Good shoes must have quality and efficiency associated with them. Whether one is an athlete late to a shoe involved in blow-the-hands activity or simply an everyday user in search of comfort and sturdiness, shoe testing must guarantee that shoes live up to their claims. This shoe testing blog will work to introduce you to the concepts, methodologies, and standards that all combine science and art to make sure that you are supported by quality and excellence in every single step. From testing material strength to ergonomic design, the blog will delve into major processes where modern footwear is considered an amalgamation of science, engineering, and design. Stay with us as we look into how quality assurance protects a consumer and revolutionizes the industry.

Introduction to Footwear Testing

What is Footwear Testing?

Footwear testing is a systematic process through which shoes are tested and rated against predetermined quality, safety, and performance criteria. Footwear testing includes evaluating the product for its durability, comfort, firmness against slips, impact protections, etc., so as to accept it as reliable and beneficial from the consumer’s point of view. This process also enables the manufacturers to discover potential defects or flaws in the design of a product before it goes into the market.

One of the most important aspects in performing footwear testing is with regards to safety and protective features. The shoes are tested as protective devices on various surfaces like providing slip resistance on slippery floors or impact absorption on physical activities. In addition, footwear generation materials are also submitted to insolvent testing suitable to consider that they do not contain any harmful substances that may harm human beings or the environment.

The performance aspect of footwear testing should never be overlooked. It checks if the shoes will hold up under extreme heat or cold, or whether they will last for long usage. Testing may be oriented towards ergonomic design, considering whether or not footwear supports natural movement and, thereby, slight strain or discomfort from being exerted on the body. Testing allows manufacturers to develop good products that perform the advertised function with durability and comfort for the end user.

Importance of Footwear Testing for Quality Assurance

Some would know the importance of testing footwear for it belongs to quality. If this pass the objective test before reaching the shoe market, testing will be judged by the manufacturers on durability, safety, and functionality. Similar to actual conditions, footwear testing ensures that the shoes can be worn comfortably in daily life, or the user may have plenty of unpleasant experiences below. Either walking or jogging or weather changes-environmental conditions-the shoes must stay in use at all times.

Another basis in shoe testing maybe the comfort and fitting factors. Ill-fitting shoes cause discomfort and peril to one’s long-term health, through foot pain or joint strain. By testing it for ergonomic consideration and material flexibility, footwear testing can promote natural movement and minimize strain, particularly for those for whom the shoes should do all: special performance or safety-a good set of sneakers or work shoes.

In conclusion, the testing of footwear is undertaken as an assurance of quality in the industry. It creates a base of trust between the manufacturer and the consumer, ensuring that the products maintain defined performance standards. The products examined are more prone to undergo less recalls or customer complaints upon sufficiently meeting the industry standards, thereby protecting the manufacturer’s reputation and the end consumer’s satisfaction.

Impact of Testing on Brand Reputation

Testing is the first step in impacting and building a brand’s reputation by assuring the customers of its quality and reliability. Products that pass established performance and safety standards are trusted by buyers, and with little doubt, the brand name itself becomes synonymous with reliability and quality value. Such a reputation will attract new consumers while taking care of existing customer loyalty.

When continuously testing products rigorously, the brands could check defective products from being launched into the market. Hence, the brands are less likely to have recalls, bad reviews, and dissatisfied customers-the ones that can wipe off a brand’s image. And, if it really does get reputational value when checking quality assurance, then that value will give away brand uniqueness from competitors and reinforce it in the market place.

Moreover, transparency in communicating testing processes builds credibility. When brands declare openly their commitment to safety and performance standards, consumer confidence is built, and the consciousness of ethical and responsible/business practices is enhanced. Ultimately, thorough testing is an investment in the health of a long-term business reputation.

Types of Footwear Testing

Durability Tests: Ensuring Longevity

Withstanding regular wear and environmental rigors is an essential premise provided by the durability tests for shoes. These tests determine the strength of the materials, abrasion resistance, and the quality of construction of the product in identifying its longevity. Through the replications akin to real-world conditions, durability testing allows us to obtain input concerning the life span of an item of footwear and its capacity to hold its functional value over time.

One such test is the flex test, wherein the shoes are flexed constantly to simulate walking or running. This helps identify whether materials that constitute the footwear are likely to fracture, split or otherwise weaken with repeated stress from use. By contrast, the abrasion resistance test assesses how well the sole and upper materials can withstand constant friction with little deterioration. Hence, these two tests draw attention to areas that need improvement leading to increase in performance of the product.

Another major element of durability testing is environmental testing. In this setting, shoes are subjected to extremes of temperature, moisture, and UV radiation to test how such conditions affect the wear and tear on shoes. When a shoe is water resistant and does not deform under heat, it can be considered more dependable for clients in all sorts of climates and conditions. All these tests feed into quality assurance, customer satisfaction, and brand integrity.

Comfort Assessments: Measuring User Experience

To ascertain its performance when worn for variable periods and in different activities, a comfort assessment must be performed. These evaluations concentrate on the fit of a shoe, along with its cushioning, flexibility, and breathability. Testers may walk, run, or stand for hours on end while giving feedback if any discomfort, pressure points, or fatigue are felt. Such valuable inputs are used by the manufacturers to refine their designs and, thus, create better user satisfaction.

Using sophisticated equipment such as pressure mapping systems that measure how the weight is distributed across the foot can enhance the reliability of the results. Information from such an analysis will reveal places where pressure is excessive or where there is little support, both situations potentially causing discomfort or injury. Thermal imaging may also be employed to check for hotspots or temperature build-up that would work against the shoes in either ventilation or sweat heat dissipation.

In the end, comfort measurements are supposed to put the end-user’s experience first, so the footwear satisfies the duties of diverse activities and environments. Considering aspects such as ergonomics, support, proper alignment, and long-term wearability on their products for better comfort and performance is the way to go for brands. Reduction of problems causing discomfort will be another goal achieved so that the experience remains pleasurable for clients.

Slip Resistance Testing: Safety and Performance

Slip Resistance Testing, in footwear, is a step for evaluating safety and performance. This testing attempts to analyze the capability of a shoe to give traction and prevent slipping and falling in any environment. Slip resistance is generally concerned with wet, oily, or slippery surfaces, which will directly affect the safety of wearers in workplaces, sports activities, and ad hoc use.

The testing involves replicating real-world situations on several types of flooring to see how well the shoe will grip. One or more recognized methods exist, usually applying dynamic or static coefficient of friction measurements in different scenarios to come up with accurate figures. By putting forth scenarios like wet tiles and oily floors, the manufacturing mechanism tests whether the shoe has reliable traction to prevent falls.

Slip resistance testing ultimately bridges consumer safety and shoe performance for the mutual cause. Shoes with great slip resistance give better functionality, permitting a person to walk confidently shouldering a slick environment. In this way, the suppliers provide products that meet safety standards while also allowing the wearer comfort and utility in normal day-to-day events along with special projects.

Footwear Testing Methodologies

Lab Testing vs. Field Testing

Whatever is the aim of an assessment, with every means having the advantage of the other, these are two essential procedures for testing the performance of footwear. In lab testing, no variables could be left to chance: surface type, angle, few ambiance conditions. Under the lab conditions, exact and repeatable measurements of slip resistance and other major factors can be tested. Typical applications of lab testing would be in certification for the safety standards or so were under identical degrees of conditions where different types of footwear can be put into the test for a performance comparison.

Field testing happens in the environment where a shoe actually gets put on and used. Thus, these considerations include how does it function with respect to actual user behavior while taking in general weather and surface wear that cannot be wholly modeled through a laboratory. Hence, field testing takes into consideration the practical performance of the shoe, so as to ascertain that it is meeting the actual needs of the wearer in day-to-day work or in special activities.

Both of the methods are good and are often used in combination. Laboratory testing sets a point of reference for safety and performance, while field testing is intended to verify this in real-life situations. Both testing methods will, therefore, provide a complete framework whereby the footwear is deemed to work and be safe in different situations and for different applications.

Wear Tests: Real-World Performance Insights

Wear tests are helpful in understanding how a footwear performs under real-world conditions. Whereas laboratory testing aims to simulate certain variables, wear tests have real users in real settings wearing them. Hence, the footwear is tested in terms of comfort, durability, and safety criteria for real-time use-and in certain cases, real-time misuse. Wear tests collect data under different kinds of situations with participants from a wide spectrum of the intended end-users to accommodate variation between end-user profiles.

Terrain, weather, and activity-type are considered factors during wear tests. They ultimately allow manufacturers to know how the footwear responds to extended wear in different environments and activities. How the sole copes with an uneven surface is one instance; resistance of materials working against moisture under wet conditions is another. Actual, measurable data is invaluable toward enhancing product designs.

Wear tests, therefore, act as the final step bridging the gap between sheer theories or laboratory successes and actual user experience. They confirm that the performance predicted in theory truly reflects reality when it comes to everyday wear. Hence, wear tests serve as thorough evaluation procedures to ensure that the products pass not just safety standards but also provide quality and function that consumers can trust.

Certification Processes for Athletic Footwear

This certification process for athletic footwear guarantees that the shoe meets accepted standards of safety, quality, and performance. Standards are set by formally recognized industry organizations and regulatory bodies and consider such factors as durability, traction, cushioning, and general safety. Tests involve laboratory tests, wear tests, and biomechanical evaluations to ascertain that a shoe is good for any activity and from that perspective serves the function of the wearer.

Material testing to ascertain strength and resiliency, including outsole, midsole, and upper materials of the shoe, forms a crucial part of certification. This is so that the footwear can withstand the rigors of repeated use while maintaining its structural integrity. Traction testing is also conducted to check the grip of the shoe on varying surfaces, so that the potential for slips or falls is minimized. Other such factors for athletic footwear include shock absorption and energy return to make it hence comfortable and supportive for high-impact activities.

Lastly, the certification process focuses on health and safety standards, that include considerations of whether the footwear adequately supports the foot to prevent injury from sprains or strain on joints. Footwear may also be reviewed vis-à-vis its environmental impact, with a few certifications requiring that the materials be sustainable or non-toxic. Certified athletic footwear thereby builds consumer confidence that the manufacturers have done their utmost to meet daunting standards for performance, safety, and trust worthy product delivery.

Emerging Trends in Footwear Testing

Sustainable Materials Testing

Sustainable materials testing in footwear is key for imposing environmental, ethical, and durability standards into the product. Testing occurs for materials that are claimed to be responsibly sourced and have less impact on the environment. Common tests include qualifying them for biodegradability, recyclability, and verification of hazardous substances. Tests ensure that the materials qualify under international sustainability certifications and consumer expectations.

During sustainable materials testing, durability is also tested and accounted for. Although sustainability remains at the center of attention, materials used in footwear have to perform optimally through the years anyway. Tests are conducted to guarantee that these environmentally friendly materials can resist wear and tear through use and hence remain functional and provide support during the product’s lifecycle. Combining sustainability and performance is critical in manufacturing a product that is ethical as well as dependable.

Sustainable materials testing focuses on the complete lifecycle picture of a product, from manufacturing to disposal. Energy use has been considered; in the case of production, the wastes produced and the choices at the end of a product’s life (i.e., recycling) are given heed by manufacturers to forge an iskfulness approach along with sustainability. The test thus provides a direct avenue towards minimizing the environmental footprint by encouraging a more transparent operational method and taking responsibility for their actions, values that the global population is appreciating today.

Advanced Simulation Technologies in Footwear Testing

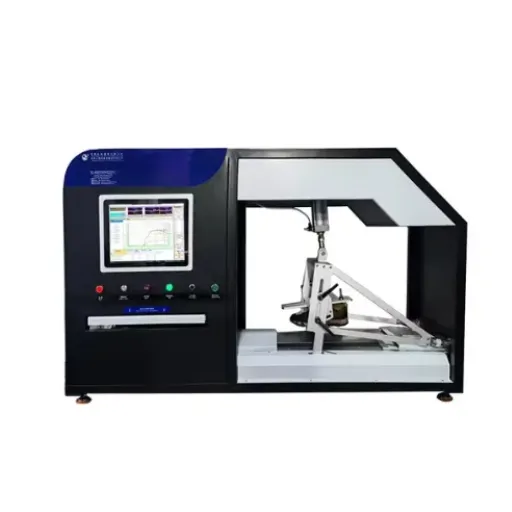

Advanced simulation technologies augment performance, durability, and comfort testing of footwear. These technologies employ computational models to infer the response of materials and designs to variable conditions of pressure, temperature, or motion. Through virtual testing, manufacturers can spot weaknesses or apropos designs for manufacturing before any physical prototype is made, thus ensuring that there is greater accuracy and less time wasted on classical trial and error.

Simulation tools provide the advantage of replicating a real-life scenario in a controlled virtual environment. They perform the forces experienced during a running or jumping activity, among others, to study essential factors such as sole durability, ergonomic fit, and impact absorption. Considering such factors early in the design will allow companies to develop better-performing footwear with greater user satisfaction while helping reduce material waste.

Beyond this, simulation technologies also promote sustainability by enhancing production efficiency and curbing utilization of physical resources. Virtual testing mitigates the need to repeat multiple iterations of a physical prototype from energy and raw-material consumption perspectives. It also makes sustainable material choices feasible since they can accurately measure the performance of a green alternative without physically testing them too much. In this way, the approach is in sync with the increased consumer awareness for eco-friendly conduct in the footwear industry.

AI-Driven Quality Control in the Footwear Industry

Production defects are prevented through AI running quality control, ensuring consistent standards in the footwear industry. Through machine-learning algorithms and computer vision, these systems carry out product inspections with a high degree of precision, identifying faults that are otherwise beyond human detection. Replacing the manual inspection method, these types of AI systems reduce human error and increase overall production efficiency.

Another good point about the use of AI in quality-control processes is its capability of analyzing huge amounts of data in real-time. Production data is gathered by AI systems and analyzed looking for patterns and anomalies that may later point to potential problems. This proactive approach ensures that high-quality products (footwear) are being produced while at the same time reducing waste and operation downtime: thus, it owns a sustainable and cost-effective production cycle.

To follow through on the aforementioned points, artificial intelligence aids manufacturers by allowing them to maintain uniformity across a large-scale batch production. With automated inspection and consistent application of pre-established quality criteria, brands stand a better chance to delight their customers. The same system also generates great amounts of data, which is used for process improvement and can help manufacturers innovate and enhance product quality in the long run. It is in this way that such a technology is being embraced by the industry to meet the consumer’s quest for dependable, durable, and ethically manufactured footwear.

Implementing Robust Testing Processes

Best Practices for Footwear Brands

Testing is an essential process in ensuring the quality of goods during shoe manufacturing. In this regard, brands should choose to conduct tests from standard methods of testing that are being accepted globally in their quality control procedures. This will give them consistent and reliable results pertaining to the durability of goods, strength of materials, and safety of products. Tests should also be performed from flexibility of outsole to strength of seams and water resistance of the products so as to recognize weaknesses in time.

Another critical practice is incorporating quality checks throughout the production line. Instead of focusing the allure of inspection on the finishing stages, a brand should consider continuous evaluation from the first inspection of raw materials all the way to after-product assessment. By doing this, the chances of defects reaching the consumer are severely minimized, while at the same time, defects are identified at the inception. Regular training of the aforesaid personnel in updated quality procedures would also be required so that all concerned really know how to uphold high standards.

Testing methods should also reflect environmental and ethical considerations. Footwear brands should want to be sure that their materials and manufacturing methods are sustainable and ethically correct. Testing could involve evaluations for environmentally friendly adhesives, biodegradable components, or checks to make sure fair labor standards are abided by. By focusing on quality together with responsibility, brands will meet and often exceed consumer expectations.

Tailoring Testing Processes for Various Shoe Types

To ensure the quality of performance, comfort, and durability, each shoe type requires corresponding tests. Athletic shoes are expected to go through high levels of impact testing, traction testing, and flexibility testing to prove that they can uphold the demands of upper-level activities. The materials for these shoes are also tested for best moisture-wicking and breathable properties, which come to be of utmost necessity while the shoes stay under intense use-the tests come to ascertain that they support and protect the athletes adequately.

Casual shoes, in contrast, often stress comfort and style. Testing for these shoes measures cushioning, fit, and general wear. Since casual shoes are often being worn for several hours, tests include assessing strategies over a time span in terms of their durability and ability to age well. Testing comfort through consumers’ trials and long-term wear tests are of primary importance in achieving expectations for this category.

Outdoor or heavy-duty opposition has more testing emphasis on toughness and weather resistance. The conditions faced are rather severe for these shoes; therefore, there are tests for water resistance, thermo insulation, heavy wear, etc. Moreover, they test the sole for good grip on a number of surfaces, while abrasion tests investigate the ability of materials to withstand rough surroundings. Thus, various ideologies under test are carved out for a footwear brand that suits all requirements of the different categories of users.

Ensuring Compliance with Industry Standards

Quality assurance in footwear testing entails extensive research and quality control measures intended to ensure that the testing procedure complies with the relevant industry standards. These standards are from the regulatory authorities to ensure that safety, durability, and performance are in place. Footwear is evaluated for the strength of materials, water resistance, thermal insulation, slip resistance, and other factors to verify that the product meets design expectations in terms of function and safety.

In order to comply with these standards, tests are conducted under set conditions that simulate reality; for example, in the abrasion test, the aim is to measure materials resisting wear with time, while in the slip resistance test, it is aimed to produce safety on different floors. Thermal tests are then carried out to check that footwear can retain insulation from extreme temperatures so that it can protect the wearer in harsh climates. Passing the test is of utmost importance in order to be able to offer consumers a reliable product.

Acceptance by the industry standards assures manufacturers not just of compliance but also of trust by consumers. Adherence has to be rigorous for the footwear to be considered safe, comfortable, and durable-from and with regard to all kinds of users. Innovation thereby helps along with promotion of accountability and quality in the making process.

Frequently Asked Questions (FAQ)

Q: What is footwear testing? And why is it important?

A: Footwear testing is a series of tests to check the safety, usage, and durability of footwear. It is considered a process that ensures the footwear being sold is up to international standards, government requirements, or customer expectations. This ensures that products are always of good quality and also minimizes returns.

Q: What types of common footwear are subjected to laboratory tests?

A: Common types of footwear tested in laboratories are generally athletic footwear, sandals, or casual shoes. Specific tests within an area may be carried out, including tests for slip resistance, breathability, and durability of materials, to analyze their performance characteristics and ensure compliance with safety standards.

Q: How do testing laboratories conduct a durability test for footwear?

A: The quality testing laboratories, employing an array of test procedures, judge the durability of footwear products. Wear tests, abrasion tests, and flex tests may take into account all these tests to quantify how well shoes hold up over the wire of time under different stresses and conditions.

Q: What is the importance of accreditation of testing laboratories in footwear testing?

A: The accreditation of laboratories, e.g., ISO 17025, is important with respect to footwear testing in that it assures adherence of the testing labs to international standards of quality and reliability. This gives brands and retailers an assurance that the processes involved in testing and the actual results are credible as well as trustworthy.

Q: What testing capabilities does a laboratory need pursuant to fulfill comprehensive footwear testing?

A: A lab should accommodate diverse testing needs, including tests for stiffness, breathability, perspiration resistance of upper materials, and midsole foams. This would allow the entire shoe to be evaluated on its overall performance.

Q: How does footwear testing assist product design and innovation?

A: Footwear testing assists in product design and innovation by analyzing material properties and their performance. Brands make innovations that meet consumer and regulatory needs by understanding how textile and synthetic materials behave under different conditions.

Q: What role do retailers play in footwear testing?

A: Retailers act as middlemen in the sales of footwear. They work with manufacturers to ascertain that their footwear products pass through FIR test of safety and performance requirements. They usually rely upon testing laboratories to test the quality of their products; this lands them with a big reputation among customers.

Q: What are important tests performed on athletic shoes?

A: The main tests performed on athletic shoes are slip resistance, abrasion resistance, and wear tests. Such tests aim to confirm that shoes give sufficient support, flexibility, and traction for the safety and efficacy of athletes.

Q: How does one confirm that a particular footwear brand meets bond requirements?

A: By contracting with accredited test laboratories specializing in footwear testing, brands will ensure compliance with regulations. Applying testing procedures and utilizing testing expertise, brands can attest that their products are safe according to local regulations and international ones with respect to restricted substances.

References

- Heeluxe | Advanced Footwear Testing – Specializes in cutting-edge footwear testing using both human and machine precision to help brands create better-performing shoes.

- Footwear Testing Services – Intertek – Offers comprehensive footwear testing, inspection, auditing, and quality assurance services.

-

Footwear Testing – Quality Control & Assurance – QIMA – Provides laboratory testing to ensure compliance and performance standards for a wide range of footwear products.