Industries ranging from aerospace to construction employ the sandwich construction techniques, which are known for their strength-to-weight ratio and structural efficiency. The ability of these materials to perform well under stress and thus increase longevity of the end product is an important criteria. Hence, ASTM C297 acts, in this case, as a flatwise tensile test applied to determine the bond strength between core and facing in sandwich panels. This blog will walk you through the basics of ASTM C297, its significance, and how this standard test method plays a role in quality assurance and engineering innovations. You will gather some critical insights into how this test ensures safer, stiffer, and resilient architectures, whether you’re a materials scientist or engineer or simply interested in testing methods.

Introduction to the Flatwise Tensile Test

Definition of Flatwise Tensile Test

The Flatwise Tensile test as per ASTM C297 is used to test the bond strength between the core and the facing of sandwich panels. A tensile force is applied perpendicular to the plane of the panel until failure ensues. The test would give an idea about the integrity and performance of adhesive or bonding agent under tension.

For the test, aluminum blocks are glued to the facings of the sandwich panel. These blocks are gripped and pulled apart so that tension is applied uniformly, forcing the stress to be equally shared across the entire bond area. The tensile force required to cause bond failure will be used in determining how strong the bond is. Lower tensile strength may indicate potential deficiencies with the material, poor cohesion, or it might have been affected environmentally.

Considering the realization about the importance of this test, it is an essential test for the aerospace, automotive, and construction industries to ensure that the sandwich panels conform to safety and performance standards. Because the test may expose weaknesses in structure, Flatwise Tensile tests also enable manufacturers to develop production procedures and standards materials toward a stronger and more reliable end product.

Purpose and Importance of the Test

Because of its tremendous importance, the plane tensile test analyzes the strength and durability of a specimen under tension. It is found out how much stress a material can take before it begins to deform or break apart due to the applied uniaxial tensile force. The information is required in every field where materials play such a vital role in safety and functionality-the aerospace, construction, and automotive fields.

One purpose of the plane tensile test is to find out the material’s tensile strength, modulus of elasticity, and ductility. These parameters give engineers information on whether a material can behave under force in a certain mode, thereby determining the suitability of the material for specified engineering applications. Knowledge about tensile properties of materials provides assurance that the materials employed in a critical structure will not fail under working forces, thus laying down the basis for designing a safe and workable system.

The potential flaws or weaknesses in a material are analyzed by plane tensile tests, which, in turn, allow manufacturers to improve their procedures and upgrade the quality of the material. Having identified such flaws and refined production techniques, industries can mitigate against product failure, increasing the life and the reliability of the finished products. Thus, an organized association of tensile plane test gives the infrastructure of performance excellence and top-class guarantee of safety-wise parameters.

Overview of ASTM C297 Standard

Applying tensile force is a crucial evaluation method for adhesion strength determining the bonding of the core of a material to its facing layers. The machine tests materials to withstand a tensile force that is applied perpendicular to its facing, allowing practitioners to record any weaknesses or defects that would otherwise jeopardize structural integrity. ASTM C297 is the testing standard for this evaluation and is commonly used to test sandwich types of constructions, including but not limited to composite panels, to ensure they satisfy a particular specification of performance.

According to the ASTM C297 standard, the fixtures are bonded to the facings of a sample specimen, which is then pulled under tensile loading. The test helps reveal whether failures may be occurring in the core, the adhesive, or in the facing. Such distinctions lay the groundwork for assessing the quality, life, and safety of materials in construction, aerospace, and automotive industries.

Plane tensile tests provide valuable data that are a matter of quality control and also interface with material development and optimization. Knowing the mode and location of failure enables manufacturers to alter their processing so that reliability is assured and safe applications in specified environments are possible. Thus, plane tensile testing stands to directly influence the improvement of materials and their adherence to engineering standards.

Understanding Sandwich Constructions

Components of Sandwich Constructions

Sandwich constructions are structural composites widely used in engineering applications for strength and lightness. They feature three components: the skin, the core, and the adhesive layer. The skin is usually made from materials that have great tensile and compressive strength, for example, metals or fiber-reinforced plastics. The core materials are usually lightweight, and can be foam, honeycomb, or wood. It imparts thickness and provides support without adding to weight. The adhesive makes the bond between the skin and the core, thus ensuring the structural integrity of the sandwich panel.

Plane tensile testing is crucial in the evolution and optimization of materials used in sandwich constructions. A thorough understanding of how each component of the sandwich panel reacts to tensile stress is necessary to ensure the construction will stand operational demands. This test informs designers and engineers about the failure modes of sandwich materials. It, therefore, permits better specification and improvement of core and skin materials to fulfill engineering criteria. Above all, by using plane tensile test results, manufacturers build stronger and more reliable sandwiches for applications in aerospace, automotive, and civil engineering fields.

Types of Core Materials Used

Depending on their characteristics and practical utilization, different main core materials are used in sandwich composite structures, such as:

Foam Cores

Polymeric foams such as PVC, polyurethane, and polystyrene are options because they are light and good at absorbing energy.

Honeycomb Cores

Using aluminum, Nomex, or thermoplastic materials, these cores offer an excellent profile of strength versus weight and are often applied in aerospace maintenance.

Balsa Wood

This wood-grown balsa is highly appreciated for its low density, sustainability, and admirable mechanical properties and is used for marine and wind turbine applications.

Corrugated Cores

These offer a combination of strength and flexibility; they offer impact resistance and are suited for industrial and technical applications.

The choice of core material really depends on the load, weight, thermal, and environmental constraints established by an application.

Common Facings in Sandwich Panels

The materials for the facing in sandwich panels constitute the first stage that will decide the ultimate performance of sandwich panels. For the most part, the common facings include:

| Facing Type | Materials | Key Properties | Common Applications |

|---|---|---|---|

| Metal Facings | Aluminum and steel | Strength, stiffness, durability, fire resistance | Construction and aerospace applications |

| Composite Facings | Fiberglass-reinforced plastic (FRP) and carbon fiber | Great strength-to-weight ratios, corrosion resistance, design flexibility | Automotive, marine, and lightweight structural applications |

| Wood-Based Facings | Plywood and MDF | Cost-saving, moderate strength and stiffness | Furniture panels and building applications |

Following the application, the selection of facing material is done to ensure strength and stiffness, material durability, and resistance to certain environmental conditions, ensuring that the panel conforms to performance standards.

Methodology of the Flatwise Tensile Test

Preparation of Test Specimens

Test specimens for flatwise tensile application must be prepared as per standard guidelines to maintain the accuracy of observations and to make sure the method of test is consistent. The materials such as plywood or MDF should be cut to size as per the given specifications in the appropriate testing standard (e.g., ASTM D1037 for wood-based panels). Specimen surfaces should be clean with none of the defects that can affect test results.

Cut edges should be smooth; if not, sanding should be done to avoid high-stress points during testing. Adhesive bonding is done between the specimen and the loading platforms. Load application needs to be uniform. The effectiveness of the test relies on the capacity of the adhesive to fully cure.

Specimen labeling is important for trackability and accurate recording of data. Each sample must be clearly marked with the batch number or material type. A specimen properly prepared should thus assure reliable results in the assessment of the flatwise tensile strength and performance of the panel.

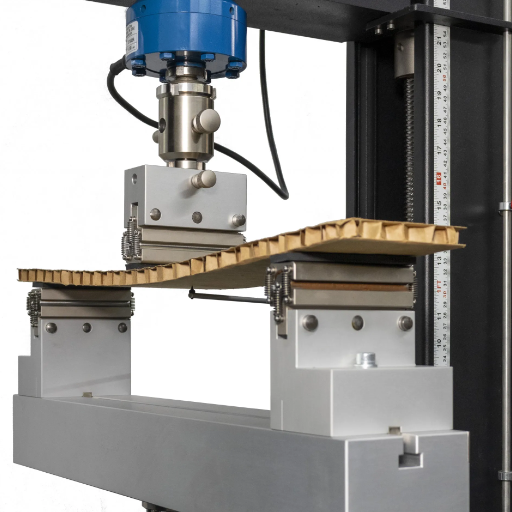

Test Setup and Equipment

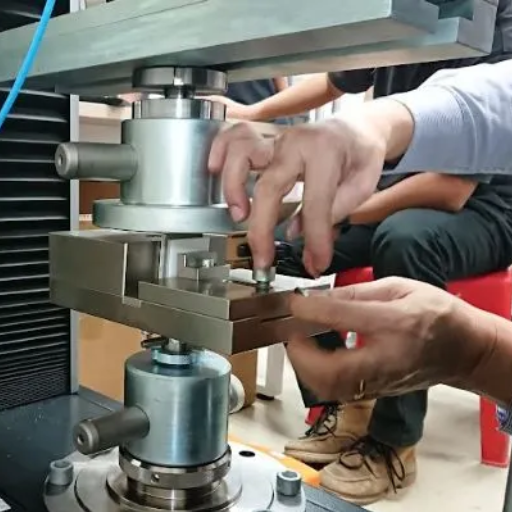

For a planar tensile test, you would perform tensile loading with a tensile testing machine with fixtures suitable for holding panel specimens. The test grips must be able to apply a uniform load all over the bonded area so that stress concentrations and premature failure due to these stress concentrations do not affect the result. The equipment must contain a load cell with a precise calibration to measure forces.

Specimens must be cut to size with their surfaces clean, flat, and free from contamination. Any bonding or adhesive layer has to be applied evenly and should undergo full curing prior to testing. Proper alignment of the specimen in the machine is very important; otherwise, uneven loading could take place, which may affect the test results.

Tensile force shall be applied by the testing machine at a steady rate until failure occurs in the specimen. The testing machine records maximum load and displacement values of the specimen at the instant of failure. These values are employed to compute the flatwise tensile strength of the panel. Environmental factors such as temperature and humidity can affect the test results. Hence, they should be closely monitored during the test. The most reliable data can be obtained only by ensuring the above setup and procedural considerations.

Loading Procedure and Measurement Techniques

The planar tensile specimen loading started after proper alignments of the specimen inside the testing machine so that the force distribution is equal. The grips should be adjusted such that the specimen will be held firmly but not stressed or distorted in any manner. As soon as the specimen has been grasped, a steady, uniaxial tensile load is applied to it by the machine, with the rate of application being controlled. The load rate should be chosen in accordance with that specified in the testing standards so that there are no abrupt variations in the force that might affect the result.

During the application of tensile load, it becomes essential to measure load and displacement with great accuracy. Advanced sensors embedded in the testing machine keep track of these parameters throughout the testing process. The maximum load together with the displacement up to the point of specimen failure is noted. Objective measurement of these parameters provides reliable values of flatwise tensile strength. The testing apparatus requires routine calibration and maintenance because errors can be introduced otherwise.

Such environmental conditions as temperature and humidity must be maintained in standard form if the tests are to be guaranteed for accuracy in the planar tensile test. Any variations in these factors may actually affect the properties of the materials and may thus affect the results of the tests. It is, therefore, best to conduct tests in climate-controlled facilities or environmental chambers so as to obtain reproducible test conditions. In this way, following the specified procedures and by using the given monitoring techniques, the planar tensile test is a reliable determination of strength properties under controlled conditions.

Applications of Flatwise Tensile Testing

Industries Utilizing Sandwich Constructions

Due to their strength and light weight, these sandwich constructions are widely used in aerospace, automobile, and construction industries. For instance, the aerospace industry depends on these materials for lightweight interior panels, fuselages, and wing structures to add to their performance efficiency and fuel economy. Flatwise tensile tests ensure these materials comply with stringent safety and performance standards under control conditions.

In a similar way, sandwich constructions are used in the automotive industry to construct structural members, floors, and body panels. Planar tensile tests allow industries to determine the bonding strength and integrity of such composite layers accurately. This testing is the major factor that assures structural reliability and safety of vehicles when subjected to varying stress conditions.

Sandwich constructions are used to manufacture lightweight construction materials that are strong in nature, such as insulated panels and bridges. Flatwise tensile testing is always used for important purposes in controlling the mechanical properties of these materials. This enables an infrastructure project to have industrial efficiency and safety while remaining strictly qualified.

Specific Materials Tested

Planar tensile loading is used for testing composites, metals, and polymers, which undergo stress in flat geometries. Such materials are selected for their special properties such as high strength-to-weight ratios, durability, and resistance to environmental degradation. Commonly tested composites include carbon fiber-reinforced plastics and glass fiber-reinforced polymers for their use in aerospace, automotive, and construction industries.

Planar tensile tests are also commonly inflicted on metals, such as aluminum alloys or steel plates. Such materials are usually intended for structural applications where the flat orientation of the material and the tensile properties under stress may affect performance and safety. By performing tests on these metals, the data obtained regarding elastic limit, yield strength, and breaking points of the material would ensure that these metals contain the quality of being used in load-bearing applications.

On the other hand, polymers and materials such as polystyrene, PVC, and polypropylene undergo planar tensile testing so that they may be studied with regard to their deformation behaviors under stress. This testing is used to establish the prima performance attributes concerning packaging, insulation, and other consumer applications so that they can be processed further to become reliable in their use. Beyond doubt, direct planar tensile testing of materials is considered essential in defining the high engineering standards in varied fields.

Real-World Examples and Case Studies

- Packaging Industry: One of the important planar tensile applications is the packaging industry. These materials undergo tensile testing, for strength, flexibility, and ability to sustain stress. Their testing is conducted by food packaging companies for assurance that the packaging will hold during transportation once storage will be undertaken. Consequently, this ensures consumer safety, wastage is reduced, and is an indication of what the testing assures-the materials in practical applications.

- Aerospace Industry: Planar tensile testing plays a crucially crucial role in the aerospace industry. Aircraft and spacecraft structures utilize lightweight composites and advanced polymers, which are subjected to planar tensile tests to ensure they can withstand extreme loads while remaining lightweight and fuel-efficient. The testing has played an important role in satisfying the much-needed enhanced safety and performance standards in aerospace and space exploration.

- Construction Materials: Construction materials such as steel and high-performance concrete are equally subjected to planar tensile tests. These tests provide information about the stress behavior of the materials when used in bridges, skyscrapers, or other infrastructure projects. By ensuring optimal strength and reliability, planar tensile testing reduces the risk of structural failures, which in turn ensures public safety in all urban developments.

As materials’ performance is evaluated in consideration of various industries, this underlines how important planar tensile testing is.

Interpreting Test Results

Understanding Flatwise Tensile Strength Data

Flatwise tensile strength data provide crucial information on the ability of a material to withstand stress applied perpendicularly to its surfaces without separation or failure. Tests measuring flatwise tensile strength are needed when core materials or composite structures are subjected to forces acting across their layers. It allows the engineer to design or select a material for an application that requires consistent performance under load.

To interpret flatwise tensile strength data, engineers usually consider parameters that are derived from controlled planar tensile tests. Controlled planar tensile tests measure the maximum stress a material can withstand before failure, thereby providing a comparative basis between materials. The results may be influenced by materials being tested, environmental conditions, and test parameters, and thus it becomes imperative to carry out these tests in a standardized manner to arrive at valid conclusions.

Having a good understanding of flatwise tensile strength really helps the construction, aerospace, and manufacturing fields. A knowledge of the limits of flatwise tensile strength in materials will allow engineers and metallurgists to make sound decisions for safety and durability in the application. Such clear and reliable data offer protection from structural failures, and thus, clearlyifies the importance of accurate tensile testing for material validation.

Significance of Results for Material Selection

Planar tensile experimental results should play a major role in selecting materials for varying applications. The test measures the action of stress exerted on the material in a flat plane to acquire strength and durability data in real-life situations. Hence, depending on the properties, engineers can judge if the material conforms to certain level requirements for design safety and durability.

Some good and reliable data would put to test the planar tensile test and reject materials to be tested if there is a possibility of the material failing under anticipated loads or under an action of some environment. Thus, only those materials which can physically stand intended applications are chosen, reducing the risks of collapse and cutting back on excessive maintenance costs. Such tests are paramount for industries where precision and reliability go hand in hand-with aerospace and construction parametric to it-backing the decision-making process.

The planar tensile tests help also to optimize the design process on the basis of materials having an ideal compromise between strength and weight. This value increases where choosing a very lightweight yet strong material is required, thereby conserving time and resources. Thus, the ultimate accuracy and value of planar tensile results put the professional’s material selection decisions on a firm data-backed footing.

Analyzing Bond Quality and Structural Integrity

It is a method most vital for bond quality evaluation and structural integrity assessment. The forces needed to actually pull a specimen are hence applied to observe the levels of stress it can handle and noticing any weaknesses that may consist of voids, cracks, or inhomogeneities. Such data will in due course correspondingly update the engineers and designers toward trusting whether the material will behave up to the expected requirements in its application.

One of the most prominent characteristics of a planar tensile test is its ability to replicate what occurs in nature when materials are exposed to tensile forces. This advantage renders it ideal for determining layer-to-layer or composite bond durability under strain. For example, any form of adhesive bonding being tested ought to guarantee safety, durability, and performance, thereby rendering the results of this test of utmost importance in the aerospace and automotive industries.

Planar tensile testing ensures exactness regarding the material choices made and bonding processes accepted at the preliminary stage. This prevents possibilities of failure on the latter stage and secures long-term reliability of the final product. The data therein provide for informed choices and promote the development of lightweight and reliable structures, hence being a top-class testing method in modern days of engineering and manufacturing.

Frequently Asked Questions (FAQ)

Q: What is a flatwise tensile test?

A: It is a standardized testing procedure used to determine material tensile properties, especially of sandwich materials. This testing is done under the flatwise tensile load of sandwich panels to test the core-to-facing bond resistance. It is used for determining the flatwise tensile strength of sandwich panels.

Q: Why is the flatwise tensile strength of utmost importance for sandwich constructions?

A: Flatwise tensile strength is paramount for sandwich constructions as it measures the strength of core-to-facing bonds. This property is, therefore, a determining factor for the assembly, performance, and structural design properties of the sandwich panel, ensuring its durability in any field of application.

Q: How shall flatwise tensile strength testing take place?

A: Flatwise tensile strength testing is conducted using special test fixtures on an Instron machine by continuously loading samples beyond their limit until rupture. The method to flatwise tensile strength includes accurate specimen preparation and conditioning to yield valid test results.

Q: Which factors influence the tensile strength of the core in sandwich panels?

A: Tensile strength of the core depends on several factors such as material specifications, insufficiencies of bond core-to-facing, and assembly processes. A proper quality control test for bonded sandwich panels is therefore useful for assessing such factors.

Q: What are the standard test methods used for conducting flatwise tensile tests?

A: Standard test methods for flatwise tensile tests are the procedures outlined to produce consistent and reliable results from specimen preparation, alignment to the testing machine, and monitoring speed of testing for tensile strength of the core.

Q: Can the flatwise tensile test be employed for custom sandwich panel designs?

A: Yes, the flatwise tensile tests may be performed for custom sandwich panel designs as well. Manufacturers could use the standard test method for flatwise tensile strength to appraise the core-to-facing bond integrity of novel constructions to ascertain they perform to the desired criteria.

Q: What does specimen conditioning come to in flatwise tensile testing?

A: Specimen conditioning unravels during the flatwise tensile testing procedure as the conditioning ensures that samples may be tested under a controlled ambient setting. This way, results are consistent, and variability due to environmental factors is kept to a minimum, which is extremely important when data on tensile strength are required.

Q: What is the effect of accelerated aging on the flatwise tensile strength?

A: The main effect of accelerated aging is generally a decrease in the flatwise tensile strength of the sandwich panels. This tests the core facing for its ability to retain the strength of the core-to-facing bond over long-term exposure to environmental conditions-albeit with respect to certain accelerated factors-or assures quality credit thereto.

References

-

ASTM – Standard Test Method for Flatwise Tensile Strength

This source outlines the ASTM C297 test method for determining the flatwise tensile strength of sandwich panels. -

Instron – Tensile Strength Composite Sandwich Constructions

A detailed explanation of the flatwise tensile strength test and its application in measuring the bond strength between substrate and core materials. -

Azdel Onboard – Flatwise Tensile Testing

Information on the Flatwise Tensile Test (ASTM C297) used in the RV industry to evaluate bond strength.