Instrument And Equipment Wholesale

2025 Compression Testing Machine: High-Precision Automation Solution

Welcome to China's leading provider of compression testing machines, which delivers top-tier solutions for material testing needs. As a trusted compression testing machine manufacturer, we specialize in designing and producing advanced equipment that ensures precision, durability, and reliability for various industrial applications.

What Is A Compression Testing Machine

-

A Compression Testing Machine (CTM) measures the compressive strength of materials by applying a controlled load until failure.

-

Used in construction, packaging, and material testing for concrete, metals, plastics, and more.

-

Available in manual, digital, and fully automatic models with varying capacities.

-

Ensures material quality, safety, and compliance with industry standards.

-

Applies force to test material behavior under compressive loads, recording data for analysis.

2025 Trends in Compression Testing: Servo-Control Systems and AI-Driven Analysis

The current situation in compression testing will, in the year 2025, see the combined forces of servo-control systems on one hand, and AI-based data processing on the other. The servo-controlled testing machines are precision equipment able to administer adjustments in real time relating to how loads are applied, plus some test parameters themselves.

These developments become quite important in the concrete test during construction work and also with the test of battery casings in the automotive field. AI-enabled software affords an even quicker data analysis, predicts material behavior, and thus speeds up decision-making. These advanced machines carry out testing with strict adherence to set industry standards, as well as in the selection and processing of materials for their design.

Essential Tests You Can Perform with a Compression Testing Machine

Discover our Compression Testing Machine's wide range of testing capabilities. This advanced material testing equipment enables detailed analysis of various materials under controlled conditions, providing essential data for research, development, and quality assurance in industries worldwide.

Compressive Strength Test

This test determines the maximum load a material can withstand before failure. It is widely used in construction to assess the strength of concrete, metals, and other load-bearing materials.

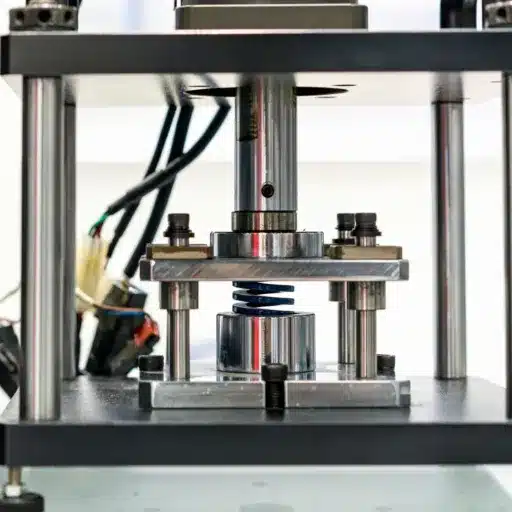

Spring Performance Test

Measures the elasticity, load capacity, and deformation of springs, critical for mechanical and automotive applications.

Packaging Compression Test

Evaluates the durability of packaging materials like cardboard and plastic under stacking and transport loads, ensuring product safety during shipping.

Cyclic Load Fatigue Test

Analyzes material endurance under repeated compressive forces, identifying potential fatigue and long-term durability in various industries.

What is the use of compression testing machine?

- Measures the compressive strength of materials like concrete, metals, and plastics, helping industries assess durability and structural integrity.

- Ensures packaging materials like cardboard and foam withstand stacking and transport stresses, preventing product damage.

- Tests springs and mechanical parts for elasticity, deformation, and load-bearing capacity, ensuring reliability in various applications.

- Analyzes medical devices, automotive components, and consumer goods under pressure to maintain safety and functionality.

- Simulates repeated stress to predict material fatigue and evaluate long-term durability under cyclic loading conditions.

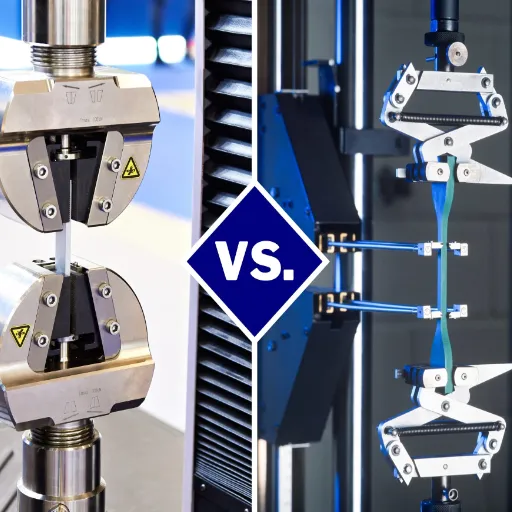

What is the difference between a tensile test and a compression test?

- Tensile tests apply force to pull a material apart, while compression tests apply force to press a material together.

- Tensile tests identify ductility and elasticity, whereas compression tests assess compressive strength and susceptibility to crushing.

- Tensile testing often results in material elongation or fracture, while compression testing causes deformation or buckling.

- Tensile tests evaluate a material's ability to resist stretching, while compression tests analyze its resistance to compressive forces.

- Tensile tests are used for flexible materials like metals and plastics, while compression tests are ideal for brittle materials like concrete and ceramics.

Videos Related to Automated UTM

Components of CTM

Choose from a variety of controller packages, grips, fixtures, chambers, extensometers, and more, all designed to perform thousands of ASTM, ISO, EN, DIN, and JEDEC industry-standard test methods. When you are ready to complete your system, contact us, and an application expert will help you optimize it for your testing requirements and budget.

View our Compression Testing Machine Price

Top compression testing machine tailored for you, our advanced technology provides reliable quality efficiently and professionally.

Pellet Compression Testing Machine

The Pellet Compression Testing Machine measures the compressive strength of iron ore and other pelletized materials. With precise electronic controls, it features a robust dual-column design and compliance with international standards. Ideal for mining, metallurgy, and quality control.

Electronic compression testing machine

The Electronic Compression Testing Machine measures material compressive strength with precision. Ideal for concrete, metals, and polymers, it features a digital display, user-friendly controls, and durable construction. Suitable for quality control, research, and structural validation.

Compression Testing Machine 2025 Data Overview

| Parameter | Description |

|---|---|

| Load Capacity Range | Machines available with capacities ranging from 1000 kN to 3000 kN, suitable for diverse testing needs. |

| Testing Versatility | Capable of testing concrete, metals, polymers, ceramics, plastics, and more. |

| Accuracy and Precision | ±1% accuracy with digital displays providing precise measurements for all tests performed. |

| Environmental Conditions | Operates effectively in lab and field conditions, with protective enclosures for high-dust environments. |

| Software and Automation | Advanced options include automated preload calculations, software for data collection, and integration with PCs. |

| Speed Range | Adjustable speed range from 0.01 to 500 mm/min for different testing requirements. |

| Crosshead Travel | Adjustable travel distance allowing tests on various specimen sizes and heights. |

| Extensometer Integration | Compatible with extensometers for detailed strain measurements during compression testing. |

| Power Supply Options | Available in 220V or 380V configurations, with single-phase or three-phase options. |

| Safety Features | Equipped with overload protection, emergency stop functions, and piston travel limiters. |

Technical Specifications: Compression Testing Machines

| Parameter | Specification |

|---|---|

| Load Capacity Range | 1000 kN to 3000 kN |

| Accuracy | ±1% |

| Speed Range | 0.01 to 500 mm/min |

| Testing Versatility | Concrete, metals, polymers, ceramics, plastics |

| Software Integration | AI-driven analysis, automated preload calculations, and real-time data monitoring |

| Safety Features | Overload protection, emergency stop functions, piston travel limiters |

| Power Supply Options | 220V or 380V configurations, single-phase or three-phase |

Why Choose Our Compression Testing Machine Manufacturers

Recognized for delivering Compression Testing Machines within precise tolerances, we focus on your needs to integrate the solutions with your systems. Our machines incorporate modern technological features like digital readouts, software automation, and reliable loaders with a range of up to 3000 kN, which assures accuracy and reliability of results for a wide range of materials.

Our compression testing machine manufacturers guarantee unrivaled relief with unmatched customer assistance, cutting-edge technology, and manufacturer support that incorporates overload safety equipment, alternate testing preferences, enhanced usability, etc.

Case Study: Enhancing Building Material Testing Accuracy by 15%

For the betterment of quality control, the leading construction company has installed an AI-operated compression testing machine to test concrete for compressive strength. This system, with its advanced data acquisition technology, also implements real-time monitoring to obtain extremely accurate and reliable test results. Thanks to the use of these advanced features and implements, the company claims a 15% increase in test accuracy, which greatly enhances the accuracy of the material selection process and guarantees the best performance from construction materials.

Further, they describe the better testing to have minimized material wastage, which contributes to cost-cutting and hence environmentally friendly construction methods. Integration of AI into this system also helps minimize time-consuming activities, such as data analysis and compiling reports, which is a boon to the process of acquiring project approvals and quality assurance criteria. Being in line with strict safety norms and reducing the project delays have set the pace for the company to take an early lead in implementing state-of-the-art technology in construction.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Expert Insights on Compression Testing Machine

What is a Compression Testing Machine used for?

A Compression Testing Machine measures the compressive strength of materials like concrete, metals, ceramics, and plastics. It is essential for quality control, material research, and structural safety validation in industries such as construction, metallurgy, and manufacturing.

How accurate are these machines?

Modern compression testing machines feature digital displays with accuracy levels of ±1%, ensuring precise and repeatable results. They comply with international testing standards, making them reliable for high-stakes applications.

Can Compression Testing Machines test different materials?

Yes, they are highly versatile. Whether you need to test concrete cylinders, metal blocks, or polymer samples, these machines accommodate a wide range of materials with adjustable load capacities and customizable fixtures.

What safety features do they provide?

Advanced models come with safety features like overload protection, emergency stop buttons, and piston travel limiters. These ensure the safety of users and the equipment during high-pressure testing scenarios.

Are software options available for data analysis?

Yes, many machines integrate with intuitive software systems that record and analyze data. These software tools provide automated reporting, preload calculations, and interface compatibility with PCs for streamlined workflows.

What should you consider when buying a Compression Testing Machine?

Key considerations include load capacity, testing versatility, precision, safety features, and power supply options. For specialized needs, look for models with extensometer integration and software compatibility for advanced analysis.

Blog Related to Servo Compression Tester

Insights from ASTM Standards for Compression Testing

ASTM D695: This standard concerns the compressive properties of rigid plastics, offering all data that are important to compressive strength, modulus, and strain. The standard makes sure that there is consistent performance of the materials with respect to structural and mechanical applications and thus helps industries in selecting materials that meet well-defined load-bearing requirements.

ASTM E9: Being intended for metallic materials, this standard describes the methods of determining compressive strength, modulus of elasticity, and yield behavior. It, hence, assures accuracy and reproducibility of results so that the material may be developed for structural and engineering applications.

Understanding the Working Principle of a Tablet Compression Machine

Tablet compression machines come in handy in the pharmaceutical industry wherein powders are turned into uniformly shaped and compact tablets. The workflow basically involves die filling, material compression with punches, and tablet ejecting. The key components, including hydraulic systems, maintain constant pressure; control systems will keep track of punch force, punch speed, and so forth. The machine is essential for making excellent tablets that conform to stricter regulatory guidelines.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

For comprehending the mechanical properties of metallic substances, ASTM E9 is still a significant standard for researchers, engineers, and manufacturers. […]

The crush strength of catalyst pellets is a critical property affecting the performance and lifetime of catalysts in various industries. […]

Catalysts have been a vital contributor in many industrial processes. They can enhance efficiency, and these are quick reactions brought […]

Where the measurement of strength and behavior of materials is the standpoint of material science and engineering, tensile and in-compression […]

Knowledge about strength and durability is very important from construction to manufacturing. The compression test is basically concerned with studying […]

Ensuring the best performance for your engine is one of the keys to the life and efficiency of your vehicle. […]

Knowing the mechanical characteristics of a material is important in understanding for what purpose it may be used. For rigid […]

With concrete serving as the essential building block for bridges and even skyscrapers, it is indeed a cornerstone of construction […]

Get a Quote for Your Compression Testing Machine Today

Looking for a reliable, high-precision Compression Testing Machine? Partner with a leading manufacturer trusted by global industries for superior quality and innovative technology. Whether you need robust testing for materials or advanced customization, we provide the perfect solution. Contact us now for a tailored quote!

Frequently Ask Questions

Q: What is a compression testing machine?

A: A compression testing machine, often a type of universal testing machine, is specialized material testing equipment designed to evaluate a material’s strength under compressive forces. It’s ideal for testing materials like concrete, metals, and plastics, ensuring they meet quality standards for industrial applications.

Q: How does a compression testing machine work?

A: The machine applies controlled compressive forces to a sample using a hydraulic or servo-controlled system. It measures the material’s response, including compressive strength and deformation, providing critical data for mechanical testing solutions in construction, manufacturing, and research.

Q: What materials can be tested with a compression testing machine?

A: This material testing equipment can test a wide range of materials, including concrete, metals, polymers, ceramics, and composites. It’s perfect for assessing material durability and performance in load-bearing applications.

Q: What is the difference between a compression and tensile test?

A: A compression test evaluates a material’s ability to withstand squeezing forces, while tensile strength testing measures resistance to pulling forces. Both tests are essential for understanding material behavior, often performed using a universal testing machine.

Q: How accurate are compression testing machines?

A: Modern compression testing machines are highly accurate, with precision load cells and advanced software ensuring reliable results. They meet global standards, making them trusted for quality control solutions in industries like aerospace and construction.

Q: Can a compression testing machine perform bending tests?

A: Yes, many universal testing machines are equipped to perform bending tests, also known as flexure tests. This measures a material’s stiffness and strength under bending stress, crucial for materials used in beams or structural components.

Q: What industries use compression testing machines?

A: Industries such as construction, automotive, aerospace, and manufacturing rely on mechanical testing solutions like compression testing machines. They ensure materials meet safety and performance standards for applications like building structures, vehicle parts, and more.

Q: How do I choose the right compression testing machine?

A: Consider factors like load capacity, testing speed, and material type. Look for a machine with versatile features, such as compatibility with tensile strength testing and bending tests, to meet diverse material testing equipment needs for your industry.