Test fixture design is rapidly evolving on the spur of innovations and efficiency in testing processes across industries. Whether it be for ensuring reliability of the product, streamlining test procedures, or for reducing costs of development, test fixture design has gained a firm foothold in modern engineering and manufacturing. This blog will explore recent methods and techniques in test fixture design that such professionals can use to make the testing environment for their projects more flexible and adaptable in overcoming the usual problems. Digging up some down-to-earth tips and best practices should help raise your test-setup knowledge a notched-up level!

Understanding Test Fixtures

Definition and Purpose of Test Fixtures

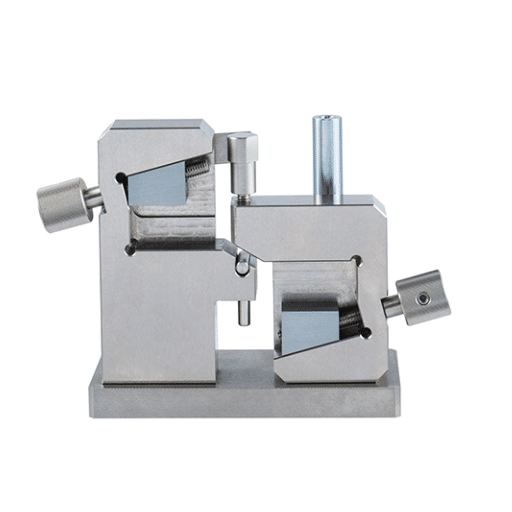

Test fixtures are tools that hold, support, or position components during testing procedures. These fixtures provide a consistent and repeatable environment so that results may be accurately made. In force-testing applications, the fixture generally acts to hold the tested sample while forces are imparted on it, so that it does not move unintendedly or become inconsistently tested.

Key Functions: Force-testing fixtures cater to special test requirements depending on what forces are applied: compression, tension, shear. They are agglutinative in holding the test samples and preventing forces from being applied. This prevents anything else from being involved in the measurement-other than the factors that are meant to be measured. This is important, I mean, for relevance and to make sure punctual deviations from the test are not considered external factors in the results.

Force testing fixtures, on the other hand, are accommodated for a high degree of adaptability. Most of these are modular, or adjustable, or custom-designed for different sample sizes, shapes, and testing standards. Their strength and reliability allow them to endure several hundred cycles of force application, thereby supporting long-term testing and product development. They are very much required to establish the performance of a product and to ensure safety and quality.

Types of Test Fixtures

A force testing fixture is an instrument designed to measure the force applied to a product or material under defined conditions. Properties such as tensile strength, compression, and shear force are evaluated with this kind of fixture. They give room for proper securing of the test sample in alignment with the testing machine, standardized testing conditions, and, therefore, the precision in results, which is a very important factor for any testing procedure in giving unvarying results and reliability of data on recurrence of test cycles.

Durability Features

These fixtures are meant to be ruggedly built to survive a large number of test cycles, especially at high levels of force. The material used to construct the fixture must be very strong and define the range of loads from light to very heavy force applications.

Flexibility & Modularity

Force testing fixtures are provided in adjustable and modular forms to accommodate a wide range of sizes, shapes, and standards for samples, thus making the fixture an indispensable test apparatus for a wide variety of applications across industries.

Force measurements have their applications in product development and quality assurance to establish if a product meets its safety and performance standards under different conditions set through specified standards. This type of testing finds application in sectors where strength and durability of materials and components are key: aerospace, automotive, consumer goods. Weaknesses can be revealed by force-testing fixtures, designs improved, thus ensuring that products conform at a higher quality and reliability standard.

Importance of Design for Test in Fixture Development

Design for test (DFT) is important to the development of force testing fixtures to ensure that the process is carried through efficiently, reliably, and yield meaningful results. By practicing DFT, engineers will be able to convey challenges in the design stage, hence minimizing errors in the testing phase and saving both time and money. Correctly designed fixtures will improve accuracy and repeatability of testing that is crucial in testing for strength and durability of products.

Key DFT Principles:

- Forces test fixtures must be created that reflect precision, repeatability, and ease of use

- A good fixture provides secure positioning of the test specimen to ensure its repeatability

- It allows the proper application of forces and ensures measuring devices are oriented appropriately

- Proper attention to detail raises the reliability of test results so that they fit performance standards

Complementing this, DFT facilitates an adaptive approach while maintaining scalability within fixture designs. Fixtures that can be modularly or adjustably configured can be used for testing assorted products, thereby multiplying utility and cost-effectiveness. Besides, considering design characteristics inclined toward safety and ergonomics augments the testing process and develops safety conditions for the operators. Therefore, installing DFT concepts would guarantee the defining requirements for force-testing fixtures in industries including aerospace, automotive, and consumer goods manufacturing in which the one-a-half-aloud-down-grade must be safety and performance.

Technical Factors Influencing Test Fixtures

Test Efficiency and Its Importance

Inherent in the design and implementation of force-testing fixtures is test efficiency, which can equally affect operational performance and cost. Test fixtures, when created-to-be-efficient, reduce the time required for testing by enabling faster and more accurate measurements of test products or raw materials, with the data being sufficiently reliable for making decisions. Manufacturers can therefore operate strictly on scheduled production and avoid delays due to faulty or inconsistent measurement data.

Repeatability

Efficiently designed test fixtures ensure that the results from each test are as close to the same as possible, thus minimizing any possibility of error caused by variable test conditions.

Value Maximization

Test efficiency ultimately helps insert the total value-maximization calculus. Efficient fixtures reduce frequent recalibration, unnecessary labor, higher costs, and newer force-test fixtures.

Last but not least, test efficiency ultimately helps insert the total value-maximization calculus. Efficient fixtures reduce frequent recalibration, unnecessary labor, higher costs, and newer force-test fixtures, thereby increasing the life span of testing equipment. Efficient force-testing fixtures come therefore to the forefront in modern manufacturing and ensure improvement in safety standards, performance, and application domains.

Accuracy in Testing: Key Metrics and Measurement

Accuracy in force testing is one of the factors ensuring constant results and reliability. Some of the key criteria include precision, repeatability, and calibration. Precision is the hallmark of a force-testing fixture that produces consistent readings that display minimal variance; hence, one can rely on this fixture for any given measurement. When discussing repeatability, we refer to ensuring that if one or more measurements are taken under the same conditions on the very same specimen, they should yield practically the same results; this confirms that the equipment performs consistently. Calibration of a testing fixture ensures it is compliant with all industry standards, thereby decreasing margin of errors and ensuring measurements lie within the accepted tolerances.

| Key Metric | Description | Importance |

|---|---|---|

| Precision | Consistent readings with minimal variance | Ensures reliable measurements |

| Repeatability | Same results under identical conditions | Confirms equipment consistency |

| Calibration | Compliance with industry standards | Reduces margin of errors |

Important Considerations

According to such metrics, frequent checking and maintenance of testing equipment are mandatory. Calibration tasks must be carried out in their intervals or upon a discovery of a deviation to have the guarantee that fixtures are within an acceptable range of set parameters. Environmental elements like heat, humidity, or vibration play a bonus role in affecting accuracy; hence, performing tests in an environment with controlled conditions is best.

Setting a delicate balance between precise measurement and practicable use is key. Contrivance priorly made complicated may in fact present superfluous complications while much more simple fixtures capable of doing the job might deliver precision with less risk of error. Focusing on these aspects will allow manufacturers to maintain high safety standards, attain optimum performance, and ensure better application results in diverse testing scenarios.

Durability Factors in Test Fixtures

Durability remains a major aspect while considering force-testing fixtures, as these components are subjected to repeated usage, extreme stresses, and varying environmental conditions. Materials in the construction of test fixtures may ultimately determine their life span. High-grade metals such as stainless steel or reinforced alloys are usually chosen because of their resistance to wear and corrosion and ability not to deform under pressure. A careful choice of material may assure that a fixture is capable of handling the loads it’s supposed to carry without too much wear or outright destructor.

Design Integrity

Fixtures will have to be engineered with high precision so that forces are distributed evenly without concentrations that bring about stresses and disallow cracking or fracturing with time. Features like reinforced joints or adjustable elements might be built in to provide more durability.

Maintenance Requirements

Regular inspection and maintenance are important for maintaining the durability of force testing fixtures. Periodic evaluations help detect signs of wear, material fatigue, or misalignments before these develop into crucial problems.

Regular inspection and maintenance are important for maintaining the durability of force testing fixtures. Periodic evaluations help detect signs of wear, material fatigue, or misalignments before these develop into crucial problems. Equip fixtures with lubricated moving parts; replace worn-out parts, ensure adequate storage conditions; all these lead to a longer life for a fixture and guarantee its accuracy and dependability when conducting tests. By ensuring proper materials, good design, and periodic care, manufacturers can ensure the greatest degree of durability and performance from their force testing fixtures.

Methods and Techniques in Test Fixture Design

New Test Methods in Fixture Design

Developing test methods for force-testing fixtures is important in achieving greater accuracy in mechanical testing and attaining efficiency. Modular fixture designs allowing for quick interchangeability of individual components for various testing requirements form one of the advanced approaches. These modular systems decrease setup time and serve as a general solution to various force testing applications, thereby granting more flexibility and productivity.

Advanced Approaches in Fixture Design

Modular Systems

Quick interchangeability of components for various testing requirements, decreasing setup time and increasing flexibility.

Digital Integration

Embedded sensors for real-time data collection and predictive maintenance capabilities.

Advanced Materials

Lightweight composites providing structural integrity while maintaining easy handling and adjustments.

Another major advancement is the digital aspects for fixture design. As the sensors will be embedded into the fixtures, these sensors may collect data in real-time while also ensuring testing was done with very high precision. In addition, digital monitoring systems can be used for predictive maintenance; if they detect that the usage of the fixture is disturbed by wear or malfunction, this process will be registered before the integrity of the testing is compromised. Therefore, this will reduce downtime and greatly maximize the reliability of the testing.

Moreover, the use of materials like weightless composite is truly revolutionary in the concept of fixtures’ design and implementation. These materials provide structural integrity while keeping the weight of the fixtures low, allowing easy handling and adjustments. Such advanced manufacturing techniques, enhanced by 3D printing, have provided new avenues for a fixture to be designed specifically for testing yet with greater performance and lesser time for making. All these developments establish efficiency and effectiveness in today’s force testing fixtures.

In-Circuit Test Techniques

Force testing fixtures are special tools employed to assess the strength, durability, and response of materials or components under various loading conditions. Test fixtures ensure that the experiment is repeatable and accurate by holding the test specimen securely and applying force through the test mechanism in a controlled manner. Fixtures, being custom-designed, can be adapted to a wide variety of applications ranging from tensile to compressive and shear testing.

Manufacturing Excellence

It is commonplace of the manufacturers of these fixtures to use durable metals or lighter composite materials for long-term reliability and flexibility in high-stress testing scenarios. Advanced methods of manufacturing such as CNC machining and additive manufacturing have ushered in a new age in fixture production-the ability to design the most complex geometries to gain the most out of performance. These production techniques offer a very attractive combination of reduced production time and potential for rapid prototyping to sculpt fixtures in response to specific testing constraints.

A combination of innovative design and state-of-the-art manufacturing results in fixtures for force testing that offer greater precision in testing and ease in processing. They contribute to quality control and product development, whereby industries can efficiently achieve their safety standards and meet their regulatory demands.

Challenges in Implementing New Test Methods

There are various challenges while implementing new test methods for force testing fixtures. First, there is a question of whether the new methods and their procedures can work with existing equipment. Legacy instruments might not support newer techniques, and might need an enormous financial outlay into either new tools or infrastructure. Initial costs go up, together with the time it takes to get on board the new system, and this deters businesses from going ahead with the upgrade.

Equipment Compatibility

Legacy instruments might not support newer techniques, requiring enormous financial outlay for new tools or infrastructure upgrades.

Training Requirements

Personnel need understanding of both practical application and theoretical concepts behind updated test methods to provide credible results.

Regulatory Compliance

Testing protocols often need to follow established industry standards, necessitating certifications or approvals that can be time-consuming.

Training and working knowledge thereof constitute the next big challenge: How can one ensure with confidence that new testing methods are administered appropriately for their accurate application? Personnel are expected to have an understanding of the practical application and theoretical concepts behind the updated test methods to provide credible results. Without adequate training, one runs the risk of errors that could nullify any advantages of the new methods. A full training plan and protocol need to be designed to overcome this issue.

Finally, companies face the challenge of compliance to regulations when developing new methods. Testing protocols very often need to follow established industry standards, necessitating perhaps certifications or approvals. It can be a very time-consuming and tricky affair but critical in ensuring product quality and safety. By navigating these challenges strategically, companies will be successful in implementing new test methods, thus further enriching their testing capabilities.

Factors Affecting Force Testing Fixtures

Calibration Methods and Their Importance

Calibration procedures are crucial to ensuring that the force testing fixtures stay reliable and accurate. Calibration is an adjustment and verification process wherein the force measuring equipment is checked to ensure that the measurements of forces are made accurately. This process guarantees that the results from the test measurements are in conformity with the accepted standards, instilling much confidence in the results. Regular calibration ensures that any errors that might creep in due to drifting or wear of instrumentation are minimized, rendering constant performance.

Typical Calibration Procedure

A very typical calibration procedure for force-testing devices is the usage of certified weights or load cells. These instruments apply known forces to the fixture, which are compared with the reading of the fixture. Any inconsistency observed is corrected with respect to the standard, to bring the equipment calibration back to proper alignment. This is an effective method because a direct comparison to force standards is available.

Periodic calibration is a must for conforming to industry standards and ensuring the quality of testing processes. If such calibration is overlooked, it could lead to accepting inaccurate data as test results and thereby endangering safety or product performance. Hence, a good calibration schedule needs to be followed with all best practices so that reliable and repeatable results in force testing applications are obtained.

Testing Efficiency and Precision

During the testing procedure, force testing fixtures must assure a smooth flow of work and the maintenance of all the necessary precision requirements therewith. These fastening systems are mounted to hold specimens against movement and guarantee consistent alignment during the enforcement of a force. By reduction of variability, one may measure reproducible results imperative in conforming to standards of an industry and ensuring the quality of materials or products under test.

Fixture Selection Considerations

- Depending upon the nature of the particular force and whether it be of tension, compression, or bending

- Along with the under-test sample properties, one will decide upon the final choice for the appropriate fixture

- The fixtures should not become a mode of deformation of the specimen during test loads

- They should be adaptable, allowing tests of specimens with various dimensions and shapes

Depending upon the nature of the particular force and whether it be of tension, compression, or bending, along with the under-test sample properties, one will decide upon the final choice for the appropriate fixture. The fixtures should not become a mode of deformation of the specimen during test loads, and, on the contrary, they should be adaptable, allowing tests of specimens with various dimensions and shapes. The force is surely testing data with the compromise, brought about by an ill-suited fixture; external factors such as slip, loosing, and misalignment mostly will begin to spoil the worthiness of such data.

The force testing fixtures need to be regularly checked and maintained so as to remain good and effective for years. The damage occurring over periods of use may cause unpredictable performance. By periodic checks and maintenance as prescribed by manufacturers, organizations maintain the integrity in their testing methods; hence safety, reliability, and compliance to standards.

Durability and Longevity of Test Fixtures

A force testing fixture is one of the primary necessities for assuring accurate and reliable measurements during the testing processes. To provide for durability and longevity, priority must be given to periodic inspections and preventive maintenance. These fixtures slowly lose performance due to the wear and tear that is incidental to its repeated use; this is at the variance of uniformity of test results. Hence, organizations must safeguard their test results through some regular inspection for obvious damage or malfunctioning.

Maintenance Guidelines

Following the test fixture maintenance guidelines laid out by the manufacturer sometimes significantly prolongs the life of the test fixtures. Maintenance tasks usually include cleaning the components, lubrication of moving parts, and calibration checks to ensure accuracy.

Early Detection

Inspections performed on a regular basis will detect any possible problems early on and prevent these issues from worsening into something requiring huge replacement or repair costs.

Proper Handling and Storage

With respect to given testing fixtures for durability, improper handling and storage definitely do contribute towards degradation. The fixtures must be employed within their rated capacity and under recommended conditions to avoid unnecessary stress. The fixtures must be placed in appropriate storage when not used to avoid excessive humidity or temperature fluctuations leading to deterioration. Certainly, when these factors are treated with care, a company manages to remain with testing systems that perform well, remain dependable, and are safe to use in the long run.

Industry Trends and Innovations

Emerging Technologies in Fixture Design

Because of the ever-increasing expectations for greater precision, speed, and flexibility in force testing, a great spotlight is cast upon force testing fixtures and their development in recent years. One of the remarkable developments is the inclusion of automated systems in fixture designs. Automated fixtures smoothen the testing process by applying forces with certainty and thereby eliminating human error situations. These systems also facilitate real-time data collection and analysis, which in turn enhances the accuracy and reliability of the test results.

Revolutionary Developments

Automated Systems

Smoothen testing processes by applying forces with certainty, eliminating human error and facilitating real-time data collection.

Modular Designs

Offer flexibility to reconfigure components for testing different items, saving costs and providing convenience.

Digital Twin Technology

Virtual simulation and remote monitoring capabilities that enhance precision and efficiency in testing systems.

Another prominent development is the impact of modular fixture designs. Modular fixtures offer flexibility to users who may want to test different items in the same system by reconfiguring components. Save costs and become more convenient than fixed or single use. Also, modular designs would embrace light and hard materials like composites and alloys for higher portability and longer use without compromising strength.

Lastly, through simulation and digital twin technologies, the design and usage of force-testing fixtures are slowly earning a new dimension. Mainly, with virtual simulation, engineers can model and predict the behavior of fixture designs before they are physically built, thereby substantially reducing the design time and cost. Moreover, with digital twin systems, managers can remotely monitor the tests while the test system itself can be updated so the test can deliver in accordance with the design intent practically. These are some ways in which the two technologies uplift the precision and efficiency levels in force-testing systems.

Future Directions in Test Fixture Development

As industries are moving towards the goal of maximum efficiency and great precision, the future direction of force testing fixtures is paved by automation, data integration, and materials improvement. Force testing instrumentation will be automated so that the process of testing will become consistent and thus repeatable, without being prone to deviations by human factors and becoming therefore more reliable. In time, the implementation of robotic calibration and self-adjusting fixtures to replace manual setups will reduce setup time and improve accuracy considerably.

Data Integration

Test fixtures designed with real-time monitoring and analytics capabilities will grant engineers insights for instantaneous decision-making through advanced sensors and IoT connectivity.

Sustainable Materials

Advanced composite materials and lightweight alloys may develop into more durable and versatile fixtures that are energy-efficient and environment-friendly.

Data integration and analytics will play a significant role in this. Test fixtures, being designed with the ability to monitor and analyze real-time data, will grant engineers with insights on instantaneous decision-making. Such systems shall rely on cutting-edge sensors and IoT connectivity to achieve efficient coordination among the fixture, the test systems, and the design platforms. The incorporation of ML algorithms could further aid in predicting wear and performance results, allowing for smarter test development strategies.

Sustainable material usage: there can be one promising direction. Advanced composite materials and lightweight alloys may develop into more durable and versatile fixtures that are energy-efficient and environment-friendly. Sustainable methods supported by additive manufacturing technologies, for instance, 3-D printing may help finish the rapid production of customized fixtures to satisfy specific testing requirements. These advancements should ensure that force testing fixtures continue to evolve and meet industry needs with the accuracy, reliability, and sustainability of the existing ones.

Frequently Asked Questions (FAQ)

Give examples of some defects in the test fixture.

Soldering and solderability problems can make improper tests, surface mount misalignment issues, fatigue failure of test fixture components, and other test fixture defects that can interfere with testing and producing poor results and thus incurring cost in terms of reworking or additional design modifications required.

How do test fixtures accommodate their specific testing requirements?

Test fixtures can be used to test differently equipped electronic devices. In-circuit test (ICT) fixtures are commonly utilized to test printed circuit boards by making contact with predetermined test points. This kind of fixture can be customized for the purpose of testing with its own special requirements that are peculiar to the DUT and, therefore, make testing very efficient.

What role does test fixture design play in the manufacturing domain?

Test fixture design is of great importance with respect to manufacturing. A better test fixture can simplify test scenarios, reduce tear down time, and thereby increase production efficiencies. With DFM and DFT principles considered, the manufacturers can assure that a fixture provides an appropriate setup to carry out more tests.

Can fixtures be used for multiple test methods?

Yes, fixtures can be used for different test methods: environmental and electrical. Test fixtures remain quite versatile to accommodate a range of testing situations in matters of prototype testing or high volume manufacturing, thereby ensuring that each device receives thorough evaluation.

What are implicit test fixtures and their importance?

An implicit test fixture is a generic terminology for a fixture that might not be explicitly defined but is crucial for the performance validation of an electronic device. Such fixtures provide enough flexibility in the test setup so that test signals and their configuration can easily vary; thus, one setup method can service a multitude of test needs.

How can test fixtures help to speed up testing?

Test fixtures speed up testing by being able to accommodate multiple tests within a single fixture, which in turn results in a reduced time required to run the various tests and thus less expenditures. This helps the manufacturers ensure their production targets are achieved while also upholding strict quality assurance standards through these rigorous testing procedures.

How does working with test fixtures improve the reliability of an electronic device?

Test fixture design with the required reliability ensures that every testing scenario is fielded uniformly. While inflicting in robust test fixture designs that are suitable to high-volume manufacturing, the manufacturer is advantaged to lessen the probability of defects and ameliorate the quality of electronic devices escorted out there.

How would high-volume production impact test fixture design?

Being a high-volume production would require good test fixtures that would ensure efficient operation at a very competitive cost. In most instances, there is a compromise for speed and accuracy hence low costs in manufacturing and maintenance. The additional design considerations and application of the fixture would be more felt in a high-volume production scenario.

References

- Grip and Fixture Solutions for Force Testing – Quality Magazine – Discusses factors like mounting hardware and proper alignment for effective force testing.

- Considerations When Testing Springs with Force Systems – Defense and Munitions – Highlights issues such as load sensor capacity and its impact on testing accuracy.

- The Importance of Force Testing Uncertainty – Scale People – Explores environmental variables like temperature, humidity, and vibration that can affect force testing.

- Tensile Testing Grips – A Guide to Buying the Correct Fixtures – AZoM – Focuses on selecting grips and fixtures based on testing type and capacity, avoiding overloading.