Coating adhesion testing is perhaps the most important test in the durability and reliability evaluation of coating materials. Coatings are usually placed under very harsh conditions-failures and degradation are brought about by exposure to environmental factors and mechanical stresses, with adhesion being one of the most important factors in the efficacy of coatings over time. This guide goes into ASTM standardized coating adhesion methods that form the basis for quality and consistency assurance. For coating confidence during actual application, whether it is construction, manufacturing, or materials research, knowledge of these test methods is a must. Continue reading to find out about ASTM coating adhesion test procedures, purposes, and importance, as well as the advantages these tests can provide for your projects.

Understanding Coating Adhesion

Importance of Coating Strength

Because coating strength remains essential to ensure the long-lasting performance of the surface in numerous applications, it protects materials from environmental factors such as moisture, chemicals, and UV radiation. With no proper coating strength, coatings are prone to peel, crack, or wear, thereby affecting the looks and structural integrity of the material underneath.

The consideration of coating strength finds paramount relevance in the fields of building, manufacturing, and car production, where sustained performance and longevity of operations are required. Good adhesion secures that the coatings resist corrosion, protect wear, and provide visual appeal as intended. Poor adhesion would serve to fail prematurely, thus raising the maintenance costs and reducing the life span of the product, thereby having far-reaching consequences concerning safety or monetary aspects.

Before the application of coatings onto their support material, the adhesion of the coating must be checked against the potential failures; thus, an adhesion testing procedure must be in place for selection of the best material and fine tuning of processes. Once coating strength issues are both detected and remedied, the professionals can go ahead with improving product performance, hence better resistance to environmental conditions and top efficiency of the project, leading to saving time and resources in the long haul.

Factors Affecting Adhesion

Many factors influence how coating material bonds with the substrate and this plays a crucial role in the performance and durability of the final product. Surface preparation rarifies as one of the main factors. It deals with cleaning of substrate or treating it so contaminants like oils, dust, or moisture do not interfere with the bond of the coating to the surface. Such treatments include abrasion or usage of chemicals to create a texture that enhances adhesion.

Key Factors Influencing Coating Adhesion:

- Surface preparation and cleanliness

- Material compatibility between coating and substrate

- Environmental conditions during application

- Chemical composition and thermal properties

Compatibility with the coating material and the substrate is another variable affecting the strength of adhesion. There should exist a match in the chemical composition, thermal properties, and surface energy for them to bond and yield a strong and lasting adhesion. For example, nonhomogeneous material properties or inappropriate methods of application may cause weak adhesion and premature failure of the coating.

Lastly, the adhesion is affected by the environmental conditions during and after the application process. The temperature, humidity, and presence of contaminants during the curing period will influence the ability of the coating to adhere properly. Thus, the environment must be controlled, and the conditions for curing maintained at an optimum level so that adhesion can be achieved and the coated product can perform at its best.

Applications of Adhesion Testing

This industry-wise application is to check and maintain the quality, durability, and performance of coated products. Thus, automotive, aerospace, architecture, and manufacturing lines use adhesion testing to determine the strength of coatings with substrates. Through adhesion tests, manufacturers may detect defects, enhance the performance of products, and avoid field failure of coatings.

However, adhesion testing is considered the main application inside production quality control. Adhesion testing for coats can be done by instrumental standards versus manufacturer specifications, thus revealing irregularities or weak deficiencies in the coating process that can be rectified prior to product release into the market. Regular testing reduces the cost of rework and keeps the customer from dissatisfaction due to early failures.

It’s an equally valuable method for testing adhesion in the R&D context as it allows engineers and scientists to develop new coatings and optimize the existing ones. With it, they can test how different formulations, surface treatments, or environmental conditions affect adhesion. Maintenance and inspection also benefit from adhesion testing in identifying degradation or failure of a coating over time, ensuring the health and functionality of critical components and structures throughout their lifecycle.

ASTM Test Methods for Coating Adhesion

Overview of ASTM D4541

The adhesion of coatings is tested by ASTM D4541, hence tensile adhesion strength of coatings to substrates. This method defines the force necessary to pull off a coating material from its substrate with a pull-off adhesion tester. In many sectors, including construction, automotive, and marine, protective coatings are considered important in terms of strength and performance.

For the application of the test, a loading fixture or dolly is glued to the coated surface by means of a strong adhesive. After curing the adhesive, the pull-off adhesion tester pulls the dolly perpendicular to the coated surface until the coating detaches from the substrate. This force is recorded and yields information concerning the adhesive and cohesive properties of the coatings.

The ASTM D4541 encompasses various testing procedures that are selected based on the substrate, coating, and type of equipment employed. This flexibility renders it a complete methodology for coating evaluation across many applications. By following this standardized method, industries can perform consistent quality control with better reliability of coatings.

Pull-Off Adhesion Testing Explained

Pull-off adhesion testing measures the adhesion strength of a coating to its substrate by applying a measurable force. The test procedure involves a dolly (either metal or plastic) being glued onto the surface of the coating. The testing equipment then applies force perpendicular to the substrate until it detaches from the coating, establishing the maximum tension the coating could withstand. In this way, it offers a direct test toward either adhesive or cohesive failure.

Pull-Off Testing Process Steps

- Surface Preparation: Clean and prepare the test surface

- Dolly Attachment: Secure dolly to coating with strong adhesive

- Curing Period: Allow adhesive to cure completely

- Force Application: Apply perpendicular pulling force

- Result Recording: Measure and document failure force

While factors such as substrate type, surface preparation, adhesive for dolly fixing, and testing atmosphere can influence the test result, surface preparation is most critical to getting an accurate measure. Improper preparatory measures, such as uneven or dirty surfaces, might give a reading that is misleading. Furthermore, the equipment and procedure used in testing must be so compatible with standard methods like ASTM D4541 that any recorded results will be comparable and consistent.

Areas of pull-off adhesion testing are greatly variable across industries, ranging over construction, automotive, marine applications, etc., meant to ensure durability and reliability of protective coatings. It helps to identify possible weak points in the coatings and therefore avoids premature failure that would almost always cost repair or maintenance. The method, by providing objective and consistent data, would assert periodic quality control measures and ensure prolonged life of coatings in the different working environments.

Comparing Different ASTM Standards

ASTM standards provide guidance on the process to be carried out for inspecting the coatings for their performance, durability, and quality in different conditions. Relevant standards among the ASTM for coatings delineate tests for their different aspects of their performance: ASTM D4145, ASTM D4585, and ASTM D3359. These standards, rightfully so, help coatings to pass the test for generalized uses through set and dependable testing procedures.

| ASTM Standard | Test Focus | Application |

|---|---|---|

| ASTM D4145 | Flexibility and adhesion under bending conditions | Metal substrates subjected to deformation |

| ASTM D4585 | Resistance to moisture and high humidity | Marine and tropical environments |

| ASTM D3359 | Adhesive strength and resistance to peeling | General coating adhesion assessment |

ASTM D4145 illustrates the flexibility and adhesion of coatings applied to metal substrates, especially under conditions of bending. It considered testing the coating in cases where the substrate can be deformed to ensure that the coating does not crack or peel within handling or installation. Very important for an environment where materials will be continuously stressed or physically used.

ASTM D4585 instead tests the coating resistance against moisture and water by simulating periods of high humidity. It finds widespread applications where high exposure to humidity exists, such as marine and tropical environments. Conversely, ASTM D3359 tests adhesive strength of coatings to a substrate by assessing how well they resist peeling and detachment. The test ensures that a coating must be capable of enduring operational stresses in practice.

Application of these standards allows industries to stimulate selection of coatings best suited for each problem/environment, thus improving the product lifespan and reducing maintenance costs.

Common Coating Testing Methods

Hardness Testing Techniques

It is essential to measure the hardness of a coating to ascertain its resistance to deformation, scratching, or indentation. This property is critical when assessing how a coating particular to a situation will perform under physical stresses or abrasive conditions. Several techniques are used to investigate the hardness of coatings, the suitability of each depending on the type of materials and their applications.

Pencil Hardness Test

Involves scratching the coating surface with pencils of different hardness grades to assess surface resistance to slight abrasion.

Indentation Hardness

Including Mohs hardness test, characterizes material surface by its ability to resist scratching by substances of specific hardness.

Pendulum Hardness

Evaluates viscoelastic behavior and coating response to repeated stresses where flexibility and durability are important.

One well-known technique is that of pencil hardness and entails scratching the surface of the coating with pencils of different hardness grades. These scratches represent a very brief assessment of surface hardness, with users having to determine from scratches what the coating can resist in terms of slight abrasion. Another very common way is the indentation hardness tests, such as the Mohs hardness, in which a material surface is characterized by its ability to resist scratching by substances of a certain hardness.

Depending on the dynamic test used, the Pendulum Hardness test evaluates the viscoelastic behavior of coatings. In essence, the tests examine a coating’s response to repeated stresses or impacts imposed on it under conditions where flexibility and durability are equally important. These hardness tests together serve industries to ensure that coatings meet performance specifications and remain reliable under practical operational demands.

Knife Test and Scrape Test

The Knife Test and Scrape Test are utilized to demonstrate how well adhesion is employed between the coating and the substrate. These tests further investigate the thin coating layer’s resistance to separation when subjected to abrasive or sharp force. In return, this yields evaluation of the coating in real-life where mechanical stress is unavoidable.

Mechanical Adhesion Testing Methods:

Knife Test

Uses sharp blade to cut crosshatch pattern, evaluating adhesion based on coating retention or peeling.

Scrape Test

Employs weighted stylus applying constant force to assess coating resistance to abrasion.

The Knife Test characteristically utilizes a very sharp blade to cut the surface in the direction of the grain, sometimes resulting in a crosshatch pattern. This separates portions of the coating, and the evaluators assess adhesion based on whether the coating stays put or peels off. A very straightforward and reliable test capable of indicating possible adhesion problems.

In contrast, the Scrape Test involves a weighted stylus or tool exerting a constant force across the coating. This force is resisted by the coating against abrasion, as observed by the damage caused by the scraping force. These two methods ensure that the coating will satisfactorily attain the quality and durability standards established for applications in hostile environments.

Corrosion Testing: Salt Spray Method

One of the methods used commonly in determining corrosion resistance of materials and surface coatings is the salt spray method; sometimes it is also called the salt fog test. The method subjects test samples to an environment of salt mist in a controlled setup, so as to mimic the detrimental effect of weeks of exposure to marine or industrial conditions. This test therefore can reliably give an estimate of how a particular material does in passing rust or degrading with time.

Salt Spray Testing Process

The apparatus is intended to create a corrosive atmosphere of fine salt mist atomized from a saltwater solution, this solution being mostly sodium chloride. The specimens in question are withheld within the chamber at certain predetermined angles so as to be uniformly subjected to the mist. The test duration is widely variable, depending on the material or coating being tested: sometimes it ranges from a few hours to many weeks.

The Salt Spray Method results help comparative study between different materials or coatings so as to allow manufacturers to evaluate and ensure a product’s longevity and performance under corrosive conditions. This test acts as a reference in the evaluation of quality and in increasing the durability of a metal alloy, protective coatings, or other materials exposed in severe conditions.

Interpreting Test Results

Understanding Pull-Off Test Results

The Pull-Off Test is used to determine the attachment strength of different coatings onto a substrate. A controlled force is applied to pull a standard loading fixture or dolly that has been bonded to the coating until the coating detaches. The force at which the bond breaks is measured and serves as an indicator of adhesive strength. Results are usually expressed as pressure-type units, such as pounds per square inch (psi) or megapascals (MPa).

| Failure Mode | Description | Indication |

|---|---|---|

| Adhesive Failure | Breakage between coating and substrate | Poor coating-substrate bond |

| Cohesive Failure | Coating material itself breaks | Coating internal weakness |

| Substrate Failure | Underlying material gives way | Substrate material weakness |

Interpreting Pull-Off Test results depends on understanding the failure mode and measured adhesive strength. There are three major failure modes, namely, adhesive failure, cohesive failure, and substrate failure. The breakage between the coating and substrate describes adhesive failure, while the coating material itself breaking points to cohesive failure. Substrate failure, on the other hand, indicates the underlying material has given way. All three failure types tell evaluators what weaknesses exist within the coating system or substrate.

Pull Off Test results are usually meant to assess the fitness of a coating for a particular application. When adhesive strength proves to be higher than required by a system environment, such coatings can be considered good. Conversely, low values may call for alternative coatings or improved surface preparation or processes. Documentation and analysis of the results must be clearly recorded so that the coatings are guaranteed to work and stay as durable as they were tested for.

Making Data-Driven Decisions

Coating-strength tests are essential to ensure longevity and durability of the coatings in any particular environment. These tests give numerical data to see if the coating can be put into an application for given performance standards. Things have to be looked into and recorded: adhesive strength, resistance to weather, and resistance to wear.

Data-Driven Decision Framework:

- Data Collection: Follow standardized test methods for consistent results

- Analysis: Compare results against environmental requirements

- Decision Making: Select coatings based on precise data

- Continuous Review: Regular assessment and adjustments

Good decisions must follow good data-collection methods and data analysis. By following standard test methods, you ensure that results are good and comparable across different tests. Test results, reviewed periodically against environmental requirements, will show where coatings really do meet or exceed expectations, and where adjustments are needed in surface preparation or processing methods.

At the end of the day, whenever decisions are to be made, it should be based on precise data, tested if necessary, for the selection of coatings that satisfy specific operational requisites. A shield of assurance is granted against risks, which might arise in unnecessary spending, consequently threatening long-term performance and durability in real-time applications.

Utilizing Results for Quality Improvement

Coating strength tests are conducted to assess the durability and performance of the coatings under some set of environmental conditions. The coating strength test checks for adhesion, abrasive and impact resistance properties to satisfy operational requirements. With correct testing of strength of coatings, a manufacturer can expect to identify weak links in their systems so that improvements could be made to blend formulating considerations with quality aspects.

Interpretation of test data coming from a coating strength test can necessitate specific adjustments to the formulation or those related to application methods. For example, should tests indicate that the strength of adhesion to the substrate is unacceptable, the coating composition can be adjusted or surface preparation methods can be changed. It is through this loop that proper reliability is built into the product so that the end product will withstand wear and tear through use in the real environment kept for a certain period.

Implementing insights from such tests fosters long-term benefits, such as lowering maintenance costs, longer service life of coated materials, and such. Before using convincing data and consistent testing, there has been a trust-building process between manufacturers and clients to ensure that products always fulfill or even surpass clientele expectations.

Choosing the Right Test Equipment

Essential Equipment for Adhesion Testing

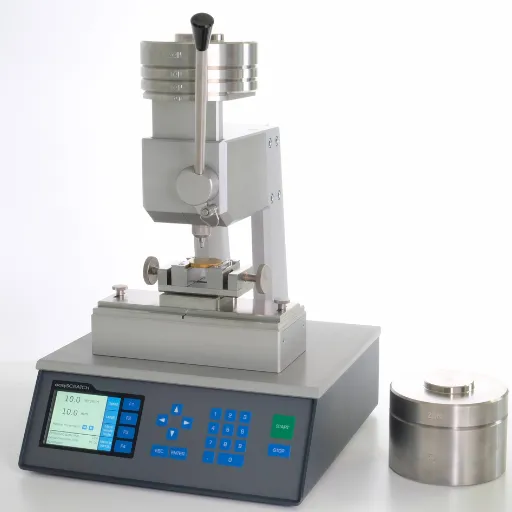

Adhesion testing requires specialized instruments in order to guarantee accurate and precise test results. One of these instruments is the pull-off adhesion tester, which measures the force needed to pull away a given area of coating from the substrate. It is one of the most useful instruments in evaluating coating adhesion under actual conditions and in carrying out quality control and maintenance assessments.

Pull-Off Adhesion Tester

Measures force needed to pull coating from substrate. Essential for quality control and maintenance assessments under actual conditions.

Cross-Cut Adhesion Tester

Features grid scoring blade for creating crosshatch pattern. Uses adhesive tape to determine coating adhesion strength.

Scrape Adhesion Tester

Measures resistance to separation using controlled stylus force. Useful for testing different coating thicknesses.

Another piece of equipment that is very important is the cross-cut adhesion tester. It has this grid scoring blade or cutting device for the coating. Then, adhesive tape is applied to determine the coating’s adhesion to the surface. Cross-cut testing gives a simple way of determining adhesion strength; hence, it is useful for laboratory as well as field-testing.

Last but not least, it is a practical adhesion-testing instrument. It measures resistance to separation by scraping through a stylus or a controlled tool applying forces on the coating. This equipment becomes more useful when coatings are tested over different thicknesses or environmental conditions. Thus, such tools promise an exact and thorough evaluation of adhesion across various industries and applications.

Recommendations for Testing Services

Reliable methods requiring guaranteed enforcement of result are to be given preference while choosing coating adhesion testing services. Selection must go for a provider with a procedure guaranteeing consistency in results and credibility, such as a standard ASTM or ISO method. These testing methods post-industry standards on their tests and ensure that any worker can put them under test in any circumstances.

Selection Criteria for Testing Services:

- Standardized Methods: ASTM or ISO compliance for consistent results

- Multiple Techniques: Cross-cut, pull-off, and scrape adhesion methods

- Environmental Simulation: Capability to test under various conditions

- Industry Recognition: Certified and accredited laboratories

- Expert Personnel: Knowledgeable staff with coating adhesion expertise

Testing services with evaluation techniques are to be selected because different materials and conditions require evaluation using different techniques. The cross-cut method, pull-off method, and scrape adhesion method can all be used in the testing of various coatings subjected to different environmental influences. Ensure that the tester is capable of simulating the environmental or operating conditions of your coatings, such as high temperature, moisture attack, or abrasion.

Lastly, the evaluation of expertise experience counts the most. Laboratory selection should be done on a basis of recognition in the industry and personnel who have an ample understanding of coating adhesion principles. The provider should be certified or accredited by an independent body to meet a quality standard so that you may be archchieved in the confidence of the testing results.

Maintaining Test Equipment for Accuracy

Proper maintenance of test equipment is essential to ensure accurate and reliable results. Regular calibration is a key part of this process, aligning the equipment’s measurements with standardized values. Calibration should be performed at intervals recommended by the equipment manufacturer or relevant industry standards. Without regular calibration, results may deviate over time, leading to inaccuracies and unreliable data.

Equipment Maintenance Best Practices

- Regular Calibration: Follow manufacturer intervals and industry standards

- Routine Inspections: Check for physical wear and environmental damage

- Environmental Control: Manage humidity, dust, and temperature

- Personnel Training: Ensure proper handling and operation

Routine inspections should also be conducted to identify physical wear, damage, or any environmental factors that might compromise the equipment’s performance. Environmental conditions such as humidity, dust, and temperature fluctuations can negatively affect sensitive instruments. Keeping the equipment clean and stored in appropriate conditions can help mitigate these risks and extend its lifespan.

In addition to this, training of personnel can hugely decrease erring. Misuse or mishandling can injure the instrument or give inconsistent results. Hence, combining regular calibration and thorough inspections with proper training can make testing equipment remain in full operational mode while also imparting a great degree of precision and confidence to testing.

Frequently Asked Questions (FAQ)

Q: What is meant by a coating strength test?

A: A coating strength test involves checking the adhesion characteristics of a coating applied to a substrate. The test measures the bond strength, cohesive strength, and overall integrity of the coating to ensure that it conforms to certain prescribed standards of functioning under all types of conditions.

Q: What methods of testing are used for coating strength?

A: Prevalent test methods of coating strength include tensile adhesion testing, pull-off strength tests, and salt spray testing. They measure the force required to remove or detach the coating from the substrate surface and evaluate numerical data regarding coating performance.

Q: How does a pull-off adhesion tester operate?

A: It sturdily pertains adhesion strength of coatings to a test area from which a coating is removed upon forced application. So, the tester gains immediate results with respect to the quantity of bond strength and loss of adhesion. Therefore, it is most widely employed in field testing.

Q: What factors affect coating strength?

A: The strength of coating depends upon many factors; substrate type, amount of coating applied, test method, environmental effects during application in terms of exposure to chemicals, with stray value given to humidity levels in the curing process. Typical environmental exposure is considered adverse.

Q: How does the test guarantee accurate results?

A: Accuracy of the test is guaranteed by the observance of international standards prevailing like ASTM, which involves a definite procedure involving used instruments suitable for this purpose and repeatability of test results.

Q: Why is chemical resistance essential in coating strength tests?

A: Chemical resistance is significant for coating strength tests since coatings are most of the time and throughout their life exposed to several chemicals. The coating’s ability to resist change in adhesion properties and maintain integrity upon chemical exposure is needed for its long-lasting performance.

Q: Can coating-strength tests be applied to organic coatings?

A: Yes. Coating-strength tests can be used on organic coatings such as automobile paint and varnish. Conducting tests on these coatings will help them evaluate their performance under various conditions and ascertain they meet industry standards for durability and adhesion.

Q: What effect does hydraulic pressure have on coating strength tests?

A: Hydraulic pressure also comes into play in some methods, for example, in tensile adhesion testing, where pressure is exerted on the coating under control as a means of assessing the strength of its bond. This reveals the efficiency of adhesion of the coating when exposed to various pressure conditions.

Q: Why is a coating integrity test conducted before coating application?

A: To confirm proper substrate preparation and to catch any potential problems, coating integrity tests should be performed beforehand. By doing this, such problems along with failures that might reduce the performance and life of the second coating could be prevented.

Q: How are tensile strength and pull-off strength distinct with regards to coatings?

A: Tensile strength describes the greatest stress a material can take while being pulled apart. In contrast, pull-off strength pertains more towards how well a coating sticks onto a substrate. Both, however, are key in gauging the overall durability and bonding capabilities of coatings in various applications.

References

- Test Methods for Coating Adhesion – A comprehensive guide to various methods for determining coating adhesion.

- Assessing Coating Adhesion – Information on ASTM standards for evaluating coating strength, such as shear, peel, and tensile strength.

- Finish Coatings System Adhesion and Test Methods – Insights into different procedures for assessing coating resistance and adhesion.

- Measuring Adhesion by Tape Test per ASTM D3359 – A guide to ASTM D3359 methods (X-cut and Cross-cut) for measuring coating adhesion in various environments.