The Four Ball Wear Testing Machine is a crucial instrument in the field of tribology that tests the ability of lubricants for wear prevention under predetermined conditions. This testing apparatus is important in the evaluation of lubricant performance, material life prediction, and robustness of materials in application involving extreme friction. Recognizing that actual environments impart trite pressures coupled with shear forces, the Four Ball Tester offers precise, repeatable measurements in both research and industrial application. This article intends to impart a detailed understanding of the Four Ball Wear Test Machine elaborating on its technical specifications, operational principles, and applications. Beside a tribology expert or an engineer, or just curious about advanced testing methods, this article would provide you with the knowledge that would be helpful for further understanding and utilization of this tool.

Introduction to the Four Ball Wear Test Machine

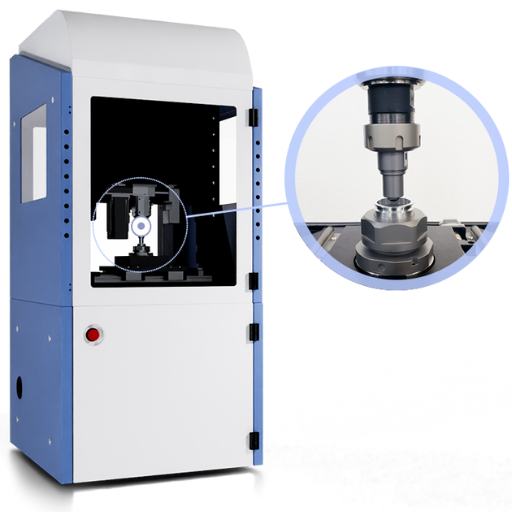

A Four Ball Wear Test Machine is a unique device for the evaluation of wear prevention properties and extreme pressure properties of lubricants at controlled environmental conditions. The machine applies a fixed load on three stationary balls arranged in a cradle, while a fourth ball is rotated while pressed against them. This is designed to simulate high-pressure contact so as to measure the size of wear scars and consequently test the performance of a lubricant. The machine delivers precise and repeatable results and hence finds wide applications in tribological research and the making of modern high-performance lubricants for industrial use.

What is a Four Ball Wear Test Machine?

Four-Ball Wear Test Machines constitute a specialized type of apparatus used in tribology for testing wear-preventing and load-carrying properties of lubricants under extremely high-pressure conditions. This machine works by keeping three stationary steel balls in a fixed cradle in a triangular position while a fourth steel ball is carried on a spindle brought into contact with the three stationary balls under a controlled vertical load and while rotating at a set speed. This action causes wear scars to be produced on the surface of the steel balls, the analysis of which facilitates the measurement of lubricant performance characteristics-wear scar diameter, coefficient of friction, the ability to reduce wear and friction under severe operating conditions, among others.

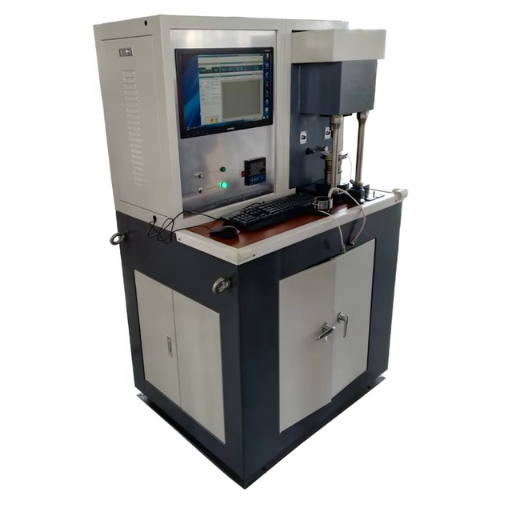

The modern Four-Ball Wear Test Machine is equipped with more advanced-drives and control systems for setting and maintaining certain test parameters, such as load, speed, temperature, and duration, with very high precision. In addition, many such machines are fitted with digital data-acquisition systems for capturing and storing real-time test data, thereby CADEnsuring test results’ accuracy and repeatability. These machines are crucial in developing lubricants, especially in the automotive, industrial, and aerospace industries, where it is very important to understand a lubricant’s antiwear characteristics under different operational stresses so as to optimize the performance and thereby maximize the life of mechanical components.

Importance of Friction and Wear Testing

Testing friction and wear is paramount to realizing how materials and coatings would survive in real operational environments. Such tests mimic mechanical stresses that a material or coating would experience to establish whether there is actual resistance to wear, coefficients of friction, and resistance to total mechanical failure. Such tribological properties evaluations are critical to those industries such as automobile, aerospace, and manufacturing wherein the reliability of components impact directly on safety, efficacy, and longevity. In evaluating the tribological properties, material engineers are in a great position to tweak the properties of materials and the concoctions so as to minimize losses due to energy and to avoid failures of components, increasing the lifespan of the system and thereby enhancing operational efficiency with reduced costs of maintenance.

Overview of ASTM Standards (D2266 and D4172)

ASTM D2266 and ASTM D4172 are the most commonly used standard test methods in tribology that sprinkle in determining the anti-wear and lubricating properties of greases and lubricants at certain operating parameters. The standard tests proposed provide a common framework for testing advanced materials so an engineer or a researcher has base results on which he/she can compare his/her work irrespective of his/her distance.

ASTM D2266 evaluates the wear preventive characteristics of lubricating greases using a four-ball test technique. It measures the wear scar diameter on steel balls subjected to a rotating motion under conditions of load, speed, temperature, and time. This test is vital for determining how well grease can provide a measure to resist friction and wear, in consideration of their application in sustained metal-to-metal contact.

But ASTM D4172 considers the wear preventive characteristics of liquid lubricants in the same apparatus but conducts the test at lower loads under less severe operating conditions that are suitable for liquid lubricants. The average wear scar diameter on the steel balls is the final data given by the tests, which give a good clue as to how this lubricant performs in situations that require moderate loading.

Function and Working Principles of the Four Ball Tester

The four-ball tester operates by clamping three balls in a cup so that they remain stationary, pressing a fourth ball, held by a rotating spindle, on them under a specified load. Here, a tribological contact point comes about, allowing for the evaluation of lubricant performance under different testing conditions. The machine performs the evaluation of the lubrication properties by measurements such as wear scar diameter, frictional forces, and temperature rise during operation. This simulates real-world conditions for contact stress and motion, providing essential information concerning anti-wear, extreme pressure, and frictional nature of a lubricant based on which predictive analysis for their actual behavior can be carried out.

How the Four Ball Method Works

The Four-ball method uses three stationary steel balls arranged in a triangular pattern in a cup, and a fourth one is rotating pressed against them under a defined load to evaluate the lubricants. Controlled rotational speed, temperature, applied loads, and test durations are imposed with precision. Sliding will be established between the rotating ball and the stationary balls that simulate boundary lubrication conditions.

Diameter of wear scar on stationary balls is an important factor that measures anti-wear behavior, frictional forces, on the other hand, assess the capability of friction resistance by the lubricant during motion, and seizure load or welding points determine and measure the extreme pressure behavior. Such results are therefore essential in determining the more applicable use of the lubricant concerning the reduction of wear, resisting ultrasonic pressures, and resisting mechanic friction in real-life scenarios.

Key Components of the Four Ball Tester

- Test Chamber: Provides the containment for the balls to be held and lubricated for particular testing conditions.

- Upper Ball Holder: Holds the single rotating ball, usually attached to a spindle to impart motion during testing.

- Lower Ball Cup: Holds the three fixed balls in a triangular pattern to provide uniform loading.

- Spindle and Motor System: Drives the rotation of the upper ball at a precise rate of speed, providing consistent motion during testing.

- Load Mechanism: Applies a measurable force onto the upper ball, simulating working pressure.

- Heating System (if applicable): Ensures controlled temperature for thermal testing and assesses high-temperature lubricant behavior.

- Temperature Sensors: Monitors temperature change in the test chamber.

- Friction Force Measurement System: Measures frictional torque during the test so as to facilitate the evaluation of lubricant performance.

- Data Acquisition System: Captures and stores data related to performance, friction behavior, wear characteristics, and seizure point for detailed analysis.

- Lubricant Dispensing System: Applies test lubricant uniformly onto the balls for maintaining consistency of conditions.

Data Acquisition and Analysis Techniques

The data acquisition and analysis techniques of the four-ball wear test machine focus on gathering and interpreting parameters in an unerring manner to attain reliable results. I employ a state-of-the-art data acquisition system to acquire real-time measurements of frictional torque, wear scar diameters, and temperature variations occurring during the test. These inputs serve to assess the antiwear and extreme pressure characteristics of the lubricant. Using advanced software, I may quantitatively analyze the wear scar data and relate such data to set standards, viz. ASTM D4172 or ASTM D2783, thus providing a detailed and comparative perspective of lubricant capacity under stringent conditions.

Applications of the Four Ball Wear Test Machine

The Four Ball Wear Test Machine is widely employed across several industries to determine the behavior of lubricants under extreme pressure and wear situations. Generally, the machine is used for testing industrial lubricants, automotive oils, greases, and metalworking fluids. It is used in product development, quality control, and comparative analysis to determine the ability of a lubricant to prevent wear and carry load, thus meeting industrial requirements and ensuring maximum longevity of equipment.

Use Cases in the Automotive Industry

In the automotive sector, the Four Ball Wear Test Machine is relevant for gauging the performance of oils, greases, and other lubricants under operating conditions of direct concern to the vehicle. Hence, it is widely used to judge the behaviors of lubricant formulations formulated for critical automotive components such as engines, transmissions, and gear systems with respect to wear resistance, friction reduction, and load-carrying capacity. Manufacturer use of the test in the high-pressure and temperature-variable environments of lubricant formulation optimization, enhances component life and assures performance to the very stringent industry specifications. This produces better vehicle performance, lower maintenance costs, and longer service life of automotive machinery.

Aerospace Applications and Testing

The Four Ball Wear Test Machine has its major applications in aerospace making the assurance of reliability and performance of lubricants possible and that are in use under high-stress components like turbine engines, gearboxes, and actuators. The extreme conditions in the aerospace environment put high temperatures and varying pressure along with long working hours in that area, demanding lubricants that can resist wear, provide lubricity, and stay stable under these conditions.

Recent data highlight developments in lubricant formulations to meet aerospace-specific standards, including MIL-PRF specifications and AS5780 requirements. Applying the Four-Ball-Wear-Test, aerospace engineers analyze lubricant film strength, wear scar measurements, and gauge the long-term behavior of lubricants under simulated operational conditions. Such precision testing reduces the risk of mechanical failure, enhances fuel economy through optimized component performance, and aids adherence to stringent safety and environmental regulations. Hence, installing the Four Ball Wear Test Machine in aerospace applications R&D and quality assurance is a strategic enabler to ensuring the technical and operational excellence of the industry.

Manufacturing and Material Testing

The manufacturing of the Four Ball Wear Test Machine involves a thorough precision engineering process of material selection to ensure durable construction and accurate working in testing conditions. The machine is generally made from high-strength steel and alloys to stand the test of extreme pressure and to resist deformation under operating conditions. Stringent quality assurance is carried out during manufacturing, including CNC machining of precision components and heat treatment using advanced techniques for improved wear resistance.

In material testing with the Four Ball Wear Test Machine, wear resistance of lubricants, coatings, and base materials is tested by simulation of extreme mechanical loading conditions. Material testing under such circumstances is essential for aerospace, automotive, and industrial sectors, as it gives a picture of the material behavior under cushioned high load conditions, allowing the choice of material deemed most suitable for critical applications. The accurate data on wear, coefficient of friction, and response to temperature do not only guarantee conformance to industry standards but also promote developments in material science and engineering reliability.

Technical Specifications of the Four Ball Tester

The actual working mechanism of the Four Ball Machine consists of pressing three stationary balls against a rotating fourth ball under controlled load, speed, and temperature. The main specs are:

Load Capacity

From about 40 kgms to 10,000 kgms is the general range, simulating different levels of stresses.

Speed of Rotation

Variable speed, normally as high as 10,000 rpm, for exact determination of friction and wear rates.

Temperature Control

Heating arrangements are provided to make testing possible at all temperatures, usually from ambient to 200°C or higher.

Test Modes

Allow for different modes of testing, including wear, EP, coefficient of friction, etc.

Accuracy of Measurement

High force, friction, and wear scar diameter accuracy of about ±0.01 mm guarantees data output.

Test Standards

ASTM D2596, ASTM D2783, and ISO 20623 serve as standards for the testing process.

This multi-test instrument is used in research and development and QC to provide critically important information on the works of lubricants and materials.

Understanding Shear Stability and Its Relevance

Shear stability is the capacity of a lubricant to maintain its viscosity under mechanical stress, which is typically associated with high shearing forces in gears, pumps, or bearings. It is a very important property that affects the performance of the lubricant because thinning of the oil or its breakdown under shear leads to poor film strength and increased wear and tear that further cause the failure of a component. Modern testing methods, such as ASTM D6278 or ASTM D5621, are used to assess the loss of viscosity due to shearing to ensure the lubricant remains durable during a variety of operating environments. Favorable conditions of shear stability are sought in applications that apply high loads at high speeds to provide uninterrupted operation.

Key Technical Specifications to Consider

The Four Ball Tester is an important machine that tests the tribological properties of lubricants, including wear protection, EP characteristics, and frictional behavior under controlled conditions. The following are the key technical specifications to consider in assessing this equipment:

- Load Capacity – The test load capacity signifies the equipment’s ability to simulate severe operating conditions. Present-day systems should go beyond loads of 10,000 N, being very important in EP characterization tests.

- Speed Range – Speed is variable, allowing testing from loads of 1,200-3,600 RPM for a broader evaluation of lubrication performance under differing application conditions.

- Temperature Control – Integrated systems for temperature control maintain constant test-adapted conditions, capable of varying from simply normal conditions up to beyond 200°C, all depending on the thermal characteristic of the lubricant.

- Wear Scar Measurement Accuracy – Wear scars should be measured with instruments such as high-resolution optical microscopes or automated systems of sub-micron accuracies to ensure the assessment of lubricant wear performance.

- Test Standard – Adhesion to standards, such as the ASTM for testing wear properties using D2266 and for EP performance using D2596, is important to align test results with commonly accepted standards.

- Data Acquisition System – An advanced machine can trace forces, torque, and temperature, furthermore supporting advanced data logging so results may be thoroughly scrutinized and reproduced.

The Four Ball Tester is unique regarding variable testing parameters, with precision testing, and standardized test protocols making it very essential in lubricant development and quality checks. Putting all these technical parameters in action makes sure the results are reliable and that the benchmark for lubricant performance is set up in a reproducible way between comparable tests.

Differences Between Various Models of 4-Ball Wear Testers

According to the latest information, the differences between various models of 4-Ball Wear Testers primarily lie in their load capacity, speed range, temperature control, automation level, data output methods, and compliance with specific testing standards.

| Key Point | Variations |

|---|---|

| Load Capacity | Ranges from 1 kg to 10,000 kg |

| Speed Range | 10-20,000 RPM |

| Temp Control | Manual or Digital |

| Automation | Manual, Semi, or Fully Auto |

| Data Output | Analog or Digital |

| Standards | ASTM, ISO, or Custom |

Choosing the Right Four Ball Wear Test Machine

Depending on the application you want to target, the Four Ball Wear Test Machine shall be selected by carefully weighing all the important parameters, i.e., testing load capacity that ideally would match force levels anticipated during the test. Next comes the speed range—must be checked against expected rotatory test speeds. Temperature regulation could be by manual or automatically digitized means, depending on how precise you want to be in temperature control. How much automation will be required? Will this be manual throughout or robotized in one way or another? This aspect will determine auto/semiautomatic/manual selection. Check the data output format required, analog or digital, for further data analysis setup. Lastly, ensure that the machine’s configuration follows necessary standards like ASTM or ISO to guarantee accurately comparable results.

Factors to Consider Based on Testing Requirements

- Load Capacity and Range: Ascertain the maximum and minimum load capacity required by the test method so that the Four Ball Wear Test Machine can accommodate the complete range of proposed forces either under or above, with no compromise on either accuracy or safety.

- Material Compatibility: Ensure the Four Ball Test Machine is compatible with the materials being tested, as various materials will have mechanical properties that may require a specialized mechanism or testing parameters.

- Precision and Sensitivity: Assess how much precision and sensitivity are required to fulfill the testing process concerning minute standards, especially where tight tolerances bear consideration.

- Testing Speed and Cycle: Establish the necessary testing speed and cycle duration according to the required dynamics of the material and its operational expectations, specifically ensuring that the material supports changeable speed where applicable.

- Environmental Conditions: Environmental conditions such as temperatures or humidity should also be taken into consideration so that test equipment operates in a consistent environment with constraints regarding these conditions so that results from testing could be well-trusted.

Budget Considerations for Different Models

While assessing the Four Ball Wear Test Machine budget, I burn my mind in extrapolating the performance side against the financial capability. Top-tier models with key features like automated data acquisition systems and enhanced environmental control would be the most expensive but deliver most in terms of precision and time efficiency. Mid-range ones attempt to strike the middle of cost and value, catering for the standard test needs while ensuring steady performance. Entry-level models are the cheapest and lack some high-level functions, hence only recommended for simple wear testing applications. Other than direct cost, I also view long-term operational expense bills, specifically maintenance and consumables, to give due consideration to whether the selected model will be under their budget now as well as in the future.

Performance Needs and Recommendations

The performance of the Four Ball Wear Test Machine must be directly related to the testing applications involved and the industrial standards applied. Such a machine is used primarily to determine friction, wear, and lubrication properties of materials under extreme circumstances. Multitudinous performance requirements about the most recent data and tendencies entail speed accuracy, accuracy of load application, and further temperature-control mechanisms. There has been an increase in use of modern Four Ball Wear Test Machines with digital control and full data-logging facilities due to their ability to deliver verifiable, repeatable test results.

For high-demand applications like testing in automotive or aero industries, utmost regard should be given to machines with enhanced load capacity (up to 10,000 N or 10 kN and above) and the maximum range of speed options to simulate different operating conditions. Software integration for detailed analysis and real-time monitoring further increases the usefulness of the machine.

For laboratories/production house centered on standard analysis, a medium-range Four Ball Wear Test Machine option that has a few basic automation features and lubricant testing modules will give a cheap yet effective way of testing. Considering recent improvements described in the searches, it is advantageous for the company to select the option with the modular design for ease of maintenance and upgradability to retain its operational effectiveness in the long term.

Reference Sources

-

Falex Four-Ball Wear Testers – A detailed document on the history, applications, and configurations of the Four-Ball EP Tester.

-

FALEX Four-Ball Wear Test Machine – Provides technical specifications and operational details of the Falex Four-Ball Variable Drive Wear Test Machine.

-

Ducom Four Ball Tester (TR 30 Series) – Offers insights into the technical specifications, including speed, load, and friction force, of the TR 30 Series Four Ball Tester.

-

Rtec Instruments 4-Ball Wear Tester – Discusses the capabilities of the 4-ball tester, including load, temperature range, and its use in EP and wear studies.