For any industrial application, safety engineering, and material science, the knowledge of the coefficient of friction between two materials is paramount. The rubber-steel interaction is of utmost importance and has countless applications in various industries, ranging from automotive tire performances to conveyor belt systems. This blog, in turn, delves deeply into the rubber-on-steel coefficient of friction, analyzing the values, the factors that influence those values, and the real-world implications. By the end, readers will receive usable insight into how this one small metric controls an extensive array of complex systems, provides operational efficiencies, and, in some instances, contributes toward safety measures. Engineers, researchers, or anyone curious about the properties of matter will find this article a basic building block for understanding this critical concept.

Introduction to Coefficient of Friction

The coefficient of friction is a pure number that measures the resistance to motion between two contacting surfaces. It depends on the type involved and the nature of their interface: factors such as surface roughness, temperature, and presence of lubricants all act as parameters. The coefficient is simply the ratio of the frictional force to the normal force, as seen in both static friction and kinetic friction. This value plays a significant role in understanding the just behavior of materials in an engineering setup, industrial safety, and everyday situations, to some extent.

Definition of Coefficient of Friction

Coefficient of friction is a dimensionless scalar quantity that quantifies the degree or amount of resistance offered during the opposite relative motion of two contacting surfaces. Mathematically, it can be expressed by the following equation:

Where Fₓ is the friction force applied and Fₙ is the normal force applied pressing the two surfaces together. This parameter is influenced by the microscopic properties of the surfaces, which include the material composition and environmental conditions such as humidity and temperature.

Some recent coefficients of friction, as published by Google, show practical values for common materials under ordinary conditions: For rubber on dry concrete, the coefficient of static friction stands at a value of almost 1.0, while that of kinetic friction for steel on ice might be as low as 0.03. Such variations emphasize the critical importance of measurement and study for individual materials during system design, especially when friction needs to be accounted for, as seen in brake-and conveyor systems.

Importance of Friction in Material Science

Friction in engineering is all about interacting surfaces; the performance, efficiency, and wear of any object are influenced by friction. Therefore, friction plays a significant role in various industries, ranging from automobiles to aerospace, in the consideration of component design, such as gears, brakes, and clutches, to provide stability and utility. First and foremost, friction needs to be adequately analyzed so that energy can be conserved and material life can be improved. This is because excessive or inadequate friction can cause mechanical failure or inefficiencies. Advanced formulations of friction-handling materials, such as coatings and lubricants, serve as a source of inspiration for engineering materials that can function more effectively over a wide range of operational conditions. The dual nature of friction—both its beneficial and detrimental effects—compels us to understand its concept when designing materials and systems.

Overview of Rubber and Steel as Common Materials

Rubber and steel are commonly used materials whose properties differ significantly enough to be essential in various industries. Rubber is flexible and stretches, providing cushioning and vibration damping, as well as sealing and insulation, due to its resilience to water and chemicals. The examples that come to mind are those of tires, gaskets, and industrial seals. Steel is robust, tough, and able to serve many purposes. Being able to withstand high stress and resist deformation is an absolute necessity for several applications, such as construction, transportation, and manufacturing. The combination of both materials is designed to achieve improved performance, as exemplified by reinforced tires or flexible components for infrastructure that require the rubber’s flexibility combined with steel’s strength.

Scientific Principles Behind Friction

Given the relation of friction, a resistive force occurs between interacting surfaces as they attempt to move or slide past one another. That is to say, this phenomenon occurs due to the microscopic roughness of the materials and intermolecular forces present at the points of contact. In magnitude, friction depends on the magnitude of the normal force exerted between the surfaces and on the coefficients of static or kinetic friction, which are constants related to the materials. While static friction prevents motion until a force exceeds a threshold, kinetic friction governs the motion at a generally lower level. The operation of numerous contrivances relies on this fundamental principle: from stopping vehicles to ensuring industrial applications, adequate friction is essential.

Surface Texture and Its Impact on Friction Coefficient

The topography of such materials affects the friction coefficients by manipulating contact points at the microscopic level. The rougher the surface, the more static and kinetic friction will be generated due to the irregularities interlocking and resisting motion. Smooth surfaces, on the other hand, would have a diminished friction coefficient due to reduced asperity interactions. However, extremely low friction values may raise concerns about stability in a system that requires controlled resistance. Some engineering applications, like precision manufacturing, will actually target to attain a certain roughness of the surface to generate friction behaviour optimized for the desired operating conditions. Surface treatments can, of course, mitigate such effects on direct surface-to-surface contact: the application of a coating or lubricant is one of the most effective ways to reduce friction and wear.

Material Properties of Rubber and Steel

Rubber and steel exhibit different material attributes that make them suitable for radically different industrial applications. Rubber is basically an elastic material; it can be stretched to a large degree, and upon removal of the deforming force, it would return to its original form. It exhibits a high degree of abrasion, impact, and low-temperature resistance, but its mechanical strength is inferior compared to that of metals like steel. Steel, contrarily, is endowed with high tensile strength. It is capable of resisting loads, fatigue, and deformation. It displays the best resistance to thermal and electrical conduction. Resisting very high mechanical stresses, steel by nature cannot be bent, stretched, wrung, or twisted like rubber. Hence, it benefits engineering purposes that are sometimes mutually exclusive.

Role of Contact Force in Friction Calculation

Friction depends strongly on contact force, as it is proportional to the normal force between two surfaces. The magnitude of the frictional force depends on the component of the contact force normal to the surface and is defined by the coefficient of friction, which essentially serves as a constant for the resistance encountered during sliding on a given material. Mathematically, it is expressed as: frictional force F_friction=normal force F_normal×coefficient of friction μ. More simply put: the greater the contact force acting on two surfaces, the greater the frictional force acting between them, for the same frictional surface. This relationship must be thoroughly understood for proper engineering modeling and evaluation, especially when considering mechanical systems, where friction significantly affects efficiency and wear.

Factors Influencing the Friction Coefficient

The coefficient of friction is affected mainly by the following:

1Surface Material Properties

The character of the surfaces in contact, such as their hardness, roughness, and elasticity, directly affects the coefficient of friction, μ. For example, smooth surfaces have lower friction coefficients, whereas rough surfaces raise it.

2Surface Contaminants

The presence of lubricants, moisture, or other contaminants in the contact zone drastically affects μ by either decreasing or increasing the interaction between the two surfaces.

3Normal Force

Although the coefficient of friction does not depend on the size of the contact area, an extreme change in the normal force may sometimes produce deformation, which could affect μ.

4Temperature

High temperatures may change the material properties (e.g., soften balata), thus changing the frictional behavior.

5Relative Motion

Static friction (before motion) is higher than kinetic friction (motion) because more force is required to overcome the initial resistance.

These sources should be considered and controlled if necessary to reduce energy loss, wear, and optimize performance, depending on the specific application.

Temperature Effects on Rubber and Steel Interaction

The rubber-steel interaction is highly temperature-sensitive, as modifications occur in the mechanical and physical properties of both materials. At elevated temperatures, rubber softens, and its elastic modulus decreases, while its resistance to deformation also decreases. This results in an increase in contact area and, consequently, increased friction. In contrast, at low temperatures, rubber tends to harden, thereby decreasing its flexibility, contact area, and friction coefficient.

Steel, in turn, exhibits more subtle changes under typical working temperature ranges. Set within certain moderate temperature limits, the structural integrity remains stable; however, any increase in heat would enlarge the steel surface area through thermal expansion and may also adversely affect the surface hardness. These changes could adversely influence the microscopic interlocking mechanisms between steel and rubber surfaces.

Together, these temperature-dependent behaviors govern all systems where rubber comes in contact with steel. For instances such as tire-road interactions or industrial machinery, specific control and understanding of these properties must be enforced to achieve the best frictional performance and resistance to wear under varying environmental conditions.

Impact of Lubrication on Friction Values

To significantly change friction values, lubrication prevents surface contact by means of an ultrathin film, through which wear and energy loss occur. Among the key factors contributing to effectiveness are lubricant type and viscosity, as well as temperature and load, which are the operational conditions. Higher viscosity lubricants provide better surface separation under conditions of extreme pressure. However, the resistance to surface movement might increase under low-speed conditions for lubricants with high viscosity. Additives are sometimes incorporated into lubricants to prevent oxidation or breakdown of thermal properties, thereby enhancing the interface’s tribological properties. One of the key effects of the lubricant’s intervention is to reduce the friction and increase the wear life of the contacting mechanical elements.

Environmental Conditions and Their Influence

Environmental conditions become essential factors in determining performance and reducing lubricant life. Changes in temperature and humidity, or contamination of the air with dust and water, affect the lubricant’s behavior. Extreme temperatures, for instance, may cause thermal degradation and changes in viscosity. Changes in viscosity will alter the film strength and impact the protection it provides. High humidity or water contamination can cause emulsification, which reduces lubricant efficiency and increases the chances of corrosion. The maintenance of best-performing lubricants with minimal mechanical wear across various operational conditions can be achieved by selecting lubricants that incorporate environmental conditions, such as temperature- or moisture-resistant additives.

Real-World Applications Across Industries

The friction coefficient has numerous industrial applications where it is used to ensure the safety, efficiency, and performance of materials. Tire-road interactions, a critical field of application in automotive engineering, are designed around the concepts of grip, braking power, and fuel efficiency. Manufacturing processes are applied when materials are shaped or formed into products. Friction is controlled, for instance, during metal forming and machining, to facilitate the flow of materials and minimize tool wear. In civil engineering, friction coefficient data are used for structural design, especially concerning load-bearing components and anti-slip surfaces. The aerospace and railway sectors require their braking systems to be perfectly balanced and fine-tuned in terms of friction for optimal performance and operational safety. On a more general note, by adjusting the material and/or surface treatment to meet a specific friction target, industries can ensure they perform appropriately within set specifications.

Automotive Manufacturing

Critical for tire performance, brake systems, and vehicle safety components

Conveyor Systems

Essential for material handling and industrial transportation processes

Industrial Machinery

Safety considerations and performance optimization in manufacturing

Automotive Manufacturing and Tire Performance

The automotive industry relies on friction and material engineering in their most advanced form to optimize tire performance and contribute to vehicle safety. From rolling resistance, grip, to tread wear, all aspects of tire performance are directly dependent on the frictional interaction between the tire and the road surface. Low rolling resistance is a key factor in ensuring a tire’s good fuel efficiency. In contrast, high levels of grip are necessary for maintaining traction when accelerating, cornering, and braking under all weather conditions. Manufacturers achieve this balance by designing innovative tread patterns and selecting rubber compounds tailored to specific temperature and road conditions. Additionally, tires undergo rigorous tests simulating wet, dry, and icy conditions to verify that they meet the standards in real-life scenarios of safety and performance. A step further are the continuous developments in material science and computational modeling, which are instrumental in maintaining the push for efficiency, safety, and sustainability within this ever-growing field.

Conveyor Systems and Material Handling

Conveyor systems are the heart of modern material handling processes, moving products from manufacturing to production, distribution, storage, and beyond. These systems come in various types, including belt conveyors, roller conveyors, and chain conveyors, each suited for a specific application. Considerations in design include load capacity, speed, and durability, all of which depend on the acceptance criteria during operations. In recent times, their enhancement has come from automation and IoT integration, enabling operations to be co-synchronized and facilitating real-time performance monitoring and predictive maintenance. These technologies increased productivity while decreasing labor-related expenditures and downtime in operations.

Industrial Machinery and Safety Considerations

In industrial settings, where safety is paramount, machinery operates in such environments. Key practices include ensuring that proper machine guarding systems are in place to prevent workers from inadvertently coming into contact with moving parts, regularly scheduling maintenance to address potential performance issues, and adhering to applicable standards, such as OSHA regulations. Furthermore, training employees on correct operational procedures and emergency responses is critical in alleviating risk. Thanks to technological advancements, professional safety is equipped with automated shut-off systems, sensors for detecting hazards, and even remote monitoring, thereby creating a balanced portfolio that actively manages safety concerns while ensuring operational efficiency.

Methods for Measuring and Optimizing Friction Coefficient

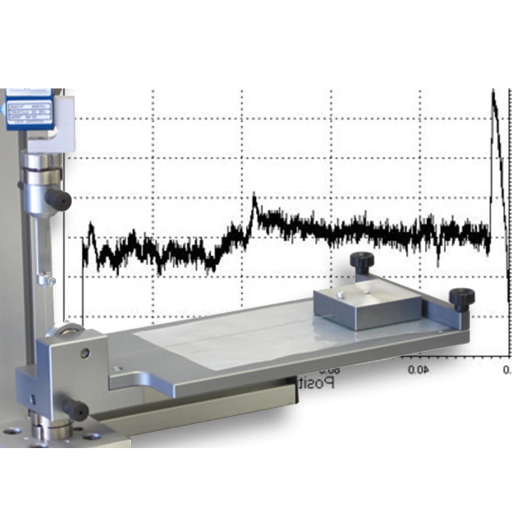

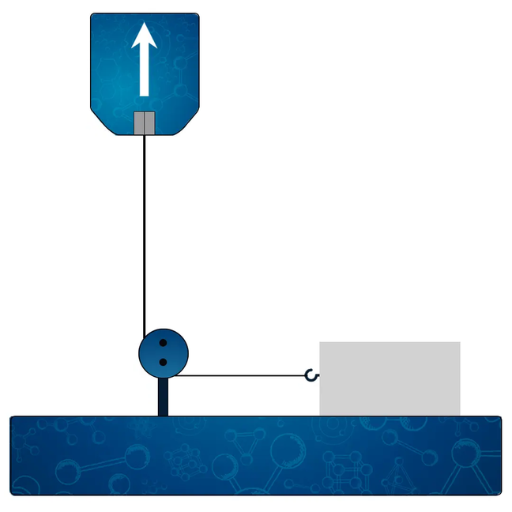

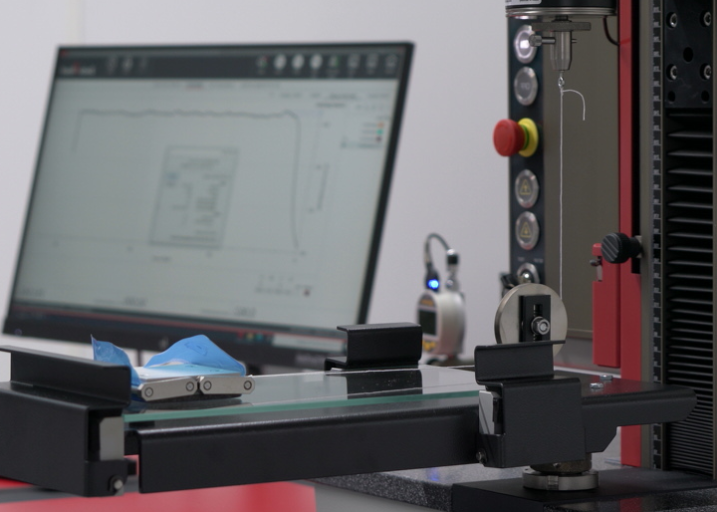

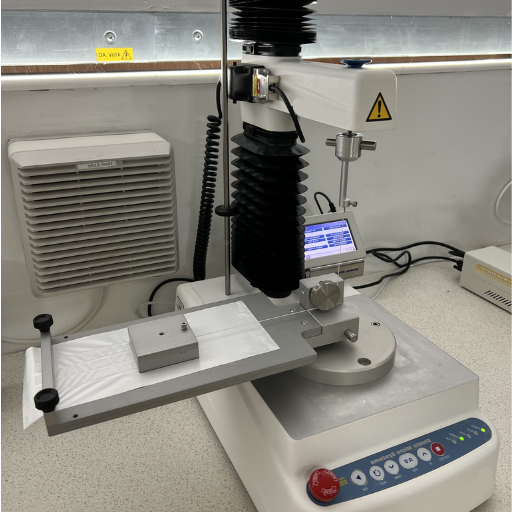

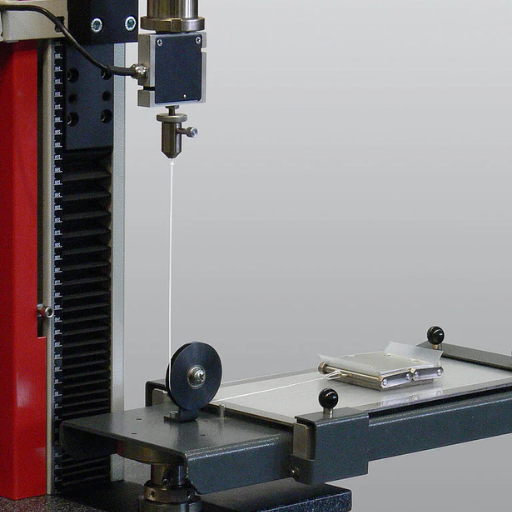

The friction coefficient measurement is typically performed by devices known as tribometers or mechanical testers, which are used to simulate the interaction between two surfaces under controlled conditions. These instruments exert a force of friction and measure it against the normal force to derive the coefficient. These tests are conducted in accordance with common ASTM or ISO standards to ensure accurate and reproducible results.

The other measures for friction optimization consider materials, surface treatment, and lubrication. A coating of Teflon, for example, may be applied in a high-friction environment to minimize friction. Areas are sometimes textured by a laser or mechanical means to either reduce the contact area or retain lubrication. Periodic monitoring and testing may be necessary to determine optimal coefficients and achieve a balance between wear resistance and operational efficiency.

Laboratory Testing Techniques for Accurate Measurement

To obtain reliable and repeatable values of material coefficients, an accurate method of laboratory testing becomes indispensable. The most popular method of testing is the tribometer test that evaluates friction, wear, and lubrication properties under controlled conditions. Tribometers produced by various manufacturers and designs, such as pin-on-disk or ball-on-flat, basically measure friction with some green sliding or rolling contact under different load, velocity, or environmental conditions.

Surface profilometry is a crucial method that measures surface roughness and texture through either contact or non-contact measurement. This procedure is crucial in evaluating the influence of surface structure on frictional behavior. Advanced spectroscopic techniques, such as Raman spectroscopy or XPS, are also employed to study the changes in surface chemistry that affect friction and wear properties.

A laboratory test should be considered valid only if conducted by standardized procedures, such as those outlined in ASTM/ISO, which ensure conformity between test methods. Conditions such as temperature control, applied load, or lubrication condition are so stringently controlled as to mimic the actual operating environment. The synergy of these methods yields data that may then be used for ultimate optimization of material performance in real industrial applications.

Advanced Simulation Tools for Friction Analysis

The focus of advanced simulation tools must be on modeling frictional behaviors under different working conditions. FEA software, such as ANSYS and Abaqus, would be used to faithfully recreate actual physical scenarios, gaining insight into stress distributions, surface deformation due to sliding friction, and the thermal effects of friction. CFD tools, meanwhile, respond to modeling lubrication phenomena to assess their influence on friction and wear in tribological systems. Through these platforms, I accomplish the prediction of performance, the selection of materials best suited for wear resistance, and the design of systems against wear. These simulations can be used in conjunction with experimental techniques to facilitate robust correlation and validation, while reducing the need for expensive physical testing.

Real-Time Monitoring Systems in Industrial Applications

In industrial applications, real-time monitoring systems use advanced sensors and interconnected networks to oversee and improve operational performance. These systems continuously stream data, enabling instant anomaly detection, cutting downtime, and enhancing decision-making with predictive analytics. Real-time monitoring enables more accurate tracking of parameters, such as temperature, pressure, vibration, and energy consumption, through IoT devices. These provide remote monitoring, promoting smooth operational procedures at geographically dispersed facilities, while increasing safety and operational efficiency. Thus, this becomes the very core of industrial process modernization and adherence to stringent regulatory compliance standards.

Reference Sources

-

Coefficient of Friction Equation and Table Chart – Provides a detailed table of friction coefficients for various material combinations, including rubber on steel.

-

Coefficient of Friction: Definition, Calculation and Values – Explains the concept of friction coefficients and includes specific values for rubber on stainless steel.

-

Friction – Coefficients for Common Materials and Surfaces – Offers a comprehensive list of friction coefficients for different materials, including steel and rubber.

-

Frictional Properties of Rubber (NIST) – A research paper discussing the frictional properties of rubber, including experimental data.

-

Steel-rubber friction coefficient: advice for your seals – Focuses on the industrial implications of rubber-steel friction, particularly in sealing applications.