Understanding Shear and Its Importance

Definition of Shear and Shear Strength

Shear is the stress that induces layers or particles of a material to slide in opposing directions. It is of crucial importance when considering how a material responds to forces exerted upon it and especially important in evaluating the texture of foodstuffs such as cookies. One of the characterizing factors for the shear concept is how a cookie breaks or perhaps crumbles with stress, so this could have direct consequences for consumer satisfaction.

Shear strength represents the ability of a substance to withstand the sliding forces that lead to its failure or fracture. For cookies, this means judging how much stress they would take to break or deform. One would perform a shear test under controlled force with the help of specific equipment to measure these characteristics. The results will characterize the cookie: if it is crisp, crumbly, or hard.

Shear strength characterization in cookies is quite useful for food production and in the quality control. This ensures manufacturers keep a consistent texture from batch to batch or can alter the recipe to achieve whatever bite is desired. The proper determination of shear properties ensures consistency in the product, hence improving customer satisfaction and complying with industry standards. These tests are particularly important for brands trying to present a particular kind of perception; hence shear strength checks become a powerful tool in the food industry.

The Role of Shear Tests in Food Science

Shear tests constitute an important measure of cutting strength for cookies, thrown in for texture and durability. The testing examines the amount of force needed to make a cut in a cookie, convincing food manufacturers to keep the standards constant in the face of consumer expectations. In quantifying this property, a shear test makes sure that the cookie is either hard or soft, according to what the brand or the product wants to establish in the market.

The tests particularly lend consistency to the product from batch to batch. Product consistency is an important aspect in creating and maintaining customer loyalty because texture change can be a big letdown and a source of negative publicity for the brand. Producers who use shear testing can very precisely alter production adjustments, whether in the ratios of ingredients or in baking times, so that every batch of the final product corresponds to the intended texture.

Shear tests further fuel innovation within the cookie industry to obtain fresh textures and formulations. For example, brands that want to sell for dunking and stability or to be very soft and chewy can use the shear-test data to optimize their recipes. This forensic approach to quality control simultaneously works to enhance creativity in developing products that meet consumer tastes.

Applications of Shear Strength Measurements

Being measured for shear strength is central to cookie quality assurance. With shear tests, cookie makers would know whether the products of their batch retain the integrity to maintain the standard quality. This information is used by the producer to adjust recipe and baking adjustments to suit the final texture, whether aimed at a crunch that goes “snap” or a soft chewy bit.

Such measurements are also very important in the preparation of special cookies that target specific taste preferences. For instance, a brand designed for those who enjoy dunking their cookies in milk can optimize formulations to keep their structural integrity against exposure to moisture. Likewise, utilizing shear data, a company for those who want soft cookies would adjust ingredient levels and processing methods to find the right tenderness.

This type of analysis of shear strength is key for innovation and product differentiation. If it is clear how different factors-for example, choice of ingredients, method of mixing, or temperature of baking-affect shear strength, then manufacturers can design novel shear strength characteristics and textures. This knowledge places too much emphasis on having alternative market offerings with which companies can differentiate themselves in better serving ever-changing customer needs.

Shear Test Methods

Overview of Common Shear Test Types

Shear tests are vital when it comes to evaluating the strength to cut the cookies, which further determines aspects of texture and structuralization. The forces are applied in a controlled manner to ascertain the ease with which a cookie is sheared or broken under a given set of circumstances. The test results are then used by the manufacturers to fine-tune the choice of ingredients, baking methods, and texture so that the standards set forth can be met and customer preferences catered for.

In other words, some commonly used tests consist of the single-blade shear test, wherein a blade applies force against a well-defined portion of the cookie until it fractures. This simple test is excellent for use in measuring shear strength and can provide definitive data on how parameter changes, such as baking time and baking ingredient ratios, affect cutting resistance of cookies. Another commonly used method is the bulk shear test, which determines the general mechanical behavior of several cookies simultaneously subjected to shear forces. This test is useful in the evaluation of uniformity and quality consistency in larger batches.

These two test methods give valuable insight to the manufacturers to factor in the considerations influencing the texture of cookies like water content, fat types, and temperature control applied in baking. Analyzing these variables gives companies the opportunity to develop processes in such a way that cookies meet certain specific consumer expectations of crunchiness or softness. Suing an accurate shear test method thereby helps to ensure that strength and good texture are well balanced in a product.

Choosing the Right Test Method for Your Sample

The correct cut test needs to be selected by the shear test method depending upon the structure and texture of a particular sample. In the case of cookies that are quite soft, the shear force has to be gentle in order not to crumble them and yet measure resistance accurately. Hard and crunchy cookies demand a method that presents a greater force so as to measure precisely the breaking strength.

Another factor that needs evaluation is the uniformity of cookie samples. For proper analysis, it is imperative that cookie samples of uniform shapes and sizes are used during testing procedures. Unusual shapes would introduce a level of variability that might confuse the accuracy of shear-strength measurements. Thus, for effective and meaningful results, controlled, standard preparation of samples should be done before testing.

Finally, there is the choice of equipment. An ideally calibrated shear tester for food product analyses ensures reliability and repeatability of the result. Equipment with adjustable parameters should be selected to cater to the requirements of both soft and hard cookies. Following through with this type of methodology will ensure the correct evaluation that corresponds to consumer preferences for texture and expectations in quality.

Factors Influencing Shear Test Results

The outcome of a shear test for cutting strength of a cookie depends on some variable factors. One of the major considerations is the moisture content of the cookie. Higher moisture content leads to softer textures, requiring less force to shear the cookie, whilst drier cookies are harder and require more force to break apart. Loose control of moisture content both at production and testing stages can make test results inconsistent.

Another important factor is the structural composition of the cookie. The ratio of fat, sugar, and flour affects the crumb structure, texture, and shear strength. Fat content may be directly proportional to tenderness, whereas sugar and flour may be responsible for firmness. The formulae of the cookies should be kept consistent to get trustworthy outcomes of shear tests.

Finally, testing itself has a role. The cookie and test temperature may affect the outcomes. Softening occurs to some degree if cookies are kept warmer, so it would require less force to cut them, and conversely, if kept cooler, they become hard. These external factors can be mitigated by choosing suitable environments and properly calibrating instruments, thus leads toward higher reliability and repeatability of shear test results.

Texture Analysis in Food Products

Texture Analysis: Key Concepts and Measurements

Texture analysis is pertinent in food evaluation for cookies toward the assurance of quality and consumer acceptance. Measuring the cutting strength in shear involves the application of force required to shear through the sample. This method is presumed best for testing the physical nature of foods under controlled and consistent conditions.

In using a shear test method for cutting strength determination on cookies, the sample is kept beneath the blade as force is applied steadily until the cookie breaks. The magnitude of the force that causes breaking is then recorded as cutting strength. Structural composition of the cookie, moisture content, and possible inconsistency in baking are some of the major factors considered to influence the test results. Calibration of the equipment and standardization of the testing conditions are important for dependable results.

The shear strength test is valued for its precision and simplicity, making it a standard tool in food texture analysis. It supplies quantitative determinations of the physical characteristics of cookies that manufacturers use for ensuring consistency in the texture and quality of the product. It is also used to study which combinations of baking times and recipes yield the desired texture, all of which further apply toward the product’s texture enhancement from the point of view of process chemistry.

Evaluating Toughness and Firmness in Baked Goods

A shear test is a relatively common test used for judging the toughness and firmness of baked products, such as cookies. This test measures the cutting strength necessary to shear through a sample. This provides an obvious indication of the structure and resistance to deformation of the product. By exerting controlled forces on the cookies, a shear test measures the firmness of the cookies. Thus, this test is highly useful in the manufacturing process to ensure steady quality and uniformity.

The outcome of a shear test depends on several factors, including moisture content of the cookie, composition of ingredients baking time, etc. Increased moisture content usually results in softer and less-firm texture, while longer baking times and lesser moisture tend to come up with firmer texture. Using the shear test, manufacturers can determine how much toughness or crispness to aim for in their recipes and processes so that their product can be adequately backed up by sensory expectations and the structural hard basis.

Especially suitable cases for this test method are where an objective set of data need reproducing and guiding instructions for production improvements, comparing different baking parameters or variations in the recipe. This is so that all cookies hit the firmness targets without using subjective assessments. Hence, shear testing is a very important tool in maintaining product quality as well as customer satisfaction.

Assessing Fibrousness and Its Impact on Quality

Fiber content in cookies, while beneficial to health-conscious consumers, is capable of undermining the structural integrity and textural quality of the product. Fibrous ingredients such as bran or whole grains tend to increase the density of the dough and provide toughness to it, which may be reflected in altered cutting strength during shear testing. Hence, fibrousness must be judged to confirm that cookies besides meeting nutritional standards also fit into specified sensory standards for crispness or tenderness.

Therefore, shear testing is used for more quantitative measurement of the influence of fibrousness on cookie texture. The shear test measures the force required to cut through a cookie and thus captures objective information on its firmness and structure. Shear testing usually confirms that greater fiber content increases cutting strength, indicating tough or dense cookies. Such information guides bakers in adjusting recipes to strike a fine balance concerning fiber enrichment versus palatability, thus responding directly to consumer demand for health and taste.

Making sure that fibrous ingredients do not compromise product quality requires very precise modifications of recipe parameters such as hydration, baking time, or fat content. Shear testing data becomes the basis for the producers to modify recipes in a way that does not compromise desired texture and structural stability. By making good use of such information, manufacturers are able to make cookies which fulfill nutritional objectives yet provide great experiential value to the customer.

Conducting Shear Tests: A Practical Guide

Tools and Equipment for Shear Testing

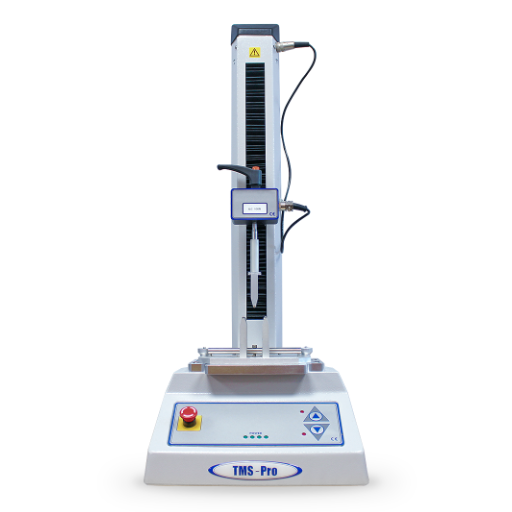

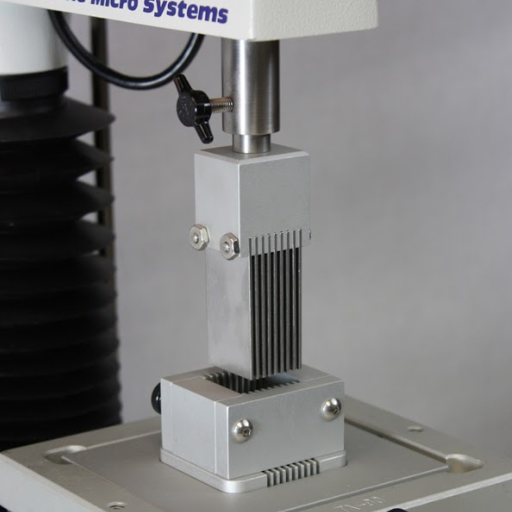

Using shear tests on cookies requires tools and equipment that provide consistent results under accurate conditions. The main instrument used is the texture analyzer, the force measurement device that measures forces needed to cut through cookie. Typically equipped with a blade or cutting fixtures for food texture analysis, the texture analyzer accurately measures cutting strength. It is absolutely necessary to have a texture analyzer both because it can apply controlled forces and collect data that can then be analyzed to evaluate the cookie’s structural integrity.

Support equipment consists of calibrated software for data collection and analysis. This software works towards analyzing the information gathered during the tests, such as peak force and total energy used to fully shear the cookie. Having precise software makes sure that the results will be trustworthy and can be compared efficiently between, say, different cookie recipes or batched. Then, depending upon the actual setup of the tests, humidity and temperature controllers might be required to further standardize conditions for the tests, as such parameters do influence the texture of cookies.

After all, sample preparation equipment is required to ensure uniformity across tests. It includes cookie cutting guides or molds to standardize cookie shapes into consistent sizes and thicknesses prior to testing. Having uniform samples reduces the possible variability of results and yields a tighter toleration with respect to comparison. Collectively, the above gadgets and equipment make a complete system for carrying out shear tests and lay the basis for the study to further enhance cookie texture.

Step-by-step Procedure for Measuring Shear Strength

- Preparing the Samples: Selecting a uniform batch of cookies will ensure consistency of testing. A sample of cookie should be trimmed according to the dimensions provided by the cookie cutting guide or mold, thereby ensuring all samples are identical in size and thickness. Should there be any difference in preparation conditions, it might render the test results meaningless.

- Calibrating the Shear Testing Equipment: Ensure that the shear testing equipment is calibrated in accordance with the manufacturer’s recommendations before proceeding with the test itself. Precision in calibration guarantees accurate measurement. Clean and align the blades or cutting mechanisms accordingly, else deviations could occur during testing.

- Performing the Shear Test: Place the cookie sample one at a time in the testing equipment, assuring it is firmly held. Start the test by activating the machine which will give the cookie a controlled application of cutting force. The greatest force registered necessary to cut a sample will be taken as the shear strength. Perform this through for all cookie samples.

- Recording and Analyzing Data: Record the results obtained for each sample under tabulated form. With these data, analyze the results to obtain the average strength of cutting for the whole batch. Think about any specific or significant differences showing in the results to gain some hint on the texture as well as the structural properties of the cookies.

This stepwise method therefore produces shear strength values that can be repeated reliably, making this protocol an important one in the assessment of cookie texture under controlled scientific conditions.

Interpreting Shear Test Results

From the analysis of shear tests results, one should make formulations concerning the average values of the cutting strength of the cookies. The average strength is generally calculated by combining individual test results across the batch, ensuring that the data represent a consistent measure of texture. One should observe patterns or irregularities in the results. For example, wide variation between samples in cutting strength would point to inconsistency in the cookie batch.

Next, look at the cutting strength values to see whether or not they meet expectations. If results are out of range, something is affecting texture and probably integrity-a divergence from the accepted method. Factors that should be investigated would be ingredient composition, baking time, or moisture content. Uniformity in shear values throughout the batch will determine production quality.

Finally, the results lead to an interpretation concerning the texture and structure of the cookies. This usually means that a higher cutting strength means a firmer texture, whereas lower values would denote a softer or crumblier texture. The results could further be used to develop an alternate production process that will apply as changes for future batches to standardize them in respect to texture. Thus, by examining the average values and significant differences along with their consequences, shear testing proves instrumental for product improvement.

Real-World Applications of Shear Testing

Quality Assurance in Cookie Production

Shear testing determines quality assurance in cookie manufacture, where it performs an objective measurement of cookie texture and cutting strength. This testing evaluates the force needed to break or cut through a cookie to establish whether it is hard or crumbly. Due to the controlled and replicable nature, manufacturers ensure that the texture is consistent in each batch, which is crucial to meeting expectations from consumers.

Shear test data provide feedback for both recipe development and manufacturing processes. If the cookie is deemed too hard or too soft, then it is either the ingredients, baking time, or processing conditions that may require adjustment to improve the product to its desired specifications. Shear testing is one of the early checks for inconsistencies, allowing manufacturers to contend with problems before they reach consumers, thus cutting down on wastage and enhancing overall efficiency.

From the perspective of standardizing product quality across facilities or between production runs, shear testing helps achieve consistency, which is the primary factor in upholding brandimage and ensuring customer satisfaction. Cookie manufacturers, by employing shear tests in conjunction with their routine QA programs, will be able to guarantee that the industry standards of their product are met and the customer expectation for texture and eating experience is fully fulfilled. This builds a great case for shear testing being an important quality tool that supports the production of cookies.

The Role of Shear Testing in Assessing Cookie Quality

Shear testing is critical in ensuring that cookies meet or exceed industry standards while also living up to consumer expectations. It measures the cutting force applied within a cookie, thus providing detailed information regarding the textural properties, crispness, and overall quality of a cookie. With these measurements on file, manufacturers can make cookies that always taste alike in keeping with the preferences of their intended target audience.

Shear testing is instrumental in meeting industry standards since it emphasizes the uniformity of cookies throughout batch production, minimizing any variability. Such consistency builds consumer confidence while maintaining a regulatory framework. An improper shear test can highlight production irregularities related to problems such as over or under baking, thereby providing opportunities for manufacturers to make a timely correction and maintain quality control.

Cookie texture translates to consumer enjoyment and satisfaction. Shear testing quantifies this scientifically, providing a crispness-average value to balance the targeted crispness and softness required. With shear testing, manufacturers produce subsequent batches pleasing consumers, thereby cementing the goodwill of the manufacturers and the consumers’ loyalty to the manufacturer.

Case Studies: Shear Testing in Action

Improving the Crispness of Biscuits

Shear tests were implemented for the purpose of investigating a lack of consistency in biscuit crispness that the large-scale biscuit manufacturer faced. Measuring shear strength of cookies in various batches made the manufacturer realize how differences in baking temperatures caused slight texture variations that were undesirable. Using shear test adjustments for baking produced a consistently good product with just the right amount of crispness and, thus, pleased customers and cut down wastage in production.

Making the Softest Cookies

This manufacturer of soft-baked cookies was grappling with finding a balance between having a crisp edge and a soft center. Using shear testing, they were able to measure and compare the cutting strength of different formulations and settle on the correct balance of moisture content and baking time needed to arrive at the final texture. Shear tests then contributed to improving the product consistency and, more importantly, supported the company’s reputation for quality.

Decreasing Batch Rejection

There were slight differences in raw ingredients that caused their premium cookie brand to reject numerous batches citing texture complaints. Using shear tests, they could investigate the range of cutting resistances present in cookies made from variable ingredient suppliers and by doing so, they were able to ensure standardization of ingredient quality which in turn minimized batch rejections with texture uniformity assured across the whole product range, resulting in huge savings and building confidence with their customers.

Frequently Asked Questions (FAQ)

Q: What is the cut strength of a cookie by shear testing?

A: The cut strength of a cookie using a shear test basically refers to the ability of the cookie to resist being cut through some shearing action, which is defined as the shear resistance force during cutting of the cookie usually by using some testing apparatus equipped with a shearing blade.

Q: How does a Kramer shear cell measure the cookie strength?

A: A Kramer shear cell is an instrument for evaluating food materials for their shear strength. In the case of cookies, the cell produces a cutting action upon a test sample, thus measuring the maximum force necessary to cut through the cookie, thereby representing its cutting strength.

Q: Why would you want to consider compression tests beside shear tests?

A: This simultaneous use of the compression test and shear test allows the structure of the cookie to be studied completely. While the shear test is used to measure the resistance force in the cutting process, the compression test determines the hardness and overall firmness of the cookie, thereby providing information pertaining to different properties of the cookie.

Q: Can the shear test be used as a force test for other food textures beside cookies?

A: The shear test is one of the tests that can apply to the texture of other foods, including fruits, vegetables, and fibrous products. It helps to test their texture and cutting strength and provides an indication of how easily these foods can be cut or eaten.

Q: What are the requirements for conducting the shear test for cookies?

A: In general, test requirements involve the preparation of a uniform test sample, calibration of the testing machine, and following a standardized test procedure for the measurement of shear resistance force of the cookie.

Q: Does the shape of the cookie have an influence on its shear strength?

A: The shape of a cookie can contribute greatly to its shear strength. A cookie with a larger surface area may be subjected to different cutting forces compared to smaller or thicker samples because of the variation in how the stresses are distributed when subjected to a shear test.

Q: What role does the knife edge sharpness play in shear testing?

A: The sharpness of the knife edge plays a very important role in that it can affect the cutting efficiency. A sharper edge would require lesser resistance force to cut through the cookies, thereby allowing a better evaluation of the cookie’s shear strength and texture.

Q: What is the difference between lap shear and ball shear?

A: The lap shear test looks at shear strength of bonded materials by applying force in opposite directions, whereas the ball shear test tests shear strength of materials subjected to a bit different configuration. Both tests can be adapted to give insight into the cutting strength of cookies.

Q: How would the viscoelasticity of cookies influence their shear testing?

A: Viscoelasticity tests of cookies would deviate the shear test results since these materials may act as elastic in moist situations and plastic in dry situations under stress, the cookies may deform differently opposed to shear stress that will affect the measure of shear resistance force.

References

-

IMADA – Cookie Hardness Test (Manual)

This source explains how cookie texture and hardness are measured using a wedge probe. -

Stable Micro Systems – Cutting and Shearing Testing

A guide to cutting and shearing tests for measuring bite force, firmness, toughness, and shear force. -

ResearchGate – Cookies Water Activity and Maximum Force in Shear Test

A study on the maximum force recorded during cutting shear tests on cookies at different storage intervals.