Key Takeaway: Friction and wear are critical factors that measure a material’s performance, durability, and reliability in many industrial applications. From aerospace components to biomedical implants, it is crucial to understand how materials interact under different conditions.

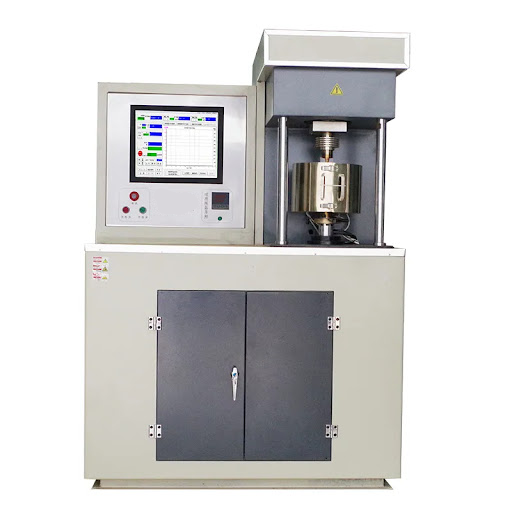

Tribometers, or friction and wear testing machines, have become an indispensable testing regime in modern material science. These machines subject samples to stresses, temperatures, and environmental conditions similar to those in the real world and yield data about material behavior. This comprehensive guide explores the basic concepts of friction and wear testing, examines the design and working of tribometers, and discusses their relevance to material science and engineering.

Introduction to Friction and Wear Testing

The friction and wear tests analyze the interaction between materials under sliding or rolling contact conditions, with friction being the resistance between two surfaces in relative motion and wear being either material loss or surface damage. They are vital in determining the durability, performance, and suitability of a material for a given application.

Testing friction and wear in the laboratory essentially serves as an environment for engineers and scientists to replicate operational conditions, enabling them to predict material behavior, redesign products, and improve reliability across manufacturing, aerospace, automotive, and other industries.

What is Friction and Wear Testing?

Friction and wear testing refers to the process of systematically studying materials under relative motion and mechanical contact. Tests determine sliding or rolling resistance (friction) and the surface degradation of the material in terms of strength, abrasion, or environmental influence (wear).

Modern friction and wear testing uses state-of-the-art tribometers in tandem with analytical techniques to simulate operational scenarios, including:

- Load variations

- Speed adjustments

- Temperature control

- Lubrication conditions

These types of data are precious in sectors such as aerospace, where precision-engineered components like turbine blades must withstand extreme conditions, or in automotive applications, where optimization of brake materials for ultimate safety and longevity is key.

Importance of Tribometers in Testing

Tribometers are invaluable in investigating friction, wear, and lubrication in rigorously controlled environments. The instruments determine the coefficient of friction and wear rates and other tribological properties that are decisive in describing material behavior.

Modern tribometers equipped with the latest technology allow users to:

- Create custom test parameters

- Monitor tests in real time

- Operate automatically

- Deliver reproducible results with great certainty

Applications Across Various Industries

| Industry | Application | Key Benefits |

|---|---|---|

| Aerospace | Testing aircraft components for wear and friction characteristics | Ensures optimal performance and safety under extreme conditions |

| Automotive | Evaluating braking systems and engine components | Optimizes friction and wear behavior under various operational conditions |

| Manufacturing | Testing lubricants, coatings, and surface treatments | Improves machine efficiency and reduces maintenance costs |

| Medical | Evaluating prosthetic and implant materials | Ensures biocompatibility and long-term performance |

| Energy | Testing materials for wind turbines and oil drilling equipment | Maximizes performance while minimizing downtime |

Understanding Tribometers and Their Functionality

Tribometers are high-precision measuring instruments for friction, wear, and lubrication between surfaces in contact. Their working principle involves simulating real-life conditions of interacting surfaces to test material performance and predict long-term behavior under specific load, speed, and environmental variables.

Different Types of Tribometers

The primary types of tribometers include pin-on-disc, ball-on-disc, reciprocating, four-ball, and nano-tribometers, each designed for specific testing requirements:

| Type | Description | Use Case | Key Feature |

|---|---|---|---|

| Pin-on-Disc | Pin slides on disc | Wear/friction testing | Simple design |

| Ball-on-Disc | Ball slides on disc | Lubricants testing | High precision |

| Reciprocating | Linear motion tests | Oscillating wear | Versatile use |

| Four-Ball | Tests lubricant wear | Lubricants R&D | Multi-contact |

| Nano-Tribometer | Nano-scale testing | Micro devices | High accuracy |

How Tribological Tests Work

Tribological testing involves simulating situations to assess friction, wear, and lubrication conditions of materials under controlled parameters. The process typically includes:

- Surface Contact: Two or more surfaces are pressed against one another

- Relative Motion: Surfaces interact through controlled movement

- Parameter Control: Variables like load, speed, temperature, and surface roughness are systematically varied

- Data Collection: Measurements include wear rates, coefficients of friction, and failure modes

Measurement of Friction Coefficients

Friction measurement involves applying force to maintain relative motion between two surfaces. The friction coefficient is simply the ratio of friction force to the normal force.

Important Note: Friction coefficients may greatly differ depending on material properties, the presence or absence of lubricants, and surface texture. These coefficients can be classified as static (occurring before movement) and dynamic (occurring during movement).

To ensure trustworthy values, parameters must be strictly controlled:

- Contact pressure

- Sliding velocity

- Environmental conditions (temperature, humidity)

- Surface preparation and cleanliness

Test Methods and Standards

Friction and wear tests follow well-defined structures to ensure uniformity and reliability of results. Standard test methods help determine coefficients of friction, wear rates, and material compatibilities under different conditions.

Common Test Methods for Friction and Wear

- Pin-on-disk tests: Study sliding friction and wear under continuous rotation

- Block-on-ring methods: Simulate operational wear conditions at higher loads

- Reciprocating sliding tests: Simulate back-and-forth motion of systems

ASTM Standards in Testing

ASTM standards provide comprehensive guidelines ensuring consistency, accuracy, and reliability across different industries:

- ASTM G99: Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus

- ASTM D3702: Standard Test Method for Wear Rate and Coefficient of Friction of Materials in Self-Lubricated Rubbing Contact

Rotational vs. Reciprocating Testing Methods

| Parameter | Rotational | Reciprocating |

|---|---|---|

| Motion Type | Circular | Linear |

| Wear Type | Abrasion/Friction | Fretting/Sliding |

| Material Use | Metals/Coatings | Polymers/Soft Materials |

| Speed Control | Continuous | Variable |

| Contact Area | Fixed | Alternating |

| Application | Bearings/Gears | Seals/Interfaces |

Key Considerations When Selecting a Friction and Wear Tester

To select a friction and wear testing instrument correctly, several factors need to be considered to optimize the testing setup for its intended application:

- Wear Mechanism: Determine if testing needs to be abrasive, adhesive, fretting, or sliding to accurately simulate real conditions

- Type of Material: Consider material type (metals, polymers, coatings) as some testers are optimized for specific materials

- Operational Parameters: Ensure the tester allows variable speed control and load range suitable for your application

- Geometry of Contact: Analyze whether the contact interface should be fixed or alternating

- Application-Specific Requirements: Account for specific applications like bearings, gears, seals, or interface materials

- Results and Reliability: Ensure the tester can measure frictional forces, wear depth, and material loss with high resolution and reproducibility

Defining Testing Requirements

The selection process should account for:

- Operational conditions (load, speed, temperature, lubrication)

- Relevant testing standards (ASTM, ISO)

- Data accuracy and repeatability requirements

- Resolution needed for material performance analyses

Material Compatibility and Customization

Material compatibility is paramount when choosing a friction and wear tester. The system should accommodate various materials including metals, polymers, ceramics, and composites under real service conditions.

Key customization options include:

- Fine-tuning parameters (sliding speed, normal load, temperature)

- Interchangeable test modules or fixtures

- Multiple test configurations (pin-on-disk, reciprocating, block-on-ring)

- Integrated analytical instrumentation with accurate sensors

Benefits of Friction and Wear Testing Machines

Reliable friction and wear testing machines offer valuable benefits across diverse industries, providing precise and repeatable measurements critical for material evaluation under real-world conditions.

Ensuring Product Quality and Safety

- Determine materials’ behavior under operational conditions

- Measure wear resistance, frictional behavior, and durability

- Predict component lifespan and reliability

- Ensure compliance with safety standards

- Identify potential problems before market entry

Streamlining Research and Development Processes

- Accelerate development cycles through faster prototype testing

- Reduce time and cost compared to field testing

- Enable early assessment of materials performance and durability

- Support innovation and competitive advantages

Contributing to Technological Innovation

- Improve material durability and reduce maintenance costs

- Develop wear-resistant coatings and lubricants

- Maximize energy efficiency for sustainable industrial processes

- Enhance reliability and safety across various performance standards

Frequently Asked Questions (FAQs)

What is a tribological test in a friction and wear testing machine?

Tribological testing is a method used to determine friction and wear characteristics of materials. In a friction and wear testing machine, force and wear rate measurements are taken under controlled environmental conditions to analyze material performance under various loads and speeds.

How does the friction coefficient relate to wear resistance testing?

The friction coefficient is a critical parameter in wear resistance testing as it determines the amount of friction between two surfaces in contact. Generally, a low friction coefficient indicates better wear resistance, meaning materials will wear away more slowly over time.

What are common measurement methods for evaluating friction?

Common methods include static friction tests, dynamic friction tests, and four-ball tests. Each provides insights into frictional characteristics under different circumstances, including variations in pressure load and lubrication conditions.

Can testing be customized using a friction and wear testing machine?

Yes, most friction and wear testing machines can be adjusted to meet custom specifications. Parameters including load, speed, temperature, and lubrication conditions can be modified to replicate specific working environments for the material being tested.

What is the importance of data acquisition in friction and wear testing?

Data acquisition involves collecting and analyzing process parameters including friction force, temperature, and wear rates, often in real-time. Advanced machines provide built-in software that can export data in CSV format for detailed analysis.

How does the block-on-ring test method work?

The block-on-ring test method involves holding a test piece under load against a rotating ring under controlled conditions. The tribological performance is evaluated by monitoring variables such as friction force and wear rate throughout the test.

What is the importance of using a pneumatic system in these machines?

Pneumatic systems provide precise control of pressure load applied to test specimens, simulating operational field conditions. This system ensures consistent and repeatable tests while allowing for automated control during testing procedures.

How can high temperature conditions affect friction and wear testing?

Temperature significantly affects friction and wear test results as elevated temperatures influence material mechanical properties, affecting friction coefficients and wear rates. High-temperature testing is essential for determining material performance under extreme conditions across various industries.

Reference Sources

-

Tribometers – an overview | ScienceDirect Topics – Provides a detailed explanation of tribometers and their role in measuring friction and wear at the microscale.

-

Tribometer – About Tribology – Explains how tribometers simulate friction and wear under controlled conditions, highlighting their applications in tribological studies.

-

Tribometers: The Fuel Behind the Automotive Industry – Discusses the importance of tribometers in the automotive industry for evaluating materials and components.

-

Friction, Wear, and Abrasion Tests and Analysis – Covers the methodology and significance of friction and wear tests in material evaluation.