The Horizontal Tensile Tester stands at the forefront of modern materials testing, serving as an essential tool for assessing the tensile properties of various materials. Whether you’re working with metals, polymers, or composite materials, understanding how these materials behave under tension is critical for ensuring reliability and performance across industries. This blog dives into the key features and benefits of the Horizontal Tensile Tester, exploring how it delivers precision, efficiency, and consistency in tensile testing. Additionally, we’ll discuss its importance in quality control and product development, offering valuable insights for engineers, researchers, and manufacturers alike. Stay tuned as we uncover how this advanced testing machine is shaping the future of material testing.

Overview of Horizontal Tensile Testing Machines

What is a Horizontal Tensile Tester?

A Horizontal Tensile Tester is a specialized type of machine for actually testing materials by the applications of controlled force in tension and the resultant tensile strength and mechanical properties. In contrast to vertical models, the testing setup in a horizontal tensile tester continues along a horizontal axis and thus is apt for testing long and delicate materials that need steady handling during the testing.

The machine works by gripping securely a material sample at both ends and then applying a controlled pulling force until the test sample yields or breaks. Key parameters, such as tensile force, elongation, and strain, etc., are recorded during the testing process. Horizontal tensile testers are normally equipped with accurate load cells and software to enable the precise collection of data and its subsequent analysis.

Horizontal tensile testers find major applications in manufacturing, construction, and research industries. Horizontal orientation turns out to be more practical, especially for materials like cables, wire, or fabric, which may need specific positioning for uniform results. By providing precision and reliability, these testers contribute fundamentally to performing quality checks and the development of materials.

Functionality of the Horizontal Testing Machine

Horizontal tensile testing machines are commonly used to determine tensile strength and elongation properties for many-a-material under set conditions. & With uniaxial force being applied to the test sample, tension is gradually increased until the material fractures. The horizontal position of the machine guarantees perfect alignment and does not permit any external interferences such as gravity to be imposed on the specimen, thus apt for testing lengthy, flexible, or lightweight materials.

Some of the key mechanical attributes measured by this machine include ultimate tensile strength, yield strength, elongation at break, etc., which are done quite accurately. Sensors and load cells communicate with the analysis system, collecting data in real time during testing and thus permitting detailed stress-strain curves to be plotted by the operator. These data are very important for elucidating the nature of the specimen when tensile stress is applied and for deciding what applications it is fit for.

Also, horizontal tensile testing machines are considered to be quite flexible and efficient. They accept samples of all sizes and shapes and hence in use across many industries ranging from textiles to metals. Their ergonomic designs allow the operators to accomplish tests with minimum setup time while maintaining repeatability and reliability of results, assisting in quality assurance and research work in materials science.

Key Components of a Tensile Testing Machine

A tensile testing machine comprises various key components, each vital in the performance and measurement of mechanical properties of materials.

Load Frame

The load frame is the skeleton of the tensile testing machine. It provides the main structural framework on which the testing process takes place. Usually, the load frame would consist of vertical or horizontal supports depending on the type of structure used, which can hold testing grips for different sizes of specimens. A stiff load frame must ensure that the application of loads is not accompanied by deformation.

Load Cell

The load cell serves as a major accessory in measuring the force applied onto the specimen at test. Because it is very sensitive, it converts applied forces to electrical signals, thus maintaining a faithful record of force throughout the testing process. Accuracy of the load cell truly dictates the reliability of the test results.

Crosshead

The crosshead applies tensile or compressive forces to the item under test, moving either vertically or horizontally depending on the design of the machine to permit the desired test force. The speed of the crosshead movement and its steadiness become important parameters in deriving results.

Grips and Fixtures

Grips and fixtures hold the specimen firmly during testing so that the specimen may not slip or that the applied sustenance may not be uneven. Grips and fixtures are designed to hold specimens of different shapes and sizes to ensure its versatility.

Control System

Modern tensile testing machines come with a control system that can be used by the operators to set the required parameters of the testing. The system will ensure consistent application of force and record data related to stress, strain, and other properties of the material that are necessary for the analysis.

Awareness of the key components of tensile testing machines enhances the user’s understanding of its operations and its importance in industry to assess material performance. This knowledge thus ensures good quality control and research results through the correct use of the machine.

The Science Behind Tensile Testing

Understanding Tensile Strength

Tensile strength being one of the important material properties is referred to as the measure of the utmost amount of tensile stress that a material can endure before fracturing. This property determines the characteristics of the material under stretching or pulling forces, which is especially crucial for various applications. Usually, tensile strength is measured using a tensile testing machine that subjects a material sample to steadily increasing force until it eventually breaks.

Tensile testing machines stretch a material specimen in a controlled manner while observing the force applied and the extension. Data are then produced from which a stress-strain curve with crucial material properties can be drawn, such as ultimate tensile strength, yield strength, and elongation at break. These properties allow engineers and researchers to confirm whether a material fulfills a set of design and performance requirements.

Industries like construction, automotive, and aerospace must deal with materials subjected to high mechanical stresses, thus being familiar with tensile strength is important. Accurately determining tensile strength ensures safety, durability, and quality for manufacturers. And this is to say that tensile testing machines have become indispensable in materials science and engineering, thus guaranteeing reliable and reproducible results for research and quality control.

How Horizontal Tensile Machines Measure Material Properties

The horizontal tensile machines measure properties of materials by applying a tensile force with great control upon the testing piece until it breaks. Generally, tensile machines include a loading frame and gripping fixtures to hold the test piece, and a force application system. A sample is mounted; gradual load is applied while measuring the force and elongation of the sample. From these measurements, material properties of importance such as tensile strength, yield strength, and elongation at break are calculated.

The machines test materials by ensuring that proper alignment is maintained throughout the tensile tests, which is a primary factor in obtaining accurate results. Force sensors measure the force applied along with displacement of the material in real time. The tests are performed under standardized conditions, thereby generating reliable data that can be compared against another data set or used for certification purposes. Metals, polymers, and composites seemingly constitute the major classes of materials tested, enhancing the horizontal tensile testing machine’s versatility across various engineering fields.

The data revealed by a horizontal tensile machine build the basis upon which engineers and researchers assess the strength, ductility, and overall performance of materials. This is a key aspect that goes into selecting the right materials for a certain application to assure performance in an outdoor condition. Horizontal tensile testing machines are commonly found in the engineering industry for such materials used in construction, aerospace, and manufacturing, where engineering and operational requirements necessitate a thorough understanding of mechanical properties.

Importance of Test Accuracy and Precision

When using a tensile testing apparatus, it is paramount that the results an engineer relies on in assessing the viability or capability of a material be indeed very accurate and very precise. Accuracy means that the values actually measured by the apparatus accurately represent the actual property of the material, whereas precision implies that the test results remain consistent in repeated tests. An operator must accept that results of tensile testing have been reliable, so those materials may have failed less in actual use.

Testing for tensile strength is very much required for the aerospace industry, construction industry, and manufacturing industry, where standards for safety and performance are very high. A slight deviation in checking for tensile strength would have compromised the structure, given enough time, for expensive repairs, or even hazards for human life. The precision will only be effective if every material is measured to the same standard at each occasion allowing for a fair comparison to specifications. Testing batches of materials need to be precise in maintaining that all products meet the standard.

Thereafter, the machine shall be calibrated periodically to maintain accuracy and precision. The machine performance is verified according to preset standards so as to minimize error in measurement. Sufficient training is given to personnel for the use of the equipment to ensure that the entire testing procedure is implemented according to the specified protocols. Consistent focus on these factors allows tensile testing to become the source of reliable, reproducible data that can be confidently used to assure secure and appropriate application of materials in various demanding environments.

Applications of Horizontal Tensile Testing Machines

Use in the Construction Industry

Horizontal tensile testing machines play a decisive role in construction by ensuring materials meet the required strength and durability criteria. These machines test the tensile properties of construction materials such as steel, concrete, and composite materials. Once properly measured for tensile strength, manufacturers and engineers are able to deduce whether a certain material will withstand the forces and stresses that it is expected to encounter in application.

The use of tensile testing machines in construction helps to verify safety regulations and standards. For instance, tensile testing is performed on steel rebar to ensure that it has the necessary tensile strength to be structurally sound in bridges, buildings, and other infrastructure projects. This reduces the chance of a certain material failing, thereby increased safety and reliability in construction.

Concurrently, horizontal tensile testing machines ensure that material innovation for construction industries is afforded opportunities. By testing new materials or composites for durability and performance, stakeholders can come up with solutions that would be lighter, stronger, or more cost-effective. This in turn supports improvements in design and efficiency while ensuring the highest standards in safety and functionality that are indispensable to modern construction practices.

Role in Manufacturing Processes

Tensile testing machines are considered crucial in manufacturing processes since they are necessary for ensuring the quality level and reliability of the materials being used in production. By evaluating parameters such as tensile strength, elasticity, and yield strength, tensile testing machines impart to manufacturers the ability to judge whether a particular material meets the requirements as stipulated in its use.

Industries such as automotive, aerospace, and electronics do rely for their quality control and research activities on tensile testing. In automotive applications, tensile testing is, for example, very important in testing the strength and durability of sheet metals and polymers that go into vehicle building.

Tensile testing also enables improvement of the processing methods by allowing for precise changes in material formulations and processing parameters. Substantial advancements in testing machines now offer a variety of computerized systems for on-line data acquisition and analysis. This, in turn, supports manufacturers in assuring the consistent quality of their products, eliminating waste, and enhancing the efficiency of production activities.

In conclusion, tensile testing machines are imperative to download operations as an integral body of data that emanates from innovation thereof, safeguards standards, and ensures material durability in almost all walks of life.

Significance in Aerospace Testing

Tensile testing machines are an essential tool in aerospace testing with their huge ability to ensure the safety of materials under extreme conditions. During their operation, aerospace components undergo enormous stresses-from high speeds in flight to high dynamics in pressure and temperature. Tensile testing machines enable the engineers to measure strength, ductility, elasticity, and other criteria of a material, which is absolutely important for safety and performance considerations in the aerospace industry.

By accurately measuring material properties such as tensile strength and elongation, these machines help detect potential weaknesses or defects early in the design or manufacturing process, and such information is crucial for deciding on materials most durable yet lightweight, including advanced composites and alloys for aircraft and spacecraft. Using tensile testing assures that the materials work in situ as expected, thereby mitigating any chance of structural failure.

More importantly, tensile testing aids research and development in aerospace engineering. These machines allow for the development and testing of new materials to cater to the ever-growing demands for better fuel efficiency, environmental sustainability, and increased capabilities of aerospace applications. Altogether, tensile testing machines directly contribute to safety, maximum performance of materials, and technological advancement in the aerospace field.

Advantages of Horizontal Tensile Testing Machines

Enhanced Accuracy Compared to Other Methods

With being set up horizontally, tensile testing machines have superior accuracy than other tensile testing methods, dignity to develop an alignment that remains consistent throughout the test process. Improvements in this regard allow the apparatus to position the specimen accurately while maintaining that alignment throughout the test, thereby minimizing measurement errors caused by misalignment or uneven stress distribution; this, of course, leads to measurements that are more reliable and repeatable. Looking at the scientific aspect of materials properties, this precision is very important since even slight deviation can create a huge difference in material performance during high-end applications.

Horizontal tensile testing machines often incorporate an enhanced load measurement system that improves the precision of data collection. The systems are so sensitive that they detect changes in force and displacement during the testing, which may only be of the order of magnitude of several microns. Such precise measurements are quite essential when testing high-strength or exotic-type specimens, which generally require detailed analysis to comply with stringent industry standards. Thus, with vertical alignment coupled with such measuring technologies, the horizontal tensile testing machine achieves greater accuracy.

Finally, these machines are set up to put out of consideration any external factors that might include vibrations, or even human interventions that weaken the credibility of test results. Horizontal tensile testing systems.a lot have been design for the comfort of the operator, keep human-induced error and environmental interference to an absolute minimum, with utmost consideration placed on making sure all testing results are clear, precise, and can be relied on with absolute certainty. These design considerations make this type of machine industry standard for situations where demanding material testing standards are encountered.

Versatility Across Different Materials

The tensile testing machines are judged for their versatility to test a plethora of materials, including metals, plastics, composites, textiles, and rubbers. Their adaptability is owing to the uniform tensile force that imparts resistance to materials to be measured and studied for various mechanical properties like strength, elasticity, and elongation. These are, thus, important in sectors like construction and aerospace, where material performance is critical.

Because of the differing nature of materials, testing configurations must often be set up uniquely. Metals generally require greater force in their testing procedures, while softer materials like textiles or elastomers need gentle holding and grip systems so as not to destroy the product. Hence, tensile testing machines compensate by providing adjustable load cells, several grip types, and test parameter alterations so that an accurate test result for each material is obtained.

Data obtained during extensive tensile testing are used for recipes of prudent material selection, quality assurance, and product development. These machines enable engineers and researchers to understand how materials behave under stress under various controlled conditions, which further leads to given knowledge on design and manufacturing. Due to their dependability and versatility, tensile testing machines are by far the most precious tool for safety, performance, and innovation-related studies across industries.

Benefits of Touch Screen Interfaces

Being human-friendly, these are easy-to-use interfaces with enormous applications in tensile testing machines. A very good interface is an easy-to-use touch interface, which makes these interfaces very easy to operate and allows the user to select parameters, run the tests, and analyze the results. Due to the simple use of the interface, less time is required to train the operator, and utmost precision is assured in projects and actual running of tests.

Yet another benefit is providing real-time testing data during the testing. Real-time display of stress-strain curves, elongation values, and material performance is possible with the use of touch screen interfaces, as the test goes on. Quick decisions can thus be taken through live feedback and the material evaluation can be done with higher precision, inside both research and industrial domains.

Touch screens are commonly customizable and so this feature allows operators to configure the interface to a testing situation. Such flexibility serves to enhance the general workflow by eliminating repetitive tasks that can be cumbersome and by accommodating different working test scenarios. Applied in conjunction with tensile testing machines, they prove to boost productivity, accuracy, and user’s satisfaction.

Selecting the Right Horizontal Tensile Tester

Key Factors: Load Capacity and Precision

Load Capacity

In selecting the appropriate horizontal tensile testing machine, load capacity may be the most important criterion. Load capacity refers to the capacity of a testing machine to apply a force on a test material without compromising its working or accuracy. To ensure credible test results, the load capacity of a machine has to be in accordance with the load range expected during testing. So for higher strength materials, a machine with a higher load rating will be required, whilst softer or thinner materials can be tested with a lower capacity machine.

Precision

Precision is very important in tensile testing because it directly affects the accuracy of data. High precision in the tester ensures that the measurements will always be the same, which then prevents any possible errors from entering the data so that it can be relied upon for further analyses. Systems with modern sensors and fine control mechanisms best serve this need, being able to perceive even the tiniest contrasts in material performance, thus serving more efficaciously in areas of quality control and research.

Balancing Both Factors

A tensile testing system is an ideal amalgamation of load capacity and very fine precision, all demanded by the very nature of testing. Though great load capacities always mark a highly versatile machine, any unnecessary load capacity adds to the cost. Another alternative is to go for excellent precision so that one can have a detailed analysis. Still, it might not be a worthy option if the load requirements cannot be fulfilled. So, one must look into the limits of application, material types, and conditions of testing to arrive at a machine aligned both along load and precision and meets one set of requirements at least effectively.

Ease of Use and User Interface

When choosing a tensile testing machine, ease of use is a central consideration. These features ensure an operator can handle the equipment efficiently without extensive training. A well-marked and intuitive control panel enables tests to be conducted swiftly, thereby reducing errors and lost time. Preset programs for testing and step-by-step setup will be complementary in this regard.

Also paramount are the software used by the operator to oversee the testing and analyze results. Depending on the manufacturer, most modern tensile testing machines provide dedicated software featuring real-time data visualization, automatic calculation, and customizable reporting formats. Intuitive software makes the testing process more straightforward while also aiding in data interpretation and report generation. Moreover, protection compatibility with all operating systems and smooth export of data tends to enhance the experience of using the tool.

Last but not least in contributing to ease of operation comes the physical design of the machine. Ergonomic-type control arrangements, perceptible labeling, and rugged frames reduce the strain that the operator would otherwise suffer through while performing the work, and this facilitates gathering of accurate test results. Machines that provide for adjustments, such as grip adjustments or test area adjustments, make sure that the machine is capable of properly testing specimens of different sizes and materials. Altogether, an elegant user interface with convenient features provides for tensile testing machines to be more practical and suitable with the diverging applications.

Compliance with Industry Standards

Tensile testing machines need to adhere to stringent industry standards so that they can be considered reliable and accurate in their results. Several organizations like ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) draw up test methods/guidelines for requirements for machine performance and criteria for calibration. If these systems are followed, then data remain consistent under different environments of tests, thereby increasing the confidence of the user.

For a tensile testing machine to be approved, force measurement, elongation, and speed must be within tolerance or levels of inaccuracies described in the standard. Calibration of the machines is a regular exercise done with respect to traceable standards to confirm that the machines conform to the performance criteria as stated in ASTM or ISO regulations. When calibration is done accordingly, it helps minimize errors and keeps in tune with the best practices around the world.

The adherence of tensile testing machines to these standards permits it to perform a broad range of tasks-from quality control in manufacturing to research and development. End users could, therefore, seamlessly compare data across different tests or different machines, thereby enhancing widespread application and acceptance. Compliance underpins not only credibility of test methods but also assures safety and durability of materials in diverse industries.

Frequently Asked Questions (FAQ)

A: Horizontal tensile testing machines are special testing gears used for assessing tensile strength and tensile energy absorption (T.E.A.) of materials. As it is set horizontally, samples may be efficiently tested through the machine, ranging from tissue paper and wire rope.

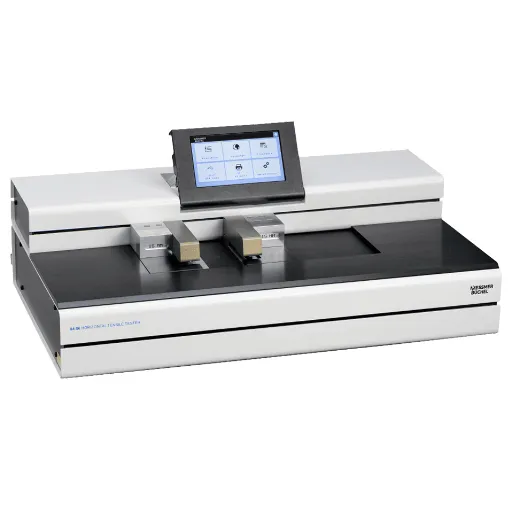

A: The model 84-56 horizontal tensile tester blends modern contemporary appearance with mechanical sturdiness. Clamps hold the specimen firmly, averaging force and strain readings during the test to arrive at an accurate determination of tensile resistance.

A: The horizontal tensile testing machine has its advantages over the vertically orientated tester, as a set of accessories can be mounted next to the machine. This configuration supports the accessibility and ease of use of accessories, especially in any form of fully automatic testing stations.

A: A horizontal tensile testing machine may be adapted to test the wet strength of paper tissue. Thus it becomes necessary to determine the tensile resistance of paper in both dry and wet states, for which one may want to carry out a complete analysis of a certain set of material properties.

A: Touch-screen compatibility and the almost intuitive interface contribute to the user-friendliness of horizontal tensile testing machines. These features allow users to carry out the actual operation and interpret the data with ease, making it easier and less burdensome for the operator to perform the tests.

A: A horizontal tensile testing machine can test a variety of materials, which include tissue paper, wire ropes, besides those materials whose tensile resistance has to be determined. Its versatility accounts for its use in labs and also production environments.

A: The horizontal tensile testing machine has very advanced detection mechanisms that measure the forces applied to the specimen and the strains experienced by them, thus allowing for very accurate measurement of tensile strength and energy absorption—at all stages of the testing process.

References

Tinius Olsen – Horizontal Tensile Testers

A detailed overview of horizontal testing machines and their unique benefits compared to vertical testers.

IDM Instruments – Horizontal Tensile Machine (MTH-150/500)

A machine designed for testing tensile resistance, elongation, and tensile energy absorption in various materials.

Envi Chambers – Horizontal Tensile Testing Machine for Wire and Cable

A description of horizontal tensile machines used for testing personal fall arrest systems and safety belts.