Top Böhme Abrasion Tester in China. Costs, effectiveness, versatility, and durability are only a few reasons why PVC (Polyvinyl Chloride) plastic is one of the most popular materials in construction and even the healthcare sector. Yet, due Pto VC material’s unique characteristics, ensuring its quality is a bare minimum to guarantee reliability and safety in applications which utilize it. This instructional guide aims to assist you with the sequential steps of conducting tests on PVC plastic materials so that you may gain a better comprehension of the effort put in verifying the properties of this material. If you are an engineer, manufacturer, or even a science-curious individual, rest assured, you will appreciate the information provided regarding the testing techniques, equipment, and practices highlighted in the guide. Continue reading to equip yourself with the vital information that will help you validate the integrity and quality of PVC plastics.

What is PVC and how is it used in Plastic Materials?

Polyvinyl chloride or better known as PVC, is a synthetic plastic widely commended for its long-lasting materials, affordability, and flexible structural elements. It can flexibly take the form of a solid or a liquid, based on the additives used. The construction industry utilizes PVC for pipes, window frames, and even flooring. It can also be found in medical devices and cable insulation. Its resistance against certain properties makes it lightweight. The broad range of industries that drag make use of PVC showcases how beneficial and purpose-serving the material is, irrespective of the industry it is been used in.

Understanding PVC: The Basics of Polyvinyl Chloride

Properties and Advantages of PVC

The versatility, affordability, and durability of Polyvinyl Chloride (PVC) stands out. Its primary characteristic is resistance to chemical and environmental degradation, which makes it suitable for indoor and outdoor applications. PVC has high tensile strength, usually between 2,600 to 5,900 psi (pounds per square inch), depending on different grades and formulations. This makes PVC durable in demanding environments like construction and industrial applications. It is also highly resistant to fire because of its composition; PVC is inherently flame-retardant due to its chlorine content.

One of PVC’s most important benefits is its energy-efficient production. As cited by the Vinyl Institute, PVC products require less energy to produce than alternative materials like aluminum or steel. For instance, the estimated energy consumption in manufacturing PVC is 20 percent less than aluminum and 57 percent less than steel.

The environmental implications of PVC’s use are softened when it’s recycled, as it is in modern recycling programs where it is converted into new pipes, flooring, cables, etc. Indeed, PVC has over one million tons being recycled annually in the construction sector in Europe alone, according to industry data.

Cross-industry Adaptability

Due to its versatility, PVC is widely used across various sectors:

1. Construction: Used in pipes, electrical conduits, and window frames, it’s versatile. Also used in roofing membranes and flooring applications is flexible PVC.

More than 40% of global PVC production serves the construction industry, underlining the importance of PVC for infrastructure.

2. Healthcare: Medical grade biocompatibility ot sterilization PVC is widely used in IV bags, tubing, and their containers.

The healthcare industry is heavily reliant upon it, with some estimates suggesting PVC constitutes around 30% of all medical plastics.

3. Consumer Electronics and Goods: Due to its lightweight and waterproof nature PVC can be found in packaging, cable insulation, and clothing. It is also extensively used in consumer electronics for casings and wiring.

Challenges and Innovations

As beneficial as PVC is, it also comes with its set of challenges such as its eco-friendliness. The production process of PVC also comes with some byproducts including dioxins that may create some issues. Nonetheless, the problems with green chemistry are being worked on. Current manufacturing techniques are now aimed at the reduction of emission of harmful substances, creation of phthalate-free products, and meeting ecological standards.

Bio-based PVC and newer methods of recycling have also been developed which increase sustainability. Life cycle thinking that combines traditional versatility with newfound green approaches leads to the growth of this polymer which makes it even more appealing for use in the 21st century.

Applications of PVC in Various Industries

The uses of PVC products and polyvinyl chloride are numerous. This is mainly because of how durable, adaptable, and cost-effective polyvinyl chloride is. Its versatility makes it one of the most popular polymers across the globe. To further elaborate, here are some areas where….

1. Construction and Building

Did you know that PVC representation accounts for 60% of the global demand from the construction industry? That is due to its high weather, abrasion, and chemical resistance. This is great for the creation of long-lasting construction materials. Here are a few applications:

Pipes and Fittings: These are used widely in both irrigation and drainage systems, as well as in water supply due to greater service longevity and corrosion resistance. Statista reported in 2023 that PVC possessed more than fifty-five percent of the share in the market for plastic piping systems.

Vinyl Flooring: Cheap, waterproof, durable, and easy to clean, PVC flooring is extremely common in residential and commercial properties alike.

Window Frames and Door Profiles: These are energy efficient products that greatly improve the insulation of a building, thereby decreasing the cost of heating and cooling systems.

2. Healthcare

The flexibility and sterilization capabilities of PVC have transformed the Healthcare sector. It is very important for a variety of medical devices and equipment. Examples include:

Blood Bags and IV Tubes: The European Council of Vinyl states that as of 2022, more than 40 percent of disposable medical devices in IV hospitals utilize PVC.

Surgical Gloves and Masks: The versatility of PVC formulations ensures high-quality protective equipment.

Medical Packaging: PVC antimicrobials are used in the safe packaging of medicines and medical devices.

3. The Automotive Industry

PVC materials help manufacture lightweight, strong, and safe components for automobiles. Some common uses are:

Interiors: PVC is employed in dashboards, door panels, and seat covers because of its flexibility and wide aesthetic potential.

Underbody Coatings: PVC’s resistance against rust and wear helps improve the lifespan of the vehicles.

The growing demand for electric and lightweight vehicles is set to propel growth in the automotive PVC industry, increasing its value at a CAGR of 5.5 percent from 2023 to 2030, according to Grand View Research.

4. Electronics

PVC is of heightened importance for safety in the electronics sector, especially when it comes to electric cables. Such applications include:

Wires and Cable Insulation: PVC is always chosen when it comes to wiring systems due to its electrical resistance and flame-retardant nature.

Household Appliances: PVC caps, thermally resistant and durable outer casings found in devices.

5. Packaging

PVC is greatly utilized in packaging, especially in food and pharmaceutical products. For example:

Cling Film: Used for preserving food quality and freshness.

Rigid Containers: Widely used as transparent plastic containers for tablets and capsules in the pharmaceutical industry.

Due to its ability to be recycled, PVC is becoming a strong candidate in sustainable packaging solutions, making advancements in technologies that enable high-quality recycled PVC.

6. Renewable Energy Systems

PVC is on the rise as a material in the renewable energy industry. For example:

Encapsulation of Solar Panels: PVC provides solar cells with extra protection and makes them more durable.

Wind Turbines: PVC casing is applied in protective sheathing around turbine parts.

Construction, healthcare, and innovative renewable energy solutions this, are just a few examples of the ever-growing sectors of the global economy that PVC indisputably helps impact. The flexibility of the product, alongside changes in sustainable production, makes sure this polymer stays the material of choice for forward-thinking industries.

Why is PVC a Widely Used Material?

Polyvinyl Chloride (PVC) is used in a variety of industries because it is easy to obtain and incredibly beneficial. The wide-scale application of Polyvinyl Chloride (PVC) plugs stems from its chemical stability, lightweight, easy formability, durability, and resistance to harsh conditions. Ranging from medical tubing to civil engineering infrastructure projects, PVC’s high customizability makes it suitable for countless applications.

Research evidence also confirms the dominance of PVC in specific markets. Market Research Future (2023) claims that the global PVC market is projected to increase at a Compound Annual Growth Rate (CAGR) of 3.5% to over $95 billion by 2030. This surge is propelled by the building and construction industry, where PVC is used extensively in the manufacturing of pipes, window frames, and roofing materials because of its durability and resistance to degradation. The fact that PVC polymer is filament from extruded ceiling tiles makes its recycling easy and surely diminishes the overall environmental impact, making its use more sustainable for modern industries.

Another important factor why PVC is so popular is because of its use in renewable energy solutions. This material is vital in the manufacturing of photovoltaic panels and parts for wind turbines which helps shift towards cleaner sources of energy. In addition, technology innovation has resulted in the production of bio-based PVC which uses renewable feedstocks and decreases the use of fossil fuels even more, thereby improving the material’s sustainability.

Its lower cost relative to other materials coupled with remarkable efficiency guarantees the use of PVC in many traditional and emerging applications. These reasons together improve its standing as a useful and critical material around the world.

How to Identify PVC Plastic from Other Materials

When attempting to differentiate PVC plastic from other materials, observe the characteristics listed below:

Marking Codes: Look for recycling code number “3” or the letters “PVC,” as these are usually marked on the material.

Flexibility: Depending on its formulation, PVC can be flexible or rigid. It tends to be softer than some of the more rigid plastics.

Appearance: While some variants might have a matte look, PVC is often smooth and glossy.

Burn Test (Caution Required): In a controlled setting, gently burn a small sample. Burning PVC creates a distinct odor of chlorine. Use this technique as a last resort.

Do not rely on a single method to confirm identification; this approach will ensure accuracy.

Ways to Distinguish PVC: Visual and Physical Inspection

Recent advances in inspection techniques, combined with keen visual attention, can vastly improve the precision of PVC identification. To further assist in distinguishing the differences, refer to the provided details below.

Flexibility and Texture

Identification of PVC can be achieved by assessing flexibility. Compared to flexible PVC, rigid PVC is substantially harder hence it is termed rigid. Additionally, flexible PVC surfaces may have a peculiar ruberry texture, while rigid PVC is usually smoother and more firm.

Color and Variation

Despite PVC being predominately white or gray for industrial use, it can be found in different colors especilly for decorative purposes. Uniformity of color on the surface of PVC, even with extended duration of use, is a sign of good quality PVC.

Density Test

Relative to other plastics like polyethylene or polypropylene, PVC has a higher density. One straightforward method is to place the sample in water. Due to its rigidity, PVC will sink unlike other lighter plastics which will float.

Heat Resistance

PVC has a moderate ability to withstand heat. When undergoing exposure, softening, rather than melting at extreme temperatures, occurs. This can greatly assist, along with other controlled laboratory equipment, in proving, or validating recognition.

Chemical Resistance

Said another way, PVC is very resistant to most solvents as well as acids and alkalis. If safe to do so, one may attempt applying a mild solvent to the material and observing its reaction, or lack thereof, as a form of distinguishing trait.

UV Resistance

Recent research shows that modern variants of PVC are often formulated with UV stabilizers for outdoor applications. When placed under sunlight over long periods, PVC undergoes some fading but structurally remains intact, in contrast to some plastics that are more readily susceptible to degradation.

The combination of all these identification methods, along with the material’s complete characteristics, enables confident determination of the presence of PVC while avoiding potential misidentification. For large-scale evaluations, misidentification precision may be provided by more sophisticated tools such as spectrometry or molecular analysis. At all times, cautionary measures must be observed in testing processes, especially when involving chemicals or heat.

Conducting the Beilstein Test for Chlorine Detection

The Beilstein test is a simple yet dependable method for qualitative analysis for detecting the presence of halogens, and specifically, chlorine in a given substance. The test leverages the volatile nature of copper halides, which are formed by halogens when they are introduced to a heated copper wire flame; this results in the emission of a green flame. Listed below are the most recent insights regarding the test and its execution:

Materials Needed

Purified copper wire free of any previous contamination

Solid sample of the substance suspected to contain halogen, chlorine

Consistent source of heat, such as a Bunsen burner or a lighter

Safety materials, including goggles, gloves, and an unobstructed space

Copper wire cutting pliers

Test tube

Test tube holder for ease of use

Procedure

Preparation of Copper Wire:

Remove all forms of contaminants and impurities from the wire using flame. The wire should be orange in color during the process of burning impurities.

Sample Heating

You can put the copper wire back in the flame and watch a color change. If the flame turns green, there are halogens present, with chlorine likely being the dominant one. The flame should always be hot and remain consistent throughout the test.

Result Interpretation

Positive

Halogens are confirmed if the green color is present.

Negative

Without the green color appearing, there are no halogens present at all, or at least not at a concentration that can be detected.

New Information Insights

With other recent changes, new tests for the presence of chlorine joined the Beilstein test through digital flame spectrometry, allowing for enhanced sensitivity when detecting low-chlorine samples. Modern safety practices also focus on reducing the risk of having direct contact with the sample while it’s heated, since some emissions are dangerous and toxic. Labs that routinely carry out the test simultaneously with other molecular analysis techniques such as FTIR tend to use it for confirming the results.

Safety Considerations

Refrain from breathing any of the fumes generated during the test. Burning of PVC or anything with chlorine produces dioxins which are hazardous.

Dioxins need to be handled with care as they are toxic, so the test should be conducted in properly ventilated spaces or fume hoods.

Other protective materials for dioxins include gloves and goggles which need to be used at all times.

While maintaining accuracy, efficiency, and safety for users, the Beilstein test remains a notable tool for chlorine detection, due to its integration with modern techniques and its preservation of accuracy from traditional methods.

Using Density and Float Tests to Identify PVC

Float and density testing are among the simplest yet discerning procedures for differentiating Poly Vinyl Chloride (PVC) among other plastics. The principle works because solid PVC is denser than water thus it can be easily tested with these simple means. The principle works by placing the sample in water and/or fluids of specific densities and checking for sinking or floating.

Steps for Conducting the Float Test:

1. Preparing the Sample: The plastic sample must be washed so that no surface contaminants will affect the testing equipment.

2. Employing Water as a Medium: Immerse the piece of plastic in a container with water (density = 1 g/cm³) and observe its behavior. Being that W- PVC will sink, its density is between 1.3 to 1.4 g/cm³.

3. Optional Use of Denser Liquids: For further testing, placing the plastic in a denser liquid such as saturated salt solution (density ~1.2 g/cm³) will aid in proving the hypothesis as most other plastics that can sink in water won’t.

Data on Plastic Densities:

|

Plastic Type |

Density (g/cm³) |

Sink in Water (Yes/No) |

|---|---|---|

|

Polyethylene (PE) |

|

No |

|

Polypropylene (PP) |

|

No |

|

Polyvinyl Chloride (PVC) |

|

Yes |

|

Polystyrene (PS) |

|

Yes, but may float in denser solutions |

Benefits of Performing Density and Float Tests:

Fast and Inexpensive: These tests only need simple materials which makes them good for initial assessment.

Non-Destructive Evaluation: Samples can still be examined later if necessary.

High Accuracy for PVC: Among all plastics, the density of PVC is distinct making its identification reliable with these methods.

Combining the float test with other supporting examinations, like the Beilstein test or infrared spectroscopy can improve the accuracy, confidence, and precision of PVC confirmation.

What are the Common Tests for PVC Plastic?

Float Test: Since PVC is denser than water, it will sink during the test, making it easy to tell apart from other plastics which float.

Beilstein Test: The presence of chlorine in PVC is indicated by a green flame resulting from a copper wire flame stirred into the plastic sample.

Burn Test: The distinctive odor and sooty flame produced when burning PVC confirms its identity.

Solubility Test: Some solvents, like tetrahydrofuran (THF), can dissolve PVC while leaving many other plastics unchanged, enabling better identification.

When taken together, these tests provide a reliable identification of PVC plastic, and they are easy to perform.

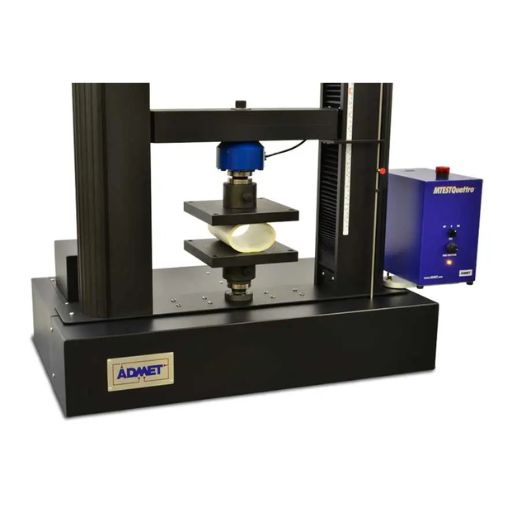

Mechanical Testing: Assessing Durability and Integrity

Mechanical assessments of PVC materials are important in determining the scope of use for their flexibility, ductility, bending yield strength, and dependability, and checking if they meet the performance thresholds. Some of the basic tests are outlined below:

Tensile Strength Test: The stretch test for PVC attempts to quantify the stress the material can endure under tensile forces before failure. Good quality PVC is believed to have a tensile strength in the 52-80 MPa range, depending on the formulation and processes of manufacturing.

Impact Resistance Test: This test verifies the capacity of the material to endure forces or shocks when applied suddenly. In general, PVC has a very good level of impact resistance which makes it suitable for use as pipes and in construction. For example, unplasticized PVC (uPVC) has greater rigidity and impact resistance than plasticized PVC.

Hardness Test: The Shore Hardness test determines how hard the surface of PVC is and correlates it with the loss of material that occurs when the surface is worn away. The values of uPVC are between Shore D 75-85 which demonstrates the effectiveness of the material in window frames and doors.

Elongation at Break Test: This test estimates the ability of the material to deform in a lengthwise direction before breakage occurs and provides some degree of indication of flexibility. It has been reported that plasticized PVC can extend to break, elongating by 200-500%, while uPVC, having a more rigid structure can’t elongate much.

Creep Testing: Creep testing analyzes the deformation of PVC over time while a constant load is applied. This test is critical for evaluating the material’s long-term performance, particularly concerning its structural, pressure-bearing capabilities.

Through these mechanical tests, manufacturers guarantee PVC’s reliability, durability, and performance, considering all potential use cases. Moreover, modern developments in testing equipment offer enhanced automation and precision, yielding accurate data for quality control and tailored design.

Chemical Tests: Solvent Resistance and Thermal Analysis

Chemical tests are extremely useful when analyzing the performance of PVC materials in consideration of specific environmental and operational conditions. Solvent resistance testing checks how submitting PVC samples to chemical agents like acetone, alcohols, and detergents affects the sample’s ability to resist swelling, cracking, or degradation. For instance, it has been proven that some organic solvents can be detrimental to PVC, despite most acids and alkalis being resisted by PVC, depending on the composition of additives within the material. These tests are crucial in determining what formulations should be used for materials that frequently come into contact with chemicals.

With thermal analysis, focus is placed on the study of the behavior of PVC concerning temperature changes. Determining glass transition temperature (Tg), melting points, and thermal stability of PVC is often done through Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA). For instance, some recent studies indicate that standard PVC generally begins to thermally decompose in the range of 200-220°C; it starts giving off Hydrogen Chloride (HCl) gas. The operational life of PVC in high-temperature environments is increased with advanced thermal stabilizers and additives developed to mitigate such degradation.

The merger of solvent resistance with thermal analysis creates a unique evaluation method for assessing the chemical durability and the limits of performance of PVC. This information is useful to material engineers for choosing the right formulations in critical applications like medical devices, piping systems, and electrical insulation, where considerable chemical and thermal stability are prerequisites. Improvements in testing methods have provided more precise results, which many industries rely on for product-based design improvements.

Flame Test: Observing the Color of the Flame and Smoke

The flame test is an important technique for evaluating materials such as PVC concerning high temperatures. Materials are tested with a direct flame and monitored for the color of the fire, the smoke produced, and whether or not the fire extinguishes naturally. In the case of PVC, the flame produced is characteristically halogenated and tends to be greenish yellow due to the chlorine atoms present in its structure. This is characteristic of compounds such as Hydrogen Chloride gas which they burn.

Recent PVC studies emphasize additional surface-level observations as they relate to the environmental and safety standards, such as dense smoke and its chemical makeup. For example, dense black smoke produced upon the combustion of PVC is an indicator and mark of thermal decomposition of carbonaceous products. Infrared spectroscopy and gas chromatography shed light on the byproducts of combustion, these new techniques provide improved data for assessing material behavior in fire conditions.

These careful observations can be utilized in construction and electronics, where fire resistance and smoke toxicity are vital components. Standardization organizations like ASTM and ISO conduct stringent fire tests on certain materials, such as PVC, due to its widespread application in various industries.

How to Perform a Burn Test Safely on PVC Materials?

Safety Considerations

Always ensure that the test is done in a fume cupboard or well-ventilated area to prevent inhalation of dangerous fumes.

Put on all necessary protective equipment which includes gloves, safety goggles, and a lab coat.

In case of an emergency, fire extinguishers or buckets full of sand should be kept nearby.

Sample Preparation

In cutting the piece of PVC, the sample should not exceed the measurement of 2 inches by 2 inches to decrease potential danger.

The sample should be placed on metal tongs to adjust one’s distance from the flame.

Conducting the Test

The sample of PVC can be used as a source of fire by setting the edges on a lighter flame.

Take note of the Green flame plus accompanied by smoke and odor during the burning. Due to the PVC’s Chlorine content, it turns into green flame plus choking smell while burning.

The Fire Needs To Be Put Out With The Sample’s Heat Source

Sample plus any remaining parts must be disposed of in line with the area’s regulations for hazardous waste. As a good practice, do not forget to burn it first.

Taking these actions allows for reduced risk and safe testing on burning PVC materials.

Preparing a Small Piece of the Plastic Sample

When conducting a burn test on a plastic sample, proper preparation of the plastic sample will enhance accuracy and safety during the entire process. Follow these steps:

Choosing the Stratified Sample

Select a small piece of the material, ideally not larger than 10mm x 10mm. This dimension works best as it easy to handle, produces less fumes, or dissolve effortlessly into air, making it ideal for testing. Its smaller size also ensures safety.

The sample is Now Ready to be Cleaned

The actual burn test cannot be started unless the piece of plastic is cleaned and free of dirt, grease, or any other form of contaminant, as its presence can gravely interfere with the results. Use alcohol-based solutions to clean the sample without leaving any residue behind.

Shaping and Cutting

Always make sure to cut using sharp utility knives or any other specialized knives. This allows for precise trimming of the plastic into desired shapes. A rectangular or square sample can yield better results. Make sure to avoid tools that have frictional heat as they will prematurely alter the sample. Finally, always put on gloves when dealing with sharp objects.

An additional thing to consider when working with thin films or sheets of plastic is safety measures. In the event that excessive melting is required before ignition, try layering the sample to allow proper prognosis of flame movement.

Look for Additives or Identifying Features

Look over the specimen for any identification markers which may include: a recycling symbol or any additives. Certain plastics such as PVC possess distinct chemical markers, while others may need more sophisticated verification processes. This check may serve as an addition to the results obtained from the burn test.

By following the outlined procedures for sample preparation, you avoid, at best, false readings and hazard, while granting exact and reliable outcomes throughout the course of the burn testing procedure.

Using a Bunsen Burner or Torch for the Test

Applying a flame, whether from a torch or a Bunsen burner, requires following specific safety protocols. This procedure is often used to determine which type of plastic sample it is by determining how it reacts to a flame. The following steps and observations are needed to get accurate results:

Set Up The Equipment

Ensure that the workspace is well ventilated because burning plastics can emit poisonous gases. Only place the Bunsen burner or torch on a stable surface free of any combustible materials. It is crucial to put on heatproof gloves and goggles before commencing for your own safety.

Sample Grasping

Use metal tongs to hold the plastic sample so that it does not touch the skin directly. No part of the body must come into contact with the piece, as it could lead to burns.

Applying the Flame

While applying the flame to the sample, ensure that it is done slowly. It is crucial to track how the sample burns, how it drips from its initial form, and how much smoke it releases.

Important Observations For Identification

Flame Color: Plastics give off their distinctive flame color, which is important for identification. Some of them include:

Polypropylene (PP) and Polyethylene (PE) usually emit a blue flecked flame and will drip as they melt.

Polyvinyl Chloride (PVC) shows a green flame being released because of Cl.

Smell of the Smoke: Burning of plastics emits distinct smells:

Chlorinated PVC can produce a pungent smell.

Acrylic can give out a sweet scent.

Polystyrene (PS) gives off a sweet-smelling fragrance.

Melted forms of some plastics (like Polyamide/Nylon) and others will shrink and curl away from the flame while still dripping or bubbling.

Record Observations:

Detailed logs are needed to compare visial olfactory observations alongside standards and tactics used for identifying the type of plastic graphic charts.

Safety Considerations:

Fumes, including ones still bound to burned plastic residues, pose obstruction hazards. For this reason, it’s important to place test enclosures outside the user’s area of working or employ extraction systems that ventilate away from the user’s area.

Applying this synthesis alongside heuristic techniques, where comparing them against polymer identification charts readily available on the web allows the vast range of possible plastic types to be precisely identified. This process step is vital when it comes down to categorization in recycling, quality control, or even details in research and design.

Interpreting the Results: Color and Odour of the Flame

Color and odor both provide essential clues about the polymer used when a burn test is performed on plastic materials. The reasoning behind this is that every type of plastic emits a certain flame and odor due to its unique chemical makeup. Underneath is the information based on the latest industry patterns and insights.

Polyethylene (PE)

Flame Color: The Tips of the flame are blue with yellow edges.

Odor: Burns produce a paraffin fragrance of fragrance which burns candle wax.

Observation: Molten material drips and slowly burns PE.

Polypropylene (PP)

Flame Color: Blazing blue with yellow striking tips.

Odor: Burns emit a sweet scent that resembles burning oil and paraffin.

Observation: Usually burns slightly more efficiently than PE but has the same characteristics.

Polystyrene (PS)

Flame Color: Captures a yellow and sooty mixture.

Odor: Distinctive Styrene Releases aromatic scent which burns rubber.

Observation: Form with no drips while burning and tends to produce black smoke.

Polyvinyl Chloride (PVC)

Flame Color: Gives off a greenish color.

Odor: Protective PVC body burns, giving off hydrochloric acid-like, irritating and sharp fumes.

Observation: Typical white smoke is generated on burning PVC, and the flame out self-extinguishes when heat ceases.

Polycarbonate (PC)

Flame Color: Cobalt blue and contains a slight orange hue.

Odor: The Faint sweet smell PC emits is a phenolic odor.

Observation: A slow burn is exhibited along with the formation of a black, charred residue.

Plastic type (PMMA):

Flame color: Bright yellow with a faint amount of smoke.

Smell: Fruity or sugary scent.

Observation: Purple flames indicating the material burns severely burns giving off popping sounds.

ABS (Acrylonitrile Butadiene Styrene):

Flame color: Yellow flame with black soot.

Odor: Sharp acrid smell like a mixture of burnt rubber or acrylonitrile.

Observation: Distinct dense black smoke is discharged.

safety measures

Burning tests produce harmful gases, especially with plastics like PVC and ABS. Always conduct tests in fume hoods or ventilated spaces. Molten drips, fumes, and other hazards require personal protective equipment (PPE) like gloves and goggles.

Following the provided instructions regarding odor and flame color will allow for more precise identification of plastic materials alongside proper safety measures alongside other tests. This is the basis of effective material classifications across industries.

What to Consider in the Inspection of PVC Pipes?

Surface Condition: Examination for cracks, scratches, discoloration, aging and any other damage.

Dimensions and Thickness: Inspection of the pipe’s diameter and wall thickness relative to its intended use.

Flexibility and Rigidity: Evaluation of the pipe’s flexibility relative to its performance expectation under varying temperatures and pressures.

Joint Integrity: Evaluation of the coupling and connection points for leaks, improper fittings, and other issues that may negatively affect functionality.

Signs of Contamination: Evaluation for residues, dirt, and other deposits that may compromise the pipe’s safety and effectiveness.

Completing these inspections on a scheduled basis will greatly enhance the durability, functionality, and safety of PVC pipes.

Checking for Physical Integrity and Defects

For the health of your PVC pipes, a meticulous inspection should be conducted to check for any signs of damage that would impact the pipes’ functionality or structure. Studies show that in many cases, the damage caused to PVC pipes over time is a direct result of environmental changes, misuse, or age. To conduct a thorough inspection, the following should always be checked first:

Fractures and Cracks: Make sure to check the surface of the pipe for any signs of separation such as splits, fractures, or cracks. Surpassing either end of the temperature scale can speed up the breakdown of PVC, leading to weakening. Various studies in the field have come to the conclusion that installations left unprotected are prone to degrading which can weaken the pipe’s overall strength considerably during UV exposure.

Surface Deformation: Look for any gaps, uneven dents, or warping along the pipes length. These kinds of deformities can happen due to shipping, storing, or external pressure. Hydro-mechanical performance is reduced while the risk of system failure is increased due to warped pipes.

Discoloration: During the inspection, aim to identify darker spots or patches that would denote loss of surface color. Chemical reactions tend to darken patches which can counter prove contaminate the pipe in use. Discoloration would also lead to inner chemical deposits which would result in a reduction of flow efficiency.

Ultrasonic Testing: Uses ultrasonic testing equipment for gauging the uniformity of the pipe wall thickness. Any deviation in thickness may impact the pipe’s ability to withstand pressure. In general, the standards impose a minimum wall thickness limit for PVC pipes with a given pressure rating.

Flexibility Test: A achievable test for elasticity is simply bending a sample of the PVC pipe. Low temperature brittle or too rigid pipe suggests degradation of the material, which is usually the result of long term exposure to temperatures, chemicals, or some other form of interaction. Under standard atmosphere, PVC pipes are designed to retain flexibility.

Impact Resistance: Other methods to evaluate the durability of the pipe are drop tests or impact tests. Superior quality PVC pipes are designed to withstand minor unintentional impacts without resulting to cracks. Otherwise, pipes that are exposed to harsh weather or freezing temperatures become more susceptible to loss of impact resistance over time.

Addressing such physical attributes in plumbing and irrigation systems promptly lessens the chances of undesirable leaks or failures. The PVC piping system guarantees durability and effectiveness when regularly monitored and maintained according to manufacturer’s recommendations.

Measuring Pipe Dimensions and Wall Thickness

Compatibility with intended uses, adherence to industrial norms, and practices rely on accurate measuring of the dimensional criteria of pipes and wall thickness. Measurement of pipes can be done through two distinct parameters:

Outer Diameter (OD): This refers to the ‘overall diameter of the pipe which is measured from the wall’s edge and the OD is crucial,’ as it determines the fitting of the pipe to its connectors, valves, or any other plumbing systems.

Wall Thickness: The material pipe of a pipe also contributes to its pressure rating as well as the strength of the pipe, thus giving it a distinct measure. It is usually represented by the schedule of the pipe (schedule40,schedule80) which signifies wall thickness in comparison to the diameter of the pipe.

Measurement Tools

To get precision in the measurement of these dimensions, the following tools should be used:

Calipers: Considered the most effective in measuring the outer diameter as well as wall boundaries.

Ultrasonic Thickness Gauges: Best used in measuring wall thickness without cutting into the pipe, particularly useful for large or fixed pipes.

Measuring Tape: Appropriate for bigger pipes when measuring circumference and calculating the diameter.

Standard Dimension Ratios (SDR)

PVC pipes are also identified and labeled using an SDR system. Th SDR is the ratio of a pipe’s outer diameter to wall thickness. Example, an SDR 11 pipe has a wall thickness that is 1/11 of its outer diameter. Increasing SDR value suggests lower wall thickness which is ideal for lower-pressure applications.

Common Pipe Dimension Example (Schedule 40 PVC Pipes)

Nominal Size: 1 inch

Outer Diameter (OD): 1.315 inches

Wall Thickness (Schedule 40): 0.133 inches

Internal Diameter (ID): 1.049 inches

Nominal Size: 2 inches

Outer Diameter (OD): 2.375 inches

Wall Thickness (Schedule 40): 0.154 inches

Internal Diameter (ID): 2.067 inches

This information shows the relationship of the diameter and wall thickness over the inner diameter of the pipes. For easy pipe selection for certain functions, measurements charts are often provided by standards and manufacturers.

Importance of Measurement

Measuring the dimensions and wall thickness of pipes ensures easy assembly, safety, and efficiency of the system. This is very important for high-pressure systems or those with stringent regulatory requirements. Complying with properly prescribed measurements and regular inspections enhances the reliability of the PVC piping system’s structure across industrial, residential, and agricultural sectors.

Evaluating the Chemical Resistance and Durability

The best feature of PVC piping is its exceptional chemical resistance—it can handle a wide array of substances without degrading. Salt, acids, bases, alcohol, and most non-aromatic hydrocarbons do corrode PVC, but not without enduring its fortitude. New data suggests that PVC pipes hold structural integrity within a pH range of 2-12, which covers most industrial and agricultural chemical solutions.

As far as durability is concerned, PVC pipes are prepared to face the test of time in terms of environmental stress and physical wear and tear. The latest studies suggest that when followed with proper installation and maintenance procedures, these pipes can effortlessly last for over 50 years. Outdoor applications benefit from PVC’s inherent resistance to ultraviolet (UV) radiation when combined with UV stabilizers or protective coatings. Other benefits include the material’s impact resistance and flexibility which enables it to withstand freeze-thaw weather cycles without cracking or warping.

A 2022 study highlights the continued adoption of high-performance formulations of PVC polymer that endure harsh industrial chemicals, including powerful solvents and oxidizers. Combined with low permeability to gases and vapors, these advancements further solidify PVC’s position as one of the most chemically resistant materials for piping systems.

Reference Sources

- Classroom Examination of Different Types of Plastics

This study involves testing procedures for PVC, such as the mar resistance test which assesses its durability against abrasive actions.

- Assessment and Development of a PVC Water Pipe with Improved Structural Properties

This study covers numerous tests conducted on PVC pipes like impact, stiffness, tensile, and hydrostatic burst pressure tests.

- PVC Handbook

This handbook focuses on performance evaluations of commercial PVC plastics and offers suggestions on their utility.

Frequently Asked Questions (FAQs)

Q: What is the most common method to test if a plastic material is PVC?

A: The Beilstein test is a common method to test if a plastic material is PVC. It involves exposing a copper wire to a flame and then holding it against the sample. If the plastic is PVC, a greenish flame is produced, indicating the presence of chlorine.

Q: How can you identify PVC materials using a mechanical test?

A: Mechanical tests, such as tensile strength tests, can be conducted to determine the durability and integrity of PVC materials. These tests help measure how the material performs under stress and its suitability for various applications.

Q: What role does thermal analysis play in PVC testing?

A: Thermal analysis is crucial in PVC testing as it helps determine the temperature range over which the thermoplastic polymer becomes malleable when heated. This information is useful in understanding the material’s thermal properties and manufacturing applications.

Q: How can you conduct a chemical inspection to identify an unknown plastic?

A: A chemical inspection can involve solvent testing, where a small piece of the plastic is exposed to specific chemicals to observe reactions. This can help identify unknown plastic materials by comparing the reactions to known plastics.

Q: What is the significance of measuring the density of PVC?

A: Measuring the density of PVC is an important way to distinguish it from other plastics. This can be done by checking whether the sample floats or sinks in water. PVC typically has a density greater than water, causing it to sink.

Q: Why is the color of the flame important in PVC testing?

A: The color of the flame is crucial in PVC testing because it can indicate the presence of chlorine. A greenish color in the flame during a Beilstein test suggests the material is PVC due to its chlorine content.

Q: What is the purpose of using a torch in PVC material testing?

A: A torch is used in PVC material testing to apply heat and observe how the plastic reacts. The burning characteristics, such as the color of the flame, odor, and presence of fumes, help determine if the plastic is PVC.

Q: How does the inspection of thermal properties help in PVC applications?

A: Inspecting the thermal properties of PVC helps determine its suitability for various applications. Understanding its melting point, thermal stability, and behavior when heated is essential for manufacturing processes and end-use conditions.

Q: What information can be obtained from a durability test on PVC pipes?

A: A durability test on PVC pipes can provide information about their strength, flexibility, and resistance to environmental factors. This helps ensure that the pipes meet the necessary standards for safe and effective use in construction and plumbing.

Q: How can the presence of chlorine in PVC be tested without advanced equipment?

A: The presence of chlorine in PVC can be tested using a simple Beilstein test, which does not require advanced equipment. By using a copper wire and a flame, the greenish color of the flame can confirm the presence of chlorine in the sample.