Instrument And Equipment Wholesale

Premium Footwear Testing Machine Manufacturer in China

Discover our Advanced Footwear Testing Machine, produced by a top-tier factory in China known for cutting-edge technology and precision craftsmanship. This state-of-the-art equipment is designed to conduct rigorous durability, flexibility, and abrasion tests, ensuring compliance with global footwear industry standards. Constructed with sustainable materials and innovative features, it provides tailored solutions to meet specific testing requirements.

What Is A Footwear Testing Machine?

-

Evaluates the durability and performance of footwear by simulating real-world wear conditions.

-

Tests key properties such as abrasion resistance, sole grip, flexibility, and stitching strength.

-

Utilized in the footwear industry for quality control, product development, and compliance with safety standards.

-

Equipped with advanced sensors and software for accurate measurements, data logging, and detailed analysis.

-

Available in multiple setups to test various footwear types, from athletic shoes to formal leather products.

Essential Tests You Can Perform With A Footwear Testing Machine

Uncover the wide-ranging evaluation capabilities of a Footwear Testing Machine. This sophisticated equipment enables precise testing of footwear properties under controlled conditions, delivering vital data for design, development, and quality assurance.

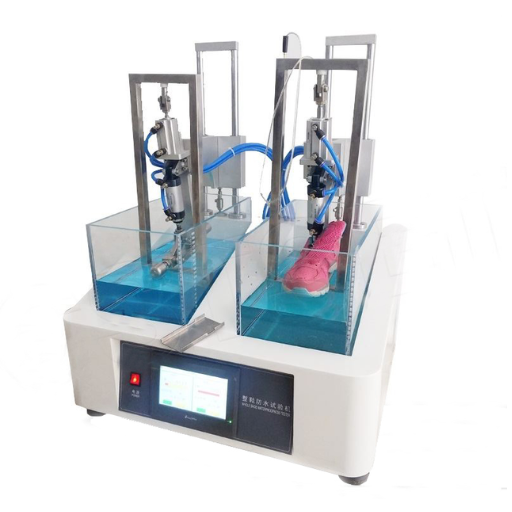

Waterproof Test

This critical test evaluates the footwear’s ability to resist water penetration by exposing it to simulated wet conditions. It measures how well the materials and seals prevent leaks, ensuring the footwear keeps feet dry in rainy or damp environments.

Softness Test

Measure the flexibility and cushioning of the footwear’s materials, particularly in the insole and upper regions. This test provides insights into comfort levels, ensuring the footwear offers a soft, supportive feel during prolonged wear without compromising structure.

Anti-Slip Test

Assess the footwear’s sole traction by testing its grip on various surfaces, including wet, oily, or uneven terrains. This test determines slip resistance, ensuring safety and stability for users in challenging conditions like workplaces or outdoor activities.

Wear Resistance Test

Evaluate the footwear’s outer materials by subjecting them to repeated abrasion against rough surfaces. This test measures the material’s ability to withstand wear over time, ensuring durability and maintaining appearance after extended use.

How to Choose the Right Footwear Testing Machine?

- Identify the specific types of tests required for your footwear materials or finished products (e.g., tensile, tear, abrasion, bending, impact, slip resistance).

- Ensure the machine is equipped with the necessary fixtures and accessories to perform these tests on various footwear components or entire shoes.

- Verify that the machine's test parameters (load capacity, speed, stroke) and sample handling capabilities are suitable for the range of sizes and materials you will be testing.

- Choose a machine that complies with relevant international and industry-specific footwear testing standards (e.g., ASTM, ISO, SATRA) to ensure valid and comparable results.

- Consider the machine's build quality, reliability, and the manufacturer's reputation for service, calibration, and technical support to ensure long-term performance.

What are the Uses of Footwear Testing Machine?

- Footwear Manufacturing: Tests the tensile strength, tear resistance, and abrasion resistance of upper materials, linings, and soles to ensure durability and quality.

- Sports & Performance Footwear: Evaluates the bending endurance, impact absorption properties, and slip resistance of athletic shoe components and assemblies for performance and injury prevention.

- Safety Footwear Production: Assesses safety features like toe cap impact/compression resistance, puncture resistance of sole plates, and electrical hazard protection.

- Material Development Quality: Used to test the physical properties of leathers, textiles, rubbers, and synthetic materials specifically intended for footwear applications.

- Quality Control & Certification: Employed by testing laboratories and manufacturers to perform standard tests (e.g., ASTM, ISO) on finished footwear to ensure compliance

Components Of Footwear Testing Machine

Select from a range of precision-engineered parts, fixtures, sensors, and more, all designed to perform thousands of industry-standard footwear tests. When ready to customize your system, reach out, and an expert will help tailor it to your testing needs and budget.

View Our Footwear Testing Machine Price

Top footwear testing machines crafted for your needs, our cutting-edge technology ensures reliable quality efficiently.

Functional testing machine

Discover our Functional Testing Machine, designed for precise footwear performance tests. It evaluates flexibility, grip, and comfort with advanced sensors, ensuring reliable results for quality assurance in diverse footwear applications.

Bending testing machine

Experience accuracy with our Bending Testing Machine, perfect for assessing footwear flexibility. It simulates real-world bending stress, delivering consistent data to enhance design and durability for all footwear types.

Durability testing machine

Unleash reliability with our Durability Testing Machine, built to test footwear longevity. It performs rigorous wear simulations, ensuring materials withstand extended use, ideal for quality control in footwear production.

Footwear Testing Machine Data Overview

| Parameter | Details |

|---|---|

| Load Capacity Range | Ranges from 0.01 N for light testing to 100 kN for heavy-duty applications. |

| Testing Versatility | Supports bending, flexibility, abrasion, and slip resistance tests. |

| Accuracy and Precision | Features high-precision sensors with ±1% accuracy and digital controls. |

| Environmental Conditions | Operates from -10°C to 50°C and 20% to 90% RH for real-life simulations. |

| Software and Automation | Includes user-friendly software with AI-driven data analysis and automation. |

| Speed Range | Adjustable from 2 mm/min to 200 mm/min for precise control of testing rates. |

| Crosshead Travel | Offers up to ±300 mm displacement for versatile specimen testing. |

| Extensometer Integration | Supports integrated or external extensometers for accurate strain measurement. |

| Power Supply Options | Compatible with 220V/50Hz or 110V/60Hz, depending on regional requirements. |

| Safety Features | Equipped with overload limits, safety shields, and emergency stop functions. |

Why Choose Our Footwear Testing Machine Manufacturers

We are dedicated to delivering top-quality Footwear Testing Machines with exceptional accuracy and durability. Whether for quality control or product development, we provide customized solutions to meet your needs.

As leading footwear testing experts, we utilize decades of experience to create reliable machines. Our designs ensure precise abrasion, flexibility, and slip resistance tests, using premium materials and innovative technology for long-lasting performance.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Expert Insights on Footwear Testing Machines

What is the purpose of footwear testing?

Footwear testing ensures quality, safety, and performance by evaluating durability, comfort, and compliance with standards. It verifies materials and designs, preventing failures and ensuring user satisfaction in diverse conditions, from daily wear to extreme environments.

What is the principle of footwear testing machine?

A footwear testing machine applies controlled forces to simulate real-world conditions, measuring responses like abrasion resistance, flexibility, and grip. It uses sensors and software to analyze material behavior, ensuring accurate and repeatable results for quality assessment.

What are the types of footwear testing machine?

Types include abrasion testers for wear resistance, flexing machines for bending durability, slip testers for grip, waterproof testers for leakage, and durability testers for overall longevity, each designed to assess specific footwear properties.

What is the advantage of footwear testing?

Footwear testing enhances product reliability, ensures safety, and improves comfort. It identifies weaknesses early, reduces returns, ensures compliance with standards, and boosts customer trust by delivering high-quality, durable footwear tailored to user needs.

What is the function of footwear testing machine?

A footwear testing machine evaluates material properties like durability, flexibility, and slip resistance. It simulates wear conditions, collects data with precision, and ensures footwear meets safety and quality standards for various applications.

What machine is used to footwear testing?

A Footwear Testing Machine is used, designed to assess durability, flexibility, slip resistance, and waterproofing. Equipped with advanced sensors and software, it ensures footwear meets industry standards through precise, controlled testing methods.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

Color fastness is a very important parameter to assess for all types of footwear, especially when evaluating its use and […]

Testing shoes and other types of footwear is important in ensuring product features, quality, usability, safety standards, and consumer expectations. […]

Footwear testing machines play a pivotal role in ensuring the quality, durability, and performance of footwear products before they reach […]

When it comes to designing and manufacturing footwear, ensuring quality and safety is not just a matter of brand reputation—it’s […]

Footwear is more than just a basic necessity; it is a critical component of performance, safety, and comfort in our […]

The footwear industry demands precision, durability, and quality to meet the expectations of consumers and ensure products perform under diverse […]

Ensure Footwear Excellence with Our Testing Machines

Elevate your footwear quality with our advanced Footwear Testing Machine! Designed for precision, it tests durability, slip resistance, and more, ensuring compliance with global standards. Contact us today to explore tailored solutions and boost your production reliability—make your quality visible now!

Frequently Ask Questions

Q: What is footwear testing, and why is it important?

A: Footwear testing evaluates durability, comfort, and safety by assessing materials and performance. It’s crucial to ensure quality and compliance with industry standards, protecting users and enhancing product reliability.

Q: What are the common footwear testing methods?

A: Footwear testing methods include abrasion resistance, flexing, slip resistance, and waterproofing tests. These methods simulate real-world conditions to measure wear, flexibility, and performance effectively.

Q: What footwear testing standards should be followed?

A: Footwear testing standards like ISO, ASTM, and EN ensure consistency. They cover safety, durability, and performance, helping manufacturers meet global regulations and market requirements.

Q: What types of footwear testing equipment are available?

A: Footwear testing equipment includes abrasion testers, flexing machines, slip testers, and waterproof testers. Specialized luminous transmittance and haze test equipment assess material clarity for premium footwear.

Q: How does luminous transmittance and haze test equipment work?

A: Luminous transmittance and haze test equipment measures light passage and clarity through footwear materials. It ensures transparency and quality, critical for innovative or decorative designs.

Q: How often should footwear testing be conducted?

A: Footwear testing should occur during design, pre-production, and quality control stages. Regular testing ensures ongoing compliance with footwear testing standards and maintains product excellence.

Q: What are the benefits of using advanced footwear testing equipment?

A: Advanced footwear testing equipment provides precise data, improves safety, and enhances durability. It ensures compliance with footwear testing standards, boosting market trust and product longevity.

Q: How to choose the right footwear testing equipment?

A: Select footwear testing equipment based on test needs, sample size, and accuracy. Ensure compatibility with luminous transmittance and haze test equipment if material clarity is a focus, aligning with standards.