Glass and tile testing machines are essential tools for ensuring material durability, safety, and compliance with industry standards. This comprehensive guide covers everything from basic operations to advanced testing technologies.

When determining the durability of materials in construction, glass and tile testing machines form an indispensable part with their multi-purpose nature. These technical-powered test tools check the performance and durability of tiles and glass under various conditions. Whether you’re a manufacturer, construction professional, or quality officer seeking answers about tile abrasion resistance or glass strength, this guide provides detailed insights into tile test machines and abrasion testing.

Introduction to Glass and Tile Testing Machines

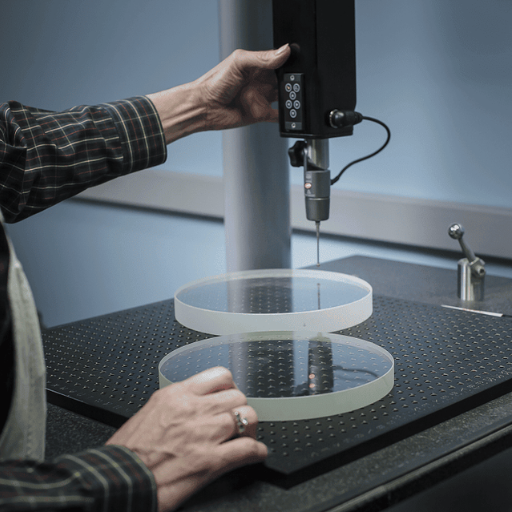

Glass and tile testing machines are specialized equipment used to test the durability, strength, and quality of glass and tile materials. These machines perform tests such as resistance to abrasion, impact, and surface wear to ensure materials conform to prescribed industry standards.

What is a Glass and Tile Testing Machine?

A Glass and Tile Testing Machine is specialized equipment that evaluates glass and tile materials for their physical and mechanical properties under controlled conditions. These advanced machines are equipped with mechanisms to perform comprehensive tests including:

- Hardness testing – Measuring surface resistance to indentation

- Coefficient of slip testing – Evaluating safety in wet conditions

- Thermal shock resistance – Testing temperature variation tolerance

- Flexural strength analysis – Measuring bending resistance

- Surface wear evaluation – Assessing long-term durability

Modern developments include AI-driven analytics and automation to enhance accuracy and speed, ensuring glass and tile products meet the highest performance and safety standards.

Importance of Testing in Ceramics and Tile Industry

Testing in the ceramics and tile industry is crucial for ensuring product performance and safety. Key benefits include:

- Quality Assurance: Verifying strength, thermal resistance, and water absorption properties

- Safety Compliance: Ensuring materials withstand environmental stresses

- Market Acceptance: Meeting international standards for global distribution

- Innovation Support: Enabling development of advanced materials

- Consumer Confidence: Maintaining consistent quality standards

Key Testing Standards (ISO, ASTM)

Industry standards ensure product quality, safety, and reliability across global markets:

- ISO Standards:

- ISO 9001 – Quality management systems

- ISO 14001 – Environmental management systems

- ISO 10545-7 – Tile abrasion resistance testing

- ASTM Standards:

- ASTM D638 – Tensile properties of plastics

- ASTM G65 – Abrasion testing methods

- ASTM C1499 – Ceramic tile standards

Types of Testing Machines for Tiles and Glass

| Test Type | Machine | Key Points | Parameters |

|---|---|---|---|

| Strength | Universal Tester | Tensile, Flexural | Load, Pressure |

| Impact | Impact Tester | Shock Resistance | Force, Energy |

| Wear | Abrasion Tester | Surface Durability | Friction, Cycles |

| Hardness | Hardness Tester | Scratch, Indent | Load, Depth |

| Flexural | Flexural Tester | Bend Resistance | Stress, Deflection |

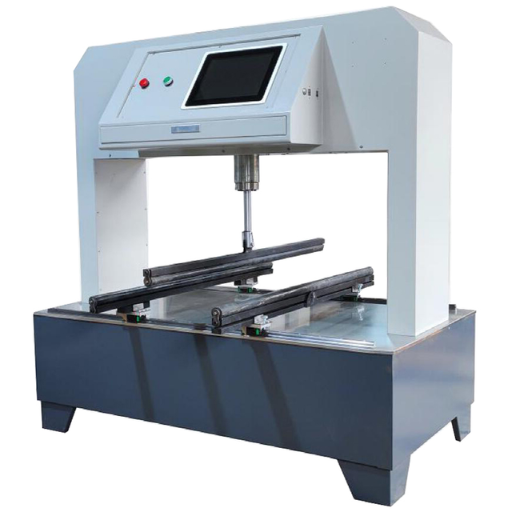

Tile Abrasion Testing Machines

Tile abrasion testing machines determine the wear resistance of ceramic tiles under controlled conditions. These machines simulate frictional forces experienced during normal use through:

- Rotating abrasive disc mechanism

- Controlled pressure application

- Sand or abrasive material distribution

- Standardized testing protocols (ISO 10545-7, EN 154)

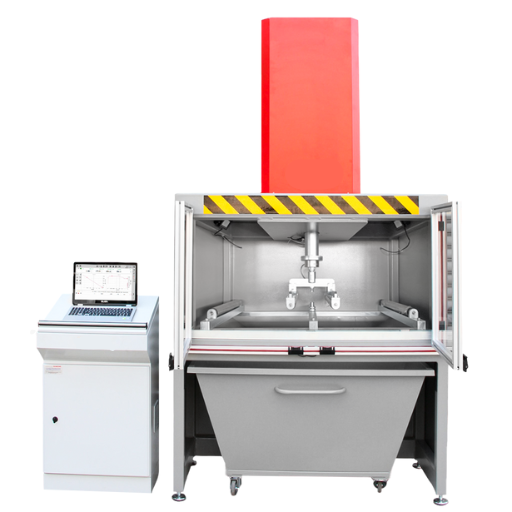

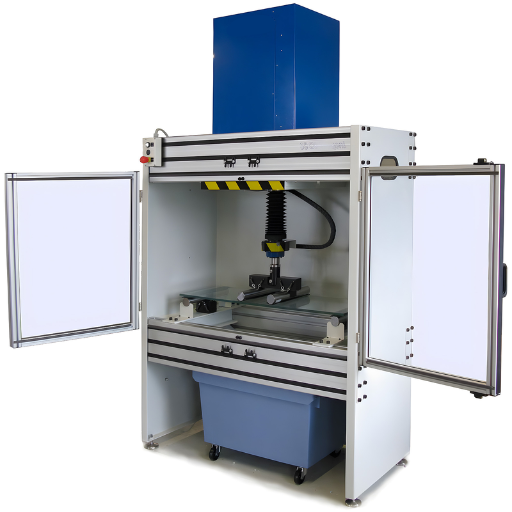

Universal Testing Machines

Universal Testing Machines (UTMs) are versatile equipment performing multiple mechanical tests:

- Tensile Testing: Measuring material strength under pulling forces

- Compression Testing: Evaluating resistance to crushing forces

- Bending Tests: Assessing flexural properties

- Material Compatibility: Testing metals, plastics, composites, and ceramics

Wear Testers and Abrasion Testers

These specialized machines assess material resistance to wear and abrasion forces through:

- Testing Methods:

- Rotating abrasion

- Sliding wear testing

- Rolling contact evaluation

- Industry Standards:

- ASTM G65 – Dry sand/rubber wheel test

- ASTM D4060 – Taber abraser method

- ISO 12947 – Martindale method

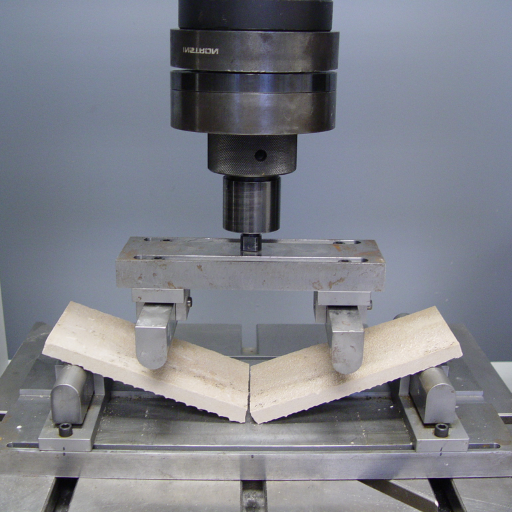

How Tile Abrasion Testing Machines Work

Tile abrasion testing machines replicate wear processes under controlled conditions through a systematic approach:

- Sample Preparation: Precise tile mounting on rotating platform

- Abrasive Application: Controlled distribution of grinding agents

- Parameter Setting: Adjustment of speed, pressure, and duration

- Test Execution: Calibrated rotational or linear motions

- Data Collection: Measurement of material loss and surface changes

- Analysis: Evaluation against industry standards

Advanced Technologies in Glass Testing

Modern glass testing incorporates cutting-edge technologies for enhanced precision:

- Laser-based Interferometry: Detecting surface distortion and micro-cracks

- Spectroscopic Analysis: Assessing optical quality and chemical composition

- Automated Stress Analysis: Polarimetry-based internal stress detection

- Acoustic Resonance Testing: Non-destructive structural integrity evaluation

Key Components of a Testing System

- Optical Measurement Tools: Laser interferometers and precision cameras

- Spectroscopic Analysis Equipment: Spectrophotometers for optical performance

- Ultrasonic Testing Systems: Internal defect detection capabilities

- Mechanical Stress Units: Force application and strength measurement

- Thermal Analysis Systems: Heat resistance and expansion testing

- Automated Monitoring Software: Real-time data collection and analysis

- Environmental Simulation Chambers: Extreme condition testing

- High-Speed Data Acquisition: Dynamic response analysis

Benefits of Using Glass and Tile Testing Machines

Quality and Safety Benefits

- Precise Material Evaluation: Comprehensive testing under various conditions

- Early Weakness Detection: Identifying problems before market release

- Standards Compliance: Meeting international regulations

- Enhanced Durability: Improving material properties through testing insights

- Consumer Safety: Reducing failure risks in real-world applications

Enhanced Quality Control in Manufacturing

Testing machines provide essential quality control benefits:

- Parameter Testing: Impact resistance, tensile strength, surface durability

- Design Improvement: Identifying weak points before production

- Automation Integration: Speed and accuracy improvements

- Cost Reduction: Preventing failures and recalls

- Standard Compliance: Ensuring regulatory adherence

Applications Across Industries

Construction and Building Materials

In construction, testing machines ensure structural integrity and safety through:

- Glass Testing:

- Impact resistance for windows and facades

- Thermal stability for skylights

- Wind load resistance evaluation

- Tile Testing:

- Abrasion resistance for flooring

- Slip resistance for safety

- Chemical exposure tolerance

Manufacturing Processes

Testing machines optimize manufacturing through:

- Quality Certification: Ensuring industry standard compliance

- Process Optimization: Reducing waste and improving efficiency

- Predictive Maintenance: Preventing equipment failures

- Material Development: Supporting innovation in product design

Quality Assurance Labs

Laboratory applications include:

- Performance Verification: Comprehensive material evaluation

- Safety Testing: Ensuring product reliability

- Standards Compliance: Meeting international requirements

- Research Support: Enabling material innovation

Frequently Asked Questions (FAQ)

What is a glass and tile testing machine used for?

Glass and tile testing machines assess the durability, strength, and performance of ceramic materials and tiles. They perform tensile, abrasion, and resistance tests to ensure materials conform to industry standards and can withstand diverse environmental conditions.

How do abrasion testers test tile specimens?

Abrasion testers subject tile specimens to controlled wear levels through rotating disc mechanisms that simulate actual use conditions. They measure the number of revolutions before wear signs appear, helping establish tile robustness and application suitability.

What types of tests can be performed by a strength tester?

Strength testers can perform bending strength tests, tensile strength tests, and flexural tests. These evaluate mechanical properties of tiles and glass to ensure they meet strength specifications necessary for construction and engineering applications.

What are the testing requirements for ceramic and glass materials?

Testing requirements vary based on application but typically include abrasion resistance, adhesion tests, and temperature resistance. Testing must align with ASTM and ISO standards to maintain product quality and durability.

Why do temperature and humidity matter in testing?

Temperature and humidity significantly influence material performance and longevity. High-temperature tests establish heat tolerance, while low-temperature tests identify brittleness risks. Accurate testing under varied conditions ensures reliability and application suitability.

What is the role of a universal testing machine in material testing?

Universal testing machines perform tensile, compression, and flexural testing on various materials. Their versatility makes them indispensable for researchers and manufacturers requiring comprehensive testing of ceramics, glass, and other materials.

Why is the Martindale abrasion testing machine important?

The Martindale abrasion testing machine provides recognized methods for determining material abrasion resistance. It’s particularly relevant for textiles and certain tile types, helping manufacturers understand product durability expectations.

Conclusion

Glass and tile testing machines are fundamental to ensuring material quality, safety, and performance across industries. From construction applications to manufacturing processes, these sophisticated tools provide the precision and reliability needed to meet modern standards and consumer expectations. As technology continues advancing, these testing systems will play an increasingly important role in material innovation and quality assurance.

Ready to implement testing solutions? Consider your specific industry requirements, testing standards, and quality objectives when selecting glass and tile testing equipment. Proper testing today ensures material reliability and safety tomorrow.

Reference Sources

-

Ceramics & Glass Testing – TestResources: This source provides insights into configuring ceramics and glass test systems, including machine series and their applications.

-

Glass Standards and Ceramic Standards – ASTM: ASTM standards are essential for specifying, testing, and evaluating the properties of glass and ceramics.

-

Comprehensive Guide to the Flexural Test – TestResources: This guide explains flexural testing methods, which are relevant for understanding material strength and flexibility.

-

A112-10 Abrasion Tester for Bricks and Glazed Tiles – Matest: A detailed description of an abrasion tester designed for bricks and ceramic glazed tiles.