Catalysts have been a vital contributor in many industrial processes. They can enhance efficiency, and these are quick reactions brought about by enhanced molecular interactions. But then again, their performance and life span greatly depend on their mechanical strength. Here arises the need for a catalyst crush test. Measuring the crush strength of catalyst particles helps ensure that the physical stresses of handling, transport, and operation within reactors can be borne by the materials under consideration. The article looks into crush strength and its big role in industrial applications, catalyst strength, and compression testing machines as a working instrument for measuring the durability of catalysts. To any person interested in improving their production efficiency or material reliability, then understanding these types of tests is a must. Read all the way through for key insights and best practices in the catalyst compression test.

Introduction to Crush Strength

Definition of Crush Strength

Crush strength is a property possessed by a material, often in the form of pellets, granules, or other solid structures, that allows it to resist cracking or deforming when put under stresses from compression. This property is important in many applications, especially for such materials as catalysts, which must not collapse under pressure during their actual working application.

Understanding crush strength is crucial so as to guarantee performance and durability under actual demanding conditions. In catalytic applications, for example, materials are subjected to very harsh conditions of pressure and mechanical stress. The crush strength of a material, therefore, is the measure of its resistance against these forces and hence greatly affects its efficiency, its life, and even its operating capacity.

Crush strength offers valuable insight into the evaluation for quality and suitability of a material for industrial purposes. Its measurements usually require the application of a controlled pressure until failure; thereby, the performance characteristic is evaluated by design or by performance. This helps with the optimization of material selection, process improvement, and consistent reliability in actual applications.

Significance of Crush Strength in Material Performance

The concept of crushing strength concerns how long a material may withstand external loads without losing mechanical properties under load. In brief, crush strength is the ability of a material to resist external pressures without undergoing harmful deformation, which ultimately attests to its real-time applicability. If one views it practically, materials used for construction, packaging, and transportation would have to meet minimum requirements for crush strength, as they are routinely subjected to certain stresses.

Industries employ these precise cracks strength results to improve product quality and safety. Based on how the material behaves under pressure, engineers can then make decisions regarding the design and materials used for an application so they correspond to the precise demands of that application. Thereby, it minimizes the possibility of failure under mechanical loads, augments efficiency, and saves on long-term repairs and costly operational interruptions.

On top of that, having the capability to assess crush strength offers the chance for optimization during manufacturing. Testing guarantees that the materials meet the predetermined standards and regulatory requirements, thus decreasing the variability and increasing the overall product consistency. Having that assurance on material behavior promotes the trust in and the reliability of all the industries such as construction, automotive, and aerospace where safety to the public and performance are at stake.

Overview of ASTM Standards Related to Crush Testing

An ASTM standard related to crush testing describes the methods and specifications regarding the strength, durability, and performance of materials when subjected to compressive forces. These standards enable the materials to meet safety and quality benchmarks across various industries. Adherence to ASTM standards allows manufacturers and engineers to have consistent and reliable test results, which further aid them in selecting materials and design.

One of the many standards cited in reference is ASTM-D695 based on which methods for measuring compressive properties of rigid plastics are specified. Such a test is vital for determining the behavior of a material under loading, including its modulus of elasticity, yield strength, and ultimate compressive strength. A similar test may be ASTM-E9-the unaxial compressive test for metallic materials-so as to provide information that may be used to verify whether particular metals fulfill specific requirements of structure and mechanical performance for given areas of application.

These standards fix the procedures for conducting crush tests, giving parameters to consider such as preparation of samples, test speed, and mode of data analysis. If these tests are under uniform parameters, discrepancies among results are reduced; such enables fair comparison and acceptance of standards across industries. Upholding such ASTM standards ensures that materials are tested accurately and in a consistent manner, thus making for a safer and more efficient engineering practice.

Catalyst Crush Testing Machines

Types of Crush Testers

Catalyst-crushing testing is generally categorized into two broad types based on their functions and applications: crush testing of single particles and crush testing in bulk. Each type plays a very specific role in determining the mechanical strength of catalyst material.

Single-Particle Crush Testers

Single-particle crush testers measure the force necessary to crush one catalyst particle. This is mostly used for testing the strength of small uniform particles and making sure that processing conditions do not break them down.

Bulk Crush Testers

The bulk crushers test the strength of a large group of catalyst particles under compressive force. This method resembles industrial conditions where catalysts are subjected to pressures in bulk and thereby assures the material’s reliability when under operational stress.

Both types of testers are important for ensuring catalyst material durability and operational efficiency.

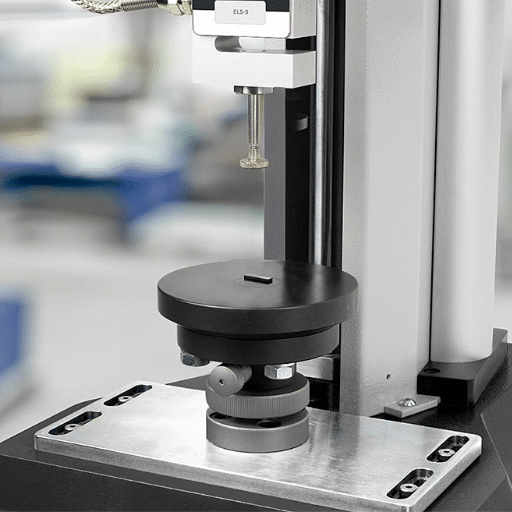

Functionality of Compression Testing Machines

Compression testing machines test the mechanical strength and measure the material’s durability under force applied on them. They are largely used to ascertain the performance of materials under forces working on compression so that they comply with the standards demanded for particular applications. These machines put pressure on samples until these become deformed or until failure occurs, thus giving information on the load-carrying capacity of the material.

Hence one way that compression testing machines play a key function in the industries is by determining the compressive strength of materials and industries such as construction, manufacturing, and chemical processing. By determining the amount of stress a material can withstand and still fail, these machines help estimate how well the material will fare under real-life conditions. This kind of test is especially important for materials used as structural support, such as concrete, composites, and catalysts in industrial processes.

Another important functionality is identifying deformation characteristics, such as elasticity and plasticity, under compressive forces. This information allows engineers to assess how materials will maintain shape and stability under pressure, which is vital for designing safe and efficient systems. Compression testing machines are absolutely fundamental for testing and ensuring the quality of a variety of materials across many applications through accurate and reproducible results.

Application of Universal Testing Machines in Crush Tests

Universal Testing Machines play the primary role in crushing tests, which are used to assess damage and performance in various materials and products. These tests carry out the ability of a given material to sustain compressive forces. Accordingly, many might insist that these tests measure whether a certain material or component will withstand pressure or present a danger to the public. The crush tests will be performed in industries such as construction, packaging, and manufacturing, where strength and durability are essential.

In a crush test, the UTM is used for applying force to the test specimen by means of compression and for measuring deformations and points of failure. The information gleaned from this test can be used by engineers and manufacturers to determine some material properties, such as ultimate compressive strength and deformation behavior. This data is useful either to optimize materials for a given purpose or to design materials that shall meet a specific requirement, be it for a load-carrying capability or a crushing resistance for instruction under certain conditions.

The UTM being very versatile makes it a great machine to attain crush tests on metals, plastics, ceramics, and composites. The critical factor is that it should provide an accurate and repeatable result upon which quality assurance programs depend and are compliant with safety standards. Bringing improvements to a material and innovative new developments in materials and designs can be achieved with the use of UTMs in crushing testing.

Methods of Crush Strength Testing

Laboratory Equipment for Crush Strength Measurement

The force of crushing is applied to break a material or deform it, and it requires instruments to measure with precision, the force so applied. Among the key laboratory equipment are universal testing machines (UTMs). These versatile machines are used for performing crush, tension, and compression tests. They are equipped with load cells to enable measurements with reliability and repeatability, so they are indispensable when evaluating a material’s performance.

Sometimes, special fixtures are fitted to the UTM equipment to hold samples of specific shapes such as cylindrical or rectangular. These fixtures grip the sample rigidly to ensure accuracy of force application during the test. Such considerations make the equipment useful to a range of industries from construction through to automotive and packaging.

The main testing equipment typically offers interfaces for several additional tools to enable the actual recording of data. Such software packages analyze the test data obtained and provide detailed information on the different facets of material performance. With such tools in place, the crush strength test carries the promise of accuracy, thus aiding research and furthering quality control.

Industry Standards: ASTM D4179 and ASTM D7084

| Standard | Focus | Application |

|---|---|---|

| ASTM D4179 | Single particle crush strength | Spherical or cylindrical particles, catalysts and powdered materials |

| ASTM D7084 | Bulk crush strength determination | Collection of materials, bulk form resistance |

ASTM D4179 and ASTM D7084 are two very familiar standards for measuring crush strength of materials, mainly in construction, packaging, and the like. ASTM D4179 concerns mainly the crush strength of catalyst particles with a single particle. This standard considers spherical or cylindrical particles and subjects them to varying forces to understand better the ability of the material to withstand it, which is a key piece of information for the sustainability of the material. Testing under this standard guarantees that the process and method of testing a material will be the same and standard for industries involved in catalysts and powdered materials.

By contrast, ASTM D7084 defines procedures for bulk crush strength determination of a given collection of materials. It measures the pressure to bring about definite mechanical failure or deformation across a bed of particles. The standard is chiefly used in industrial applications where particles must be able to resist collapse under load in bulk form, thereby enabling the manufacturers to fine-tune the material characteristics for performance and reliability.

Both standards are equally needed to secure quality assurance and consistency in industries. These protocols enable companies to ensure that their materials comply with requisite mechanical property criteria, decrease the failure rates of the materials concerned, and thus enhance the safety and efficiency of products. The adoption of ASTM D4179 and ASTM D7084 tests indicates the importance of these tests in ensuring enhanced methods of material testing and quality control.

Step-by-Step Process of Conducting a Crush Test

-

Preparation

Starting with sample preparation according to the test procedure, ensure that the material sample meets specifications for dimensions, cleanliness, and conditions (if any) as per ASTM D4179 or ASTM D7084 standards. The accuracy and reliability of results depend upon proper preparation.

-

Test Setup

Install the sample in the testing apparatus, ensuring that the sample to be tested lies perfectly aligned, avoiding errors during testing. The equipment used shall be compliant to the standards mentioned herein and shall be calibrated to record force accurately. Set the apparatus to apply a compressive force controlled and steady on the sample.

-

Performing the Test

The test starts by applying a force at a specified rate. Watch the instrument to guarantee force application uniformly across the specimen. Observe the sample for failure-cracking or deformation. The data from the testing process, including maximum force applied, are recorded for analysis.

-

Analyzing Results

Once the test has been completed, analyze the data to obtain the crush strength or durability of the material; compare the result against required limits or standards, if any, to check compliance, and prepare complete documentation of the findings for quality assurance.

Depending on the above, a manufacturer will be able to assess material properties using crushing tests that ensure production of dependable, high-grade, and safe products.

Factors Affecting Crush Strength

Material Composition and Its Impact

One of the factors that hugely determine crushing power includes the composition of material. A material with greater density or one with tightly bonded molecular structure generally tends to perform better under crushing pressure. For example, metals like steel or titanium are generally reputed for their extremely high crush strength in their rigid atomic arrangements, while softer materials like plastics would tend to deform very quickly under the same forces.

The presence of certain additives or even treatment may change the performance of a material. For example, the introduction of elements such as carbon would create alloys with far superior strength and durability. Metals could also be heat treated, e.g., annealing or tempering, to alter the internal structure, which presents a relatively better resistance performance to applied pressure, that is not susceptible to weakening or fracturing. Hence, such enhanced materials find their applications in heavy-duty or specialized tasks.

Finally, the presence of impurities and flaws in a material plays a significant role in decreasing its crush strength. Changes in composition, such as different fiber concentrations quarter way through a composite or inhomogeneities in concrete-air pockets, lessen the capacity of that material in resisting compressive forces. Thus, there must be stringent controls and assurance through testing during manufacture whereby composition consistency is maintained, and safety and performance standards are met by all materials.

Effects of Temperature on Crush Strength

High Temperature Effects

- Thermal expansion creating internal stresses

- Degradation in polymers and concrete

- Softening of metals reducing load capacity

- Water evaporation in porous materials

Low Temperature Effects

- Increased brittleness

- Higher likelihood of cracking

- Potential for sudden failure

- Changes in material flexibility

Being a crucial factor, temperature acts upon the crush strength of a material. At high temperatures, most materials expand thermally and thus an extra amount of internal stresses reduce their structural abilities. High temperatures would lead to degradation in some compositions such as polymers or concrete and create weakening out of the strength. Conversely, on very low temperatures, they become more brittle and hence more likely to crack or shatter under compression.

For example, in concrete, exposure to elevated temperatures can lead to evaporation of the pore water, thereby disturbing its cohesive structure and, hence, to a very great extent, compromising its strength; whereas metals soften when highly heated and, therefore, lose their capacity to resist compressive loads. Hence, this phenomenon stresses the importance of consideration of the thermal effects during material selection and structural design, particularly in areas where temperature range is fluctuating or extreme.

Consequently, to counteract temperature-induced reductions in crush strength, the material must either be engineered or modified to suit its working environment. Heat-resistant alloys, temperature-stabilized composites, and special coatings are examples of such materials for increased durability. Also, conducting thorough testings under simulated environmental conditions makes sure that a material is reliable and safe under the given temperature range.

External Conditions Influencing Crush Test Results

External conditions acquiring significance in dictating the outcome of a crush test, for the test aims to gauge the toughness and strength of materials under real conditions. Temperature, for example, is an important external condition that potentially affects the materials. An extremely high or low temperature may affect the properties of the material mechanically in such a way as to endanger its structure or reduce its resistance to compressive forces. Therefore, testing for temperature variation will give an accurate representation of how the material will perform in a real-world environment.

Another important part of the external conditions is the humidity. Some materials degrade under long exposure to high levels of moisture or periodic changes in humidity: corrosion in metals or swelling in wood-based products, for example. The greater the fidelity with which these conditions can be simulated during crush testing, the better we can spot the weaknesses and proceed with treatments or coatings that resist moisture.

Environmental pressures, including vibrations or mechanical impacts too, may affect the integrity of test results. For example, continuous shocks or stresses may be imposed on materials during transportation or operation in high-impact industries. Factoring in these variables while testing will ensure materials uphold the levels of durability prescribed for their applications. The knowledge of these external conditions, as well as their consideration during the design and testing phase, ensures greater safety, efficacy, and reliability in practical use.

Real-World Applications of Crush Strength

Importance in Construction and Engineering

The crush strength is extremely important when we talk about construction and engineering because the material must be able to resist forces without yielding under those forces. Usually, these materials undergo heavy stresses, like self-weight, dynamic loads, and environmental forces. To assure long life and safety, great crush strength is required from these materials of concrete, steel, and composites.

Crush strength basically helps engineers choose materials for specific applications in construction work. For example, building foundations and columns will have huge compressive loads imposed on them; hence the materials should be chosen such that their crush strength is really high so that they do not deform or collapse. In the same cases, in engineering, pipes, beams, and supports all must resist developing stresses. Therefore, crush strength is a very important parameter for the selection of a material.

Crush strength testing further enhances safety and reliability. Materials undergo testing under set conditions with a view to predict their possible failure modes and design structures that heed proper safety standards. Consequently, this speculating approach diminishes the incidences of stressor failures and enhances the general strength-based construction and engineering project, which must withstand demanding concert environments.

Impact on Manufacturing Processes

Crush strength testing greatly influences manufacturing processes, ensuring safety and performance requirements are met before any materials are subjected to production. The test vanquishes manufacturers from putting materials with weaknesses or inconsistency into production that could very well result in product failure during service. Through strength testing, the manufacturers can be able to pick stronger materials that will fit the purpose at hand, thus producing safer and reliable products.

Crush strength testing helps manufacturing processes ensure quality. They test the crush strength to make sure that materials of the same batch maintain consistency and meet the standards; conversely, it aids in testing for lowest yield and rejects that cannot meet the standards, thereby streamlining manufacture. Emphasizing material strength testing ensures the manufacturing of quality goods that meet both industrial and customer expectations.

Lastly, it instills some innovations in the manufacturing industries; knowing materials’ limitations and capabilities allows engineers and designers to execute new processes and technologies that require greater performance and endurance. Thus, this propels the progress of the manufacturing industry from construction to consumer goods, rendering the manufacturing industries adaptive and forward-looking.

Case Studies: Successful Use of Crush Testing in Industry

Automotive Industry Safety Standards

Crush testing chiefly works to improve vehicle safety by subjecting car frame materials to evaluation of structural integrity and crashworthiness for meeting certain safety standards. Impact scenarios are simulated so engineers may find weak points in the materials to redesign components that better shield the passengers. This development approach transformed crash safety, which nowadays works to reduce persons injured and killed on the road.

Packaging Industry Durability

The packaging sector is largely dependent on crush tests to ascertain the ability of materials to withstand transportation and storage stresses. For instance, cardboard boxes and shipping containers are tested for the amount of pressure they can take before collapsing. This allows manufacturers to design the products optimally and choose materials that effectively protect the goods while reducing waste and cost. The use of crush testing has benefited the evolution of stronger and more efficient packaging solutions.

Construction Industry Materials Validation

Build things using crush testing to ascertain the strength of materials like concrete or steel. This determination gives engineers confidence that a building or infrastructure can withstand certain loads and environmental factors, like heavy winds or earthquakes. It is through this testing that architects could produce safer and more durable buildings, leading to changes in construction technology and engineering.

Frequently Asked Questions (FAQ)

Q: What is the crushing strength unit?

A: The crushing strength unit is a measure used in order to define the maximum load a material can bear before it fails. The crushing strength unit is generally expressed as megapascals (MPa). The insert is used to study the strength of a material under compressive loads.

Q: In crushing strength tests, how is the maximum load established?

A: In the tests for crushing strength, a controlled force is applied to the specimen with the help of a strength tester or test fixture. The load is applied gradually to the point of failure of the material, from which the crushing strength of the specimen can be calculated.

Q: Is a cylinder used in the crushing strength test?

A: A cylinder is used in some cases as a test fixture in crushing strength tests. The cylinder allows testing of materials such as extrudates or single pellets by giving a uniform surface for the load application, leading to reliable results.

Q: Does crushing strength depend on the shape of the specimen?

A: Yes indeed, specimens’ exact shapes may have an important bearing on the crushing strength. The cylindrical ones may actually have a load radial strength and axial strength characteristic that differs from those on a flat form or irregularly shaped specimens, thereby affecting all such test results.

Q: What is radial crush strength?

A: Radial crush strength is the capacity of a material to withstand crushing compressive forces applied perpendicularly to its surface. This concept is applicable in considering tubes or cylinders under a load distributed radially.

Q: How do flexural tests relate to crushing strength?

A: The flexural test reveals the bending properties of a material, which shed some light on the overall strength characteristics, including crushing strength. Although flexural strength is determined differently, both tests give some information on the behavior of the material under load.

Q: What role does a transducer play in measuring crushing strength?

A: The transducers convert the mechanical load applied to a specimen into an electrical signal for precise measurement of the crushing force in testing. Knowing this all ensures accurate and reliable results.

Q: Which factors can lead to failure in crushing strength testing?

A: The potential risk factors leading to failure in crushing strength testing might include improper specimen preparation, load being applied off-center, and conditions of the environment in which tests are being carried out. It is imperative to understand these different factors to have test results that are intact.

Q: How are crushing strength tests used in assessing materials?

A: They characterize a material’s behavior under certain load conditions. This becomes important for applications such as tablet crushing or other structural applications.

Q: What is the importance of the control unit in crushing strength testing?

A: It is the control panel in crush strength testing that decides the test parameters, for example, the rate of loading, application of load to the specimen, and collection of data. It allows the test to be performed under controlled conditions with consistent and reliable results.

References

Definition of Crushing Strength – Mindat – Explains crushing strength as the pressure applied to a cube of material, often measured in pounds per square inch (psi).

Units of Measurement for Compressive Strength – Polyfoam XPS – Discusses compressive strength measurements, typically expressed in kilopascals (kPa), the SI unit for pressure.

Crushing Strength – The Wood Database – Describes crushing strength as the maximum weight wood can bear when compressed parallel to the grain.