When it comes to testing for durability and strength in geotextile materials, precision and accuracy are paramount. The ASTM D6241 test method, created expressly for determining the resistance to punctures of geotextiles, requires specialized pieces of apparatus so that test results can be trusted and consistent. The geotextile puncture fixture is a design entity that has been engineered to with some of the harsher demands of the standardized test. This article looks at the importance of the ASTM D6241 test and the implication of the right geotextile puncture fixture in ensuring compliance, consistency, and performance of materials. Be it a civil engineer, manufacturer, or quality control person, knowledge about this fixture and its functions can be considerably helpful in expediting the testing process and upholding the standard of materials. Stay with us to learn about its design, application, and benefits.

Introduction to Geotextiles

Definition and Types of Geotextiles

Geotextiles are permeable fabrics that work with soil in itself to separate, filter, reinforce, protect, or drain. They are usually made of synthetic materials such as polyester and polypropylene and find their place in construction and engineering works for stabilization of soils and erosion control.

There are three main types of geotextiles according to their method of manufacture:

- Woven geotextiles are created by weaving synthetic fibers to give them high tensile strength and so suitable for reinforcement and load distribution applications.

- Non-woven geotextiles are made by bonding thermoplastic fibers, thus giving them excellent filtration and drainage capabilities.

- Knitted geotextiles are created by interlocking loops of yarn; thus, theoretically, they lie between being very flexible and functional.

Each type of geotextile has its own set of functions depending upon its design and material composition. Woven geotextiles are best for construction of roads and applications where there will be heavy-load bearing. On the other hand, non-woven geotextiles are best used for drainage and filtration works. In any case, knitted geotextiles remain less common but can be fabricated to suit specific requirements for either filtration or protective barrier. This knowledge would then be useful in making the right choice of geotextiles for a given project, guaranteeing greater performance and durability.

Applications in Civil Engineering and Beyond

Considered a laboratory in various facets, geotextiles have been introduced to the massive field of civil engineering for diverse opportunities, owing to their capability to make one or other improvement to some civil-engineering activity. In road-building construction, they stabilize layers of poorly graded soil that would deform under heavy traffic loads. Geotextiles also enhance the drainage system; they permit water to seep through but do not allow sediments to pass. This feature is especially useful where erosion or sedimentation is dominant due to heavy rainfall.

Besides road construction, in erosion and slope stabilization works, functions are equally offered by geotextiles. They assist soils on steep slopes to resist landslides and erosion by water; thereby, making such value-giving type of erosion and slope stabilization works in riverbank protection, retaining wall construction, and shoreline stabilization to make the projects durable and safe in such difficult conditions.

Geotextiles are applied in environmental engineering projects like landfill construction and the broader field of waste containment. They act either as liners or as filters that keep harmful substances from entering the soil and groundwater around them. In this way, one installs geotextiles toward the protection of the environment within the sustainable engineering spectrum. That is, one may say that these varied uses reflect the flexibility of geotextiles in confronting structural as well as environmental problems.

Importance of Geotextiles in Environmental Protection

The environment is safeguarded by geotextiles as contamination barriers for soils and water resources. It is in landfills where they find most of their applications as liners. Thus, they prevent the leakage of leachates containing harmful contaminants from the landfill site into the surrounding environment. This crucial function maintains ecosystem integrity and protects public health from deleterious effects.

Key Environmental Benefits:

- Erosion control and soil stabilization

- Prevention of contamination in landfills

- Sustainable water management through filtration

- Protection of aquatic ecosystems

Erosion control is another major charge of geotextiles. The materials stabilize soils by stopping displacement, thus reinforcing slopes, riverbanks, and coastal areas. Consequently, their use saves fertile land from washing away and lessens the sedimentation of waterways, both of which are crucial for the sustenance of aquatic ecosystems. Geotextiles serve as great materials in fighting erosion caused by wind, water, and human activities.

Besides, geotextiles also promote sustainable water management through drainage and filtration. They allow water to flow through while being able to retain sediments and debris, which helps keep drainage systems in good operation and reduces flooding. Such functionality, hence, supports long-term environmental sustainability by conserving resources and alleviating natural disasters.

Understanding Geotextile Testing

Overview of Geotextile Test Methods

Geotextile testing implies many methods under which the properties and performance of the geotextile material are tested. These tests provide assurance to ensure the proper function and durability of the product with the necessary quality for the intended use of geotextile materials. These methods can generally be divided into three broad categories: evaluating physical, mechanical, or hydraulic properties. Each evaluates a different facet of geotextile performance.

Physical Tests

Include thickness, mass per unit area, and apparent opening size (AOS). These are sufficient to test basic characteristics and compatibility of the geotextile with applications.

Mechanical Tests

Concerned with strength and resistance of geotextiles under loads. Tensile strength, tear strength, and resistance to puncture are typical measurements.

Hydraulic Tests

Focus on permittivity and flow rate, ensuring that the geotextile can control the flow of water without eroding the soil or becoming clogged.

AOS testing, for example, specifies the size of particles that can pass through the geotextile; this property would be exceedingly important in designing filtration and drainage systems. Therefore, the combined test methods give an overview of the geotextile’s performance and serve the engineers in selecting the most suitable material for their projects.

Significance of ASTM D6241 in Geotextile Testing

This ASTM D6241 is a very important and necessary, standard for testing puncture resistance of geotextiles and related products. Such method determines the ability of materials to resist penetration by a sharp object, which is a measure of its durability and fitness to application. ASTM D6241 simulates the conditions under which the geotextiles are expected to perform in the field, thus rendering the materials capable of enduring the mechanical stress applied to them during installation and finishing.

This is important because it ensures that standard methods for testing give a very little measure of performance of products under adverse conditions. This standard is of importance also for products intended to be used for their puncture resistance under drainage systems, roads, landfills, etc. The test method provides critical information to engineers and planners in evaluating materials that minimize the risk of failure and increase the longevity of constructed systems.

Furthermore, ASTM D6241 aids in the development of industry specifications and quality assurance. A company shall apply these standards to the design and manufacture of geotextiles so as to satisfy industry specifications and requirements. The standard, therefore, promotes global consistency, safety, and performance by defining a uniform test procedure for geotextiles in various applications and trades. Hence, ASTM D6241 becomes an important tool considered in ensuring that geotextiles are satisfactorily applied in and retained for use over time in critical engineering construction applications.

ISO Standards Related to Geotextile Testing

Since geotextile testing is concerned with quality, ISO standards are considered benchmarks to ensure reliability and consistency in various applications. The tensile properties of geotextiles and geogrids are the focus of ISO 10319. The standard lays down procedures for wide-width testing to apply loads properly to materials so that their strength and elongation may be accurately measured. When these procedures are respected, much can be assigned to the use of geotextiles in diversified civil engineering works by manufacturers and engineers alike.

| ISO Standard | Test Method | Application |

|---|---|---|

| ISO 10319 | Wide-width tensile test | Tensile properties of geotextiles and geogrids |

| ISO 12236 | Static puncture test (CBR) | Puncture resistance against sharp objects |

| ISO 13433 | Dynamic perforation resistance | Resistance to impacts from falling objects |

This other relevant standard is ISO 12236, covering a static puncture test method also known as California Bearing Ratio. It is mainly designed to test geotextiles for puncture resistance confronted with sharp objects and point loads. It comes in handy when tests involve conditions under which protective layers or separation barriers are important since it measures the durability and resistance of certain material in those instances. Incorporating ISO would ensure geotextiles perform to their best ability in cases of high mechanical stress.

ISO 13433 also covers the method of assessing the dynamic perforation resistance of geotextiles. This method tests whether geotextiles can resist impacts from falling objects, simulating circumstances pertaining to mechanical damages. In terms of applications related to transportation or heavy equipment where forces detrimental to the geotextile may be exerted, adherence to ISO 13433 becomes significant. If the standard is implemented in conjunction with others, the stakeholders may be reliably assured of the geotextiles’ qualification for safety and functionality under prescribed stringent terms, while at the same time maintaining worldwide uniformity.

The ASTM D6241 Geotextile Puncture Test

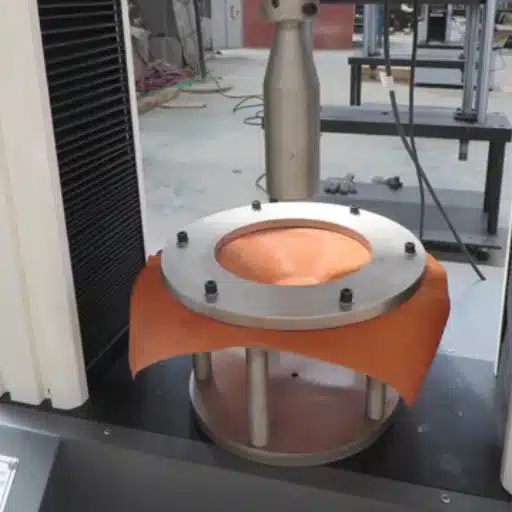

Overview of ASTM D6241 Protocol

As one of the most established standards of testing, ASTM D6241 tests the puncture resistance of geotextiles. This particular method measures the force needed to have a probe penetrate the geotextile material under specified conditions. Designed for reproducibility and comparability, ASTM D6241 is particularly important for evaluating geotextiles used in hard applications-reinforcing roads, stabilizing structures, or providing critical separation in construction work.

Testing Procedure Steps:

- Securely mount a geotextile specimen into a test frame

- Apply force via a circular puncture mechanism

- Steadily increase force until specimen fails

- Measure maximum force exerted as puncture resistance

ASTM D6241 caters to materials of different thicknesses and strengths, therefore providing a wide scope of application for geotextiles. Emulating field conditions on stress ensures performance reliability. ASTM D6241 carries significance in that it provides the exact value of puncture resistance of a geotextile, helping the stakeholder to choose the right material for the right application. By following this standard protocol, manufacturers and engineers can ensure that their products fulfill safety and performance criteria, thereby lessening the chances of failure in important projects. This, in turn, makes geotextiles more reliable and useful in infrastructure and environmental application.

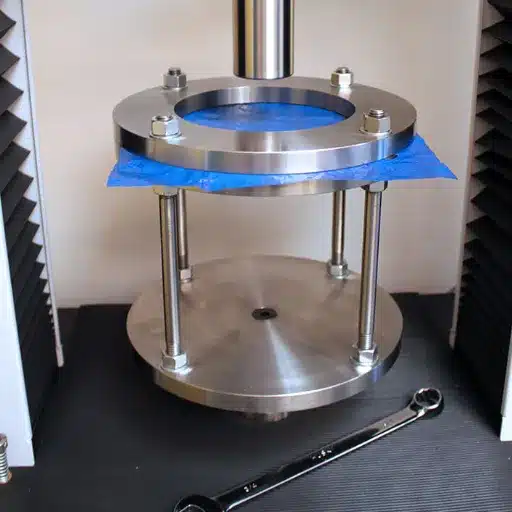

Equipment Required for ASTM D6241 Testing

The equipment needed to carry out an ASTM D6241 test accurately is essential to ensure precise observation and result. The principal equipment consists of a hydraulic or pneumatic testing machine with the application of a controlled force. The machine should thus be of adequate capacity to exert the force necessary for the measurement of the puncture resistance of the geotextile material.

Primary Equipment

- Hydraulic/pneumatic testing machine

- Gripping mechanism

- Puncture probe/plunger

Measurement Equipment

- Load cell for force recording

- Computer/software system

- Data analysis tools

Also necessary is a gripping mechanism that will hold the geotextile sample firmly during testing so that the clamps cannot allow slipping or deformation of the material. A plunger or puncture probe is needed that has been designed according to ASTM D6241 standards to apply a consistent force and thereby measure a material’s resistance to puncture.

Among other components, a measuring device is necessary-that is, a load cell, for recording the force applied during the test, and a computer or software system for analyzing and keeping records of the analysis results. All equipment must be calibrated correctly before the actual testing in order for it to achieve an acceptable level of accuracy and to meet the requirements of ASTM D6241 testing.

Interpreting Test Results and Data

ASTM D6241 testing consists of interpretating test results by analyzing load data recorded to quantify the material’s resistance to puncture. The puncture strength of a particular material is usually the force corresponding to the highest value attained during testing. This value thus becomes essential in assessing the material’s durability for application under heavy or sharp loads.

Critical Analysis Points:

- Examine data for irregularities or inconsistencies

- Look for unusual changes in load during testing

- Check for equipment misalignment issues

- Ensure proper documentation of test conditions

One must also examine the data for irregularities or inconsistencies that could cast doubt on its accuracy. For instance, unusual changes in load or misalignment of the testing equipment during operation are examples of such anomalies. If such an anomaly is encountered, the test should be repeated, placing emphasis on securing better control during testing, so the results can be regarded as trustworthy. Proper documentation ought to be maintained for every test that the laboratory undertakes regarding conditions important to environmental factors and the particulars of the materials tested so that comparisons can be made or for future reference.

As a respective final step, it is of utmost importance that the data be checked against the unicist performance standards and specifications for the role that the material shall serve. Due to this, this step usually checks safety and functional norms. Based on the above-described sequence of steps, depending on the test results, one may obtain highly valuable insights regarding the behavior of the material and decide on applications where puncture resistance is more of a concern than anything else.

Industry Standards and Regulations

Overview of ASTM and ISO Standards

The ASTM International and ISO are the two very prominent bodies that develop technical standards for universal application. ASTM is concerned with the realization of consensus standards that affect all aspects of materials, products, systems, and services, thereby encompassing safety, quality, and efficiency across industries. ISO, on the other hand, is a manufacturer of international standards in the interests of facilitating trade, innovation, and safety while establishing some measure of global uniformity. Both bodies provide guidelines to aid industries in staying on the regulatory side and ensuring operational excellence.

ASTM International

- Consensus standards for materials and products

- Focus on safety, quality, and efficiency

- Wide acceptance in construction and manufacturing

- Regulatory mechanism for various industries

ISO Standards

- International perspective on compatibility

- Management systems and sustainability

- Global consistency and interoperability

- Quality assurance worldwide

ASTM standards find broad acceptance in such fields as construction, manufacturing, and materials testing. They set distinct criteria for material properties, safety, and testing methods. For example, ASTM standards are often used to determine materials’ strength, durability, and resistance under predetermined conditions, thereby assisting the safekeeping of the products and their quality. ASTM standards thus serve as a regulatory mechanism for various industries and an assurance of quality.

Whereas ISO standards cover more from an international perspective of compatibility and interoperability, they cover management systems, environment sustainability, and product quality. For example, ISO 9001 lays down the foundations of a quality management system with the intent that the products and services established around the world should be of consistent quality. ASTM and ISO standards work together to spur innovation, keep industries safe, and bolster trust across the field.

Compliance and Quality Assurance in Testing

Compliance and quality assurance in testing are necessary to ensure that the product satisfies all established standards, that it is safe for use, reliable, and effective for its intended use. Testing operations that adhere to internationally recognized standards and regulatory frameworks would offer consistency and credibility to the outcomes. These standards provide reference points against which the results can be measured so that all procedures conform to the internationally accepted guidelines and best practices.

Key Compliance Requirements:

- Systematic monitoring of compliance rules and testing methods

- Protocol implementation to minimize errors and ensure documentation

- Quality assurance audits and regular reviews

- Traceability assurance of all test results

All the compliance rules a certain organization must adhere to should be systematically monitored and managed by testing methods applicable to it. For that, one has to put protocols in minimizing errors, documenting procedures, and ensuring traceability of results. Quality assurance could require audits or reviews to ensure that the testing environment remains intact and that equipment, procedures, or environmental factors do not present any kind of risk to the integrity of the test results. Through rigid methodologies and clearly defined in writing tests procedures, organizational stands for transparency and trustworthiness of testing.

Ultimately, continuous compliance and quality assurance in tests help toward development, thus sheltering industries and consumers. It is important that end users trust on the products they use, while industries benefit in staying competitive and having a good reputation in the global market. Those who uphold these principles thus allow progress while setting too high a standard for safety and quality.

Implications for Manufacturers and End-users

Indeed, requirements for compliance and quality assurance can be significant for manufacturers. When going through rigorous testing standards, manufacturers could assure their product could satisfy the laws of the countries of sales and fulfill safety regulations. Such procedures instill consumer confidence, and at the same time, prevent legal liabilities and product recalls. In attractive high-quality products, an organization may well build a name in the market that could come to its aid against any competition in this ever-demanding global economy.

| Stakeholder | Benefits | Outcomes |

|---|---|---|

| Manufacturers | Product compliance, consumer confidence, legal protection | Market reputation, competitive advantage |

| End-users | Safer products, reliability, performance assurance | Reduced risk, increased satisfaction |

| Regulatory Authorities | Standards compliance, innovation support | Trust, global uniformity, consumer protection |

These very procedures allow end-users to have access to safer, reliable, and more efficient products. They could use their purchase with total confidence, without suspicion of malfunction or hazard to their safety, thus ensuring consumer trust for that brand name. Ultimately, the guarantee of quality reduces hazards for the end-users and increases their satisfaction since quality is reflected in the product that fulfills or exceeds the expected performance.

Collaboration between manufacturers and regulatory authorities achieves these aims. Companies that prioritize quality and safety should not only satisfy the requirements of the legislation but should work toward creating a climate for trust and innovation. All parties, including the manufacturers, stand to gain from this synergy, as it guarantees progress in standards while safeguarding the well-being of the global consumer base.

Emerging Trends in Geotextile Testing Technologies

Innovations in Testing Equipment and Methodologies

Recent technological advances pertaining to the testing of geotextiles have furnished methods and equipment that ensure accurate and efficient assessments in regard to the performance of materials. Among the most significant achievements in this regard is an automated testing system through which human error is substantially reduced and methods can be rendered consistent in their application of results. These systems support tests for tensile strength, permeability, or puncture resistance, all standardized, so that the results would be irrefutable for quality assurance.

Automated Testing Systems

- Reduced human error

- Consistent application of results

- Standardized testing procedures

Digital Analyzers

- High-resolution imaging

- Real-time sensor feedback

- Microstructural analysis

Another innovation is the use of digital analyzers during testing. These analyzers take advantage of imaging and sensor technology to check for material properties with a greater degree of accuracy. For example, high-resolution imaging can be used to analyze fabric together with defects from a microstructural perspective and sensors can offer real-time feedback during the conduct of a test. In turn, these developments pave the way for even more accurate monitoring of test surroundings, and ensure that materials strictly meet performance needs.

Sustainability Focus

Also, breakthrough developments kept sustainability in their view. New approaches cover eco-friendly testing practices that allow waste minimization and energy conservation by way of testing. Considering sustainability in the forefront, these innovations aid global initiatives in curbing environmental damage, nevertheless ensuring the foremost testing standards. Combined, these advancements thus meet the growing needs for reliable, efficiently conducted, and responsible testing solutions for geotextile.

Impact of Technology on Testing Accuracy and Reliability

Remunerative technological advances brought forth the accuracy and reliability of the testing process in general. Automated systems and high-end software allow a very precise measurement of the characteristics of a material, thus leaving very little room for human errors. On the contrary, computer-aided tools ensure a swift analysis of data such that even complicated measurements can be done with absolute accuracy and reproducibility. The resolution and simplicity of these technological solutions contribute good service towards expediting the testing process and also towards providing more reliable solutions conforming to industry standards.

Technology Benefits

- Sensor-based technology for real-time monitoring

- Detection of minor deviations in material properties

- Continuous quality control capabilities

- Enhanced confidence in test results

Due to the sensor-based technology and real-time monitoring, a test considers being a little bit more reliable. The modern sensor is capable of detecting even less significant deviations in material property for which very detailed insights are obtained that were nothing but a wish in the past. These technologies also allow for the continuation of the tests so that quality control can be carried out for longer durations. The real-time feedback allows for assurance that materials comply with state-provided specifications, which would be helpful in the increase of the level of confidence in the test results.

This technology can help produce more precise environmental conditions during testing. Simulation tools may generate almost unlimited varieties of real-world scenarios, and the environmental chambers can contain them to test using materials under conditions they will face in actual use. In short, technology supports assuring test results whereupon researchers and manufacturers can rely for the development of a product meeting the expected criteria of performance and safety. All these again prove the importance of technology toward ensuring the standard of adeptness in testing.

Future Directions in Geotextile Testing

Technologically enhanced are the testing processes, considering precision, efficiency, and sustainability. The advancement of automated testing machines will thereby lessen human errors during the testing process and generate more dependable results. It will also lower the time and resources needed for testing, thus bringing benefits to both the researchers and the manufacturers.

Long-term Environmental Testing

Development of tests that simulate long-term environmental effects on geotextiles, providing insights into aging under varying climate conditions.

Sustainable Testing Practices

Focus on waste reduction, recycling of testing samples, and use of non-toxic testing agents to minimize environmental footprints.

The other important focus should be on the development of tests that simulate the long-term environmental effect on geotextiles. These tests can possibly give us some indication as to how the geotextile will age in the varying conditions of climate change and long-term exposure to the elements. Better knowledge of a geotextile’s life would allow us to design and develop products for the future life, which would be more resilient and sustainable.

Sustainability has been a driving force behind innovations, the latest being conscientious testing practices. Waste reduction, recycling of testing samples, or non-toxic testing agents are all becoming very important. Accordingly, the overall pressure is to shrink down environmental footprints, so that even testing does not contradict sustainable aims of geotextile applications.

Frequently Asked Questions (FAQ)

Common Questions About Geotextile Testing

Q: What are geotextile testing fixtures used for?

A: The test fixtures for geotextiles are necessary instruments used to carry out strength tests on geotextiles, including tensile, puncture resistance, and slippage tests. These fixtures ensure the proper clamping and positioning of the test specimen during testing to obtain valid test results used in civil engineering applications.

Q: How do I set up a tensile test on a universal testing machine?

A: Set up for a tensile test on a universal testing machine for geotextiles requires cutting the test specimen to the required dimensions in accordance with ASTM D4595. The test specimen is then clamped between two steel rings, taking care to ensure the crosshead is correctly aligned so the force is applied evenly. The test must then be conducted by observing the particular test requirements to capture data in the specified manner.

Q: Under what standards are geotextiles tested?

A: Geotextile tests are governed by various standards, such as ASTM D4595 for tensile strength, ASTM D4833 for puncture resistance, and ISO 10321 for geosynthetics in general. Each standard sets forth the conditions and requirements necessary for obtaining test results that are trustworthy and valid.

Q: What kinds of tests can be conducted on geotextiles?

A: The observable tests you can perform on geotextiles include tensile tests, puncture resistance tests, abrasion resistance tests, and water flow tests. Said properties check shall hence include specific properties of geosynthetic materials to be used in civil engineering projects.

Q: Why is the ASTM D6241 puncture fixture important?

A: The ASTM D6241 puncture fixture is important as it provides a standard method of testing the puncture resistance of geotextiles. This is necessary because it measures the force required to penetrate the fabric accurately, which is essential to ascertain its potential strength in actual use.

Q: What are nonwoven geotextiles, and how are they tested?

A: Nonwoven geotextiles are permeable fabrics used in civil engineering for drainage, separation, and reinforcement. It is important to perform standard tests such as ASTM D4595 for tensile strength and ASTM D4833 for puncture resistance on these materials in order to ensure their suitability for a particular need.

Q: What is the purpose of geosynthetic clay liners in relation to geotextile test fixtures?

A: A GCL is normally installed with a geotextile so as to form an additional hydraulic barrier in some civil engineering projects. Determining the interaction of GCLs and geotextiles through test apparatuses helps prove their co-functioning ability against erosion and water management.

Q: What does the dry test for geotextiles consist of?

A: Dry testing of the geotextile material usually refers to the testing of its physical properties without the intervention of water. These tests include tensile strength and abrasion resistance tests to ascertain the strength of a geotextile and its durability in dry conditions.

Q: How does the type of fabric affect the performance of these materials?

A: Another significant factor affecting geotextile properties is the choice of fabrics-made either woven or nonwoven. These fabrics offer different possibilities of tensile resistance, resistance to punctures, and permeability and so are selected based on their application among other factors in civil engineering.

Q: How does slippage affect the testing of geotextiles?

A: In cases when slippage occurs during the testing of geotextile fabrics, an inaccurate reading, as well as the result, may be achieved. It is necessary to follow the test requirements and clamp the test specimen firmly to reduce slippage, thus obtaining reliable data on the strength of the material and performance.

References

- ASTM D6241 – Geotextile Puncture Fixture – Universal Grip Co. – Provides details on the ASTM D6241 standard for measuring the puncture resistance of geotextiles and related products.

- ASTM D6241 Standard – Thwing-Albert – Explains the standard test method for static puncture strength of geotextiles using a 50-mm probe.

- ASTM D6241 Puncture Test Fixture – Raagen – Describes a puncture test fixture designed in accordance with ASTM D6241 and ISO 12236, including its components like the probe, sample clamp, and holder.