A guided bend test is an essential step in the assessment of weld quality and integrity. Now a question: what happens when a test fails? It becomes those welders and the quality control professionals, a frustrating and puzzling circumstance. Why did the failure occur? What does it say about the welding process? And most importantly, how can these issues be identified and addressed? This article deals with some of the common reasons for guided bend test failures, as well as some suggestions for troubleshooting so that you can pinpoint problems and improve welding procedures. Whether you are fresh into welding or an experienced professional, finding the root cause for test failures will heighten your career producing strong and reliable welds. Continue reading to get some expert advice and actionable steps that will surely make your welds fly through the test!

Understanding the Bend Test

What is a Bend Test?

A bend test is one of the most widely used procedures in determining the quality of a weld and its reliability. In a bend test, a welded specimen is subjected to bending at a given angle or degree to see whether the weld can resist deformation from the bending action without cracking or breaking. This means that this procedure checks the ductility, strength, and soundness of the weld and the heat-affected zones that must conform to certain accepted standards.

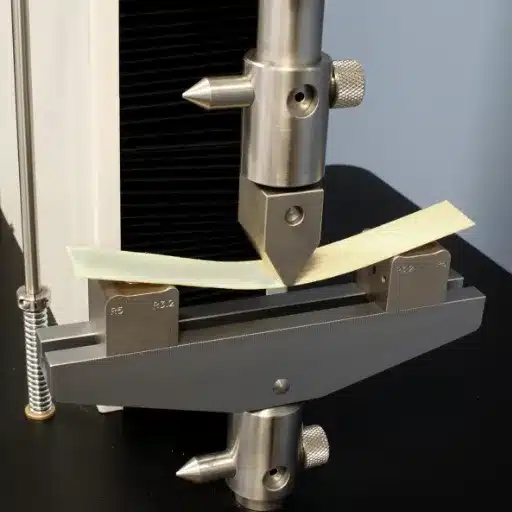

During a guided bend test, a fixture is used to guide the specimen physically during bending; thus, force is applied uniformly, giving consistent and reliable results. Internal or external defects such as cracks, porosity, and incomplete fusions can be examined in this test, which may or may not be visible from the surface. The most commonly performed guided bend tests are face bend, root bend, and side bend, with each test focusing on a different zone of the weld for assessment.

A number of factors ranging from poor welding technique, inappropriate filler materials, and joint preparation can bring about failure cases in guided bend tests. Analyzing the failure and determining its reason is necessary for the advancement of welding procedures; when a specimen fails, this means the weld has shown to be lacking in strength or integrity, and its consideration must be one of the healers for safety standards and quality assurance.

Importance of Strength and Ductility

Strength and ductility are fundamental properties of materials which determine their performance and serviceability qualities. Strength refers to the taking up of resistance by a material to an applied force which tends to break it. Ductility is the ability of a material to undergo deformation under tensile stress before it fails. Both these properties ensure that the welded components are able to take the static and dynamic service loads applied to them.

Key Properties:

- Strength: Resistance to applied forces that tend to break the material

- Ductility: Ability to deform under tensile stress before failure

- Combined Effect: Ensures welded components can handle static and dynamic service loads

Loading capacities that a structure in different fields like construction, automobile, aerospace, etc., ought to bear is attributed to strength. Welds found to be of inadequate strength may lead to failure of a structure; this poses great danger to the safety of human life and loss to property. Tests of strength, i.e., guided bend test, enable us to say with safety that a weld is capable of bearing the stresses for which it has been designed.

Ductility complements strength by allowing welded materials to undergo deformation without fracturing. Environmental stresses, therefore, contribute to the sudden failure of a system, as it adapts to load variations, or absorbs energy during impact. A highly ductile behavior contributes positively to the resilience of the structure, thereby increasing reliability under changing or extreme environmental conditions. Hence, welding must balance strength and ductility for safe application and durability in various applications.

Types of Bend Tests

Bend tests are crucial for determining whether a welded or metal specimen resists deformation without breaking. They ascertain the ductility, strength, and flexibility of materials while detecting possible defects such as cracks, lack of fusion, or porosity. Among the very common ones are guided bend, free bend, and semi-guided bend tests.

Guided Bend Test

In the case of guided bend testing, a fixture guides the specimen mechanically while bending to a fixed angle or radius. It is especially useful for testing weld joints because it may reveal weaknesses or imperfections that would otherwise affect the performance of the material. Guided bend tests are considered more reliable because of their controlled setup and accuracy in observing defects.

Free Bend Test

The free bend test allows the material to bend freely without certain fixed constraints, with a given load or force. The method is comparatively simpler and mostly used for evaluating the general ductility and formability of metals rather than for the detection of surface or internal faults.

Semi-Guided Bend Test

This test is a fusion of guided and free bend tests, where the material is supported but not fully constrained during bending. Semi-guided tests offer practical opportunities when studying the deformation limits of materials without excessive external control over the movement of the sample.

These tests are crucial for establishment where structures and materials must work safely under stress. Depending on the application and the parameter under study, each type of test casts a very valuable glimmer of understanding.

Common Causes of Bend Test Failure

Material Defects

Common causes of guided bend test failures include several root causes, the major ones being material defects, test method problems, or inconsistencies in the preparation of materials. Defects such as inclusions, voids, or cracks compromise further the structural integrity of the sample being tested and set the stage for a premature failure during the bend. The defects may come into existence during the manufacturing process or during processes of poor handling or storage.

Common Material Defects:

- Inclusions that compromise structural integrity

- Voids or air pockets in the material

- Cracks from manufacturing or handling processes

- Poor storage conditions leading to contamination

Processing the tests incorrectly causes a higher incidence of error when results are inconsistent with the accuracy they should measure. For example, uneven force should be applied during the test, the sample should be improperly positioned under the testing jig, or it may be tested at the incorrect temperature range, all these will lead to inaccurate results and premature failure. Doing tests according to the standards will keep this error from creeping in.

Finally, the failure of the test can occur if the material preparation has been inconsistent, such as improper machining and surface finishing. Such flaws are found on a surface that has rough edges, unintentional notches, or residual stresses, which can induce cracks during bending. To achieve test reproducibility then, the attention paid to sample preparation must be beyond reproach, and test standards must be properly followed.

Improper Testing Techniques

An improper testing technique may lead to a failure of a guided bend test. One of the difficulties may originate with the incorrect positioning of the sample in the testing device. If misalignment occurs in testing, the sample will be subjected unevenly to stresses, causing premature failure or incorrect assessment of ductility by the material. Therefore, centering and orienting the sample correctly shall be an important consideration for good test results.

Another common cause of problem might be the wrong choice of bending speed or force in a test. More than enough force or excessive speed in bending may cause an artificial stress to be generated, not found in an actual situation elsewhere. Likewise, insufficient force from bending may debar proper evaluation of material capacity in withstanding strain without cracking. To avoid these problems, the application of force and speed should abide by the test standard.

The final cause of failure in guided bend testing is improper or poor maintenance of equipment. Wear and tear on the equipment, like bending rollers or fixtures, could have modified test parameters, which in turn affect test validity. Therefore, regular inspection and calibration of testing equipment shall ensure accuracy and consistency in its performance. Best practices in minimizing errors and ensuring the maximum reliability of guided bend test results can be followed if these steps are instituted.

Inadequate Preparation of Test Samples

Improper preparation of the samples can greatly jeopardize the test results in a bend test. Factors such as inappropriate dimensioning of specimens, roughness of side walls, or improper edge preparations will cause stress concentrations or uneven load distributions during the test. Any of these could prematurely cause failure or give false results, rendering the test untrustworthy. Therefore, it is of utmost importance that samples meet dimensional and surface finish requirements before they are used to arrive at test conclusions.

One key factor that often interferes is the inadequate inspection of samples. Failure to detect internal and surface defects may mislead interpretations of material quality: For example, cracks, porosity, or inclusions that have escaped inspection will be detrimental to the integrity of the test piece. Thus, inspection and a good level of defect removal, where feasible, must be undertaken before the test to avoid such risks.

Consistent sample preparation procedures must always be standardized so that reliability can be assured. This includes following the dimensional tolerances, following either machining or grinding to achieve a smooth surface, and generally cleaning the sample of contaminants such as oils or dirt. If these steps are implemented, the guided bend test will sincerely display the true mechanical properties of the material and not erroneous results due to improper preparation.

Mechanics Behind Bend Test Failures

Impact of Material Properties on Test Outcomes

The ductility is one property considered critical concerning material behavior in which it deforms without breaking. Materials considered extremely ductile, such as various metals, tend to bend gracefully without cracking and have fractures. Conversely, with others classified as low ductility or brittle materials, there is the propensity to witness these crack failures under the stresses of bending imposed by the test. This is why the relationship exists and this is also why materials must be tested for ductility before any structural application is carried out upon them.

Another big consideration is the composition and microstructure of the material. The presence or absence of certain elements may influence its performance in the bend test. Variations may, for instance, include changes in carbon content or the presence of inclusions, which would possibly weaken the material and adversely affect its performance in a bend test. Moreover, an ill blast heat treatment may alter the grain structure of the material, thereby making it more vulnerable to failure. A proper understanding of these parameters, followed by due process, is key to foreseeing how the material would behave under bending stress.

Lastly, external factors such as temperature can have an influence on the results. For instance, certain materials experience changes in their mechanical characteristics when subjected to higher and lower temperatures, which may distort the results in a bend test. Performing tests in consistent, controlled conditions excludes variables that might otherwise confound the material’s true mechanical properties. Eliminating these factors will, playing their role, render a guided bend test with a much more accurate judgment of the reliability of the material.

Role of Weld Quality in Bend Tests

During bend testing, weld quality plays a vital role in how the result pans out since it can influence the joint strength, ductility, or overall integrity of the weld. A good quality weld should resist cracking, incomplete fusion, or any other defect during the bending process. Test failures often occur because flaws appear in the weld zone; such flaws serve as weak points when put under stress.

Factors Affecting Weld Quality:

- Proper welding parameter settings

- Selection of appropriate filler materials

- Adequate base material preparation

- Clean weld area free from contamination

For maximum results during bend tests, it has to be welded accordingly, and the standards have to be followed. Setting the welding parameters, selecting the right filler material, and properly preparing the base material are all key factors that affect weld quality. Likewise, cleaning the weld area thoroughly and ensuring no contamination during welding minimizes the risk of introducing any defects into the weld that could threaten the mechanical properties of the material during testing.

Prior to performing a bend test, it might have made sense to ensure weld quality, so that test results actually reflected the material’s capability under stress. Constant inspection, standards, and proper training for welders all lead to welds of consistent performance. A weld quality focus will yield more reliable bend test results and a clearer insight into how the material behaves in given conditions.

Analyzing Bend Failure Modes

Bend failure modes generally observed during testing include crack, tear, and excessive thinning. Cracking occurs when the material does not permit sufficient ductility or if there are internal imperfections, which extensions occur under stress. Tearing results from the concentration of stresses in weak locations, such as discontinuities or defects in the weld. Excessive thinning occurs when the material stretches unevenly, signalling inconsistency in either thickness or strength of the material.

| Failure Mode | Characteristics | Common Causes |

|---|---|---|

| Cracking | Material lacks sufficient ductility | Internal imperfections, brittle materials |

| Tearing | Stress concentration in weak locations | Discontinuities, weld defects |

| Excessive Thinning | Uneven material stretching | Inconsistent thickness or strength |

Evaluation of failure modes begins with assessing the place and nature of defect occurrence. When cracking or tearing is centralized in the weld joint, it could indicate insufficient weld penetration, porosity, or wrong filler materials. Contrarily, defects in the base materials may point to issues with composition, heat treatment, or manufacturer’s inconsistencies. Careful visual and microscopic examination is paramount in identifying possible failure causes.

Avoiding these failures means material and process quality assurance. This includes checking for proper material selection, welding standards, and inspection during fabrication. Besides these variables, bending process parameters should be optimized- including bending angle, temperature, and pressure-for reducing material defects. In short, through these means, bent components may find better reliability in actual usage.

Preventing Bend Test Failures

Best Practices for Material Selection

To avoid bend test failures and obtain dependable components, proper material selection is a must. Initially, materials shall meet mechanical properties required by the intense situation such as tensile strength, ductility, and toughness. One should therefore consider certified materials meeting published specific industry specifications, for example, ASTM, ISO, to give consistent quality and performance.

Material Selection Checklist:

- Verify mechanical properties meet application requirements

- Ensure materials have proper industry certifications (ASTM, ISO)

- Check compatibility with bending processes

- Evaluate material thickness and grain orientation

- Conduct pre-bend inspection and testing

Another aspect of the evaluation must be the material’s aptitude for the bending processes. Factors such as material thickness, grain orientation, and hardness should be compatible with the specific details of the bending process so as to diminish the possibilities of cracking or any other imperfections. Soft metals or those with great ductility will generally fare better in bending applications since they fracture under stress less readily.

Lastly, inspection before bending is crucial. Any tests, hardness testing, microstructure analysis, and checks for the chemical composition could reveal potential flaws or inconsistencies at their earliest stages. Thus, if pure free or undesirable material with impurities, defects, or properties is ensured, it, therefore, highly helps reduce the possibility of any failure during or after the bending operation.

Implementing Correct Testing Techniques

The importance of employing testing techniques for forging successful bending processes lies in the ability to identify material properties and potential flaws, beforehand. Hardness testing is one of the most effective testing methods; it tests the material’s ability to resist deformation. Hence, it checks if the material is strong enough for bending. Hardness tests like the Rockwell tester or Brinell tester will very quickly and reliably tell you if a material is fit for an application or not.

Hardness Testing

Tests material’s resistance to deformation using Rockwell or Brinell testers

Microstructure Analysis

Reveals internal inconsistencies, impurities, and grain structures

Chemical Composition

Ensures material purity and compliance with industry standards

Another testing method is the analysis of the microstructure. Viewing the material’s internal structure with a microscope may reveal all kinds of inconsistencies such as impurities, grains, or inclusions that diminish the integrity of the material during bending. The microstructural analysis becomes extremely important for any requirement of possible points of stress or areas not able to withstand pressure well enough. With such knowledge, manufacturers can better plan their processes to ensure that failures are averted.

Testing the chemical composition of the material will ensure that no undesirable elements or contaminants, which may weaken the final product, are present. Along similar lines, a manufacturer will use various methods such as spectroscopy to test purity and verify that the material meets industry standards. When all testing methods are brought together, manufacturers will be able to achieve safer products with higher quality and thus induce lower levels of wastage and operational risks.

Ensuring Proper Sample Preparation

A careful preparation of the sample is the key to a successful guided bend test because improper preparation will lead to tests that are either inaccurate or unreliable. The guided bend test is intended to establish the ductility and soundness of welds by bending a prepared sample to a predetermined angle. A failure is more or less guaranteed when defects in preparation occur along with a defect of the material or the welding process itself.

Another common reason for test failure is inadequate surface preparation. If the test specimens become contaminated with oil, grease, rust, or the like, it will be detrimental to the weld and the test results will be uncertain. Dimensional uniformity, along with smooth edges, are important preparation procedures. Anything inducing an inconsistency will be a cause for stress concentration, thereby leading to premature failure which would really be unrelated to the weld quality.

Poor welding practice also contributes to the failure of tensile specimens. Issues such as incomplete fusion or porosity and slag inclusions reduce the ductility and strength of the weld and may result in the failure of the test specimen in the bend test. Good welding procedure along with adequate acceptance criteria of preliminary inspections and methodical preparation of the test samples would greatly improve the reliability of the guided bend test results and assure the confidence enter quality standards.

Expert Insights on Bend Testing

Industry Standards and Guidelines

Failures during guided bend tests imply a bad weld practice, defective materials, or sample preparation. Reputed standards, for example, those set by the American Welding Society (AWS) and the International Organization for Standardization (ISO), one ensures the quality of welding beginning with sound fusion method, inspection, and observation of established procedures. They further state that if any such variable as base metal, weld position, deposition, or heat input should be different from that laid down for the weld, then the failure of the test is minimised.

Key Industry Standards:

- AWS (American Welding Society): Sets welding quality standards and procedures

- ISO (International Organization for Standardization): Provides global standardization guidelines

- Testing Requirements: Visual inspection, radiographic, and ultrasonic testing

Other factors causing the weld to fail in a bend test include incomplete penetration, porosities, and slag inclusions. Such flaws diminish the structural integrity of the welded assemblies, thus contributing to their fractures under bending stress. The standards suggest carrying out a visual inspection, a radiographic test, or an ultrasonic test for acceptance before proceeding to the next stage of welding. Making sure to maintain a clean and contamination-free area will help reduce weld inconsistencies.

Proper test specimen preparation is generally important for accurate test results. Test edges must be made smooth and even with no burrs, grooves, or irregularities since such factors will induce stress that may cause premature failure of the specimen during testing. Using the standards for specimen dimensions and bend radius should achieve results that are comparable and reliable for different evaluations. Abiding by this guideline strengthens the welding steps in general and increases the success of the tests, ultimately uplifting confidence in the structural quality.

Case Studies on Successful Bend Tests

Structural Steel Weld Testing

A prime example of the successful bend test: structural steel. The weld specimens were prepared with utmost precision conforming to standard procedures as far as their dimensions and finishings of the edges were concerned.

Pipeline Welding Inspection

In the oil and gas industry, to ensure reliability of pipeline welds under high pressure, the bend test was employed. The test samples were subjected to stringent quality control before testing.

Aerospace Component Evaluation

Bend testing is crucial to the weld quality evaluation of lightweight alloys for aerospace components. The specimen was tested under stringent conditions mimicking high-stress scenarios.

Future Trends in Bend Testing

Bend testing will witness a heavy infusion of technology and data analytics. Automation will shorten tests and ensure repeatability of the results. Robotics in systems can enhance efficiency by eliminating manual interventions and preventing human factors that could skew the results. This development is certainly needed where precision is paramount; aerospace applications are an example where material performance becomes critical.

Emerging Technologies:

- NDT Integration: Ultrasonic and acoustic emission monitoring for real-time insights

- Predictive Modeling: Machine learning for material behavior prediction

- Automation: Robotics systems for consistent and repeatable testing

- AI Analytics: Pattern discovery and accurate forecasting from testing data

Then, from the NDT branch, they make an attempt to influence the future of bend testing: ultrasonic, and acoustic emission monitors are being developed to grant real-time insights into the behavior of the material during testing without damaging the specimen. Combining those methods with traditional bend tests then allows for an even more detailed look at material quality.

And this is important: with predictive modeling and simulation, engineers are able to predict material behavior under stresses before actually testing them physically. Machine learning and AI are thus contributing to evaluating massive amounts of testing data, discovering patterns, and providing more accurate forecasts. These are the technology-oriented improvements in making bend testing more efficient while serving sustainability measures with optimization in material usage and waste minimizing.

Frequently Asked Questions (FAQ)

Q: What is a bend test?

A: A bend test is a method employed for discovering whether or not a material in question, especially welds, is ductile, or compromised in any way. This was achieved by application of a specified degree of bending stress, such that deformation occurs to a certain extent in the specimen under special conditions, yet the material may fail if the required mechanical properties are not met upon undergoing stress.

Q: Why does a bend test fail?

A: A bend test can be failed for various reasons, such as lack of fusion in the weld joint, incorrect choice of filler metal, or improper setting of the machine. Inclusions, pores, or embrittlement in the base metal can be other causes, all obstructing its strength or ductility of the material.

Q: What is a CNC bending machine?

A: A CNC bending machine is a computer-operated machine used to bend metal components accurately. Such machines are better able to produce very complex geometries and maintain quality control through programmed specifications during the bending operation.

Q: Does welding affect bend test results?

A: The welding procedure influences quality aspects of the joint intermixed with the degree of penetration, bead shape, and presence of slag being able to influence the mechanical properties of the weld. Incorrectly welded electrodes are prone to defects which may cause the bending test to fail.

Q: What is a guided bend test?

A: Guided bend tests include those in which a test specimen is bent over a predetermined radius using a jig. The procedure ensures uniform bending and increases the ability to accurately determine the weld’s integrity and ductility.

Q: Why is the selection of matter important for bend tests?

A: The choice of matter is a factor because mechanical properties vary from one substance to another, carbon steel to alloys. An inappropriate choice may never have the required strength and ductility, thereby increasing the risk that a bend test fails as a result of premature box failure or excessive deformation.

Q: What is the importance of ductility in passing a bend test?

A: Ductility describes how materials like metals can deform under stresses without breaking. In general, in a bend test, a material with greater ductility will absorb more energy and deform to a greater extent until failure occurs, thus implicating the likelihood of passing the test.

Q: How does a welder play a vital part in ensuring the success of a bend test?

A: A welder can make corner cuts concerning the performance of the weld according to specs and ensure that the weld joint hardly has any defects. A good welder would be able to minimize problems like lack of fusion and undercut, hence jeopardizing the weld that would have otherwise led to a failure through testing.

Q: What is the effect of ambient temperature on bend tests?

A: Ambient temperature influences the mechanical properties of materials such as their ductility. At low temperatures, some materials might become brittle, thereby increasing the likelihood of failure during a bend test. Temperature conditions must, therefore, be considered before testing.

References

-

Problem Passing Guided Bend Test On 5083 Base Alloy – Discusses common reasons for failure, such as discontinuities in the weld and lack of fusion.

-

Plate Bend Test Failures GMAW – Highlights issues like the “direction of roll” and other factors leading to high failure rates.

-

Bend Failure Mechanism of High-Strength Steel – Explains how non-metallic inclusions and defects from the hot rolling process can cause failures.