Tensile strength is a basic yet very important notion in material science and engineering used to characterize the durability and performance of a material under tension. Whether designing a tall skyscraper, trying to source materials for manufacturing, or just thinking about how various substances behave under tension, understanding the external tensile stress and ultimate stress is important. These properties define how well materials can resist breaking forces and are also central to common applications in assuring safety and efficiency. This article will go into the key elements of tensile strength and the difference between tensile stress and ultimate stress, focus on their practical significance in the real world. Now, let us fathom the science that makes the materials strong and reliable!

Introduction to Tensile Strength

What is Tensile Strength?

Tensile strength is the maximum tensile stress a material can support before it breaks or fails. It measures a material’s ability to resist being pulled apart by forces applied in opposite directions. This property is vital to envision the durability and effectiveness of materials used in different fields like construction, manufacturing, and engineering.

Key Categories of Tensile Strength:

- Yield Strength: The stress at which a material undergoes permanent deformation

- Ultimate Tensile Strength: The maximum stress that can be sustained by a material before breaking into two or more parts

- Breaking Strength: The stress at which the material fails completely

Such distinctions offer valuable insight into the behavior of a material under specific stress limits, hence aiding engineers and designers as they select materials for different applications.

Knowing tensile strength matters for practical reasons such as safety, reliability, and efficiency. For instance, materials with suitable tensile strength are used in bridges, airplanes, and building structures so that they can carry the load and resist external forces without failing. Through the testing of tensile strength, the industry can optimize designs, avoid structural failures, and promote innovation, which in turn guarantees the safety of persons and equipment involved.

Importance of Tensile Strength in Various Industries

Construction Industry

Tensile strength guarantees that materials used for bridges, skyscrapers, or residential buildings do not collapse under stress arising from heavy loads, winds, or seismic activity, all of which threaten human lifetime and service life of the structures.

Automotive & Aerospace

Materials with high tensile strength are used for reinforcing vehicle and aircraft while remaining lightweight. This balance is necessary for better fuel efficiency, performance, and safety of passengers.

Manufacturing & Product Design

Industries increase tensile strength testing to check for the usability of materials in products such as packaging, cables, and textiles, ensuring product reliability and waste reduction.

Overview of Tensile Testing

Tensile testing, or tension testing, serves to assess the force capacity and deformation behavior of a specimen under a load. It mainly aims at determining a material’s tensile properties, including tensile strength, elongation, and modulus of elasticity. By applying a calibrated tensile force, engineers or material scientists can evaluate the substance’s response under stress and thereafter predict its behavior under service conditions.

Testing Process:

- The specimen is gripped and pulled at a uniform speed until fracture

- The highest load value a material can withstand is recorded

- The point of plastic deformation is identified

- Results help assess material suitability for specific applications

Testing tensile strength is required across a variety of industries to ensure the safety, security, and quality of materials used in fabrication. For instance, construction uses it to make sure steel or concrete will bear a load imposed by structures, while textiles use it to establish the durability of a fabric. Gaining knowledge of the tensile properties of materials thus serves industries in improving performance and minimizing hazards and failures.

Key Concepts in Tensile Strength

Definitions of Stress and Strain

Stress

Stress in the material is the internal force per unit area developed within the material whenever an external force acts on it. It indicates how much load a material can endure before it deforms or fails. Typical units include Pascals or pounds per square inch.

Strain

Strain refers to the deformation or displacement occurring in a material as a result of applied stress. It is a dimensionless quantity, given by the ratio of change in length to initial length, indicating material flexibility.

The setting of the field of materials science and engineering is the understanding of the stress-strain relation. These properties not only determine the reaction of materials when forces are exerted but also ensure the design of structures and components that are safe to use. From stress and strain, industries can work out how materials behave in varying environments and hence improve the durability and safety of such materials.

Understanding Ultimate Tensile Strength (UTS)

Ultimate Tensile Strength (UTS) means the maximum tensile stress which a material can withstand before it disintegrates under pulling forces. This is indeed a very important aspect whereas it is most commonly used by engineering and material sciences to determine how strong and reliable a material is under tensile forces. The UTS is measured in units of force per unit area, such as Pascals (Pa) or pounds per square inch (psi).

For UTS, material testing in tension is performed until the material fails. Along with this, the stress and strain are recorded while the tensile test is carried out, and the maximum stress that is applied to the material just before breaking is termed as its UTS. This property is useful in figuring out how materials withstand the load and is also the reason for the prevention of any catastrophic failure in any structure or component during an extreme application of stress.

UTS knowledge proves vital for industrial use, wherein one has to select materials for application, performing construction works, automotive engineering, etc. It will assist engineers in selecting materials that can safely and efficiently carry a given load. UTS provides a robust means for industries to develop mutually sustainable and cost-effective systems while reducing risks involved with a potential mechanical failure.

Yield Strength vs. Ultimate Tensile Strength

| Property | Yield Strength | Ultimate Tensile Strength |

|---|---|---|

| Definition | Maximum stress before permanent deformation | Maximum stress before complete failure |

| Deformation Type | Transition from elastic to plastic | Material breaks completely |

| Application | Design for functional operation | Determine maximum load capacity |

The major difference between these two properties is the nature of their working principles. Yield strength is used in designing to ensure that a material or a system is operating within its functional life period when it undergoes no damaging permanent deformation, while UTS is employed to determine the strength of a material against rough use, abuse, or harsh working conditions. Together, yield strength and UTS direct engineers and designers towards appropriate choices of materials that offer good performance and protection against failure.

Calculating Tensile Strength

Tensile Strength Formula and Explanation

Tensile Strength Formula

TS = Tensile Strength

F = Maximum force or load applied (Newtons or pounds)

A = Cross-sectional area (square meters or square inches)

Step-by-Step Guide to Calculate Tensile Strength

- 1

Measuring the Cross-Sectional Area (A): First is to find the cross-sectional area of the material. Consider an accurate measurement of width and thickness, calculate the area in square meters or square inches. - 2

Apply Force (F): Force is applied slowly until it breaks, and the maximum force applied just before failure is noted down and recorded in Newtons or pounds. - 3

Use the Formula (TS = F/A): Employ the tensile strength formula and substitute the values of force (F) and cross-sectional area (A). Make sure the units are consistent to get valid results. - 4

Write Down the Result: The tensile strength value should be recorded and checked against standard values for the material tested in order to ascertain its performance characteristic.

These steps will enable you to find the tensile strength of a material, which gives insight into its tendency to undergo failure under tension.

Common Pitfalls in Calculating Tensile Strength

Unit Inconsistency

Using improper units for force and area, say pounds for force and square meters for area, may lead to erroneous results. Always ensure compatible units.

Poor Sample Preparation

A defective or uneven test specimen may compromise data quality by inducing inaccuracies into the cross-sectional area or fostering uneven stress distributions.

Equipment Issues

Misalignment of testing equipment, calibration defects, or ignoring environmental conditions like temperature or humidity could alter results considerably.

Practical Applications of Tensile Strength

Tensile Strength in Engineering and Construction

Tensile strength is an essential factor in engineering and construction since it determines whether a material can withstand forces that could elongate or actually fail the material. It is a basis for material selection for projects requiring robustness and structural integrity. Commonly chosen materials include steel, concrete, and composite materials with an aim of having high tensile strength that ensures reliability and safety in the field of construction.

Key Applications:

- Civil Engineering: Bridges, buildings, and structures that support heavy loads and environmental stressors

- Reinforced Concrete: Combines tensile properties of steel with compressive strength of concrete

- Mechanical Engineering: Cables, gears, and bolts designed to avoid deformation or failure under stress

When tensile strength is taken into consideration, engineers could predict how a material will behave under certain conditions and improve their designs depending on performance suitability and cost. Construction materials are regularly tested and are maintained by asking for adherence to standards of the industry so that the structures remain durable and safe in some time.

Material Testing: The Role of Tensile Strength

Tensile strength is imperative for material testing because it is a measure that defines the resistance and behavior of a given material while subjected to being stretched under tension. This property helps an engineer understand the maximum amount of stress that can be applied to a material before it ruptures. By knowing the tensile strength of a certain material, one industry will find it appropriate for reliability and performance in applications requiring durability and resistance to pulling forces.

Tensile strength testing mostly works by stretching the sample of a material up to the point of fracture. This test generates data such as yield strength, ultimate tensile strength, and elongation at fracture. Based on these data points, designers and manufacturers select materials that will provide adequate service (i.e., do not fail prematurely) under anticipated load conditions.

Real-World Examples of Tensile Strength Importance

Bridge Construction

Steel cables have to be strong enough to bear heavy tension forces and contribute to the safety and longevity of the structure. Engineers need materials with high tensile strength for supporting applications to withstand dynamic and static loads including vehicle loads, environmental forces such as wind, and thermal expansion.

Aerospace Industry

Aircraft components experience significant stresses during flight, takeoff, turbulence, and landing. Materials like carbon composites or aluminum alloys used for fabricating aircraft structures must have good tensile strength to endure these stresses without failure, ensuring optimum performance and passenger safety.

Medical Devices

Tensile strength is needed for medical devices like surgical sutures or orthopedic implants. Such devices must remain enduring under bodily stress while maintaining integrity and functionality for extended periods, reducing the chance of device failure and enhancing patient outcomes.

Expert Tips for Measuring Tensile Strength

Best Practices for Conducting Tensile Tests

Sample Preparation

Accurate tensile testing requires that the specimen first be prepared properly. Get the sample cut or shaped according to the standard from start to finish so that results may be consistently trusted without discrepancies. Being free from defects such as cracks, scratches, and irregularities, samples impair testing results and yield erroneous measurements.

Machine Setup

The setting of the testing machine is of equal importance. Align correctly in the grips so that the specimen is not slipping or being subjected to uneven forces during the test procedure. Calibration of the measuring apparatus must be done on a regular basis, and the loading rate must be set in accordance with the material to be tested.

Data Analysis

Results should be studied carefully and recorded systematically. Enter data including material type, dimensions of the sample, test conditions, temperature, and humidity so that interpretation of test results will be carried out against these contextual factors while relating scores to industry standards or product requirements.

How to Determine the Yield and Breaking Strength

Determining Yield Strength:

The yield strength of a material can be found by running a tensile test. The tensile test comprises the slow application of a uniaxial force to the sample with deformation or fracture as the result. The essential data are supplied by the stress-strain curve obtained after the test, and the yield strength is set at the point where plastic deformation starts in the specimen. There is usually a clear indentation from the straight line of the curve indicating that the material is not going back to its original form on removal of the stress.

Determining Breaking Strength:

Ultimate strength or breaking strength of the material is obtained by breaking or fracturing the material through the continuation of the tensile test. It is the maximum stress a material can withstand before failure. On the stress-strain graph, this is the peak value of stress. Breaking strength is very important to test the toughness and durability of the material, as in requirement mechanical strength is taken into consideration.

To get accurate results for yield strength and breaking strength, all tests should be performed under those testing conditions required by one of the international bodies such as ASTM or ISO. One must also give attention to sample preparation, calibration of test equipment, and stable environmental conditions during the actual test conduct. Test results can be only as good as the conditions under which the test was conducted, hence the utmost importance of these factors in material evaluation and quality control.

Utilizing Tensile Strength Data Effectively

Tensile strength data is highly important for design and selection of materials. In order to safeguard a product and ensure that the engineers and designers optimize the working of their product, they must know the maximum tensile force that a material can withstand. This information is crucial to choose from the set of materials able to fit a particular application range, from construction to manufacturing.

Key Considerations: While consulting tensile strength data, it will be advisable depending upon the testing condition under which the data has been recorded. When parameters are kept standard, the data applied in various industries could be dependable. For instance, obtaining values of tensile strength may be a good basis for deciding on the thickness of the material or on the decrease of unimportant weight of the design without risking structural integrity.

Finally, tensile strength data can assist in developing performance criteria under field conditions. The information remains essential to anticipating failures and fare well in the prevention program during design or manufacture. By proper integration of tensile strength data, professionals can balance durability, cost-effectiveness, and performance to ensure the product meets standards and requirements.

Frequently Asked Questions (FAQ)

Q: What is tensile strength?

A: Tensile strength is the maximum amount of tensile load a material can withstand while being stretched or pulled before it fails. It is determined by calculating the ultimate tensile stress, generally given in megapascals (MPa).

Q: How to calculate tensile strength?

A: The tensile strength of a material can be calculated by using an equation, which is the force needed to break the material divided by the original cross-sectional area of the test piece. This gives the stress on the material at the failure point.

Q: How do yield strength and tensile strength differ?

A: Yield strength is the stress at which a material starts to deform plastically, and tensile strength is the maximum stress a material can bear before failure. Both are important mechanical properties of materials.

Q: Does the cross-sectional area affect tensile strength?

A: In tensile strength, the cross-sectional area is important in terms of calculation. The greater the cross-sectional area of the test piece, for a given force required to break the material, the lower the tensile strength value shall be, since tensile strength equals force divided by area.

Q: How can materials be compared on tensile strength?

A: They are compared by measuring the tensile strength of various materials in megapascals. Depending upon their composition and treatment, the tensile strength of a given material, be it carbon steel or other types of alloy, can vary widely.

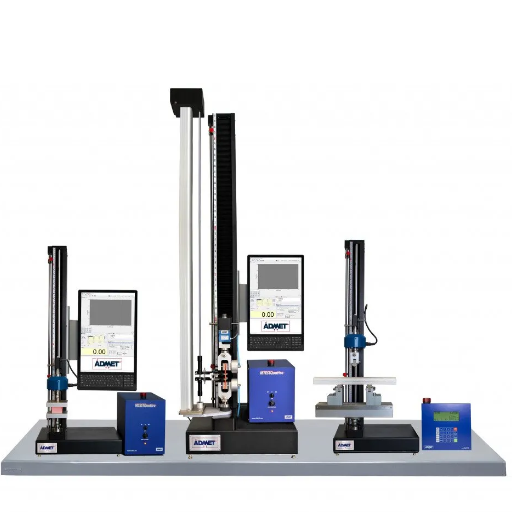

Q: What is the utility of the tensile test machine?

A: A tensile test machine is used to measure the tensile strength of a material by applying a load until the specimen fails. The data generated will be used to construct a stress strain curve which further aids analysis of the properties and behavior of the material under stress.

Q: Is there a relation between hardness and tensile strength?

A: Hardness can correlate with tensile strength, as harder materials typically also have a higher tensile strength; though such a relationship can be more varied, and each material has to be tested separately for its tensile strength.

Q: Why is the stress strain curve important in tensile strength testing?

A: The stress-strain curve shows how the material varies with deformation under the tensile load. It shows critical points such as the yield point and ultimate tensile strength, which give engineers knowledge regarding the mechanical property and behavior of materials under stress.

References

- Xometry – Ultimate Tensile Strength (UTS): Definition and How It Works

Explains how to calculate tensile strength by dividing the breaking force by the material’s original cross-sectional area. - Testronix – What is Tensile Strength? Definition, Formula & Importance

Provides the tensile strength formula and its importance in material testing. - Engineers Edge – How to Calculate Tensile Strength and Moment of Inertia

A forum discussion on tensile strength calculation and testing methods.