When it comes to grasping the toughness and impact resistance of materials, two test methods come into play-the Charpy impact test and the Izod impact test. These two tests are used by engineers, material scientists, and manufacturers to understand the behavior of materials when subjected to an application of sudden force and harsh conditions. But what sets one test apart from the other? Though they seem similar at first, the methods are different in setup, testing criteria, and selection, which could hugely influence material selection as well as consequently affect project outcome. The article explores the key differences between the Charpy and Izod testing methods, enabling you to understand the basic principles behind each and their respective advantages and usefulness in practical terms. Whether you are a professional practice or just a curious eventuality, the guide will give you the insights that empower you to make informed decisions and increase your knowledge. Stay with us as we look into the two testing methods and uncover what makes these two indispensable in the materials world.

Overview of Impact Tests

What is an Impact Test?

An impact test assesses the ability of the material to withstand sudden stresses put upon it. It tries to get quantification of the toughness or the break-resistance offered by the material in their opportunity to a high-speed loading. This permits judging the performance of materials under usual working of sudden shocks or stresses.

Impact tests are ordinarily conducted by using a special-purpose machine which causes an impact of very controlled magnitude on the specimen, generally by dropping a hammer or pendulum on it and measuring the energy absorbed by the specimen during fracture. The most familiar and widely used impact tests are the Charpy and Izod, with the chief difference being in the set-up of their specimens and the way the specimens are struck against during testing.

By imparting values of durability, ductility, and performance onto a material, an impact-test result may become an answer key. Such information comes in very handy in industries like construction, automotive, and aerospace, where stringent safety and reliability standards are imposed on materials. The impact resistance value helps engineers and manufacturers consider and decide whether a material is usable for a particular application.

Importance of Material Testing

Material testing is very important because safety, reliability, and performance must all be guaranteed for the materials applied in different contexts. Thus, when tested through virtually all available means, an engineer will come to know how a material will respond to various types of forces, be it a different environment or long-term usage. This further facilitates or enables engineers in the decision-making process of choosing the correct material for a particular purpose.

Testing materials helps reduce the risk involved in the process. For instance, construction materials must bear heavy loads and resist extremes of weather without failing. With testing, designers and manufacturers may find if there are weaknesses or vulnerabilities in the materials, which might lead to real-world failures and hazardous consequences or costly repairs.

The trials of materials further foster innovation and efficiency, allowing industries to test fresh material combinations or improved technologies for better performance, lower cost, and sustainability objectives. If industries such as construction, aerospace, and automotive work to create safer and smarter designs while knowing the exact properties of a material, regulatory standards will get complied with, and progress is promoted.

Applications in Various Industries

Material testing helps ensure quality and safety in various industries. It ensures, for instance, that in construction, structural elements such as concrete, steel, or composites resist stresses, corrosion, or environmental effects in general, and so on. This guarantees that the buildings and infrastructures are durable and keep their occupants safe by minimizing chances of structural failures.

Likewise, the aerospace industry subjects material tests to find out if its components are capable of withstanding extreme conditions like high temperatures, pressure, and vibrations. Through testing, aerospace materials are certified for industrial acceptance, although with greater strictness than normal, raising the level of innovation within the industry towards designing solutions for being lightweight and efficient.

The automobile sector depends upon material testing for making cars with better performances, fuel efficiency, and safety. The testing enables manufacturers to select among materials capable of withstanding under mechanical stress, environmental exposure, or dynamic forces so as to ensure safer, more sustainable, and longer-lasting cars. These processes emphasize the importance of material testing for reliable and advanced industrial applications.

Charpy Impact Test

Methodology of the Charpy Impact Test

Charpy Impact Test measures the toughness of a material by standard procedure. This method of testing determines how much energy a material can absorb at fracture under a high-speed impact. Energy absorption is, therefore, a measure of how well the material can resist impacts, sudden forces, or dynamic forces.

The testing procedure involves placing a notched test piece in the machine horizontally. A pendulum is then released and allowed to freely strike the specimen at the notch. The notch serves as a stress concentrator and controls-topink-fracture in the specimen at least. The instrument measures the change in height of the pendulum before the strike and after so as to determine the energy absorbed by the material during fracture.

Depending on the type of analysis performed on these test results, an engineer or manufacturer can conclude material behavior as it is subject to a given condition, such as low-temperature or high-strain-rate conditions. Consequently, the knowledge gained could be harnessed for better material selection in various industries such as automotive, construction, and aerospace, where impact resistance is a prime consideration for a material’s performance.

Equipment Used in Charpy Testing

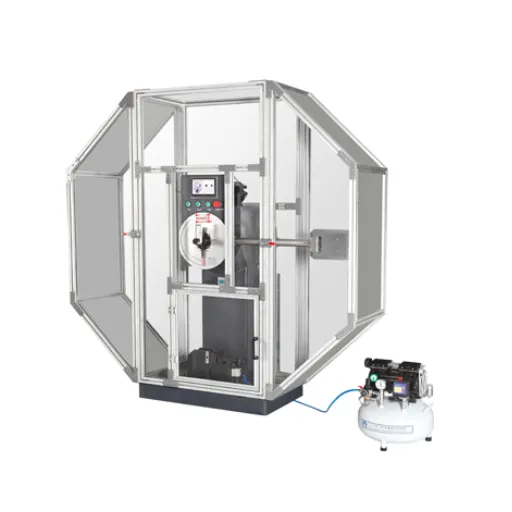

Several crucial pieces of equipment are involved in providing precise and reliable results during the Charpy impact testing. The most crucial piece of equipment is the Charpy impact testing machine, which has a heavy pendulum set to hit the notched test specimen and then measure the energy absorbed during the hit. The motion and energy of the pendulum are calibrated very precisely.

Other than the instrument, the test specimen also holds heavy significance. Normally, standard test specimens are rectangular, with a notch machined at the center. The notch is important for concentrating stress during the test-and thereby-the assessment of the behavior of a material in fracture under a given condition.

Supporting tools include the specimen holder for holding the sample firmly during the test and safety equipment for the protection of operators. Measuring devices will be included, or alternatively external, for measuring parameters such as energy absorbed and fracture pattern. Together, these tools and components offer a strong setup for the efficient and precise perform of Charpy impact testing.

Testing Conditions and Standards

Testing conditions pertaining to Charpy impact tests are strictly defined with the end-goal of maximizing the precision and reproducibility of the results. Standardized conditions could be set up with specific temperature ranges, modes of material preparation, and exact dimensions for the specimen. Usually, the specimen will be a rectangular bar with a V-notch, because the notch will help concentrate the stress to give rise to a clean fracture. Typically, tests are conducted at different temperatures to evaluate the behavior of the material under a variety of environmental conditions.

Everyone follows Cherpy standards, typically ASTM E23 or ISO 148, to ensure global consistency in the Charpy impact testing procedure. Both the standards control specimen size, test equipment calibration, performing procedures, and result interpretation. Emphasis on standardization will guarantee enhanced reliability of the test and the ability to compare resultant data meaningfully in various studies and industries.

Proper controls and good laboratory practices should be used to conduct testing. Test equipment should be calibrated for energy reading with accuracy, while sample alignment should be perfect in the holder to maintain consistency in measurement. Environmental factors such as humidity and contamination should also be kept at a minimum so as not to affect the test results. By conditioning the test under these standards, the integrity and applicability of the Charpy impact test results can be ensured.

Izod Impact Test

Methodology of the Izod Impact Test

An Izod Impact Test is a standard procedure of assessing impact resistance in materials. A specimen that has been notched is fixed vertically in a vise with the notch facing the direction of the striker. The pendulum hammer is dropped from a known height, hitting the specimen at high velocity. Measuring the energy absorbed by the specimen during fracture gives the materials’ impact strength.

During such a test, careful specimen preparation is crucial to ensure consistency among tests. Specimens must conform to stipulated dimensions, having a V-shaped notch machined to an exact depth and angle, creating a stress concentration point. This notch is necessary to simulate conditions; in the field, many materials experience failure at points of high stress. Environmental factors such as temperature could affect the results, so tests are usually carried out under standardized conditions to ensure reliability and comparability.

Being one widely used method, it thus obtained the value in construction, automotive, and manufacturing in the building of products. By testing with shock load, one can draw conclusions regarding the tough characteristics of a material. Depending on the impact resistance of a material, engineers and designers will research impact-resistant materials for applications.

Equipment Used in Izod Testing

The Izod-testing equipment is capable of physically measuring the impact-energy resistance with high accuracy and reliability. The major constituents of the structure of the Izod-testing machine are the impact testing machine, a pendulum, and a specimen holder. The impact testing machine houses the pendulum, which is raised and then dropped in the process of striking a sample in order to measure the energy absorbed by it.

Being weighted, the pendulum free-swinging is calibrated in such a way as to give a definite amount of energy on impact. The pendulum is raised to a defined height to maintain consistency from one test to another. All through the test, the pendulum hits the notched specimen with a measured force so that the value of impact resistance of the material can be determined accurately. The design of the pendulum and the test setup ensures that results can be reproduced even when conditions vary during testing.

In order to carry out the testing, the specimen holder firmly secures the material sample. Usually, the samples are notched to present a point of stress concentration, allowing for consistent fracture patterns and more accurate evaluation of the material toughness. This combination of apparatus makes sure Izod impact tests will deliver reliable, comparable results necessary in engineering and manufacturing.

Testing Conditions and Standards

Izod impact tests are performed under specifically defined conditions to ensure the trustworthiness of the results. The sample material subjected to testing is said to be at room temperature unless anything to the contrary is stated. However, at lower or higher temperatures, the test could be performed to learn more about how tough the material is with respect to particular environmental conditions. This way, a controlled testing atmosphere coupled with constant and reproducible data becomes a learning mechanism with which applications can be made in weather variations.

Among the organizations establishing standards for Izod impact testing include ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization). These standards list the sample’s size, how exactly the notch is placed, and the stepwise conduct of the test procedures. There lies the importance of these standards in respect of having the results in precise terms as well as comparable to another laboratory and material.

Industries such as automotive, construction, and aerospace require adherence to such testing norms. These standardized conditions are essential so that particular materials meet their safety and performance requirements. The manufacturers and engineers, in turn, decide which materials to choose in conformity with standards, thus working towards making safer and stronger products.

Key Differences Between Charpy and Izod

Test Method Comparison

The two methods share the same objectives but vary greatly in their methods and set-up, in terms of orientation of the test specimen during impact testing. In Charpy, the specimen is placed horizontally, supported on both sides, and impacted in the center by the striker. In contrast, Izod keeps the specimen vertical, clamped at one end, with the pendulum impinging at the free end.

The other difference comes on scratches and the use of a specimen. An indented specimen with a notch is tested in both, so the stresses are concentrated and simulate real-life faults. The difference lies in the orientation of the notch. The Charpy test is designed to have the notch face away from the striker. Conversely, the Izod test has the notch facing the striker. Hence, these contrasting setups are known to give contrasting values and reflect what happens to materials under these specific conditions.

Several other points can be made about this variation in energy values measured and their implications. The Charpy testing equipment records the energy absorbed by a specimen, in joules, as the pendulum breaks the material. This energy value shows the material’s resistance against sudden failure. The Izod testing gives more or less the same information but often for smaller or localized assessments. Both configurations are important for industries requiring precise material selection to ensure structural integrity and safety.

Specimen Configuration

Dimensions of the specimen are an important feature for the Charpy and Izod impact tests. The specimens are standardized, which guarantees a reproducible and reliable result. It is essentially a small rectangular piece of material with a defined notch. The function of this notch is to localize stress through the testing process. Real-life scenarios could be considered where a material could fail at points of stress or imperfections.

For the Charpy test, the specimen is supported horizontally between two fixed supports so that it behaves like a simply supported beam. The notch is facing away from the striking side, so the pendulum hits the surface directly opposite to the notch. This tests how the specimen will resist impact forces due to bending.

The Izod test has a different setup, with the specimen kept vertically and clamped at one end to represent a cantilever beam system. The notch faces the impact of the pendulum, making it more of a concentrated impact on the notched section. This particular setup allows the toughness of materials to be evaluated under different boundary conditions from those of the Charpy test. Both of these tests play a vital role in studying material behavior when subjected to sudden loading conditions.

Pendulum Impact Mechanism

The pendulum impact mechanism is a device in which the material is subjected to dynamic loading for studying its behavior. This system works by releasing a pendulum from a known height, so the specimen is hit by the pendulum with a given energy. The energy absorbed by the specimen during fracture or deformation is thus recorded for providing information about the impact toughness of the material.

The working of the mechanism depends upon certain fundamentals of conservation and transfer of energy. At the initial height, the pendulum possesses potential energy which is converted into kinetic energy as the pendulum moves downward. When the pendulum strikes the specimen, the energy possessed by it is partly absorbed by the material in deformation or fracture, or both; the rest of the energy remains with the pendulum in the form of kinetic energy in its swinging beyond the specimen. Thus, the difference in initial and final energy of the pendulum gives the calculation of absorbed energy by the test material.

The pendulum impact mechanism is commonly used in tests such as the Charpy or the Izod impact tests. These methods ascertain whether the material is suitable for applications involving the possibility of sudden forces or impacts. Reliable data from such a test is extremely helpful in providing for safer designs of structures and products by ensuring that the materials can be subjected to certain degrees of impact and yet give due consideration to its durability and performance.

Advantages and Limitations

Accuracy of Charpy vs Izod Tests

The accuracy of the Charpy and Izod impact tests depends on the chosen parameters and its operational conditions. These two methods provide a means of measuring the low-temperature toughness or low-temperature impact strength of materials, but they do exhibit methodological differences and differences in the kind of data they provide. The Charpy test is generally considered more reliable in applications that require knowledge about the behavior of a material in horizontal configurations, as the specimen is supported at both ends. On the other hand, the Izod test is more frequently used where vertical configuration plays an important role in the material behavior due to its cantilever-like arrangement.

One crucial factor affecting the accuracy is the way specimens are prepared and placed during testing. In the Charpy test, a notched beam is subjected to impact to simulate stress concentrations on the specimen. The Izod test employs the same concept of having a notch but with a different location. A true comparison can only be made by keeping all other factors consistent, such as specimen dimensions, material compositions, and environmentally conditioned temperature testing conditions. Any variation in these conditions can lead to result inconsistency, thus underscoring the importance of strict adherence to the standards in performing the tests.

As such, when followed under the standardized guidelines, both tests are valid for their respective purposes. Usually, the Charpy test is favored when determining ductile-to-brittle transitions in materials, whereas the Izod test is more advantageous for quality control in testing perpendicular impacts on smaller specimens. The selection of one of the two methods will largely depend on the application under consideration and the kind of information required relative to how the material performs under impact.

Cost-Efficiency of Each Method

The income versus cost analysis of the Izod and Charpy impact tests is influenced by the equipment, specimen preparation, and procedure used. Usually, the Charpy test is considered more cost-effective when considered for large-scale applications because of its standardized equipment and ease in specimen preparation. Because it allows a single test operator to quickly test multiple samples, this is a fairly practical choice for industries requiring high volume testing.

Izod, in contrast, is more suited to applications where a smaller specimen is used or if there is a need to analyze the impact forces in detail along a given plane. While usually the equipment and setup for an Izod test could be comparable in cost to a Charpy test, higher accuracy with smaller samples could make it worthy of the investment. This sort of test would be very much of value to any application looking at quality control where the localized impact performance of the material under test becomes important.

Finally, the decision rests on what process is pursued, meaning size-wise. For larger-scale tests conducted in a broader region of tolerance, the Charpy test would be more economical. On the other hand, the Izod test may cost a little bit more overall but is far more specific for smaller and very controlled tests. Both tests provide a medium point between the price and what they offer, depending on the material-testing priorities of the user.

Suitability for Different Materials

When deciding on materials fit for both Charpy and Izod impact tests, one has to look into the structural and mechanical parameters of the material. Both test methods assess the impact-resistance of materials, but addressing one or the other is better depending upon material characteristics and testing needs.

The Izod test is used efficiently for determining impact resistance with materials of higher brittleness or for smaller-size samples. It focuses on accurately measuring the impact force. This makes it great for use with polymers or composites or in other applications where minor variations in resistance might have significance. This tailored approach is effective when small differences truly matter.

Conversely, the Charpy test specification is best suited for larger samples or those expected to have more generalized testing conditions. It is most often used on metals or other ductile materials for a broader perspective on their impact toughness. Thus, the purpose of this test is for obtaining a wider understanding of the material’s sturdiness as such are commonplace in industrial applications or large evaluations.

Frequently Asked Questions (FAQ)

Q: What distinguishes Charpy from Impact Test?

A: The Charpy and impact test differ mainly in the manner of application and how the specimen is prepared. The Charpy test utilizes one specific type of V-notched specimen and measures energy absorbed during fracture, while other impact tests, like Izod, work on different specimen shapes and notches. Both of these processes serve to determine the impact resistance of a given material, and are particularly concerned with brittle materials.

Q: How does one operate a Charpy impact tester?

A: A Charpy tester functions by releasing a hammer from a set height onto a notched specimen. The energies absorbed by the specimen while fracturing are measured to determine its toughness and impact resistance. This method standardly tests the charpy impact resistance of notched specimens.

Q: What types of material are subjected to testing on Charpy?

A: The Charpy test is generally used to test brittle materials and is most applicable to test impact resistance in metals, polymers, and composites. It is the main test for determination of their toughness in various applications, especially in environments where impact loads may be expected.

Q: Why is it important to observe the amount of energy absorbed in the Charpy test?

A: This energy absorption by a material in a Charpy test is taken as a measure of toughness. The greater the value, the better the resistance to impact, materials on which there is always an impact load going to be used in structural application.

Q: What is the significance of the Charpy V-notch?

A: The Charpy V-notch is a very important feature of the Charpy test specimen. It produces a concentrated stress point for fracture under impact loading. This makes testing for impact resistance and toughness more meaningful, especially with respect to either comparison tests between two different materials or with testing in one material under certain changes.

Q: In what way(s) do the Izod and Charpy methods differ?

A: The primary difference between the Izod and the Charpy method lies in the orientation of the specimen and the notch configuration. The Izod test has a vertical specimen with a side notch while the Charpy test has a horizontal specimen with a V-notch. Both methods are used to measure impact resistance; however, the results can often differ among materials and testing conditions.

Q: What are the standard test methods to measure impact resistance?

A: Standardized methods for testing the impact resistance are the Charpy test, Izod test, and other non-instrumented impact tests. These test methods are employed to measure the toughness of materials and are instrumental in the mechanical testing of materials in order to make sure the material meets safety and performance standards.

Q: Can the Charpy testing apply to plastics?

A: The Charpy testing is also applicable for plastics. The standardized method adapts to doing toughness tests and impact resistance measurements on different plastic materials so manufacturers can ensure that their products will be able to withstand various environmental and mechanical forces acting on them.

Q: What is the role of a digital impact tester in the field of impact testing?

A: A digital impact tester makes impact testing more accurate and efficient. It measures the impact resistance of materials more precisely and allows for more detailed tests than mechanical testers.

References

-

Difference between IZOD and Charpy Test – Explains the key differences in specimen position and notch direction between the two tests.

-

Izod vs Charpy Impact Test: Which One Is Suitable for Your Needs – Discusses the energy load differences and their applications in testing ductile materials.

-

What is the difference between IZOD and Charpy Impact Tester – Highlights the differences in pendulum size and testing setup.

-

Izod and Charpy Test for Impact Testing – Provides a comparison of how the samples are held and struck in each test.