Composite fiber reinforced polymer materials, simply composites, are critical in contemporary engineering and manufacturing work and possess tremendous advantages such as minimal weight, ruggedness, and high strength-to-weight ratio while being custom fitted to achieve pre-set few conclusions. Nonetheless, utilizing these promising materials to their fullest extent without skill at an art, there is a necessary to appreciate and comprehend the art of Composites Testing. This will ensure that the materials pass the rigorous quality and safety expectations of the markets including aerospace, automotive, construction and energy. In this regard, there will be an examination on what compositive materials are and why testing them is imperative as well as how compositive materials are tested. Regardless of whether you are a professional engineer, designer of products or someone interested in the newest technology made possible by materials science, this article is meant to help in understanding the nature and reasons for testing of composites that are enhancing the performance and creativity of composite structures.

Introduction to Composite Materials

Scientists working in materials science accomplish the creation of composite materials by mixing at least two different materials to get a better material overall properties. Normally a composite material consists of fibers or particles the so-called reinforcement and a matrix in which the fibers are embedded, such materials are meant to have higher strength, stiffness or efficiency compared to the materials components called parts. For instance, carbon fiber can be used to make lightweight structures and applications such as automotive parts whereas body of boats can be made of fiberglass for its other useful properties. Because of their specific characteristics, the composite materials are crucial in fields that require high levels of performance such as aerospace, automotive and energy industries.

Definition and Characteristics of Composite Materials

Also referred to as composite materials, these are materials created via convergence of dissimilar materials which possess a wide range of different physical and chemical properties due to the stiffening or reinforcement of the material with a matrix. This is achieved while enhancing mechanical, thermal and chemical capabilities of the composites higher than those attainable with the individual materials applied.

Based on latest reports, some manufacturing techniques like 3D printing and enhancing the placement of fibers have assisted in improving the efficacy and application of composites. Composite materials are characterized by their high specific strength to weight ratios, corrosion resistance, and tunable structural capabilities. These characteristics have led to the incorporation of these materials in various advanced innovative parts and structures, which include, but are not limited to, aviation light weighting, Electric vehicles (EV) batteries housing closure, or wind blades size improvement, advancing the performance of these industries.

In the present days, there is also a tendency to apply sustainable materials, bio-composites particularly, and therefore reducing the environmental footprint and bases for such composite include renewable fibers and therapeutic biodegradable matrix elements.

Types of Composite Materials

Composite materials can be broadly categorized into polymer matrix composites (PMCs), metal matrix composites (MMCs), ceramic matrix composites (CMCs), carbon-carbon composites, and hybrid composites.

|

Type |

Matrix Type |

Reinforcement |

Characteristics |

Example Use |

|---|---|---|---|---|

|

Polymer Matrix (PMC) |

Polymer |

Fiber/Particle |

Lightweight |

Aerospace, Automotive |

|

Metal Matrix (MMC) |

Metal |

Ceramic/Fiber |

High Strength |

Aerospace, Thermal Apps |

|

Ceramic Matrix (CMC) |

Ceramic |

Oxide/Non-Oxide |

Heat Resistant |

Turbines, Engines |

|

Carbon-Carbon |

Carbon |

Graphite Fiber |

High Temp Toler. |

Aerospace, Braking |

|

Hybrid |

Mixed |

Mixed Fibers |

Tailored Props. |

Sports, Biomedical |

Applications of Composite Materials

1.Aviation field

The application of composite materials in design of airframe and spacecraft is very wide as they offer high strength with less weight, are resistant to corrosion and do not get affected in high temperatures. These are wings, body panels, and thermal insulators available shields.

2.Car Making

To facilitate manufacturing of vehicles, there was a need to use composites in reducing weight and enhancing fuel consumption without compromising on safety. These were used on body parts, frames and cabin sections.

3.Human Health

Due to the mechanical compliance and biocompatibility, composite materials have been used to fashion and create medical devices and implants. Some of the common uses in this category are in the manufacture of bone plates, dental implants and prosthetic devices

4.Wind Power

Composites are extensively applied in wind energy to produce the blades of wind turbines. This is due to their high tensile strength and low weight which improves the generation of power and slows down the degradation process significantly.

5.Ship Industry

Boats, ships and submarines are built using composites for their lightweight nature, resistance to the infectious sea water and long service life.

Overview of Composite Testing

Testing of composites could be simply outlined as an empirical assessment of the mechanical, thermal and chemical properties of composite materials to evaluate whether or not they meet the requirements for use. The most basic of these tests is the tensile test, during which a material is pulled and the elastic forces within the specimen will cause the material to increase in length and to decrease in thickness, whereas in a flexural test, the material is deformed but does not break. It includes such processes as DSC and TGA for evaluating if a composite is stable or how well it performs at elevated temperatures or under cold conditions. The ability of the component to withstand repeated cycles of loading without failure is determined via fatigue tests and defect(s) especially internal defect(s) would be assessed using non-destructive techniques such as ultrasonic examination which neither cutting nor disassembling the item. This reduces the costs but also keeps the actual structural component as intact. This use of testing ensures that composites are more reliable and safer for applications where specific industry standards are present.

Importance of Composite Testing

It is paramount to apply compounding testing for particular stresses which arise for particular materials in different sectors like aerospace, automotive, construction and bureaucracy of nuclear power. Adaptability of composite materials to stringent working conditions is verified by demicarb under the most critical operational environments. These activities are carried out to make sure that the process is within limits as described by international norms, reduce chances of breakdown and/or enhance the longevity of the components. The development of advanced testing methods such as fatigue and non destructive testing offers more insights in the formation of the properties of the material and more understanding that assists in the innovation of the composites.

Common Composite Test Methods

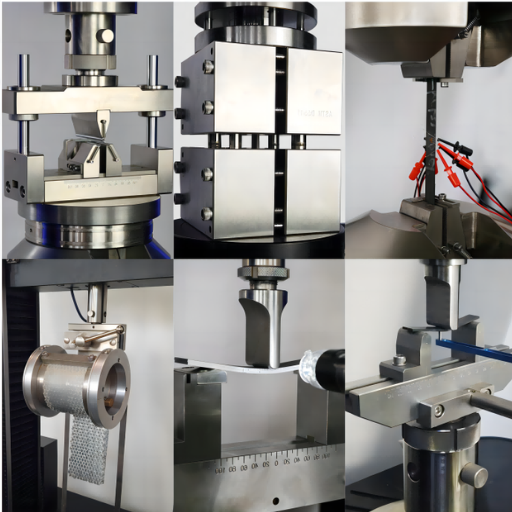

Common composite test methods include tension, compression, shear, flexural, impact, fatigue, creep, and non-destructive testing (NDT).

|

Test Method |

Purpose |

Key Parameter |

Example Use |

|---|---|---|---|

|

Tension |

Measures tensile strength and modulus. |

Strength |

Structural analysis |

|

Compression |

Assesses compressive strength and behavior. |

Stiffness |

Load-bearing studies |

|

Shear |

Evaluates shear strength and interface quality. |

Shear Mod |

Adhesion testing |

|

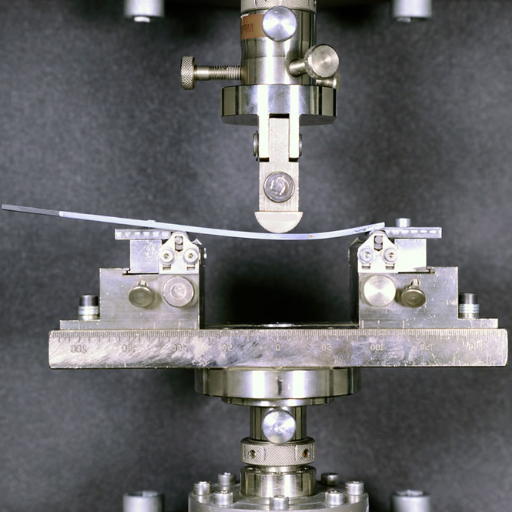

Flexural |

Determines flexural strength and stiffness. |

Flex Mod |

Beam performance |

|

Impact |

Tests resistance to sudden forces or impacts. |

Energy Abs |

Damage tolerance |

|

Fatigue |

Studies endurance under cyclic loading. |

Fatigue L |

Durability testing |

|

Creep |

Monitors deformation under constant load over time. |

Time Def |

Long-term performance |

|

NDT |

Inspects defects without damaging material. |

Defect Det |

Quality control |

Mechanical Testing of Composites

Testing of Components Mechanical testing of different components composites is equally important in order to assess whether their mechanical properties are consistent with the design and performance motives. In this regard, testing is used to verify physical properties including strength, stiffness, longevity and damage tolerance. By performing flexural testing, you can see how much a material can take a bend stress before it breaks and modulus of elasticity for bimaterials if any. Impact testing enables the assessment of energy absorbing capacity of the composite material when it is struck by a force suddenly. One can also discern its damage resistant capacity through impact testing. Fatigue testing assesses how far the components are able to go without damage under repeatedly changing strain. These standard tests are very helpful in development, checking and usage of composite materials in almost every field of activity.

Mechanical Testing Techniques

Mechanical tests are imperative for determining the capabilities of composite structures. Fracture, tensile, and compression tests come in handy in assessing material properties such as the degree of stiffness, the capacity of energy absorbed, and fatigue stresses. All tests are designed in such a way that they replicate the active environment of the elements. The analysis encompasses all relevant tasks of the material’s most effective utilization within the product designing context.

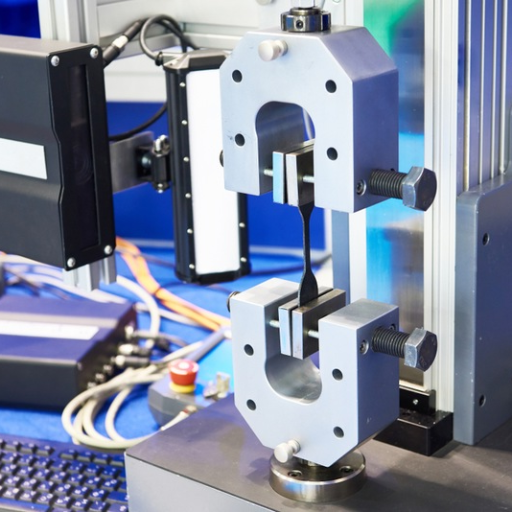

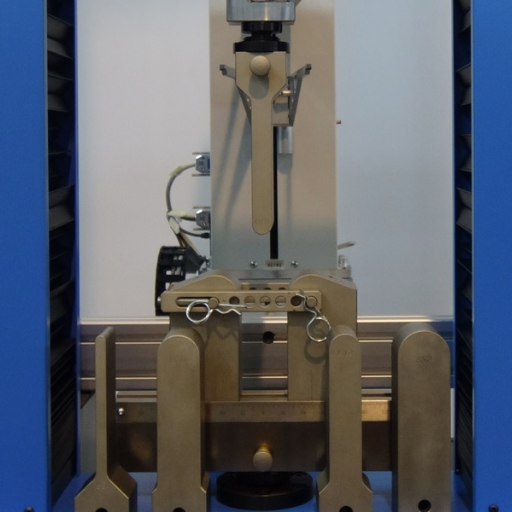

Tensile Testing of Composites

In composite materials, tensile tests are done by imposing axial tensile forces and measuring the material’s reaction. The test enables the determination of the elongation limit at break, tensile strength, and modulus of elasticity of materials that would otherwise fail in tension. The specimens are prepared in appropriate forms and tested with a universal testing machine in which the load and the change in length of the sample are measured. The intricate anisotropic feature inherent in composites prompts special consideration for lay-ups and loading angles during the test as these do account for a large distortion of test results. In this regard, tension tests offer useful information that aids in the enhancement of materials and guarantees that all the required engineering features are met.

Compression Testing Methods

This is a very important test in materials to assess their behavior under a compressive load and characteristics such as compressive strength, modulus of elasticity, and deformation. A few standardized testing procedures used in the case of metals in particular include ASTM E9 and ASTM D695 for plastics. The specimens are specified according to the material and objective, which are usually cylinders, cubes, or rectangular prisms, and tested. The load is applied either by a universal testing machine with plain compression platens or by specialized compression fixtures on matched testing setup until failure or permanent deformation is achieved.

Such factors as the proper position of the specimen, the rate of load, and the supporting conditions have a very significant impact on the accuracy of the measurement. For example, compression testing is heavily used in different industries, especially in the construction, aviation, and production industries. The materials must be tested under real compressive loads, to either ensure proper strength and performance of a structure or in production for product quality.

Shear Testing Procedures

This test comprises of applying forces parallel to the apply plane causing shear failure on the tube. The test will determine when the sliding loads will result in the materials sliding along internal failure planes. Common practices involve one shear or two shear tests of individual lap joints and these have been found to closely imitate operating conditions. The specimen should be arranged properly and the load should be applied smoothly with equal magnitudes in order to achieve proper results. Such practical implementations for shear tests are in the automotive and building industry as well as the aerospace industry to correctly assess the performance of materials without introducing failure-tier snags such as rivets and glue joints.

Fatigue and Environmental Testing

The subject of fatigue and environmental testing is quite important because it shows if the material can sustain a repeated stress and will not deform. Fatigue and environmental testing shows how long the material will last when subjected to various conditions such as corrosion, temperature or humidity. These fatigue tests focus on layers of repetitive loading which are used in order to determine the percentage safety X – component stress and failure of components is determined with respect to time. Environmental testing, however, is concerned about the stability of the material with respect to changes in external environment or even conditions similar to the ones in which the material is expected to operate. The conducted both these types of tests helped to provide useful information needed for the estimation of the long-term durability of the product and the fulfilment of the specific requirements of the designed product.

Understanding Fatigue Testing

Fatigue testing is the determination of characteristics of materials with respect to repetitive loading of the material. These models allow much better definition of the actual problem, as they include and model parameters such as load amplitude, load frequency and type of load. And patterns that were earlier unaddressed, as those that define failure points, are now enhanced by the use of relevant learning techniques. All the above ensures that the goal of fatigue testing has reached, even gone beyond the current expectations of the modern world of engineering, a fact that is of no trauma to materials science as it is in fact a bedrock for material functionality.

Environmental Testing of Composite Materials

Environmental testing of composites materials involves the determination of the performance and reliability of the materials under analogous or certain real-world conditions. The factors include humidity, temperature changes, ultra-violet exposure, and chemical environment which affect the mechanical response of the composites by a great extent. New technologies like accelerated testing and cyclic testing are designed to study the strength, stability and durability of the composite materials. Such tests are ubiquitous in sectors like aviation, transport or shipping where operational constraints on the material used, its resiliency and longevity must not only be present but also applied during their useful lifespan.

Non-Destructive Testing (NDT) for Composites

Such analysis is an important aspect that deals in examining the composite materials without altering the structure. Some of the traditional methods used in measuring the efficiency of the composite components include ultrasonic inspection, radiography and infrared testing. For example, ultrasonic testing involves the use of high-pitched sound waves to find out outer or inner voids, cracks or delaminations in composites etc. Radiography makes use of radiations such as X-rays or gamma rays in order to locate defects that are present beneath the surface of the material. Lastly, thermography monitoring systems employ the thermal imaging cameras to detect heat patterns and gradients in the composite which serve as a guide to determine the presence of weak areas or damages.

These techniques help maintain the integrity of composites in many different areas. Not only does non-destructive testing allow for the early and accurate identification of damage, thus ensuring reliability standards are met, it also lessens operational costs by preventing catastrophic failure-saving measures which prolong the useful life of composite materials positioned in high performance sectors.

Testing Equipment and Services

Testing of composites without compromising their structural properties utilises various devices such as ultrasonic testing probes, x-radiography machines, thermovision equipment and acoustic wave sensors. High-frequency ultrasonic devices allow for inspecting the inside of objects, whereas x-ray or gamma ray provides for Chinese bamboo made structures. The hot/cold viewing thermography is used for the purpose of fine defects identification while the acoustic emission generated waves during loading process of material deformation as well as glasses of assembles of cracks and usias monitorheration.

NDT services are customarily performed by work teams with access to sophisticated and designated equipment due their particular functions. The range of these services encompasses inspection, defect assessment, failure investigation, or performance appraisal. The current technological advances are exploited by these experts to assure the material conformity with class standards, reliability objectives, and protection provisions.

Essential Testing Equipment for Composites

The testing of composites is a very sophisticated affair as it concerns the determination of their mechanical, structural and dependability. The classic experiments involve the use of universal testing instruments or machines, where parameters like maximum tensile, compression or flexural strengths are measured. There are some more advanced universal testing machines that include extensometers for accurate strain reading levels during load application.

The thermal analysis equipment such as DSC and TGA are very important especially in checking heat degradation factors and other related features. Apart from that, there are industrial based non-destructive testing systems which rely on the use of ultrasonic energy to detect and locate interior defects such as disbonds or voids.

The other essential equipment for composites testing and analysis includes among others dynamic mechanical analysis (DMA) to study the viscoelastic characteristics and behaviour under different environmental conditions such as temperature and stress, while micro-CT gives an ability to see very high detailed textured images of the internal structures of the composite material. Utilization of this range of testing equipment in the process of material examination provides for an all round optimization and abidance to quality stipulations.

Laboratory Testing Services

The laboratory testing service contains a great number of analytical processes aimed to verify the effectiveness and health safety of materials, and their conformity to legal requirements. Offering better services, modern techniques like tensile, compressive, fatigue, thermal test regimes and cutting edge systems for mechanical/physical property analysis evaluation are made use of in laboratory. Methods such as ultrasonic examination and radiography are used to find flaws without destructing the material. In addition to that, composition assessment methods like spectroscopy and chromatography are often employed in the characterization of a material. Such services are essential in many sectors as they ensure that products are made to the specified quality.

ASTM Standards for Composite Testing

The ASTM standards for testing composites stipulate the method and conditions under which the material properties, mechanical integrity and effectiveness of composite materials can be evaluated. For mechanical properties, standards such as ASTM D3039 that deals with tensile behaviour of polymer matrix composites and ASTM D7264 which tackles flexural behavior are included. Thermal analysis methods include ASTM E1356, glass transition determination and ASTM D3418 for melting beahviour determination. Besides this, ASTM D7137 test method provides a way to when resistance to impact damage is challenged and eventually leading to the levels at which a component is expected to fail. These standards provide consistent methods that are reproducible and precise and obey the policies on quality control upheld in of the aerospace construction and automotive energy industries and do across others. Best practice standards assure standardization in stress testing of materials in both steel static and steel dynamic performance.

Reference Sources

-

Intertek – Composite Materials Test Methods: Covers testing for thermoset and thermoplastic composites, laminates, fiber-reinforced composites, and more.

-

Aerospace Testing International – A Guide to Composite Materials Testing Techniques: Discusses a range of mechanical tests like tensile, compressive, and shear tests.

-

Instron – Composites Testing: Provides insights into mechanical tests such as tensile, compression, and bending, adhering to ASTM and ISO standards.

-

CompositesWorld – Composites Materials Testing: A trusted source for news and information on fiber-reinforced composites manufacturing and testing.

-

AddComposites – Mechanical Testing of Composites: Focuses on tensile testing and other fundamental mechanical tests for composite materials.

Frequently Asked Questions (FAQs)

Q: Composites Testing: What Is It Needed for?

A: Composites testing involves testing the mechanics and useful features of Composite materials. They consist of two or more distinctly different materials. Without it, sectors such as aerospace, car making, and building would not meet the required safety and functional levels. This allows the manufacturers of polymer matrix composites to bend the design for efficiency and strength.

Q: What Problems Commonly Arise During Composite Testing?

A: Problem Composites testing can become difficult due to several reasons. Some of these reasons include different material properties, the presence of special test fixtures for composites, and inability to reproduce the actual conditions in the lab. Moreover since composites are anisotropic in nature, testing has to consider this property which makes these results hard to understand.

Q: What is tensile testing of composite materials, how is it done?

A: Tensile testing is considered as one of the primary techniques in composite testing that helps in determining the stiffness and the everlasting capacity of substances. In this method, the composite sample is loaded uniaxially to its breaking point. The response of the material under load is represented by tensile strength, modulus of elasticity, and elongation at break, making them very useful parameters.

Q: How important is it that polymer and matrix composite materials possess a short beam strength?

A: Short beam strength of polymer matrix composites is an important design parameter that quantifies the ability of the material to withstand shear forces through its thickness. In this test short-beam strength is evaluated by loading a composite beam that is supported at its ends in order to determine the magnitude of shear strength when bending is beyond the limits. It is also helpful in determining the ability of composite materials for different applications.

Q: In the area of composite testing, when are different fixtures used?

A: Composite test fixtures are specially made, laboratory devices whose function is to hold composite samples firmly during test efforts. They are crucial in ensuring the test results are not only accurate but also repeatable. This includes meeting the special properties and shapes of various materials with suitable fixtures, such as those used in tensile and compression testing, which may vary in design and features.

Q: Where do these testing laboratories fit in composite testing?

A: Testing laboratories have a significant importance when it comes to trainings in the area of composite materials. Such wild results require robust and laborious testing that is only possible in laboratories. In such laboratories, various tests, among them tensile, compression, and shear, are conducted to establish the mechanical behavior of composites. Also, they aid in the formation of guidelines on testing procedures, which is important for the uniformity of results from different materials.

Q: What is the difference between composites due to how they are made and other materials?

A: Composites often have a better performance in terms of strength-to-weight ratio than conventional materials since they are engineered. Each material’s properties that should be enhanced for performance purposes are put together in a composite which Disappears its presence’s weight. For this reason, they find themselves in products where the weight has to be kept to a minimum, for instance many elements found in the aviation and motor industries.