The coefficient of friction (COF) is one of the most important factors to take into account and is paramount in many industries like packaging, manufacturing, automotive, and construction among others. ASTM D1894 is a universally accepted method for testing the friction measurements between the two surfaces and thus gives very important information about the performance and compatibility of the materials. This article discusses the ASTM D1894 test method and its applications, dissecting the procedure, main considerations, and the impact of precise COF measurements. If you are a quality assurance worker, an engineer, or simply someone who is interested in material science, this manual will give you the tools to easily comprehend friction testing and its significance in product development and performance optimization.

Understanding the Coefficient of Friction

Definition and Importance

The coefficient of friction (COF) is a measurement that quantifies the degree of sliding resistance between two contacting surfaces. It is a non-dimensional value and its calculation involves the division of the frictional force by the normal force that is holding the surfaces together. COF is a key concept in the study of material interactions in all sectors, ranging from product packaging, through industrial machinery, to the consumer sector, e.g., boots.

This parameter is a safety measure in the first place, but also an efficiency and performance aspect in the second. A higher coefficient of friction leads to greater sliding resistance, which is essential for tires and conveyor belts where grip is critically important. On the other hand, a lower COF is a great asset for non-stick coatings or lubrication systems, which are mainly designed for the reduction of resistance and wear.

The COF knowledge assists the manufacturers in creating the products that will achieve the required functionality while being made of the materials that are the most durable and user-friendly. Furthermore, the COF being accurately measured enables the engineers and quality control teams to foresee the behavior of the materials under real-world conditions, thus making products safer and more reliable for both consumers and industries.

Applications in Various Industries

The comprehension and quantification of the Coefficient of Friction (COF) are decisive factors in the various industries, which in turn dictate the design of products, the control of quality and the implementation of safety measures.

- Automobile Industry:In the automobile industry, COF is the primary factor to determine new tire tread designs that will give better grip and safety. To put it differently, researchers have found that a higher COF between the tires and the road surface leads to a substantial decrease in the distance required to stop a vehicle, thereby giving control in both dry and wet conditions. The modern tire companies depend on the exact measurement of COF to achieve the right mix of traction, wear resistance, and performance in general.

- Packing Industry:In the packing industry, it is COF that determines the approaches to be taken regarding the safe movement and transport of the materials. For instance, the flow of plastic films in the machines is highly affected by the surface friction. By optimizing the COF, the suppliers may prevent the production lines from being interrupted and at the same time make the lines more efficient.

- Building Industry:COF is an important parameter in building, especially when it comes to flooring materials. According to OSHA guidelines, floors with a COF above 0.6 are deemed safe for pedestrian use. The precise measurement of COF enables the designers to create the non-slip surfaces, thus minimizing the chances of accidents occurring in the workplaces and public areas.

- Fashion and Textile Industry:The textile industry employs COF to determine the quality and texture of the fabric. For instance, a low COF is connected with the softest and most luxurious fabrics, whereas a high COF may suggest that the material has good wear-resisting and durability. This information helps brands to gear their products according to the preferences of the consumers.

- Aviation Industry:Manufacturers of aircraft study COF to secure the bonding of such parts as the landing gear systems and to analyze how quickly materials wear out in high-performance conditions. The increase of COF testing facilities has been directly proportional to the development of safer and more efficient aircraft.

The Continuous, precise COF analysis has been a great force behind the industries that can innovate and still keep safety, reliability, and efficiency as their core elements.

Factors that Affect the COF Values

For COF (Coefficient of Friction) values, several principal factors had their say, evert told a different story about the performance. Surface roughness is one of the big and smooth surfaces; in general, they have a lower COF value due to the little amount of interlocking that happens, but then again, the rougher surfaces keep adding to the friction. Mechanical relief is reinforced by the use of surfaces in the materials that are of the utmost strength or quality under extreme mechanical or environmental conditions.

The type of material that is involved in the contact is another major factor that has a say in the issue. The combination of different materials gives the corresponding COF value with some of them being more or less likely to cause high friction due to special characteristics, molecular or structural. Metals, ceramics, or polymers interactions can yield a range of frictional behaviors depending on their composition and surface treatments.

Last but not least, environmental conditions like temperature, humidity, and the presence of lubricants have a very strong impact on COF values. With high temperature, the material can either expand or soften thus leading to a change in friction and on the other hand, the lubricant works to reduce COF by forming a boundary layer in between the surfaces. These factors, when monitored and managed properly, will not only guarantee the safety of the operation but also ensure the longevity of the materials used across different applications.

Common Testing Methods for Coefficient of Friction

Static vs. Kinetic Friction

Friction has two forms: static friction and kinetic friction, which both come into play when two surfaces are in contact and try to slide against each other. Static friction is the force that opposes the commencement of motion between the stationary surfaces; it has to be overcome before an object can start moving. Kinetic friction, in contrast, operates between two surfaces that are already in motion over one another.

Kinetic friction is usually less than static friction as overcoming the initial interlocking between surface irregularities requires more force. After the object has begun to slide, the irregularities do not have the same chance of engaging and therefore, the smaller magnitude of kinetic friction takes over. For instance, to push a heavy box it requires a lot of force to overcome the static friction initially and then less force is needed to keep the box moving due to the kinetic friction which is lower.

Knowledge of the disparity between static and kinetic friction is key in areas where the motion needs to be controlled with great precision. Engineers and designers usually take these forces into account to guarantee the efficacy and safety of mechanical equipment, transportation systems, and material handling. Taking into consideration the static and kinetic friction rightly, it is possible to achieve better performance and material wear reduction on the involved materials.

Overview of ASTM D1894

ASTM D1894 is a norm that delineates a test method for measuring the static and kinetic friction coefficients of plastic films and sheets. The test assesses the sliding of materials together, which in turn is the major factor in their nature and applications, such as packaging or down the manufacturing line. ASTM D1894 by the way of giving a numerical value to these frictional properties helps in the selection of materials that are likely to perform the required functions.

The test method consists in moving a fully loaded slider of one material on the surface of the other. The force needed for the start of the motion (static friction) and the force necessary to keep the motion (kinetic friction) are measured by very accurate devices. The outcomes are provided in terms of coefficients thereby giving a common platform of comparison for the friction characteristics of different materials. Consequently, it becomes possible for the manufacturers and designers to select among the materials those that would yield the best and most durable performance.

Due to the above-mentioned attributes, ASTM D1894 is largely trusted and hence very commonly applied in both areas of quality control and product development. By giving out the information concerning the frictional behavior of the materials, the standard acts as a main player in guaranteeing the product’s reliability and efficiency across every industry. This testing method if applied it would mean that companies could improve the compatibility of materials used, extend their use-life and optimize their performance at end-use.

Other Relevant ASTM Standards

ASTM standards are interrelated since they tackle different sides of the same issue which is material testing and evaluation of performance. Specifically for frictional behavior, ASTM G99 is another important standard. It describes the wear testing through a pin-on-disk method thus allowing manufacturers to quantify wear rates and gain insights into the material’s durability under given conditions, thereby making sure that the materials are optimally used in real-life applications.

ASTM D1894 is the other standard that takes the spotlight; it determines the coefficient of friction of plastic film and sheeting. This method is extensively utilized in all sectors to evaluate the smoothness and handling characteristics of thin materials which are critical for packaging, manufacturing and other applications where accuracy is important.

For product performance areas where high reliability is a must, ASTM D7027 is the standard that provides the tubing. The standard describes a ball-on-disk sliding wear test to obtain tribological characteristics such as friction and wear resistance. Together, these ASTM standards create a unified approach that improves and measures the performance of materials consistently and reliably throughout their lifecycle of products.

Coefficient of Friction of Plastic Materials

Friction of Plastic Film

The friction of plastic film can be defined as the resistance that arises when the surface of one film comes into contact with that of another. Understanding this property is significant in the production and letting of plastic films since it also determines how well they would function in the respective application like packaging, wrapping food, or even industrial usage.

Friction is usually expressed through two main values: the static coefficient of friction (COF), which gives the strength needed to start moving, and the kinetic COF, which is the strength needed to continue moving afterwards. Generally, these values are derived under standard testing conditions, such as those described in ASTM D1894, so as to get results that are dependable and can be reproduced. The data gotten informs the manufacturers so that they can adjust their film formulations or surface treatments for the particular application.

Films that have low friction values would be the ones for which easy gliding or separation is needed, whereas higher friction can help to keep the film stable and prevent it from sliding inadvertently during the application. By means of the COF of plastic materials, manufacturers can not only improve the performance of the film but also guarantee the quality of the film over the varying end-use conditions.

Testing Methods for Plastic COF

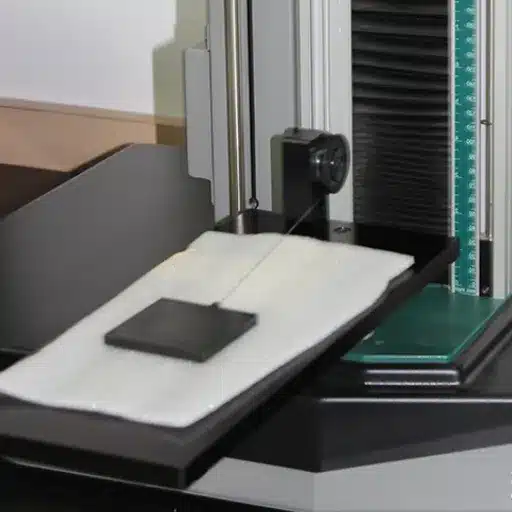

There are different standardized methods available for COF (coefficient of friction) testing on plastic films which guarantee the same result and reliability in testing. One of the methods that are most commonly used includes the Horizontal Plane Test where a piece of film is placed on a horizontal surface and another material is moved across it under controlled conditions. The force that caused the movement is recorded and this value is used to compute the COF. This method yields both the static COF (when the materials are not in motion) and the dynamic COF (when the movement has already started), thereby providing a full picture of the frictional behavior of the film.

The inclined plane test is also widely used for plastic COF testing. The film is inclined at an angle when the test object is placed on the surface and the angle is slowly increased until the object starts sliding. The angle at which sliding occurs can be considered to be measuring the COF. This method is particularly advantageous in scenarios where an understanding of the material’s performance on slopes or rough surfaces is needed.

Manufacturers can accurately determine the COF of their plastic materials in different situations using both the mentioned methods. It is necessary to carry out these tests under standardized and reproducible environmental conditions, such as temperature and humidity, to guarantee the reliability of the data. Manufacturers can then use these results to adjust their production processes and, consequently, develop high-performing materials suitable for specific applications, thereby increasing the overall product performance and customer satisfaction.

Impact of Surface Roughness and Temperature

Surface roughness and temperature are among the major factors affecting the performance and life spans of materials, especially in factories. Surface roughness can determine the extent to which the material opposes motion (friction), how long it lasts in terms of wear (wear resistance), and if the coating or adhesive can stick to it (bonding). Smoother surfaces tend to have less friction and wear while with rougher surfaces, the opposite condition might lead to faster degradation but at the same time to higher adhesion.

As for temperature, it affects material strength, elasticity and thermal expansion. High temperature can soften materials so that they either bend or break, whereas low temperature can make them brittle and prone to cracking. Besides, the combined effect of temperature and surface roughness can be of great importance as at times temperature fluctuation may cause changes in surface characteristics that will eventually lead to the downfall of material performance in challenging environments.

In order to maximize material durability, it is necessary to take into account not only surface roughness but also operational temperatures during the design phase. Periodic assessment under conditions similar to the actual environment can reveal possible weaknesses and guide the engineers in selecting the right materials and processing techniques. Furthermore, materials not only specified for their intended temperature range but also for surface quality will surely result in overall efficiency and longer product life.

Using a Coefficient of Friction Tester

Different Types of Available COF testers

Coefficient of Friction (COF) testers are very good measuring instruments for knowing the frictional force that opposes the movement of two surfaces sliding on each other. The testing machines are commonly in use in a number of sectors like packaging, automobile, industry, and material testing. Here is a rundown of some of the most important types of COF testers that are out there, along with their properties and specifications:

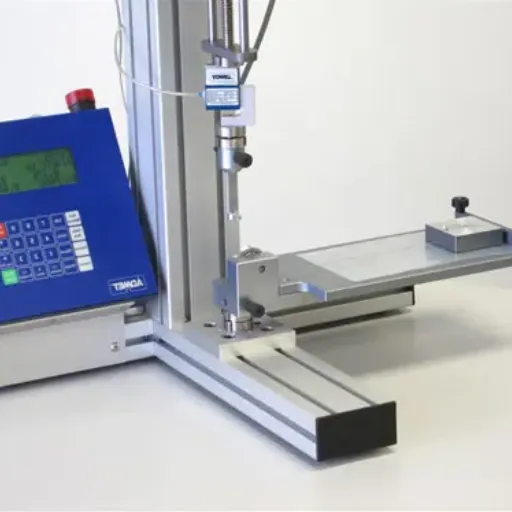

1. Horizontal Plane COF Testers

- Description: These testers measure the frictional force on a flat horizontal plane where materials slide against each other.

- Applications: Commonly used in the packaging industry to test films, paper, and plastic sheets.

- Key Features:

-

- Stable platform providing accurate and repeatable results.

- Testing capacity often ranges up to 200N or higher.

- Automated force sensors with high-resolution outputs.

- Example Specifications:

-

- Accuracy: ±0.1% of the full scale.

- Speed range for sliding tests: 50 mm/min – 500 mm/min.

2. Inclined Plane COF Testers

- Description: These testers determine the angle at which one material begins to slide against another.

- Applications: Ideal for testing materials like flooring, coatings, or surface additives in construction and interior design industries.

- Key Features:

-

- Adjustable angle control with digital or manual settings.

- Built-in sensors to monitor slip events.

- Example Specifications:

-

- Angle range: 0° to 45° with 0.1° precision.

- Testing surface dimensions vary by model but are generally around 10″ x 10″.

3. Multi-Functional COF Testers

- Description: Designed to handle multiple types of friction and wear testing, these are versatile devices suitable for advanced material evaluations.

- Applications: Used for high-precision material testing in sectors like aerospace and research institutions.

- Key Features:

-

- Compatibility with multiple test environments (wet, dry, high temperature).

- Modular attachments for static and dynamic COF testing.

- Example Specifications:

-

- Temperature testing range up to 300°C or higher.

- Static and dynamic COF resolution of 0.001.

Choosing the right COF tester depends on the specific material properties, the testing environment, and the required accuracy level. Advances in COF testing technology ensure precision and reliability, enabling industries to enhance product safety and performance.

Calibration and Maintenance of Testers

Calibration and maintenance of COF testers are vital to the attainment of precise and consistent results. Calibration means that the tester is adjusted to have the same performance as the recognized standards, hence the maintenance of accuracy during the measurement process. Regular calibrations should be done as per the manufacturer’s instructions or in accordance with the relevant industry standards to circumvent inaccuracies that may be caused by the gradual drift of the equipment.

Routine maintenance is indispensable to the longevity and dependability of the tester. Amongst the actions involved in routine maintenance are cleaning the components, checking for wear or damage, and replacing parts that have broken down. Providing that the tester’s moving parts are lubricated and cleaned of dirt, this will not only enhance the performance but also prevent breakdown due to mechanical causes. Adhering to routine maintenance schedules will mean that there is little or no downtime associated with the maintenance work or that the chances of unexpected failures are slim.

Finally, it is very advisable to keep a log of calibration and maintenance activities. The log serves a dual purpose, that is, the tracking of performance trends as well as ensuring of the tester is in the best possible condition. It is also imperative that the staff is taught everything about the proper use and care of the equipment, for improper handling could result in either unintentional errors in measurement or damage to the equipment. The COF testers can always be relied upon to deliver accurate and reliable results over time, if calibration and maintenance are done consistently.

Interpreting Test Results

It is very important to concentrate on the major values that are given, such as the coefficient of friction measurements, when interpreting the results of tests carried out by COF testers. These results represent the resistance level between two surfaces to sliding and are widely accepted for assessing safety, functionality or material performance. The particular readings must always be compared to preset standards or benchmarks that pertain to the particular application being tested.

In order to achieve precision it is necessary to make sure that all the environmental and testing conditions are as per the specifications. External factors such as temperature or surface contaminants can have a large impact on the readings obtained. By going over the conditions, one gets a clearer picture of the extent to which they deviate and also that the test results accurately represent the performance of the materials under the usual usage conditions.

Last but not least, any discrepancies or strange patterns in the data should be questioned in detail. Repeated trends seen in many tests are more trustworthy than single results and can lead to an understanding of the causes like wear or material loss. The comprehensive recording of all procedures, results and interpretations serves the purpose of traceability and also that of contributing to decisions being made based on the findings.

Conclusion and Next Steps

Summarizing Key Takeaways

It is very important to do a thorough data analysis in order to ensure that the test results are accurate and reliable. Sometimes, the same patterns are observed in different tests which can help to discover the root cause of the problem, for instance, the material might be losing its properties or it could be losing some of its physical aspects. In such cases, a trend might be understood better through the help of a reliable foundation that has been built up through proper data analysis. Meanwhile, large differences or strange occurrences in the dataset, although they might be detected, should not be just thrown away as unimportant, but rather, they should be looked into very deeply so as to make the insights clearer.

One of the major advantages of a proper data analysis process is that it provides a good record of the entire process: i.e. the procedures, results, and interpretations. The documentation acts as a perfect backup for the scientists’ credibility and, moreover, allows for the decisions to be made based on the evidence that is well-supported. Properly organized records remove any vague points and at the same time, they are a source of future analysis or validation that is quite invaluable.

Afterwards, there should be a continuous method of improving data collection and analysis. Reliability will be further increased by giving the highest priority to uniformity in testing and continuously comparing the results with the previously set standards. Stronger ties and more openness in communication among the team members will also contribute towards a proper understanding and application of the findings in solving the most important problems.

Implementing COF Testing in Your Processes

To implement COF testing effectively, I start by identifying the specific materials and conditions relevant to my application. I ensure the testing equipment is calibrated and follow standardized procedures to guarantee consistent results. Regularly analyzing trends in the data helps me pinpoint factors influencing performance, and I document every step to maintain traceability. By integrating these findings into my processes, I make informed decisions that enhance reliability and efficiency.

Future Trends in Friction Testing

Friction testing is changing continuously as a result of new technology and an increasing demand for accuracy and eco-friendliness. The main trend is the combination of automated and AI-driven systems. These innovations simplify the testing process, reduce human error, and offer real-time data analysis, which speeds up and improves the quality of decision-making. The use of AI in research allows researchers to create different situations and foresee the results which, in turn, leads to less necessity for physical testing.

Moreover, the shift towards eco-friendly testing methods is another trend in friction testing. Due to more awareness of environmental issues, different industries are trying to cut down on waste and energy during friction testing. New materials and lubricants are being produced that offer superior performance while complying with strict environmental standards. This change not only helps industries to meet the regulations but also supports their sustainability goals.

Moreover, the use of nanotechnology is a major factor that significantly affects the area of friction testing. Nanostructured coatings and materials are considered as a new and very promising way of enhancing micro-level performance. Friction testing devices are being developed to probe forces and interactions at the nanoscale, thereby providing scientists with a better understanding of the material properties. These innovations are needed in the aerospace, biomedical, and microelectronics industries where precision is required. All in all, these trends are driving friction testing towards the future with better accuracy, efficiency, and sustainability.

Frequently Asked Questions (FAQ)

Q: What is the Coefficient of Friction Test?

A: The Coefficient of Friction Test is a method that has become widely accepted to measure the amount of friction force acting upon two materials in contact. The test reveals the static or resting and kinetic or sliding coefficient of friction, which are the main factors when predicting the behavior of the materials in motion relative to each other.

Q: What is the technique used to measure static and kinetic coefficients of friction?

A: Among the various options available, many test setups can be used through the inclined plane and sled techniques to make the measurements of static and kinetic coefficients. During the sled test, a known weight is pulled over the selected friction surface, and the force needed to overcome the friction is captured for coefficients calculation.

Q: What are the major testing standards related to the coefficient of friction test?

A: The coefficient of friction, among others, is evaluated under various standardized tests, such as ASTM D1894 and ISO 8295, that propose methods for measuring. The stated standards present requisite practice for assuring the correctness and dependability of the results obtained from the diverse materials under examination.

Q: Which instruments are used in the coefficient of friction testing process?

A: Typically, a tribometer and a test stand with a sled are the main instruments employed in coefficient of friction testing. Tests are performed by devices built to introduce a normal force that pushes the surfaces in contact and control the frictional force created to be measured in the course of the test.

Q: Why is it crucial to determine the coefficient of friction of packaging materials?

A: The measurement of friction for packaging materials is very significant in verifying their proper functioning in the real applications of the package. The coefficient of friction can have an impact on the ease of sliding between the packaging materials, which is an important factor in automation and also in the transportation process.

Q: Which are the factors that may affect the coefficient of friction test results?

A: To name some of the factors that may lead to variability in test results, the type of material surfaces and their texture, the weight of the sled, and atmospheric conditions are worth mentioning. Though negligible, changes in these factors might cause significant peaks and troughs in the data, which can lead to an erroneous average coefficient of friction.

Q: How can the coefficient of friction be determined from testing data?

A: The coefficient of friction is the measure of the frictional force to the normal force pushing the two surfaces together. Thus, the value of the frictional force recorded during the test is divided by the weight of the sled to obtain the value of the coefficient.

Q: What role does dynamic friction play in the accuracy of the coefficient of friction tests and its interpretation?

A: Dynamic friction, commonly referred to as the kinetic coefficient of friction, is of great importance in testing and applications where materials can move against each other. Having the knowledge of dynamic friction is one of the vital aspects in the prediction of a material’s sliding behavior under continuous conditions, which is a great help considering design and safety issues.

Q: Are the tests of the coefficient of friction applicable to an extensive variety of materials?

A: It’s true that for a plethora of materials, including different types of plastics, metals, and composites, testing of the coefficient of friction can be applied. Very flexible testing methods are adopted and they can be easily modified to accept a vast range of surface attributes making it possible to have an all-embracing analysis in the areas of material selection and application.

References

-

DDL, Inc. – Provides detailed insights into ASTM D1894, the main standard for coefficient of friction testing, and its applications across industries. Visit DDL, Inc.1.

-

Westpak – Offers information on their testing services and methodology for coefficient of friction testing, adhering to ASTM D1894 standards. Visit Westpak2.

-

ZwickRoell – Explains the ASTM D1894 standard for testing the static and dynamic coefficients of friction, particularly for plastic films. Visit ZwickRoell3.