Composite materials offer the perfect combination of strength, weightlessness, and versatility and act as revolutionaries to several industrial fields. Yet, performance evaluation under different stressors is necessary to guarantee reliability and safety in aerospace, automotive, and civil engineering applications. This guide will give a comprehensive overview of mechanical test methods on composite materials, underlining essential methods and their importance to the evaluation of material performance. If you are a materials engineer, a researcher, or an industry professional, this article will offer an overview of prominent testing methods, along with insight into their ability to maintain the composite material’s integrity and function. Get ready to sift through the scientific basis behind these testing methods and see how they bridge the way for modern material innovation.

Introduction to Composite Material Testing

Overview of Composite Materials

Composite materials are combinations of two or more substances engineered to ensure better properties than what the separate ones have. They usually consist of strengthening material, such as fibers, embedded in a matrix that holds the reinforcement together and transfers the load. This very structure makes the materials light and strong, tough, and environmentally resistant in many respects, thereby boosting applications.

One of the advantages of composite materials is that they are very versatile. By varying the type and orientation of the reinforcement phase and matrix, composites can be tailored for a given requirement in mechanical, thermal, or chemical performance. For example, fiber composites find wide application in aerospace, automotive, and construction because of their high strength-to-weight ratios and resistances to fatigue or corrosion. Moreover, composite materials provide much design freedom where engineers are capable of producing geometries that are difficult to obtain with traditional materials.

The same features that give composite materials their properties also make the material difficult to work with: complex manufacturing, high cost, implementation into a production line, and lack of recyclability. The behavior of composites when submitted to varying stresses and environmental conditions is often quite different from the behavior of traditional materials, and thus special methods have to be employed to evaluate the performance of composites. Unveiling these characteristics is crucial because only then the full potential of these great materials can be realized, ensuring that they will yield consistent results in applications of critical importance.

Importance of Composite Material Testing

Composite material testing should be done to ensure reliability, safety, and efficacy in doing these materials for any critical applications. Once composites are forced to behave differently from that expected of them under given conditions, improper design of an engineering item or structure may ensue, leading to a potential failure. The tests provide strength characteristics for durability and some other mechanical properties that serve as input into the selection of the material and its application design.

Another pivotal aspect of the testing of composite materials is quality assurance. The testing ensures that the composites conform to the specifications and to performance criteria. Thus, it ensures consistency in the manufacturing processes. This is especially crucial for aerospace, automotive, and construction industries, for whom material performance stands directly in the way of safety and functionality. Testing also helps to uncover manufacturing defects, such as voids or delamination, which could weaken materials because of integrity loss, thus affecting their strength.

Ultimately, composite testing inspires innovation as it highlights unforeseen factors in material behaviors and limitations. This knowledge, in turn, enables researchers and engineers to propose new formulations and designs that push the envelopes of composite capabilities further. By attaining the full scope of material use, industries gain the freedom to design solutions that weigh less, uphold strength, and ensure sustainability while ushering in progress in multiple areas. Comprehensive testing thus becomes a must-have to harness the full benefits composites have to show in practical applications.

Applications in Various Industries

With their excellent strength-to-weight ratio, durability, and versatility, advanced composites have seen wide use in a number of industries. The aerospace industry is one of the major users of composites to make aircraft lighter without compromising the structural integrity of the aircraft, hence improving fuel efficiency and improving performance, thereby stating the importance of composites in modern-day aviation.

The automotive industry employs composites for designing lightweight, yet strong vehicles to reduce emissions and improve fuel efficiency. Their uses are increasingly being found in conventional and electric vehicles where weight and efficiency optimization are crucial. Also, their composites find applications in panels, reinforcements, and suspension systems where strength and aesthetics are concerned.

This is another important area of application in renewable energy, with composites being used in the fabrication of wind turbine blades. Blade materials must be light and yet mechanically strong to resist the varying forces caused by winds. Similarly, composites are also found useful in the construction of bridges, facades, and reinforcement, thus providing a sustainable and durable option in front of changing demands for green infrastructure. Composites, in general, keep tiptoeing on innovation from aerospace to renewable energy.

Types of Composite Materials

Common Types of Composite Materials Used

These composite materials are broadly classified according to their matrix components, such as polymer matrix composites, metal matrix composites, and ceramic matrix composites. These widely allow for versatile industrial applications. Below are some of the widely used composite materials and their details.

Carbon Fiber-Reinforced Plastic

It is a high-performance material with an excellent weight-to-strength ratio, stiffness, corrosion resistance, etc. It finds applications in aerospace, automotive, and sports equipment manufacturing. The worldwide carbon fiber market size was valued at roughly $4.7 billion in 2022 and is expected to grow at a CAGR of 9.1% from 2023 to 2030. Some applications of CFRP include aircraft components like fixed wings, fuselage panels, and frames in automobiles, where lightweight structures are essential.

Glass Fiber Reinforced Polymer (GFRP)

GFRP outcomes around one of the most common type implicated materials used in costruction simply because it is cheap and has good mechanical properties. This type of polymer fiber-enhancing materials; with a high tensile strength, and corrosion-resistant with versatile applications; is used in wind-turbine blades, construction panels, and marine works. Statistical figures indicate that the GFRP reaches nearly 65% of the global fiber-reinforced polymer market, presenting its dominance in applications where the other competing polymer-fiber materials cannot offer a cost-effective and durable solution.

Aramid Fiber Composites

Aramid fibers like Kevlar are known to be very lightweight and hence impact-resistant. These composites find applications in ballistic protection, helmets, and aerospace structures. Because of their superior toughness and resistance to fracture, more use is finding aramid fiber composites in military and safety equipment.

Metal Matrix Composites (MMCs)

While the aluminum alloy is nanostructured and matrix is rather crystalline with large grains, MMCs have a metal matrix like aluminum or titanium reinforced with ceramic or other fibers. They share the characteristic of metals in their ductility and heat resistance, while reinforcement materials impart them with better mechanical properties. These composites are widely used by automotive and aerospace industries in the manufacture of engine components and heat exchangers. Aluminum MMCs have grown to be a greener way of reducing weight in a vehicle and improving its fuel economy.

Natural Fiber Composites (NFCs)

NFCs are famed for having environmentally friendly properties. Made of renewable fibers such as jute, hemp, or flax, they serve as an alternative material for industries in search of a carbon-lowering agent. In many cases, the NFCs are used in the automotive interiors, furniture, and packaging. Natural fiber composites market was $3.8 billion in 2021 and is expected to witness growth at significant rates because of increasing demand for greener materials.

Ceramic Matrix Composites (CMCs)

CMCs provide a good resistance to working temperatures and strength, thereby giving them an edge over other materials in gas turbine engines, aerospace engines, and industrial cutters. Due to newer developments, they have now attained good oxidation resistance, and their usage can, therefore, be extended to adverse environments. The CMC market is expected to record a CAGR of over 11% in forthcoming years, owing to advancements in thermal management systems.

Composite materials have been harnessed by industries to accomplish superior performance, sustainability, and efficiency, thereby initiating innovation in varying sectors. The composite technology evolving today appears to create better applications matching global concerns, such as renewable energy and green materials.

Advantages of Using Composites

Composites impart numerous advantages across industries and are therefore a core element of modern technology and engineering. Here are some of their prime benefits:

Lightweight Yet Strong

Composite materials provide an exceptional strength-to-weight ratio. Carbon fiber composite, for instance, is five times stronger than steel but weighs five times less. Such a feature is exceedingly needed in aerospace, automotive, and wind energy applications, where the weight reduction translates into better efficiency and performance.

Corrosion and Chemical Resistance

While metals will be prone to corrosion and attack by chemicals, the composites, in contrast, increase the durability of structures and products. Such attributes, of course, are immensely valuable in adverse environments, such as in marine and industrial chemical settings.

Transport Energy Efficiency

Lightweight composites, when used in vehicles, save fuel. A report states that for about every 10% reduction of weight in a vehicle, the fuel efficiency can be increased by nearly 6%-8%. This goes a long way in keeping emissions and environmental impact in check, thus supporting global climate goals.

Design Flexibility

Composite materials can be molded into complex shapes, which allow the crafting of new designs without losing their structural credibility. This freedom allows engineers to create products and structures that are highly optimized but would be difficult or impossibly produced with more conventional materials.

Sustainability and Recycling

Current advances in composite technology are oriented toward finding green alternatives, such as in bio-composites with natural fibers like hemp or flax. Also, recycling methods like pyrolysis or chemical processing are gaining ground to recover materials from composites, thus putting an end to sustainability concerns.

High Heat Resistance

Ceramic matrix composites (CMCs) are being considered for high-temperature use, such as jet engines and gas turbines. They can stand high temperature, high above the capacity of conventional metals, reaching temperature up to 2,400°F (approximately 1,315°C) contributing toward increased efficiency in thermal management system.

The composites are further opening new possibilities, such that industries, in turn, can work toward sustainability and efficiency.

Mechanical Testing of Composites

Tensile Test: Procedure and Interpretation

Tensile testing is the principal method for determining the mechanical properties of composite materials. The test procedure starts with the preparation of a standard specimen, usually in a dog-bone or rectangular form, to rightly administer stress to the test specimen under consideration. The specimen is then fitted into a tensile testing machine, in which controlled tension is applied along the longitudinal axis of the specimen at a steady rate until fracturing occurs. Along the way, the maximum force applied, elongation, are among the key parameters being recorded.

Testing primarily aim to evaluate tensile strength, modulus of elasticity, and strain-at-failure properties. Those properties are tensile strength that is the maximum stress that a material can withstand before it breaks; modulus of elasticity that is the stiffening or resisting-to-deformation property; and strain at failure, which gives information about the ductility of a material. Such properties in fact are important towards the determination of its application suitability, especially in harsh environments.

The interpretation of results involved drawing a stress-strain curve. Herein, stress was calculated from force and cross-section area, while strains were calculated from elongation and original gauge length. The plot contains important points like the elastic limit, yield strength, and ultimate tensile strength, which give an idea of the material’s behavior under load. With such information, engineers can go on to predict performance and modify composites to work more efficiently and last longer in real-world applications.

Compression Test: Key Considerations

Compression tests help us study materials for means of their behavior under compressive load. In contrast to tensile testing, compression testing considers the ability of the structure to resist forces that push the specimen from one end to another. These tests are necessary to ascertain something like compressive strength, elastic limit, and modulus of elasticity- properties used for applications involving structural stability and loading-bearing capacity.

In compression tests, the specimen will be compressed in a controlled manner until it reaches failure or deformation, depending on the criteria of the test. The factors to keep in mind are the geometry of the specimen, as it directly influences the result accuracy, and the type of material tested since different materials behave differently under compression. For example, while concrete, a brittle material, may fail suddenly, a ductile material such as metal deforms gradually before failure.

Compression tests yield necessary information for engineers in applying and designing materials for real-world use. These tests are vital for safety and reliability since materials have to take compressive force and yield without compromising on integrity. Considering these points will enable an engineer to make informed decisions toward the selection and further optimization of materials for various applications.

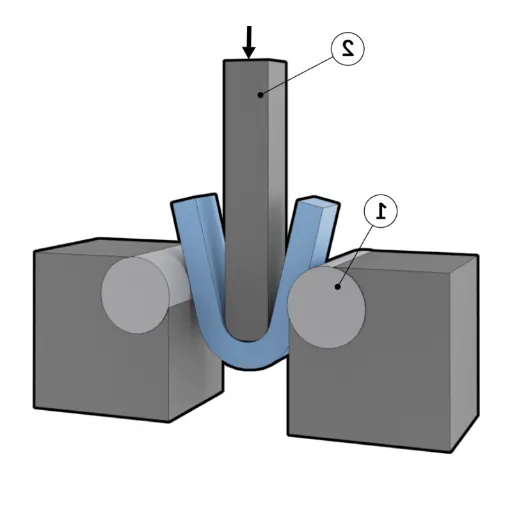

Shear Test: Understanding In-Plane Shear Testing

Shear testing puts materials to the test to observe how forces act upon them in sliding the various layers, i.e., a shear stress. The discipline of engineering exerts forces parallel to a surface, measuring a material’s ability to resist such forces, i.e., shear strength, stiffness, or failure upon stress. These are important material properties, having numerous applications, particularly in aerospace parts, bridges, or high-performance composites.

One common method for in-plane shear tests is thus the use of an appropriate shear frame or fixture that firmly holds the material while the force is applied. The loading conditions set up by this ensure a pure shearing motion in the specimen without the introduction of other stress types like bending or compression. Results from the shear test usually include the shear modulus-and-the capacity of the material to deform elastically under shear stress-and ultimate shear strength-that is, the maximum stress the material will withstand before it fails.

Shear properties are important for safety and reliability in engineering designs. If a material applied in a critical application lacks enough shear strength, deformation or cracking, and ultimately failure might occur with the structure, constituting a hazard. Proper measurement of shear behavior in-plane allows for materials to be chosen and components to be designed that will perform satisfactorily under the required conditions.

Testing Equipment and Laboratory Setup

Essential Testing Equipment for Composites

For an effective evaluation of composite materials regarding properties and performance, one needs specialized testing equipment. These tools and instruments provide detailed information about mechanical, thermal, and physical properties, ensuring that composites satisfy the extreme needs of their applications. Here’s a brief overview of essential testing equipment with their picture and brief description:

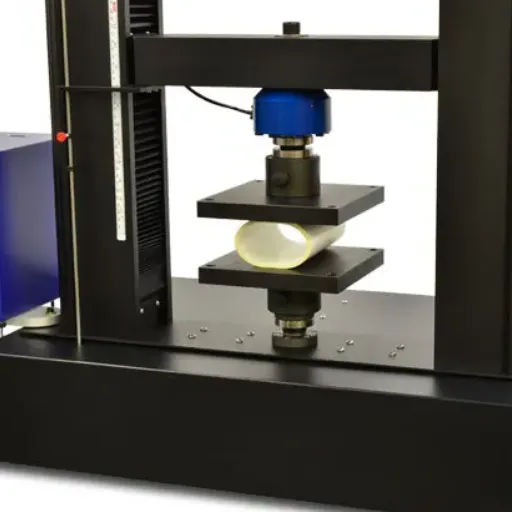

Universal Testing Machine (UTM)

The universal testing machines are very important to test the mechanical properties of composites. These machines are used for tensile strength testing, compressive strength testing, and flexural testing. The contemporary UTMs are equipped with an advanced software and a high precision load cell to produce accurate readings. A typical tensile test for a carbon fiber-reinforced composite might need a UTM that can take loads of well over 100 kN with grips that can hold the fragile material appropriately.

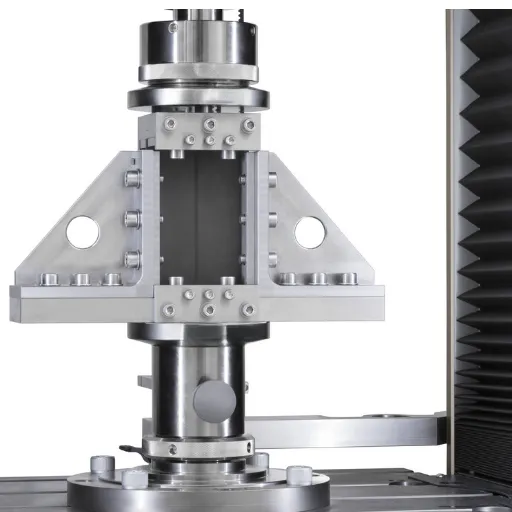

Prepare for Shearing Test

It is very necessary to carry out shear testing to evaluate the strength that the composite material may have against an applied shear force. Typical techniques of shear tests include measuring the interlaminar shear strength of a short-beam specimen to test its bonding between the composite layers. The more versatile and costly shear-testing equipment can provide predictive analysis for various loading modes within the framework of standards such as ASTM D2344.

Dynamic Mechanical Analyzer (DMA)

The DMA tests composites for their viscoelastic behavior, properties related to the storage modulus, the loss modulus, and the glass transition temperature (Tg). Such tests are important for determining the damping and stiffness properties of materials over a temperature range.

Scanning Electron Microscope (SEM)

The SEM helps analyze the microstructure of composites, providing information about fiber-matrix adhesion, void content, and defects. Such information obtained through high-resolution images is utilized for further improvements in material formulations and in material processing.

Thermal Analysis Equipment

Thermal analysis includes instrumentation such as differential scanning calorimeters and thermogravimetric analyzers, operating as means of testing for the general thermal stability, degradation, and heat resistance of the composite. For instance, a TGA can give an indication about the thermal stability of aerospace composites up to 400°C.

Impact Testing Machines

Used to simulate sudden loading or impact situations and measurement of the resultant performance of the composite under such situations. Falling weight or pendulum impact test machines crush the specimens to evaluate impact energy absorption and damage resistance according to standards like ASTM D7136.

Non-Destructive Testing (NDT) Instruments

The role of NDT techniques is to identify flaws or defects in composite structures without impairing them. Ultrasonic scanners, radiographic methods, and thermo-graphic cameras are some of the most popular methods. For example, ultrasonic phased-array can identify internal cavities and cracks in complex parts like wind turbine blades.

Fatigue Testing Systems

Fatigue testing systems determine the endurance limit of composites through cyclic loading. These systems are very important for materials used in the automotive and aerospace industries as components subjected to repetitive stress over long periods.

Utilizing these sophisticated systems, engineers and researchers assure composite materials for their respective applications, solving big problems. Investment in sophisticated equipment is a big step toward achieving an even higher level of industry standards and bringing innovation in composite technologies.

Laboratory Setup for Composite Testing

A well-equipped laboratory is imperative for the successful conduct of composite testing. This typically includes key instruments like universal testing machines to evaluate mechanical strength, environmental chambers to emulate changes in temperature and humidity, and microscopes for analyzing microstructural properties. Such equipment is crucial in defining the performance and durability of composite materials passed through various conditions.

Precise data caused by testing can be ensured when temperature and humidity are strictly controlled in the laboratory environment to reduce any external influence on material behavior. In other instances, testing is strictly under set protocols prescribed by relevant international organizations to warrant repeatability of data collection.

Finally, safety is of foremost importance in any laboratory organisation. Proper material storage, proper ventilated workspaces, and PPE for researchers are all standard precautions. When implemented, a full-circle safety policy guarantees protection for all personnel involved and maintains the integrity of the testing process, thus creating a conducive and safe working environment for research.

Calibration and Maintenance of Testing Equipment

Proper calibration and maintenance of testing equipment is crucial in obtaining precise results at all times. First come the calibrations, adjustments of the equipment to ensure it fulfills specific standards, thereby resulting in errors during measurement to a minimum, and ensuring that tests of a similar nature produce uniform results. Calibrations must always be done either following manufacturers’ instructions or according to relevant regulations to maintain the accuracy of the equipment over time.

Maintenance is meant to keep the equipment functioning and fit for use for a long time. It entails periodic checks, cleaning, and replacement of parts that show signs of wear and tear. When a good preventative maintenance schedule is in place, unexpected breakdowns are less likely to occur and interfere with research activities or adversely impact results.

Both calibration and maintenance activities must be documented to satisfy traceability requirements and comply with quality standards. Such documentation can be used to observe trends, forecast problems, or demonstrate adherence to protocols during audits or reviews. Maintenance of equipment according to a programmed schedule in a well-documented manner would ensure the good and reliable performance of this equipment, which ultimately leads to the success of any laboratory operation.

Challenges in Composite Material Testing

Material Variability and Its Impact on Testing

Material variability has a bearing on the accuracy and reliability of the testing of composite materials. These are nonuniform materials because their constituent materials undergo process and age differently with exposure to an environment. Hence, these differences may develop inconsistencies in the test results, thus making it difficult to give definite material properties. For example, differences in fiber orientation with resin distribution and voids can act as sources of inconsistency in the performance of materials under load. These factors emphasize the need to control variability so as to make test results valid and reproducible.

Standardized methods must be less flexible to counter material variability. ASTM (American Society for Testing and Materials) and ISO (International Organization of Standardization) have developed well-accepted methods to reduce variability due to sample preparation, testing environment, and variations in testing procedures. These standards help generate comparable data by providing standard test conditions. In addition, testing several samples and subjecting the test results to statistical analysis may be beneficial in determining patterns and removing outliers due to variability.

In the field of non-destructive evaluation technologies, advancement deals with developing methods for assessing and reducing material variability before performing destructive tests. Ultrasonic scanning methods, X-ray imaging, and thermal analyses might be employed to detect internal flaws or inconsistency in composite materials without affecting their state. These technologies thus offer more information on the material properties and enable manufacturers to modify manufacturing processes to lessen variability. Addressing material variability is basically the key to produce reliable data that supports the proper use and application of composite materials in safety-critical applications.

Complex Failure Modes in Composites

Composite materials can fail in numerous complex modes depending on the loads and on the environmental conditions they are subjected to. One of the most common of these modes includes matrix cracking, fiber-matrix debonding, fiber breakage, and interlaminar shear failure. Any of these failures can act on its own, but frequently they occur in conjunction with one another, and the co-actions make it very difficult to assess the behavior of a composite structure in the presence of stress.

Excessive tensile or shear stress within a resin or polymer matrix usually results in matrix cracking: microcracks that grow during loading. Fiber-matrix debonding takes place if the bond between reinforcement fibers and the matrix is impaired, bringing down the strength and stiffness of the composite. Fiber breakage is another major failure mode where the reinforcing fibers fail by tensile, compressive, or bending stresses that ultimately reduce the material’s capacity for bearing load. On the contrary, interlaminar shear failure is the result of weak bonding among the composite layers, usually introduced by out-of-plane stress.

Manufacturers prepare an appropriate material system or weave to counter these failure modes. For instance, resin-fiber combinations are selected so that they can provide good adhesion and mechanical properties, while computational models and non-destructive evaluation methods are used to pinpoint weak areas early on in the design market. To synthesize these complicated failure modes is an essential step to enabling the use of composites on the field under heavy-duty applications-lifting fields where safety and performance are of utmost importance.

Common Testing Errors and How to Avoid Them

Another common testing error is underpreparing samples for tests. Underprepared samples render test results either inconsistent or false, erroneously supporting or dismissing the performance or durability of a material. For the sake of consistency between test batches, preparation guidelines must be followed with every sample using a standard procedure for business, size, and manufacturing conditions. From such practice differences, variabilities could be introduced into test results.

Another kind of error is disregarding test conditions and materials’ environmental influences on performance. Temperature, humidity, or chemicals all can drastically affect material properties. In the case where conditions do not mimic actual-use conditions in the laboratory, the data can be considered void concerning real application. By controlling and documenting environmental parameters, tests can indeed forecast the behavior of materials under genuine working conditions.

The last item is inadequate data analysis, which commonly leads to poor decision-making. Some errors may arise in interpreting test results in the absence of statistical evaluation, thereby concluding incorrectly on the material’s reliability or safety. Enhancing data analysis approaches, and cross-verifying findings against accepted benchmarks will reduce some of these risks. Data visualization supported by peer reviews will ensure your conclusions are accurate and trustworthy.

Frequently Asked Questions (FAQ)

Q: What are the basic types of composite material tests?

A: Tensile test, compression test, shear test, and flexural test constitute the basic testing methods for composite materials. These tests provide mechanical properties of composites such as tensile strength, compressive properties, and shear strength, which are very important to assessing the performance of composite laminates.

Q: Why is testing important for composite laminate materials?

A: In developing a composite laminate material, testing is essential; it assures the material of meeting its required specifications and performance standards. By employing several composite testing techniques, engineers can evaluate a composite’s strength and duration and their respective uses applied in aerospace and other fields.

Q: What are common standards used in composite testing?

A: Standard test methods commonly employed for composite material testing are ASTM D3039 for tensile testing, ASTM D695 for compressive testing, and ASTM D6671 for shear testing. These are standards that explain how to test composites to achieve uniformity and reliability in data.

Q: How does the anisotropic nature of the composites affect testing?

A: Because composites are anisotropic, their mechanical properties do change according to direction. Consequently, to obtain an accurate determination of all modes under which the material can behave when loaded, testing in all modes or in different orientations of the material must be carried out to understand the directional behavior under those loading conditions. Testing of composites because of this variation in directional properties is done to learn thoroughly the various modes in which materials perform.

Q: What are some common test fixtures used in composite testing?

A: Some common test setups for composites encompass grips for tensile testing, compression platens for compressive tests, and apparatus for shear tests. These fixtures securely hold composite specimens while ensuring that the applied load is uniformly maintained to permit proper measurement of material properties.

Q: What is compression after impact testing?

A: Compression after impact testing refers to methods wherein evaluation is done for residual compressive properties of composite materials after having been subjected to impact loading. This testing is essential to determine the durability and performance of composite laminates under real-time functioning, where an impact could occur during use.

Q: How are woven composites tested differently from the other composite types?

A: For woven composites, testing follows the same general methods as for other composites, but it may be more oriented toward shear strength and tensile properties of the materials, given the particular fabric structure. The interlacing of fibers influences the mechanical properties of woven composites, and hence tests specific to these effects need to be considered to gauge their performance.

Q: What is the use of test software in the testing of composite materials?

A: Test software is crucial in composite material testing, as it collects, analyzes, and reports data. It processes test data acquired from the numerous composite testing methods and presents it in a form whereby engineers interpret the results and make intelligent decisions as to the performance of materials and their suitability for certain applications.

References

-

Mentis Sciences – An Introduction to 6 Different Types of Composite Testing – Covers common tests like tensile, compression, shear, and flexure, along with standard testing procedures.

-

AddComposites – Mechanical Testing of Composites – Focuses on tensile testing and its importance in understanding composite material properties.

-

Aerospace Testing International – A Guide to Composite Materials Testing Techniques – Discusses a range of mechanical tests, including tensile, compressive, and shear tests.

-

NASA – ASTM Test Methods for Composite Materials – Provides detailed information on standard test methods for identifying and evaluating composite material characteristics.

-

ATS Labs – Composite Material Testing – Explains various testing methods like tensile and compression testing, and their applications in predicting material performance.