With durability and fatigue simulation being in the spotlight today in engineering, there is a possibility of inventing ingenious and durable designs for various industries. Engineers analyze materials and components subjected to stress on a repetitive basis to find out their response and potential failure. This article thoroughly examines the fundamental principles of fatigue analysis, the processes involved in fatigue and durability simulation, and their importance in optimizing a product’s performance characteristics. By having an in-depth understanding of this kind of analysis, engineering, and design activities become much safer, and the lifespan of a system can be significantly extended. A thorough investigation will be made of the rationale, tools, and applications that underscore the importance of durability and fatigue analysis in excellent engineering.

Understanding Durability and Fatigue

Durability describes the capability of any material or product to resist wear, pressure, or damage through a normal life expectancy from usual operating conditions. Durability is a performance criterion that ensures reliability, thereby reducing the need for frequent repairs or replacements, and providing cost-effectiveness and consumer satisfaction.

Fatigue represents the gradual weakening or failure of a material resulting from repeated stress or cyclic loading. Stress below the material’s ultimate strength may create microscopic cracks that grow into larger cracks over time, ultimately leading to failure. Understanding fatigue is crucial in predicting the service life of a component and ensuring its safety in applications such as transportation, infrastructure, and manufacturing.

Definition of Durability and Fatigue

Durability refers to a material, structure, or system’s ability to resist wear, decay, or deterioration over time while maintaining its functionality under specified operating conditions. It considers long-term performance and ability to withstand environmental conditions, mechanical stress, or chemical exposure. According to the latest data insights, advancements in materials science have enhanced the durability properties of certain key materials, such as composites, alloys, and polymers. These materials are now commonly used in critical industries such as aerospace, automobile, and construction.

Conversely, fatigue is considered a progressive and localized form of structural damage that occurs when a material is subjected to cyclic loading. Trends further indicate the increasing importance of fatigue analysis in modern engineering design. Advanced computational tools and predictive algorithms are being utilized to simulate fatigue behavior, enabling engineers to design components that mitigate the risk of failure. New search data indicate an increase in fatigue-related failures in aging infrastructure; therefore, incorporating durability and fatigue analysis into design practices is crucial for ensuring that systems are future-proof.

The Importance of Fatigue in Engineering

Fatigue in engineering refers to the weakening of a material caused by cyclic loading, which leads to structural damage that accumulates and eventually results in the sudden failure of structural components. It is of utmost importance, as it represents one of the significant causes of mechanical failures in the aerospace, automotive, and civil infrastructure industries. The understanding of fatigue behavior essentially deals with the study of the repeated application of stresses that cause microscopic cracks, which spread and lead to component failure after a specific period.

In mitigating fatigue, material selection is the first line of defense, ensuring that materials with high fatigue resistance, such as certain alloys, are used in applications where cyclic loading is expected. Stress analysis, followed by design refinement, including the use of finite element analysis (FEA), is then employed to identify areas subjected to cyclic loads and to predict stress levels more precisely. Novel design solutions that minimize stress concentrations, such as the use of fillets, are also essential factors for fatigue mitigation. Appropriate maintenance, with regular inspections and non-destructive testing (NDT), ensures early detection of potential fatigue problems.

Key Concepts in Durability Analysis

Durability analysis aims to assess and evaluate the structural integrity and expected lifespan of materials or components under various environmental and operational conditions. Central to this theory is the concept of material fatigue, wherein failure may occur due to repeated stress cycles over time. By applying modern approaches, such as finite element analysis (FEA), it is possible to simulate real-world working conditions and assess stress distributions, as well as calculate critical points of failure. Conversely, environmental conditions, including temperature fluctuations, humidity, and corrosivity, are significant considerations that affect the performance capabilities of materials. Therefore, durability predictions are made accurately through material testing and lifecycle simulations, by current standards, ensuring the design is both safe and reliable over the intended service lifespan of the installation or product.

Core Methodologies in Fatigue Analysis

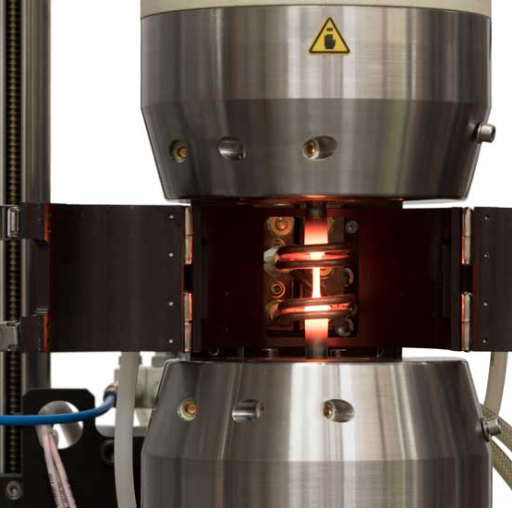

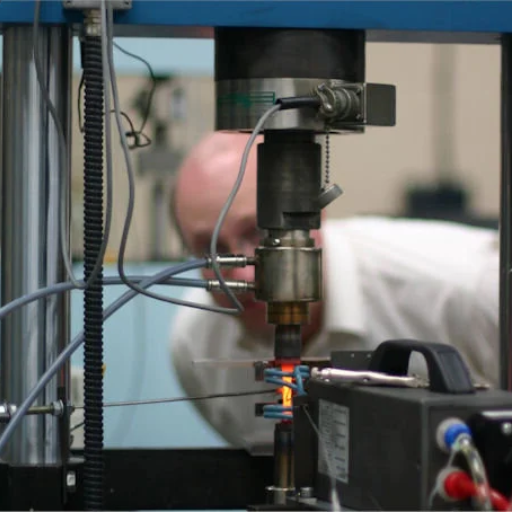

1. Experimental Testing

Experimental testing is a core methodology in fatigue analysis, where material behavior is studied in the laboratory under controlled and measured conditions of cyclic loading. Rotating bending tests, axial fatigue tests, crack growth monitoring tests, and others provide prime data regarding fatigue life, crack initiation thresholds, rates of crack growth, and their respective S-N curves, all of which are essential for design purposes.

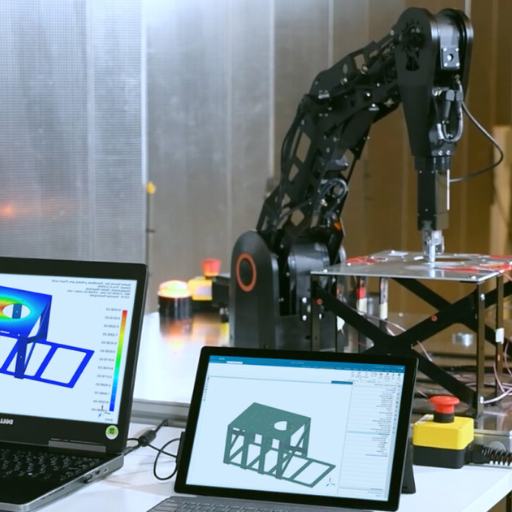

2. Finite Element Analysis

Finite element analysis is a computational approach used in fatigue analysis, stress analysis, and loading simulations over a specific geometry. FEA thus allows for an accurate assessment of sites of localized high stress, providing information about apparent zones of fatigue failure.

3. Damage Accumulation Models

Damage accumulation models describe the fatigue process in service, where damage accumulates over time. These models, together with variable amplitude loading data, become estimates for the remaining fatigue life and maintenance criteria.

4. Non-Destructive Evaluation

The non-destructive evaluation techniques include ultrasonic testing, X-ray inspection, thermography, and various others that monitor structural integrity without altering the material. NDE thereby establishes the early detection of indications for the occurrence of fatigue damage, thus saving time in intervening and preventing the actual failure.

Overview of Fatigue Simulation Techniques

Simulations of fatigue processes are advanced computational techniques for assessing the life and performance of materials under changing stress conditions. Such simulations utilize the finite element method, combining it with a specific fatigue model of material behavior to provide precise predictions of fatigue failure. These techniques integrate real-time loading patterns, environmental factors, and material inputs to improve the accuracy. For example, variable amplitude loading, which more closely approximates operating conditions, is used by engineers instead of constant amplitude loading to better capture the actual stresses imposed during service.

Current techniques include multiscale modeling, which enables the consideration of microstructural effects when examining fatigue behavior, as well as the use of machine learning methods that further enhance prediction ability by identifying patterns in large datasets. Furthermore, coupled thermal-mechanical simulations are employed to study the interactions between thermal loads and mechanical stresses, allowing for the early localization of potential fatigue hotspots and providing design optimization to extend component life, ensuring reliability and safety, a matter of concern in high-temperature applications such as turbine blades or automotive exhaust systems.

Load Characterization and Its Impact

Load characterization is instrumental in studying the component in question under specific forces and stresses while it is in operation. It defines the type, magnitude, direction, and frequency of loads. Loads can be static, dynamic, thermal, or a combination of these factors. Accurate characterization of loads enables engineers to predict how materials behave under various operating conditions—especially in high-performance environments. In aerospace or automotive systems, if cyclic or transient loads are not adequately characterized and resolved, the resulting premature fatigue could limit operational efficiency or lead to catastrophic failure. Advanced computational models and testing techniques, such as strain gauging or digital image correlation, are crucial in this respect to ensure the design meets performance and safety standards under real working conditions.

Structural Integrity Assessments

Structural integrity assessment involves evaluating whether a system or component can withstand anticipated loads and environmental conditions throughout its service life. it is done through a combination of theoretical modeling, finite element analysis (FEA), and thorough material testing. Non-destructive testing (NDT) methods, which detect flaws without impairing the structure, including ultrasonic and radiographic inspection techniques, are heavily relied upon. Real operating conditions are simulated to predict failure modes, fatigue life, and ensure compliance with industry standards. Other advanced diagnostic tools and predictive maintenance methods enable the anticipation of risk mitigation, ensuring safety and optimal performance under varying conditions.

Benefits of Implementing Durability and Fatigue Analyses

Durability and fatigue analyses must be conducted in any engineering or operational endeavor, as they offer numerous benefits. Reliability and durability are enhanced through scrutiny to identify potential points of failure, and design modifications are made to that component to withstand real-life stresses. This will prevent a great deal of unplanned downtime, maintenance, and repair, thereby leading to overall increased efficiency. Additionally, they provide a measure for attaining stringent regulatory and safety standards, thereby eliminating any further legal and operational issues. Engineers have the opportunity to develop further cost-effective material use and design improvements, working toward sustainable and high-performance systems by simulating operating conditions and predicting performance.

Cost Savings Through Predictive Maintenance

Predictive maintenance is a system that uses data analytics, sensor technology, and machine-learning algorithms to forecast machinery breakdowns before they occur. This strategy aims to address problems before they cause equipment failure, thereby preventing unplanned downtime, extending the lifespan of vital machinery, and optimizing maintenance schedules. Estimates from reputed sources suggest that predictive maintenance can reduce total maintenance costs by 30% while cutting downtime by 40-50%. Monitoring KPIs such as vibration, temperature, and pressure helps an organization maintain efficient operations while avoiding emergency cost repairs. Hence, implementing these best practices within industrial systems would yield significant commercial value to the company in the short term.

Improved Product Reliability and Safety

Predictive maintenance practices lend themselves to higher reliability and safety for the products. Constant equipment monitoring for any anomalies reduces the cases of unexpected equipment failures that could adversely affect processes. By applying the power of advanced analytics, machine learning algorithms, and IoT-enabled sensors, the exact moment a breakdown is expected can be identified and resolved, thereby mitigating the possibility of dangerous situations. At the same time, predictive maintenance keeps systems operating within their ideal limits, minimizing wear and tear and extending equipment life. Enterprises that employ these strategies not only enhance reliability but also ensure the highest safety standards, thereby protecting both human operators and assets.

Reduced Time-to-Market with Effective Simulation Tools

By providing superior simulation tools, I facilitate the rapid development of project design phases, thereby offering market advantages in terms of time. These tools enable virtual testing of prototypes on the shoes, thereby eliminating trials and errors associated with actual prototypes. In addition, they provide an in-depth understanding of system performance under various conditions, enabling any issues to be identified and resolved from the outset. The workflow augmented by simulation software will enhance collaboration and efficiency, thereby ensuring that products comply with the standards required before production, ultimately providing a competitive edge in volatile market environments.

Applications Across Industries

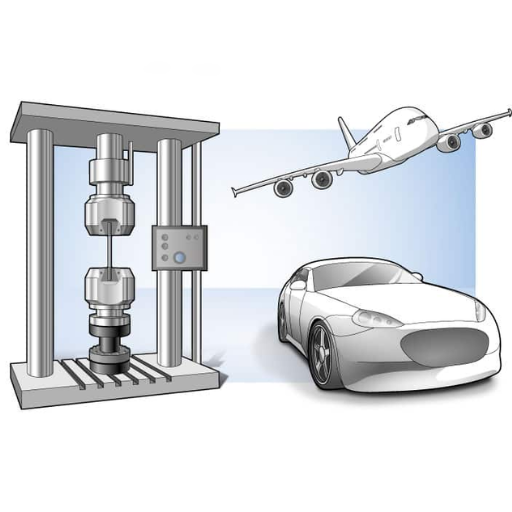

Durability and fatigue simulation find application in various industries, imparting predictive accuracy to the product’s lifespan and performance under cyclic loading.

- The automotive industry utilizes simulations to ensure the safety and integrity of parts, including chassis, suspension systems, and engine components, over time.

- Aerospace Sector: Fatigue analysis is conducted for a sufficient duration to ensure compliance with the stringent requirements for aircraft parts under extreme working conditions.

- Manufacturing: From simulations, machinery and/or tool design are optimized in terms of wear and failure predictions, thus improving operational efficiency and lowering maintenance costs.

- Energy Sector: Fatigue analysis of wind turbines and other renewable energy systems helps ensure they are protected against failure due to repetitive stresses caused by environmental factors.

- Consumer Electronics: Durability tests ensure that products can withstand repetitive use, thereby enhancing the customer experience and extending their lifespan.

Durability and fatigue simulations take the industry to higher performance in cost-efficient development and reliable products.

Fatigue and Durability Simulation in Automotive Engineering

Within automotive engineering, assessing fatigue and durability is crucial in predicting the time duration and performance of vehicle components under service conditions. These analyses focus on cyclic load-to-resistance scenarios of materials and structures under various loading methods, including thermal stresses and vibrations generated during operation. Importance is given to key approaches like analysis using the finite element method, or FEA, where FEA allows one to undertake modeling and solving complicated geometries. Further inspection is conducted to locate failure points before the development of new prototypes.

Advanced simulations take into account material properties, load histories, and environmental conditions to simulate the stress-strain response of structures with the most fantastic accuracy possible. For example, BIW structures, chassis systems, and powertrain components undergo intensive computational simulation testing under the highest standards for their reliability and safety. By using such predictive tools early on in the design stages, automotive manufacturers can achieve minimum material consumption, fewer design alterations, and lower product research and development costs to deliver a safer and longer-lived car. This detailed analysis also yields eco-friendly production scenarios, characterized by reduced waste and improved energy efficiency.

Aerospace Industry: Ensuring Structural Integrity

Maximizing structural integrity ensures aircraft meet highly stringent regulatory requirements and remain safe and reliable. With advanced materials, such as composites and titanium alloys, being extensively used to improve the strength-to-weight ratio without compromising durability, technologies like computational modeling, non-destructive testing (NDT), and fatigue analysis carry an equally important role in identifying potential weaknesses and ensuring components can withstand operational stresses over time. The integration of real-time monitoring systems for predictive maintenance, which minimizes the possibility of failures and optimizes lifecycle performance, is a recent advancement. All these improvements together are making aerospace systems safer, more efficient, and longer-lasting.

Construction Applications: Load and Durability Simulation

Load and durability simulation in construction relates to evaluating structural integrity, material performance, and long-term resilience to various stresses. Advanced computational modeling tools, such as the finite element method, are typically employed to predict behavior under different load cases, including static, dynamic, and environmental conditions. They consider material properties, design details, and externally applied stresses, such as wind and seismic activity, to identify potential points of failure. Being a simulation of real-world conditions, engineers can optimize designs for optimal safety and efficiency, thereby saving on costly physical testing iterations. Additionally, the incorporation of durability prediction models enables the planning for materials’ degradation over time, promising sustainable and reliable construction practices.

Emerging Trends and Challenges

A prominent trend in fatigue and durability simulation is the use of machine learning and artificial intelligence to make more accurate predictions and reduce computational time. Different algorithms will analyze complex datasets to identify patterns and optimize the performance predictions. Hybrid simulation techniques are also gaining popularity, as they combine physical testing with virtual testing to reduce costs and enhance model fidelity. Nonetheless, the core issues remain focused on having the correct inputs and material models capable of emulating real conditions. Furthermore, modern designs are increasingly complex, requiring more reliable computational resources, which in turn leads to higher development costs and technical barriers. These issues require constant innovations in simulation tools and cooperation from different fields.

Current Trends in Durability and Fatigue Simulation

Several notable trends are shaping durability and fatigue simulation, driven by advances in technology and shifts in industrial demands. First, the integration of AI and ML to enhance predictive accuracy in fatigue analysis is gaining increasing popularity. These algorithms can expedite the process of accurately pinpointing areas under stress, thereby reducing the time spent on product development. Second, there has been a rise in the use of cloud-based simulation platforms over the past few years because they provide scalable amounts of computational resources and support workflows that facilitate collaboration across teams in global locations. Third, multi-physics simulation methods are being increasingly utilized. These methods integrate structural analysis with thermal and fluid dynamics analyses to fully comprehend how the material behaves under real-life conditions and to design complex, resilient products. Designing with this method gives a significant advantage.

The Future of Fatigue and Durability Analysis

The future of fatigue and durability analysis will see a greater emphasis on computational power, more impressive integration of machine learning algorithms, and material modeling. In this future, cutting-edge simulation platforms will surpass the state of the art by incorporating AI predictive analytics to identify failure modes more quickly and accurately than ever before. Digital twins will enable real-time monitoring of systems, which has been possible only for well-understood, simple systems so far. Predictive maintenance will then prevent inevitable random failures. Innovations in multi-scale modeling will also advance material-level fatigue analysis by linking microscopic and macroscopic behaviors and utilizing this understanding to optimize designs for durability. All this will together result in more efficient, economic, and robust engineering solutions.

Reference Sources

-

Structural Integrity | Durability & Fatigue Solutions | HBK – This source provides integrated solutions for testing, analyzing, and simulating durability and fatigue behavior.

-

eFatigue: Fatigue Analysis on the Web – A platform offering modern fatigue analysis tools and technology accessible via web browsers.

-

Improve Machine and Component Durability with Fatigue Simulation Analysis – Discusses how simulation software like Simcenter 3D integrates fatigue assessment into the design process.

-

Durability Analysis & Simulation | HBK – Offers insights into HBK’s durability simulation tools and their powerful analysis capabilities.

-

What is Fatigue Analysis? | SimScale – Explains the importance of fatigue analysis in designing and optimizing durable and reliable products.

Frequently Asked Questions (FAQs)

What is durability and fatigue simulation?

Durability and fatigue simulation analysis is conducted on materials and structures under variable loading conditions to identify any performance issues and potential life interruption. Engaging software, such as SolidWorks and CAE, enables engineers to perform durability calculations and assess fatigue strength, ensuring structural integrity in the long run.

How does one utilize vast calculations for product design?

Durability calculations have a significant influence on product design, as they help identify potential failure points well before the development process begins. By executing load simulations on a design, engineering teams can validate their concepts and modify them as necessary to address fatigue and durability concerns, thereby ensuring the product’s reliability.

What are some of the software tools for fatigue analysis?

Some of the software programs most frequently used for fatigue analysis are Ncode, Reliasoft, and Brüel & Kjær. These programs are designed to process large amounts of data and provide significant analytical power, enabling engineers to obtain stress results and use them to calculate the number of cycles required to fail different materials and structures.

In durability simulation, how is fatigue strength considered?

Fatigue strength is said to be the maximum load under specified cycles at which a material does not fail. In durability simulation, knowledge of fatigue strength is used to ensure component reliability when subjected to cyclic loads within their respective working duration.

What is the importance of the mesh in durability and fatigue analysis?

The mesh divides a complex structure into smaller elements for durability and fatigue analysis. Additionally, an effective mesh will yield an excellent stress result; engineers will then be able to identify how the loads are distributed throughout the structure, ultimately aiming to improve durability simulation accuracy.

Modal analysis is applied to durability simulation in which way?

Durability analysis is enhanced by modal analysis, which identifies the natural frequencies and mode shapes of a structure. This information helps understand the component’s response to dynamic loading conditions and may help foresee any durability problems that might arise due to resonance or other vibrational effects.

What is the factor of safety, and what is its relation to fatigue and durability?

The factor of safety is a design parameter because it provides a margin of safety, comparing the material’s strength to the expected loads. In consideration of fatigue and durability, the factor of safety underlies the prevention of failure from cyclic loads by ensuring the design can withstand any unexpected stresses and loads during its working life.