally derived instructions, so the same results are produced in each single product. By eliminating manual adjustments or corrections, manufacturers can establish other workflows focused on enhancing production rather than addressing redundant delays.

Moreover, another factor is that the operational processes of CNC bending offer a smooth transition from one product design to the other. Quick updates of the programming allow changes in production runs without incurring prolonged downtimes. This way of working encourages time efficiency while still allowing enough flexibility for different customer requirements, with CNC bending turning out to be a valuable component for industries that need both speed and precision.

Reduced Material Waste and Enhanced Repeatability

A major advantage of CNC bending is that it reduces material wastage. With precise programming and advanced automation, the process above ensures each bend is made properly while preventing errors that cause material scraps. This precision maximizes the use of raw materials and thus, saves the manufacturer money, making CNC bending commercially viable. On the other hand, CNC bending boasts superior repeatability qualities, favoring mass production. Once the program is loaded, the machine will duplicate exact specifications on multiple runs. Such accuracy guarantees that every product will meet standards, especially in quality-dependent industries such as automotive, aerospace, and construction.

Environmental & Operational Benefits:

- Environmental Efficiency: Decreased waste conditions reduce environmental impact

- Cost Reduction: Lower material costs and high production efficiency

- Waste Minimization: Minimal environmental emissions from excess waste

- Sustainable Manufacturing: Focus on precision machining centers

In decreased-waste conditions and improved repeatability lies environmental and operational efficiency: a manufacturing setup gains with low cost of materials and high productions and, meanwhile reducing excess waste with its nominal environmental emission. Thus CNC bending is one of the fabrication processes in focus for present-day sustainable and precision machining centers.

Materials and Versatility

Types of Materials Suitable for CNC Bending

CNC bending is a very versatile process allowing for a wide range of materials to be bent, hence giving the industries some degree of flexibility. The most popular materials used in CNC bending are metals like aluminum, steel, stainless steel, copper, and brass. They are assessed for bendability, strength, and the ability to retain their structural integrity upon bending. Aluminum, for instance, is light and corrosion-resistant, so it finds use in aerospace and automotive applications. Steel and stainless steel, on the other hand, because of their strength, are used in construction and heavy machinery.

| Material Type | Properties | Applications |

|---|---|---|

| Aluminum | Light, corrosion-resistant | Aerospace, automotive |

| Steel & Stainless Steel | High strength, durable | Construction, heavy machinery |

| Copper & Brass | Good conductivity, bendable | Electrical components, decorative |

| Special Plastics & Composites | Flexible, lightweight | Electronics, consumer goods, packaging |

Non-metallic materials are CNC bendable if they possess just the right kind of properties. CNC machines can bend special plastics and composites to accurate shapes, provided they are sufficiently flexible and strong. Such materials are used in applications requiring lightweight components such as electronics, consumer goods, and packaging solutions. In this way, CNC bending highlights its versatility and does not limit itself to working with metals.

The material selection for CNC bending depends on the application, though durability and expected environmental conditions are taken into consideration. The engineers and manufacturers analyze various factors like thickness of the material, tensile strength, and the expected load found to be most suitable. CNC machines accommodate these variations so the production can be carried on efficiently with the least material wastage and with precision and consistency ensured for various materials.

Considerations for Material Thickness and Shapes

When deciding about thickness and shapes, the primary considerations are the functionality and performance of the resultant material. The thickness must be sufficiently large to resist the forces imposed; all environmental conditions such as moisture, cracks, temperature may cause failure in the form of cracking, warping, or deformation. Oftentimes the engineer will carry out simulations for strength and stresses to confirm if the thickness considered satisfies safety and performance requirements set by the application.

Design Considerations:

- Shape Impact: Simple geometries ensure uniform strength distribution

- Complex Requirements: Special requirements dictate complex geometries

- Functional Features: Weight distribution or aerodynamics influence shape choices

- Manufacturing Precision: Advanced machining maintains precision in complex shapes

- Structural Integrity: Avoid manifestation of structural weaknesses

The shape of the material also affects its efficiency and suitability for certain design or structural requirements. Simple geometries usually ensure uniform strength distribution, while complex geometries are dictated by special requirements. If for example, a design uses weight distribution or aerodynamics as another feature, it uses curved or angular shapes related to the opposite. These, however, may need advanced machining to maintain precision and avoid the manifestation of structural weaknesses.

Meanwhile comes manufacturing efficiency. Choice of material and shape have a direct bearing on production methods, such as machining, cutting, or molding. In this scenario, thinner materials are usually easier to mold but require greater care during handling so as not to cause damage. Likewise, more complex shapes may lengthen production or result in wasted materials. Addressing this holistically establishes that functionality takes precedence over production efficiency and material conservation.

Working with Metals: Steel, Aluminum, and Alloys

This equipment CNC bending machine bends and shapes various metals such as steel, aluminum, and alloys in an accurate manner. CNC stands for Computer Numerical Control, meaning the bending is done automatically under the control of a computer. The machine will produce highly accurate bends following programmed instructions, reducing operator error and ensuring consistently good results.

CNC Machine Capabilities:

- Bending sheets, tubes, and pipes to precise angles

- Creating irregular shapes with high accuracy

- Processing various metals from soft aluminum to hard alloys

- Quick delivery of complex requirements through programming

- Versatile applications across automotive, construction, and aerospace

Certain abilities of CNC bending machines are well established in the metal fabrication industry: competing sheets, tubes, and pipes bent to a precise angle, or to an irregular shape. CNC bending machines find applications in industries such as automotive, construction, and aerospace. Different specifications can be programmed into the machine to quickly deliver a complex requirement.

The prime advantage of a CNC bending machine is that it affords great efficiency and accuracy. One with CNC will get time across shorter periods while lessening material wastage. These machines process a variety of metals, from less hard metals like aluminum to the harder ones such as alloys or steels. A high degree of versatility emerges from this adaptability for production requirements. Being precise and reliable makes CNC bending machines an indispensable entity in modern-day metalworking processes.

Choosing the Right CNC Bending Machine

Factors to Consider: Production Volume and Budget

Production volume and budget are two crucial factors affecting considerations. One must evaluate production volume when it comes to selecting a CNC bending machine. High-volume productions usually need exploitations with more automation and have complementary processing speed as this step is crucial for effective fulfilling demand. At low production volumes, simple and affordable, yet very precise and reliable, models will do. Depending on your production needs, your machine should be matched to be of highest performance and served the best way economically.

High Volume Production

- More automation required

- Complementary processing speed

- Crucial for fulfilling demand

- Higher initial investment

Low Volume Production

- Simple and affordable models

- Precise and reliable operation

- Cost-effective solutions

- Lower complexity requirements

The very second factor to consider is that of budget. CNC bending machines have prices differing one from another, depending on the features, size, and level of automation they presuppose. Though the higher-class machines may have more functionalities, they may not be pertinent to every operation. Balance the initial investment with the long-term advantages of reduced labour costs, improved accuracy, and increased output.

The choice of a CNC bending machine will mainly depend on your production volume and available budget. Getting a machine that consistently produces results, minimizes wastage of materials, and fits your scalability needs, all without exceeding your budget, guarantees efficient metalworking processes and a good ROI.

Material Compatibility and Required Precision

The CNC bending machine is a computer-controlled apparatus used for bending sheet metal and other materials into precise shapes and angles; in doing so, this equipment can ensure a more accurate and efficient process through the automation of the bending operation via programmable control. The user has to accept preset parameters into the CNC code, thereby creating identical and repetitive bends, which becomes a great deal of necessity for industries requiring extreme precision.

Material Compatibility Factors:

- Material Types: Steel, aluminum, copper, and various metals

- Thickness Variations: Different capacities based on material thickness

- Material Properties: Consider bendability and structural integrity

- Tool Requirements: Different dies or bending radii needed

- Quality Assurance: Prevent cracking, warping, and minimize wastage

Material Compatibility-A very important consideration when employing CNC Bending Machines. These machines can attract different types of metals: steel, aluminum, copper, etc. Depending on the thickness and properties of the material, the capacity of the machine and the required tool may vary, such as different dies or bending radii. Setting these parameters correctly would ensure that the material being bent would neither crack nor warp and thus retain its quality finishing with an acceptable wastage range.

Precision is yet another vital aspect of CNC bending machines. They are essentially geared toward meeting tight tolerances and complex bends so they can be used in applications where accuracy is considered paramount. Such industries include aerospace, automotive, and heavy construction. CNC-based machines programming and automation further reduce human error in the manual operation of the bending process, which necessarily has to be minimized so as to carry out bending work with absolute precision in even large volumes. Thus, CNC bending machines would be an indispensable tool in today’s manufacturing world that involves a perfect amalgam of compatible materials and precision.

Evaluating Different Types of CNC Bending Machines

CNC bending machines are an advanced tool that carries out automated bending of materials, usually of metal, into varied shapes and angles. CNC, Computer Numerical Control, means that the machine utilizes pre-programmed software to carry out bending operations very precisely and with consistency. These machines have become a much-needed part of the manufacturing process since the formation of materials into intricate designs requires utmost accuracy, involves wastage, and also prone to errors.

| Machine Type | Best For | Applications |

|---|---|---|

| Press Brake Machines | Sheet metal bending with great precision | Intricate shapes, complex designs |

| Tube Benders | Cylindrical materials | Pipes, tubes, automotive exhaust |

| Roll Benders | Creating curves or circular shapes | Large-scale flexible applications |

Various CNC bending machines are available to satisfy different manufacturing needs, including press brake machines, roll benders, and tube benders. Each kind corresponds to materials or geometries. For instance, press brake machines are generally used for bending sheet metal with great precision for intricate shapes, whereas tube benders are designed to work with cylindrical materials such as pipes and tubes. Roll Benders are, however, best for creating curves or circular shapes, allowing flexibility on a somewhat larger scale.

Precision alone cannot be counted as sole benefits of CNC bending machines; they facilitate efficient and scalable processes. Repetitive tasks are automated, which consequently lowers the level of manual labor required while at the same time speeding up production; furthermore, CNC being computer-programmed guarantees manufacturers’ consistency of results even if large-scale runs induce output, thereby widening its application scope from automotive industry to aerospace. These aspects significantly contribute to the importance of CNC bending machines in today’s manufacturing world.

Frequently Asked Questions (FAQ)

What is a CNC bending machine?

CNC bending machines are the operations that lead to bending metal sheets and tubes to precise angles and shapes. They involve the procedures to enhance the precision, effectiveness, rigidity, and capability of bending operations by greatly reducing manual handling through one or more computer programs.

How do CNC tube bending machines operate?

CNC tube bending machines are hydraulic types that may have power more or less dependent upon the size and strength of the particular job being undertaken. The machine positions the tube, presses with force, with the help of bending tools, for achieving precise and repeatable bend angles.

What are the advantages of CNC bending?

CNC bending solutions are appreciated for numerous benefits, including increased precision, shorter time in production, less labor cost, complex-shaped formations, and larger radius bending. These machines can bend just about anything, particularly metal tubes, and are hence employed heavily in shipbuilding and manufacturing industries.

What Are Different Types of Bending Machines?

There are different types of bending machines like hydraulic bending machines, pipe bending machines, and mandrel tube bending machines. These different kinds of machines serve different working purposes, such as bending metal tubes or sheets having different cross-sectional shapes.

What Is Mandrel Bending?

Mandrel bending is a tube bending technique where a mandrel is inserted into the tube to support it during the bending process. It prevents wrinkling of the tube inside the bend and keeps the integrity of the tube inside the bend, which, in turn, allows for tighter bend radius and higher-quality finished products.

How does CNC tube bending improve the production efficiency?

CNC tube bending improves production efficiency by automating the bending process, which otherwise might require manual labor and different set-up processes, etc. With automation of the bending process, faster changeover times are possible, consistent quality can be maintained, and more parts produced in less time, which finally results in lowering the cost and increasing throughput.

Can CNC bending machines work with complex shapes?

Yes, CNC bending machines are able to work with complex shapes and configurations very precisely. The computers can easily modify the bend angles and subject the tubes to complex bending operations for applications in which advanced bending solutions are required.

What can be processed by a CNC bending machine?

CNC bending machines accommodate different materials ranging from metal sheets to hydraulic tubes to metal tubes. This versatility allows for different types and thicknesses of materials, i.e., for a variety of industrial applications.

What are hydraulic systems in CNC bending machines used for?

Hydraulic systems are crucial to CNC bending machines, imparting the force required for bending the materials with flexibility. High hydraulic pressure ensures smooth operation, achieving bends with large radii and precise angles while maintaining the integrity of the materials.

References

- Everything You Ever Wanted to Know About the CNC Bending Process – A detailed overview of CNC bending and its automation process.

- What is CNC Bending? – Sheet Metal Fabrication – Explains the manufacturing process and the role of CNC press brakes.

- CNC Bending Machine – Provides insights into the machine’s functionality and its uses.

- How does CNC Metal Bending Work? – Explains the fabrication process and precision of CNC metal bending.