Testing complex systems and components can often be a daunting challenge of precision, reliability, and adaptiveness to suit project needs on a case basis. A custom test fixture design paves the way for creating solutions tailored for testing purposes, thereby reducing the time required for tests, imparting efficiency, and ensuring accuracy of results. Whether you test electronic circuits, mechanical assemblies, or integrated systems, custom-making a fixture is just the answer to good measure against utility and innovation. In this blog, we are going to look at the relevance of the design of custom test fixtures, the benefits that it provides, and how its design can be modified to meet particular testing needs. So, let’s jump in and see how these testing solutions can help change your processes and push the performance of your product further.

Understanding Test Fixtures

Definition of Test Fixtures

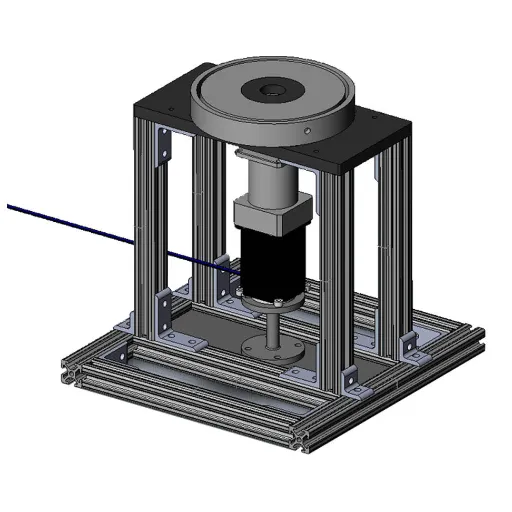

Test fixtures are crucial gadgets that engineers and manufacturers use to hold, support, and position a test subject during some procedure. In particular, force-testing fixtures are used to apply known forces to a material or component or to measure their responses to given conditions. This class of fixture is required so that secure holding of the subject occurs and a reliable setup can be made so that reliable measurements can be repeated.

The prime intent of a force testing fixture is to assess the strength, durability, and performance of a material or product. Tests normally consist of applying tension, compression, shearing, and bending forces, thereby giving a true indication of how a material or product will perform when faced with such forces in real life. Using a standard fixture gives testers a reliable basis for comparing data, which they can use to detect possible weaknesses or failures in the design.

Force test fixtures can be customized for different applications with varying needs. Depending on the size and shape of the specimen under test and the materials it is composed of, the fixture must be designed accordingly. A good fixture shall facilitate the test so that it can be performed with minimization of errors, ensuring consistency in results from test to test; it matters for safety and efficiency. These fixtures serve as major elements upon which quality control, research, and development efforts in such industries as aerospace, automotive, construction, and manufacturing are all based.

Role of Custom Test Fixtures in Testing Processes

Custom test fixtures play a critical role in force testing processes to provide accuracy, repeatability, and reliability of measurement systems. Force testing needs to be controlled in how exactly a specimen is held or positioned during testing in order not to destroy the results or create inconsistencies. Custom fixtures are engineered for that particular material or component so that it is aligned properly, is mounted tightly, and is therefore needed in order to obtain correct results.

Custom solutions are unique in their ability to cater to unusual shapes, sizes, or materials. A test sample that cannot be properly supported by standard fixtures may result in poor testing and unreliable results. Custom design confronts these issues by providing a solution that enhances both the quality of the testing procedure and the accuracy of the results obtained. This aspect becomes imperative when an industry is concerned about product safety and performance, such as aerospace or medical device manufacturing.

Besides, special test fixtures raise the efficiency of testing by abridging establishment time and the chance of operator error during test procedure. It is worth remarking that most good fixtures fit nicely with the test equipment, and this makes for very quick and easy operation. This frees more time for other activities and also makes the overall test setup safer. Custom test fixtures provide consistency between tests, therefore greatly contributing to the concepts of quality assurance and industry-standard lucidity.

Types of Test Fixtures

Force testing fixtures are specialized tools meant to measure accurately the forces being applied during a wide variety of procedures. The test specimen is firmly positioned in such devices, and they work to simulate forces that a real test may face during tension, compression, or shear. Hence, by constant application and removal of any variability, force testing fixtures ensure results that are reproducible and reliable.

Usually, force testing fixtures are used to examine materials testing, such as assessing strength, elasticity, and durability of materials. For instance, a tensile testing fixture might keep pulling on the sample until the sample fractures and gains information about the tensile strength of the material. Conversely, a compression testing fixture monitors the behaviour of materials under load. Such tests are very important in product development to ensure that the product conforms to safety and performance standards laid down by the regulatory authorities in industries such as construction, manufacturing, and aerospace.

Furthermore, force testing fixtures are essential for quality control. They provide manufacturers a way to recognize possible weaknesses and implement improvements before products can reach consumers. These test fixtures must be very precisely constructed so that tests applied to two batches of one product give the same results, so that test results can be accepted and regarded as reliable, thus building confidence in the manufacturing process and, eventually, the manufactured product itself. Being versatile and accurate, force testing fixtures help greatly in the area of engineering and production quality.

Applications of Custom Test Fixtures

Manufacturing Sector Applications

In manufacturing, force-testing fixtures contribute to the ensuring of consistent quality of products. These fixtures measure the force required to perform specific functions, such as pressing, pulling, or twisting, on the components involved. Any given particular measurement identifying a product defect or variation is so accurate that a defective or substandard product could not pass. In effect, industries involved in the manufacturing of mechanical parts, electronics, and consumer goods would require such fixtures.

The force-testing fixtures find their key use in assembly processes where they are employed during and after assembly to confirm correct fitting and fastening of parts. For example, a fixture can be employed to determine the pressure to snap or press elements together to ensure that parts are reliably fastened and will withstand operational requirements. This guarantees smooth assembly operations while minimizing the occurrence of products reaching consumers with operational malfunctions.

Force testing fixtures are very important in quality control laboratories. Testing allows engineers to simulate several force conditions that a product may be subjected to in actual use. Products can be checked for durability and performance under standard conditions, thus ensuring maximum customer satisfaction. All these applications increase production consistency, improve engineering designs, and guarantee safety standards in manufacturing.

Automotive Industry Uses

Force testing fixtures are critical in ensuring the safety and reliability of automotive components. These fixtures test parts such as brake and suspension systems and seatbelt mechanisms under various load and force conditions. Thus, simulation of real-world conditions helps engineers identify potential weaknesses in parts and ensure that they meet the safety and performance standards prior to their integration into vehicles.

Force testing also furthers the durability and efficiency of automotive design. It assists manufacturers in assessing how materials and components perform with long-term use so as to prevent failures under repeated use and environmental stresses. Testing fixtures also help optimize designs to reduce material failures further and provide macro-level enhancements in terms of fuel efficiency through the use of lightweight but durable parts.

Such force testing fixture further helps automotive companies apply various industrial regulations and standards. By subjecting a component to a rigorous set of tests to validate their performance against safety requirements, these companies instill public confidence. This procedure serves both to protect the end-user and to ward off expensive recalls and claims, thereby working for a more dependable and competitive automotive industry.

Aerospace Testing Requirements

Force testing fixtures play a primary role in aerospace testing whereby it assures the durability, reliability, and safety of components during operational life. These test fixtures simulate the escalating forces that aerospace parts are exposed to, like high loads, vibrations, and thermal stresses. In applying enforceable forces, materials and components are examined under close consideration of their integrity and performance before going out in the field.

The main objective behind force testing in aerospace applications is to achieve stringent safety standards and regulatory requirements. The airframe, the engine parts, and the control systems are tested so that they cannot be brought into operation until these tests demonstrate that all these components withstand various mechanical stresses without failure. Force testing fixtures provide these measurements and repetitive results so that engineers may locate the weaknesses and modify the designs with another security standard.

The use of force testing fixtures minimizes risk during operation, as well as keeping operational failures to a minimum. This assures safety for both passengers and crew while improving the service lifeability and reliability of aerospace systems. Performance validation through force testing allows the aerospace community to focus on innovation while ensuring the highest level of safety and efficiency.

Benefits of Customizing Force Testing Fixtures

Improved Adaptability to Unique Testing Requirements

Force testing fixtures are customized to ensure they meet the particular requirements of some aerospace testing scenario. Standardized force testing fixtures may not allow special component designs or complex operating requirements, leading to inaccurate results or inefficiency. When testing fixtures are tailored to the exact parameters of a test, they allow for variables such as component size, configuration, and force distribution to be properly accounted for in giving more precise data.

Enhanced Accuracy in Measuring Forces

Force testing fixtures act as an instrument for precise and reproducible measurements performing varied tests. They are designed and developed to maintain specimens rigidly within their respective planes, basically aligning the forces and measuring them by force transducers accurately. The disregard for inconsistency caused by unremitting interference or misalignment drastically increases the test results.

Testing Across a Wide Range of Specifications

Force testing fixtures are designed in many ways and so they remain of a very versatile nature, and able to encompass needs from different industries. These fixtures can be adjusted to test force ranges, from the very small forces applied to delicate components to the big forces applied to heavy-duty materials.

Able to accommodate the specific tests of novel designs and new materials in aerospace engineering; as the technology advances, new testing requirements will appear, hence compelling tools to align with the new testing protocols. Custom fixtures give the flexibility to go along with new testing requirements, hence assuring efficient testing and trustworthy results as industry requirements get more complex.

Lastly, bespoke force testing fixtures offer seamless integration with existing testing set-ups. Interface with present equipment or conform to given test standards, such can never make operations inefficient or too expensive. This flexibility only boosts the reliability of the test results while making critical tests less prone to human error.

Other aspects that influence the accuracy of measurements include the switchability of testing fixtures for particular testing scenarios. Adjustable designs enable the apparatus to accommodate basically shaped specimens or special applications and can even provide perfect alignment during testing. This, again, reduces the chance of error entering measurements and increases the chances that the results reflect the real performance of tested materials or components.

Finally, force-testing fixtures are often integrated with advanced measuring tools, such as sensors or a digital testing system. This integration reduces human errors and gives the highest accuracy through automatic and consistent data collection. Stability, on one side, customization, and on the other side, technology, provide improved accuracy, which makes these fixtures indispensable in respect to industries with reliable force measurements.

This ability guarantees any manufacturer to test the performance, safety, and durability of a product permanently under specific conditions, irrespective of the application.

One prime benefit of force testing fixtures is that they cater to the various types of materials under test and different geometries thereof. Should the item be rigid or flexible, or even small or large, these fixtures assure utmost accuracy through their configurations and grip-fitting possibilities. Possessing these attributes enables them to render services to industries like aerospace, automotive, medical devices, and consumer goods, wherein product requirements very often might radically vary.

Furthermore, test fixtures allow for the testing of different load parameters such as tensile, compression, and shear forces. This ability ensures comprehensive testing, thereby providing valuable data that manufacturers can use to improve product quality. By accommodating a broad spectrum of parameters and test criteria, these fixtures are vital in ensuring that products conform to industrial specifications and consumer expectations.

Design and Manufacturing Processes

Initial Design Considerations for Custom Fixtures

The first considerations in designing any custom force testing fixture should be the intended application of the fixture, the compatibility of materials, and the testing parameters involved. The gross design is based on the common application of the fixture. In its simplest terms, the fixture must withstand the appropriate force, whether tensile in nature, compression, or shear. Having such a clear objective will allow a compatible fixture to be designed against the testing of the product or material in question.

Material compatibility is another very important consideration in the design of the equipment. The materials chosen for the fixture should never interfere with the test results nor allow deformation during testing. For durability and precision, it is common practice to choose high-strength, non-deforming materials. Assessing the chemical and physical properties of the test specimen would help avoid any reaction or mismatch during the testing process.

Finally, test parameters must be carefully defined so that the fixture can take into account parameters such as load ranges, sample size, and other environmental conditions. An adjustable or modular design could allow testing different specimens; wherever applicable, the alignment of the sample should be precise for consistent and accurate force application. Careful assessment of such factors at the design stage will serve to meet both the technical requirements and long-term reliability of the completed fixture.

Material Selection for Durability and Performance

| Material Type | Properties | Applications |

|---|---|---|

| Stainless Steel | High corrosion resistance, durability | Adverse environmental conditions |

| Aluminum | Lightweight, easy handling | Assembly and lightweight applications |

| Tool Steels | High hardness, wear resistance | Heavy-duty, high-impact applications |

| High-Performance Polymers | Chemical resistance, lightweight | Specialized chemical environments |

Proper material selection for the force testing fixture ensures durability, precision, and consistency in its performance. The materials must be able to endure the application of repeated mechanical stresses without any deformation, wear, or destruction. Metals are usually preferred by virtue of their high strength and resistance to fatigue. Stainless steel is highly resistant to corrosion and is generally chosen in circumstances where fixtures would be exposed to adverse environmental conditions, while aluminum is a lightweight alternative aiding in its facile handling and assembly.

Higher hardness or wear resistance properties may be needed for components that tool steels and must be heat-treated metals. Stability under prolonged usage is ensured by these materials, whereas structurally, they maintain integrity even under high load, impact, or a sudden shock. For heavy work, non-metallic materials like high-performance polymers and composites could also be selected. These, however, may lack long-term strength and rigidity and should be considered carefully with the intended use of the fixture.

Proper surface treatments or coatings can generally increase material performance, mainly in terms of friction reduction, corrosion protection, or wear resistance. Protective coatings such as anodizing, for aluminum, or plating, for steel, are able to extend the life expectancy of the fixture. In the end, it always comes down to selecting the materials that best fulfill the operational demand for strength, longevity, and environmental suitability to realize a force testing fixture that can readily accomplish its intended use.

Final Production and Quality Assurance

The final production phase of force testing fixtures focuses on such areas as precision, durability, and engineering specifications. Manufactures using CNC machining or additive manufacturing are chosen, depending upon the specific tolerance and material integrity desired. Each individual component will pass through the standard quality process to confirm conformance with required dimensions and strength, as well as with the test fixture’s functional purpose, while returning components that do not meet these standards.

Exceptionally comprehensive testing of the functionality of the mechanical and environmental specification by which the fixture performs ensures the quality of the assurance. The same set of criteria goes through load restrictions, measuring dimensional accuracies, and conducting repeated test cycles mimicking actual use conditions. In addition, surface protections or coatings are checked to ensure that they are capable of resisting the required cases of wear, corrosion, or environment. The primary aim of these steps is to ensure that the fixture remains entirely reliable and functional throughout its operational lifetime.

Combining high-precision production methods and quality control enables manufacturers to develop force test fixtures that will give accurate results every time. These are critical components in test setups, as safety is ensured, with assurances that tests are run under reliable circumstances to evaluate the materials’ properties or test performances under conditions of applied forces. End-users can rely on the final fixtures that meet industry standards and efficiently perform in rigorous environments.

Impact on Testing Accuracy and Efficiency

Improving Testing Accuracy with Custom Fixtures

Force testing fixtures provide an integral role in making sure that the material or component testing is truly accurate by producing consistent and repeatable results. They custom hold the test specimens in such a manner so as not to risk their slippage during testing or misalignment. Fixtures thus applied with utmost accuracy as per test parameters help direct and measure the forces properly in order to yield data that have absolute reliability, which are then taken into consideration for narrowing down and making decisions.

Moreover, custom fixtures: from another aspect of view, bring streamlining and faster capability to the testing procedure. By adapting the fixture to the exact dimensions and properties of the material or product, test setups become much more streamlined, thereby saving lots of time that would have otherwise been spent on adjustments or reconfigurations. This efficiency becomes a shared value in high-throughput arenas wherein a large number of samples must be subjected to tests under identical conditions.

During testing, force fixtures provide safety in custom applications. Safe fixtures appropriately secure a specimen, thus reducing the risks that create instability and injure testing equipment or operators. Through the use of custom fixtures, companies can achieve improved accuracy while ensuring smoother operations and upkeep of industry-standard requirements that promote safety and performance.

Greater Efficiency in Testing Workflows

Force-testing fixtures are the cornerstone for any testing procedure in delivering repeatable and reliable results. These are specially made fixtures to hold the specimens during the test in a manner customarily accepted to reduce ambiguity caused by incorrect alignment or movement. Ensuring uniformity encourages less setup time and spur testing workflows; chances for delays and loss of productivity are thereby minimized.

Custom fixtures can be designed as required, considering the testing needs, thereby maximizing efficiency of the equipment to be tested so as to be closely aligned to an industry standard with little chance of an error in it. These fixtures are made so that they cater to different specimen forms, shapes, and materials. This high level of precision provides greater accuracy to the tests, without the need to keep adjusting or interfering manually.

Moreover, the safety of the operations can be improved by force testing fixtures, while the possibility of incorrect results is decreased, thus contributing to cost efficiency in the long run. Fixtures ensure that the specimens being tested remain stable and cannot move. This reduces disruption downtime caused by welding or calibration on the test equipment. So, with a single investment in sturdy fixtures, companies will be able to depend upon a consistent level of performance, while keeping workflow interruptions to a minimum due to strict quality regulations and safety standards.

Enhancing Overall Product Quality

Enhancing product quality through force testing fixtures plays a great role in assuring accurate and reliable test results. These fixtures hold components or materials during force-testing procedures that measure strength, durability, and performance. The less variability resulting from movement or misalignment, force-testing fixtures deliver consistent and repeatable results, letting the manufacturer catch any possible defects in the product. Such an emphasis on accuracy cascades into outcomes of finer quality.

The force testing fixtures buy some time for the products to get ready for quality scrutiny. It’єstablish accidental real-life conditions or simulated forces, stresses, and vibrations that the product may undergo during its lifespan so that manufacturers and prospective buyers can identify weak points and rectify the design. This way, companies can make their products more outstanding and highly durable. Firms are assisted in maintaining conformance to accepted safety and performance standards in their industry, cutting down on incidents of defective products that might cheapen public perception and customer patronage.

Force testing fixtures also help to smoothen the manufacturing process and promote better efficiency. Since these fixtures eliminate inconsistency and reduce errors during testing, they speed up decision-making and improve quality control. Data acquired during testing can also be put to analysis to improve the manufacturing processes, which can ultimately enhance product reliability. By applying force testing fixtures to their operations, companies can assure product quality at the highest standards while remaining competitive in their industries.

Frequently Asked Questions (FAQ)

Q: How does a custom force testing fixture work?

A: A Custom Force Testing Fixture imparts a controlled force onto the UUT to carry out functional tests that measure the device’s ruggedness. The setup can also be rearranged concerning the test points and configurations accepted, such as in-circuit or bed-of-nails testing.

Q: What are the advantages of a bed of nails test fixture?

A: Bed of nails test fixtures provide a good solution for high-volume production testing at lower costs. These test points are important in testing a lot of things at one time on a printed circuit, thus increasing efficiency and decreasing testing time.

Q: Explain the importance of software as a test in a testing environment.

A: The test software is important in the testing environment as it controls automated systems and processes to ensure that tests are properly carried out. In conjunction with custom test fixtures, it records data, controls test cycles, and produces reports to assist in analysis.

Q: How do I make sure that my custom test fixture has good electrical connections with the DUT?

A: To make sure that good electrical connections are made, the custom test fixture should have its own test pins and connectors that correspond perfectly to those on the DUT. Any misalignment here would result in poor contact between the test fixture and the test unit, resulting in incorrect test results.

Q: What are the benefits of leveraging automation with fixture development?

A: Automation greatly helps fixture development in that it smoothens the testing process. Automated systems can be coupled with custom test fixtures to fasten testing, eliminate human errors, and obtain consistent test results across several prototypes and PCBs.

Q: What would be typical uses of custom test fixtures in production tests?

A: Typical applications of custom test fixtures in production tests include validation of RF component functionality, confirming the proper applications of wireless devices, and cycle testing PCB to detect faults prior to mass production.

Q: Can custom test fixtures be applied for prototype testing?

A: Of course, custom test fixtures can be highly used in prototype testing. They can be customized for early-stage designs and product specifications to comprehensively test the different components and ensure that they meet desired performance criteria before moving into high-volume fabrication.

Q: What role does a jig play in custom test fixture design?

A: Custom test design-based jigs combine functions of stability and alignment of the DUT during testing. The jig maintains the position of an UUT for accurate measurements, hence reducing the chance of any mistake during testing.

References

- Custom Fixtures – Instron – Provides custom fixtures for various applications, including bend, peel, and holding tests.

- Designing and Manufacturing Custom Functional Test Fixtures – EMC Tech – Specializes in designing custom functional test fixtures for parts, components, and sub-assemblies.

- Gripping Fixtures and Attachments for Force Testing Systems – CSC Force – Offers a variety of gripping fixtures and accessories for specific force testing needs.

- Test Fixture Design, Custom Equipment, & Industrial Automation – Team Pipeline – Experts in test fixture design, custom equipment, and industrial automation with turnkey solutions.