Top Plastic Testing Equipment in China. Plastics are a key feature of modern life. They fuel whole new industries and transform the myriad of products that people use daily. However, how do manufacturers make sure that these materials are more than just basic structures by checking functional parameters such as performance, robustness, and safety for multi-purpose functions? This is where plastic testing comes in. It is a systematic procedure that checks the craftsmanship of a given product as well as aids in providing the value of trust that a given product, like a medical device or an automobile part of an expensive car, possesses. This article looks into the intricacies of plastic testing, including its significance, methodologies, and the most important parameters that establish a material’s performance. From your perspective, whether as an industrialist, manufacturer or someone interested in guaranteed standards of quality, brace yourself as we take you through the mastery of plastic testing.

What Are the Common Methods for Plastic Testing?

Plastic testing includes several methodologies that evaluate the material’s characteristics and performance. Common methods include:

Tensile Testing – Tests the strength and increase in length of a plastic specimen when pulled apart, which assesses its bending and stretching capabilities.

Impact Testing – Tests the toughness of the material under sudden force or impact.

Thermal Testing – Tests the effect of heat on a plastic specimen, for example its melting point and thermal stability.

Hardness Testing – Tests the amount of deformity or surface abrasion on a plastic material.

Chemical Resistance Testing – Tests the behavior of plastic when subjected to various chemicals to check it against certain specifications.

These methods are necessary in measuring the quality, precision, and flexibility of the plastic material for its intended use.

How is Polymer Testing Conducted?

The analysis of polymers is done using sophisticated technology within their physical, mechanical, thermal, and chemical domains through systematic procedures termed as polymer testing. Such tests guarantee that quality benchmarks and functionality norms are met and polymers can be reliably used in intended applications. Below are the primary stages and methods associated with polymer testing:

Sample Preparation – The treatment starts with fabrication of test samples on predefined standards including measuring frames and description outlines e.g., ASTM or ISO. Throughout the polymer testing stages, exact sample preparation leads to securing uniform and accurate outcomes which is fundamental in qualitative testing.

Mechanical Testing – Other state-of-the-art equipment used is tensile testing system, which measures tensile strength, elongation, and modulus among other attributes. To gauge impact resistance, Charpy or Izod impact tests are done to quantify the amount of energy the material can withstand under different forces while still maintaining structural integrity.

Thermal Analysis – During thermal analyses, other techniques such as Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) are used. While DSC assesses the changes in the crystal-shaped and amorphous regions within the sample, TGA analyzes decomposition and thermal stability.

Chemical and Environmental Resistance Tests – To assess how polymers endure exposure to UV light, humidity, or corrosive chemicals, simulated harsh environments are created. Polymers relevant to the automotive and construction industries, for example, are subjected to testing for fuel exposure and environmental degradation.

Microscopic and Structural Analysis – The advanced microscopy methods like Scanning Electron Microcopy (SEM) provide information on the surface morphology, fractures, and distribution of additives or fillers within the polymer at the nanoscale.

Rheological Testing – The processability of polymer melts is determined by examining their flow and deformation with rheometers and viscometers. This is crucial for materials intended for injection molding or extrusion.

Dynamic Mechanical Analysis (DMA) – Assesses the range of viscoelastic properties within a polymer across a wide temperature spectrum to estimate its response to dynamic or cyclic loads.

As per the latest reports, the global market for polymer testing services is projected to expand by approximately 5.8% annually between 2023 and 2030, primarily attributed to heightened utilization of advanced materials in packaging, automotive, and aerospace industries. The application of artificial intelligence (AI) and machine learning within testing frameworks is transforming polymer characterization by streamlining processes and improving the speed and accuracy of assessments.

Through the meticulous analysis of polymers with respect to these criteria, industries are able to assure the performance, safety, and durability of the material in varying conditions.

What Are the Key Testing Procedures for Plastics?

Plastics are tested through various procedures that check their mechanical, thermal, chemical, and physical properties. These tests validate that the plastics fulfill industry benchmarks and are appropriate for their specific applications. Below are some of the key procedures performed on plastics, along with the most recent advancements and their importance:

Tensile Testing

Tensile tests evaluate the stretching strength of a plastic, obtaining parameters such as maximum tensile strength, elongation at break, and Young’s modulus. As per ASTM D638, this test is useful for manufacturers to determine the applicability of the material in regard to mechanical stress during use. Modern systems can combine AI-enhanced predictive modeling with simulations of long-term stress conditions, further optimizing development cycles.

Impact Testing

Impact resistance remains one of the most important properties for materials in automotive or construction. Plastics are tested for their resistance to sudden force using Charpy and Izod impact tests. Advances in testing systems offer the capability to dynamically measure impact strength under actual conditions, thus improving reliability.

Thermal Properties of Materials

The reaction of any material to the change of temperature is termed as thermal properties. The primary methods are Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA). Recent work states that with the addition of machine learning, laboratories are now able to better predict melting points and thermal stability. For instance, the global market value of polymer testing surpassed 4 billion dollars in 2022, owing to improvements in thermal testing technologies.

Chemical Resistance Testing

Aggressive chemicals can often be encountered by plastics that can inhibit their performance. Tests determining the level of resistance of a material to solvents, acids, and other chemicals is crucial in healthcare and packaging. In terms of informal standards, ISO 175 and ASTM D543 offer suggestions for chemical resistance testing. With new automated systems, hundreds of samples can now be tested at the same time which boosts productivity.

Testing the Hardness

Hardness represents a material’s ability to resist surface penetration and it is usually measured by Shore or Rockwell scales. In industries such as electronics, digital hardness testers are important for fast and accurate readings for quality control purposes.

Environmental Stress Cracking (ESC) Testing

Environmental stress cracking (ESC deterioration) is a prevalent phenomenon that occurs when materials undergo mechanical stresses and simultaneous chemical interactions. It can be assessed by applying mechanical tensile stress to defined samples in the presence of selective solvents. The ESC testing process has been facilitated by the addition of modern imaging systems which allow for the detection of micro-cracks during early stages of development.

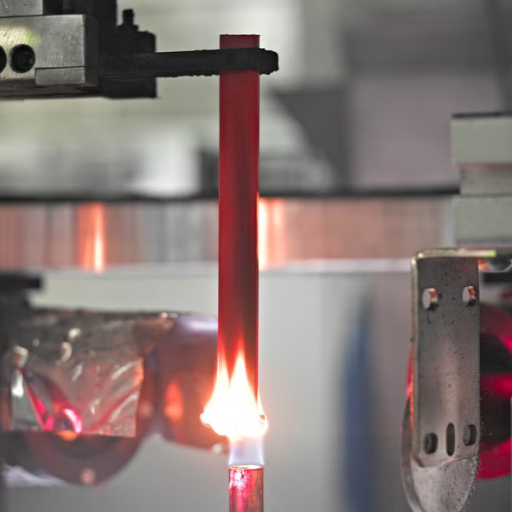

Flammability Tests

Plastics employed in construction, electrical parts, and automobile interiors exhibit potential safety risks, of which flammability is the most dangerous. Within this field, there are a few standards which set guidelines on testing materials for structural fire protection such as UL 94 which specifies how flame resisting attributes of a material should be assessed. AI based systems are now capable of more precisely replicating fire conditions which increases accuracy of the data obtained and reduces errors due to experimental variations.

These evaluation methods use real-time surveillance, AI, and data analytics to modern augmenting features, such as real-time tracking, protect data integrity, and ensure accuracy that plastics are lightweight, robust, and appropriately tailored for modern needs. Competition within the industry is likely to increase as they strive to adopt advances in testing technologies in response to the projected 8.5% growth in the global testing equipment market between 2023 and 2030.

Understanding Melt Flow in Plastics

Melt flow, or melt flow index (MFI) as referred to in the plastic industry, is one of the most important features concerning the production domain involving polymers. It indicates how easily a polymer flows when molten at particular temperature and pressure conditions. This is denominated in grams per 10 minutes and helps in estimating viscosity and thermoplastic workability. The MFI value is inversely proportional to molecular weight, meaning the higher the molecular weight, the lower the melt flow index. Thus, it is most applicable to analyze the material’s merit for processes like injection molding or extrusion.

With every passing year, the accuracy of measuring melt flow is becoming increasingly vital, especially for manufacturers with stringent production and performance benchmarks. Automated melt flow testers and other advanced equipment have provided greater accuracy, yielding reliable results even in automated high-testing conditions. Recent reports claim the melt flow testing market is set to increase by around 6.7% annually till 2027, driven by the wide adoption of engineered plastics for automotive parts, packaging, and even healthcare.

Melt flow diagnostics aid in the crafting of sustainable materials. For example, the MFI for most recycled plastics is not consistent which constrains their processing and utility. Change monitoring of melt flow characteristics enables refinement of formulation strategies which improves the overall quality of recycled materials. The advancement of AI technologies alongside real-time data surveillance is improving the speed, precision, and versatility of changeable melt flow testing processes to serve contemporary industrial requirements.

How Do You Assess the Quality of Plastic Materials?

Evaluating the quality of plastic materials requires ascertaining primary properties that affect their performance and appropriateness for particular use cases. Basic tests include evaluating mechanical parameters like tensile and impact strengths which reflect durability. Thermal analysis, such as assessing the melting point, evaluates heat resistance. Moreover, an indisputable inspection for the presence of surface flaws or defects is also conducted. More advanced methods like spectroscopy or melt flow index testing may be conducted to evaluate composition and processing attributes of the material. These assessments are made to ensure that the material made of plastic meets the standards and expectations of the devised conditions.

Why Is Quality Control Crucial in Plastic Manufacturing?

In plastic production, it is crucial to maintain quality control to ensure that safety, functionality, and performance criteria are met based on industry standards. The presence of low-quality or faulty plastics can result in severe consequences, including the failure of a product, hazardous safety risks, and damage to the environment. Failing to meet the basic standards is especially critical within the automotive or medical software industry, as it may lead to life-threatening failures. Additionally, the International Organization for Standardization (ISO) has done research and states that businesses that maintain strict quality control policies waste less and cut manufacturing expenses by 20% economically.

More Advanced methods like evaluating tensile strength, impact resistance, and chemical stability offer quantifiable assessment on the strength and reliability of a given plastic. From 2021 to 2026, there is a predicted 5.2% growth in the Testing Inspection and Certification (TIC) industry which shows an increasing focus spotlight on quality control and assurance practices, estimates a report by MarketsandMarkets.

Furthermore, by reducing the amount of waste, quality control plays a role in environmental conservation. Recent studies highlight the possibility of integrating recycled plastics while still aligning with sustainability goals, provided strict regulation and testing is maintained. Overall, quality control goes beyond compliance; it serves as a focal point for garnering customer confidence and boosting the brand value.

Which Testing Machine is Best for Plastic Testing?

Your evaluation of the features in question, including tensile strength, impact resistance, thermal behavior, and even chemical composition, will guide you in selecting a testing machine for plastic. The following are some of the more sophisticated and frequently utilized machines aimed at plastic testing, along with recent updates for your informed choices:

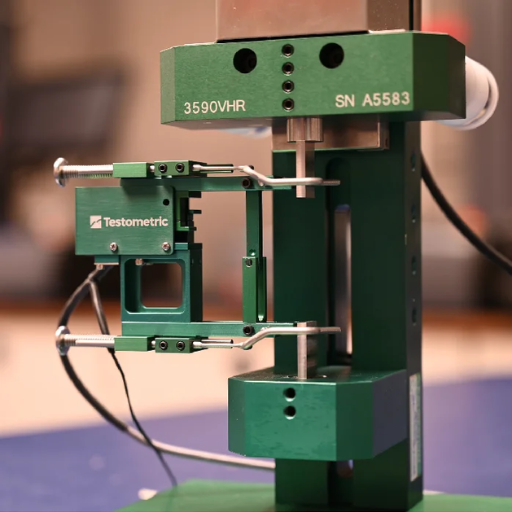

Universal Testing Machines (UTMs)

For testing plastics, Universal Testing Machines are likely the most flexible instruments. They are used for checking the longitudinal, compressive, and flexural strength of plastic materials. The accuracy and configurability of testing processes in the UTMs are also notable with the Instron 6800 series. Typically, UTMs are outfitted with force transducers that can measure a variety of plastic types, ranging from soft polymers to rigid materials, thanks to their wide active load ranges.

Impact Testing Machines

By the standards for determining the material’s ability to withstand sudden loading, Charpy and Izod impact testers are among the most common ones used. Such machines assess the toughness and the fracture resistance of plastic. The Tinius Olsen IT503 is one of the widely used models featuring advanced optical encoders, providing loss of energy and test precision. Such systems are critical in industries like automotive and aerospace, where material durability is important.

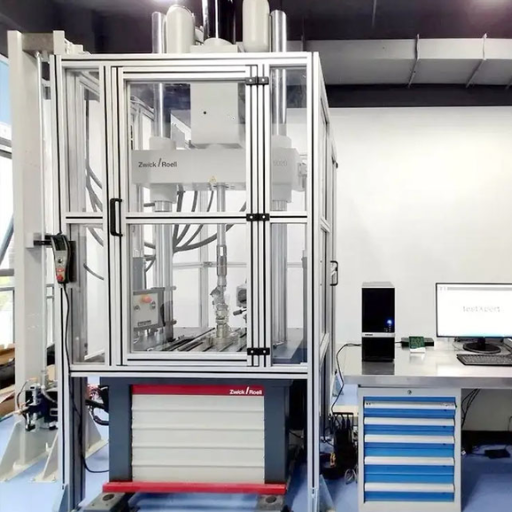

Melt Flow Index (MFI) Testers

MFI devices conduct tests by estimating the rate of molten plastic flow to determine its processability. Advanced devices, including the ZwickRoell Mflow system, carry out automated measurements on thermoplastic materials, highlighting consistency and repeatability. This test offers manufacturers a means to refine extrusion and injection molding processes.

Thermal Testing Machines (DSC, TGA)

Another important consideration when analyzing plastic materials is their thermal characteristics; differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) are integral for this purpose. In measuring the glass transition temperature and melting point, DSC, for instance, does that while TGA quantifies weight changes associated with temperature to provide data on decomposition or stability. For specialized labs that require fine precision, the TA Instruments Discovery DSC is widely used.

Rheometers

Rheometers determine the flow and deformation characteristics of plastic materials undergoing force. They are crucial for measuring the viscosity and viscoelastic behavior of polymers in their solid and molten states. Incorporating temperature control and dynamic oscillatory testing, the Anton Paar MCR series rheometers exemplify modern technology.

FTIR Spectroscopy Machines

Fourier-transform infrared spectrometers (FTIR) scan and study the chemical compositions of plastics for analysis and identification. For precise materials characterization such as the identification of polymer contaminants, additives, and degradation, the Thermo Fisher Nicolet iS50 FTIR spectrometer features advanced detection capabilities.

Primary Factors:

Trustworthy results: Achieving valid and repeatable results requires exploration of automation capabilities and advanced high-resolution sensors.

Ensuring the machines meet relevant ASTM or ISO standards will guarantee that the results produced and shared across stakeholders in the plastic industry are trustworthy and not compromised.

The nature of the material to be tested: Construction, medical, and industrial grade packaging technologies have flexible and rigid plastic components that dictate the selection of tools and equipment to be utilized for testing and evaluating processes in respective domains.

Expenditure and upkeep: Unlike traditional models, advanced equipment tends to feature lower upkeep and software maintenance costs, but this remains to be assessed on a lifetime expenditure basis.

Sectors selecting appropriate pieces of equipment tailored to particular operational functions will achieve compliance with relevant directives, alongside sustaining the quality and resilience of the plastic materials in alignment with contemporary environmental concerns and performance requirements.

What Are the Quality Results Expected from Testing Procedures?

The testing procedures carried out on plastics must provide accurate results that inform whether the material has met the quality standards. These results usually provide records on the strength, durability, and flexibility of the material, as well as the durability against external factors like heat, chemicals, or reinforcement by pressure. Safety assurance alongside consistent performance up to legal regulations must also be validated by tests. Precise and correct information obtained from testing assists in establishing any weaknesses with the materials and ensures that the product can be used for its specified purpose, whilst precalculated standards would be fulfilled which directly affects the reliability of the product and customer satisfaction.

How to Interpret Tensile Strength Results?

Tensile strength is the measure of the maximum tensile stress a material can sustain before failure and is extremely impactful in determining a material’s applicability. In general, tensile strength can be divided into three common types:

Ultimate Tensile Strength (UTS): refers to the maximum stress a material can withstand when being tested i.e. the maximum enduring force before material breaks. Steel for example, is around 400-550 MPa and aluminum alloys are around 200-500 MPa which means metals have a UTS. UTS measures to what degree a material can withstand a load without breaking.

Yield Strength: yield strength is the amount of stress at which a given material begins to deform plastically and is measured either in Megapascals (MPa) or pounds per square inch (psi). Yield strength of stainless steel grades is 250-350 MPa signifying that materials under construction have metallurgically high yield strength to sustain loads when applied, work.

Fracture Point: material breaks after reaching its ultimate tensile strength, tensile it’s the mark wherein a fracture occurs. This aids engineers in evaluating failure risks in critical environments such extreme pressure or temperature conditions.

Practical Interpretation of Mechanical Testing

While interpreting the results of a tensile test, one needs to keep in mind the following aspects:

Verification Against Applicable Requirements: The results for the tensile strength should fall within the bounds of the guidelines specific to the particular industry and also any relevant international standards (e.g., ASTM, ISO).

Account for Operational Loads: Based on the tensile strength, the material is able to withstand unexpected stress ranges, safety factors should be accounted for in the design calculations. For example, components employed in the high-stress industry may warrant the use of materials which possess a tensile strength range of 1.5-2 times the expected load.

Think About The Operating Environment: The corrosion aspect as well as fatigue and temperature influences on material performance need to be considered. For example, some polymers and composites are adequately over moderate stresses but fail when exposed to UV radiation or elevated temperatures.

Industry Developments

The last decade in materials science witnessed the emergence of ultra-high-performance materials such as ultra-high-strength steels (UHSS) and carbon fiber reinforced polymers (CFRP). The former allows the use of metals in automotive applications where low weight and high strength are needed, as its tensile strength exceeds 1,000 MPa. The latter, which is used for making aerospace parts as well as other sporting goods, combines these characteristics, making CFRP possess an exceptional tensile strength of up to 3,500 MPa.

Accurate assessment of the results of tensile testing will ensure the appropriate choice of materials which improves the performance, safety, and longevity of the product.

What Does a Hardness Test on Plastics Reveal?

Hardness test on plastics provides key parameters of their effectiveness in withstanding deformation, indentation and wear of high impact force. This metric is essential in automotives, aerospace and other packaging industries as it offers insight towards performance and durability. Furthermore, a plastic’s ability to endure mechanical stress and heat, or chemical exposure are important marker to gauge durability.

Several methods exist, including the Shore (Durometer) test and the Rockwell hardness test. The Shore test, measured on scales of Shore A and D, gauges the softer thermoplastic and elastomer indentations of softer thermoplastics. A good instance is given by thermoplastic elastomers which range between Shore A 20 and 90, showing their flexible to rigid spectrum.

On the other hand, the indentation depth under a given load in harder form is referred to as the Rockwell hardness test, one of the most common for harder forms of plastics. Outcomes of these tests assist in choosing materials that require certain degrees of scratch resistance or strength. For example, engineering plastics like polycarbonate are used in areas that are impacted a lot, like eye protection devices due but have a value of M70 to M85 in Rockwell hardness grade, making them ideal.

In addition, hardness testing helps manufacturers maintain quality control by monitoring the metrics of materials throughout the production process. The relationship that exists between the value of plastic hardness and physical characteristics like the tensile strength or the flexural modulus allows engineers to estimate how the material will perform and behave when subjected to actual mechanical loads, thus assuring cost and function effectiveness in production.

Case Studies: Plastic Material Testing in Various Industries

Automotive Industry

The automotive sector employs plastic hardness testing in the durability and safety evaluation of several components. For instance, bumpers, dashboards, and other interior trims contain thermoplastic polymers that have to withstand rigorous mechanical wear as well as environmental elements such as UV and temperature cycle exposure. An industry report from last year also noted that the use of advanced plastics like polycarbonate blends was stated to reduce the weight of the vehicles by 50% which improves fuel economy without compromising safety.

Medical Industry

Devices and medical equipment use materials that must undergo numerous regulatory prerequisites, like biocompatibility and resistance to sterilization. Hardness testing plays a critical role in assuring that certain plastics like PEEK (polyetheretherketone) and polyethylene endure multiple cleaning cycles and repetitive physical stress. For example, several implantable devices, catheters, and syringes go through extensive testing to confirm their mechanical reliability. Industry standards, including Rockwell and Shore hardness testing, have shown a significant decrease in product failures of 30% according to a study conducted in 2022.

Consumer Electronics

The casings of most consumer electronics are made out of hard plastics in order to safeguard the sensitive internal parts. Impact resistance and scratch hardness are put on extensive tests using ABS or Polycarbonate. A recent market analysis shows that advanced plastic testing methodologies have increased the average consumer device lifespan by 15% in customer satisfaction and sustainability.

Construction

Hard plastics such as High-Density Polyethylene (HDPE) and PVC comprise a significant portion of construction due to their used as pipes, insulation, and window frames. Hardness testing verifies that these materials resist moisture, high load, and other environmental stresses like mechanical ones. In a study done in 2023 consistent quality testing of construction grade plastics was shown to reduce maintenance costs by 25% over five years.

Aerospace

Safety and performance during extreme conditions for aerospace lie in weight distribution, making advanced lightweight composites and PEEK critical. Hardness testing of materials like turbine blades, seat structure insulations, and wiring using advanced plastics is critical in confirming their strength for use. A research report done in 2023 claims that better material testing technology has led to a 20% increase in the adoption of plastic components for aircraft during manufacturing.

From these case studies, it is clear how the performance of industry innovations in plastic hardness testing impacts quality assurance. Such testing is critical in meeting compliance requirements, and at the same time, creates developments that propel sustainable growth across industries.

How Is the Quality Control of Plastic Products Maintained?

The quality control of plastic parts is accomplished through various tests and measures. These measures include evaluated benchmarks in strength, endurance, hardness, and fortitude against environmental heat or chemical attacks. Frequent inspections done during the period of production ensure uniformity as do advanced devices such as automated scanning devices. Their use permits early defect detection. Adherence to other industry regulations and certifications add in more assurance that the products pass the safety and performance requirements during various stages of production.

What Role Do Testing Techniques Play in Ensuring Plastic Safety?

Hygiene and quality assurance tend to rely on different methods when it comes to testing plastic materials. In the best cases, methods of plastic testing use non-destructive techniques such as those involving computer tomography. The range of products that are offered today describes the importance of examining fabrics for identifying whether they measure up to the business’s set criteria. This ensures the elasticity, resistance to impact, stability towards temperature, and chemicals match expectations. Around 2023, more than seventy percent of manufacturers will shift to robotic techniques for testing automation, which, according to the report, results in a 25% decrease in faulty products during production.

Another market report highlights that robotic and automated techniques increase the degree of precision and efficacy in detecting flaws in products. As far as standards set by the environment and other rules are concerned, there is a certain distinction in testing techniques. Examples include constitutive tests such as evaluation of migration, for safety tests used to determine if packaging plastics are safe to be consumed.

Standards set for evaluation purposes, plastic parts used in surgical devices are deemed to be made to ISO 10993. Orthopedic, plastic and even pediatric surgeries tend to make use of these materials provided the patients are human. Attention to ecology results in sustainable development and [csmeans eco-friendly ideas] concepts regarding the assessment of bioplastic degradation. Such as methodologies including pyrolysis testing and examination, combined with accelerated aging simulations.

Innovative approaches to testing are not only helping industries maintain product efficacy, but also building reliability, sustainability, and safety for consumers and the environment.

How Are Packaging Materials Evaluated for Quality?

The evaluation of packaging materials for quality entails a complete range of tests, including, but not limited to, checking durability, safety, sustainability, and conformity with industry standards. Assessment of mechanical attributes and environmental impact makes use of both sophisticated and traditional techniques in modern quality control processes. Below are some of the key factors and methods involved:

Physical and Mechanical Testing

Physical testing of packaging materials seeks to determine tensile strength, compression resistance, and burst strength. For these materials to endure shipping, handling, and stacking, the aforementioned factors must be in a particular range. The International Safe Transit Association (ISTA) also has standardized protocols for many of these such as drop tests and vibration testing along with many other that seek to test in conditions simulative of actual shipping practices.

Barrier Properties Evaluation

Barrier properties is one of the most important qualities, especially concerning food and pharmaceutical packaging materials. These tests measure resistance to moisture and gas (oxygen and carbon dioxide) as well as odor transmission so as to maintain freshness. Permeation testing, where advanced instruments are used to evaluate the permeability rates of materials, is one of the best methods for this purpose.

Chemical Compatibility Testing

It is important to evaluate the interaction of the packaging materials with the product they contain. Chemical compatibility testing ensures that no harmful chemicals are diffusing into the product and that the packaging does not degrade, react with, or have any detrimental effects on the content. This is very important in industries like pharmaceuticals, cosmetics, and chemicals.

Sustainability and Environmental Testing

Biomechanical assessment methods of testing integrated with the concept of sustainability such as biodegradability, compostability, and recyclability have been on the rise due to the focus on ecofriendly packaging. A 2021 report by McKinsey & Company suggests that almost 60% of consumers prefer sustainable options for packaging. This forces companies to credibly test these options in an environmentally friendly manner.

Regulatory Compliance Checks

Packaging needs to follow defined legal and self-imposed standards of the industry, like the FDA for food contact materials, or the European Union’s Packaging and Packaging Waste Directive. Testing ensures that materials will not be fined and will keep the consumers safe by having these guidelines in place.

Visual and Aesthetic Assessment

Apart from carrying out the planned purpose, packaging needs to be appealing to the eyes and enable branding ventures. Strategies such as printing, coloring, and surface finishing need to be done at very high standards for the customers to perceive it positively and improve market value.

Examining the quality of packaging materials is relevant in all processing and logistics workflows that aim to deliver products in a safe, reliable, and sustainable manner. These days, virtually every packaging material is being monitored in real-time \(for example, through AI and IoT sensor integration\), prospective simulations are feeding the ever-increasing industry standards fueled by customer demands, and in many cases, exceeding expectations put forth regarding accuracy, sustainability, ecological safety, and other facets of value.

What Are the Challenges in Testing Plastic Materials?

There are various challenges associated with testing plastic materials. One of the foremost issues continues to be maintaining uniform caliber because of the variability in fabrication processes and raw materials. Assessing the lasting endurance of plastics is another difficult area that relates to the effects of temperature changes, UV light, and chemical interactions. Adding to the complexity of the testing is sustainability and recyclability because it involves determining the lifecycle impact and compliance with environmental frameworks. Such challenges, however, require offering an optimal balance between performance, cost efficiency, and ecological conscience.

Dealing with Thermoplastic Properties in Testing

The reason that various industries employ thermoplastics is that they are easy to work with and can be remolded after being heated. Even though they spread across a range of industries, their peculiar characteristics require them to be put through unique standards to be tested under a variety of conditions. One such method that commands attention is the use of thermal techniques on thermoplastics. As an example, materials like polyethylene (PE) and polypropylene (PP) have defined crystallization and melting temperatures which affect their incendiary usability. Differential Scanning Calorimetry (DSC) is used widely for these thermal studies, particularly in providing accurate information regarding thermal changes such as glass transition temperature (Tg) and melting.

An additional important factor includes mechanical evaluation which measures the degree of tensile stress, damageable static loads, and final length under extreme tension. Understanding these elements aids in assessing load and stress-controlled actions on thermoplastics. More recent studies indicate that PC (Polycarbonate) displays noteworthy resistance towards impact (Izod notch impact strength values reach 850 J/m) in comparison to GPPS (General purpose Polystyrene) which has less impact resistance.

As thermoplastics are put through extreme real-world use, their chemical resistance properties need to be thoroughly tested as well. For instance, the resistance of polyvinyl chloride (PVC) to acids and bases is conspicuously high which makes it one of the best options for the chemical processing industry for pipes and fittings. Testing involves subjecting samples to the appropriate chemicals of interest while controlling the environment to evaluate degeneration or change in properties.

Technologies that are yet to be mainstream, such as computerized 3D deformation analysis and Fourier-transform infrared spectroscopy (FTIR), are increasing the value of these tests by making them more accurate and reliable. Such developments enable researchers to look at, obtain, and analyze something at the microstructural level while in action, therefore enabling real-time performance monitoring.

Through the application of new techniques and technologies alongside the development of refined methodologies for testing, the limitations placed on the functional and sustainable temperature of the environment can be achieved while using tested thermoplastic materials.

How Does Recycling Affect Test Results?

The steps taken in the recycling of thermoplastics may add additional complexities that could affect test result analyses. As a result of contamination, the mechanical, thermal, or chemical properties of a polymer’s additives or aged compounds such as impurities, can have a drastic impact on its performance. As an illustration, subsequent processes of melting and cooling during the recycling stage result in a decrease in molecular weight, which in turn reduces tensile strength and elasticity. Research from ScienceDirect indicates that some recycled plastics suffer significantly, with a 15-20% decrease in impact resistance when compared to virgin plastics.

Moreover, unclean contaminants such as leftover food residues and adhesives as well as other types of polymers, can impede the precision of the results. Changes and monitoring processes are usually performed by means of differential scanning calorimetry (DSC) or, more frequently, with Fourier-transform infrared spectroscopy (FTIR). For instance, oxidation, which is known to happen with the recycling of materials, can result in a form of chemical degradation that FTIR can detect.

In response to these problems, industries incorporate modern cleaning, sorting, and material improvement procedures. Outcomes have been improved through the use of compatibilizers which enhance the performance of blended polymers. Also, some literature indicates that a blend of recycled and virgin materials can be used in a manner that balances sustainability and performance. Considering these aspects makes the dependable testing of recycled thermoplastics attainable, meeting performance as well as environmental requirements.

Overcoming Difficulties in Materials Testing

Challenges around the properties of materials and their impurities, as well as the discrepancies within recycled content, pose quite a challenge for the testing of materials, especially with regard to thermoplastics emerging from polyhydroxyalkanoates. Nonetheless, newer testing methods and technology have marked a positive change towards the resolution of these problems.

Amidst the developments in analysis, techniques such as FTIR and DSC have emerged which allow for the comprehensive study of the structure of the thermoplastics. Moreover, FTIR serves a greater purpose of polymer identification whilst also spotting impurities, DSC, on the other hand, aids in determining thermal characteristics with terms like melting, crystallinity and overall heat involved. A case study from Advanced Materials Research showcased that the use of FTIR in conjunction with other analytical tools had an over 30% improvement in accuracy for spotting contaminants using FTIR.

In an attempt to address many of these hurdles, one focal point that has received attention is the mechanical performance of materials. Information available in public domains indicates that the use of systems with automated impact and tensile testing has changed the paradigm by offering a reproducible approach to testing that eliminates variations associated with human dealings. A 2023 industry analysis reported that the integration of high-resolution systems into standardized testing reduces the margin of error up to 20%.

Moreover, the use of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is being incorporated in materials testing. These technologies aid in forecasting performance using prior information and other process parameters. A 2022 pilot project that implemented AI-based testing frameworks noted a reduction of about 15% in analysis time alongside increased accuracy in the results obtained–a remarkable achievement.

Incorporating these advancements enables recycled thermoplastics testing industries to resolve dealing with the challenges of attaining complex, actionable insights while minimizing resource expenditure.

Reference Sources

- Creating an Educational Website on Plastic Waste Recycling – UPI Journal

Explores the methodologies for recycling and repurposing plastics, possibly incorporating quality assessment.

- A Study of a Plastic Recycling Center’s Feasibility Analysis and Plan – WPI

Investigate the recycling of plastics regarding testing and equipment construction.

- Students’ Awareness of Plastic Recycling – Academia.edu

Shares knowledge concerning the awareness of plastic recycling and associated testing activities.

Frequently Asked Questions (FAQs)

Q: What are the common methods used for plastic testing?

A: Common methods for plastic testing include tensile testing, melt flow tests, hardness testing, and impact resistance tests. These tests help in evaluating the properties of plastics such as strength, durability, and flexibility.

Q: How is tensile strength measured in plastic materials?

A: Tensile strength in plastic materials is measured using a tensile testing machine. The specimen is stretched until it breaks, and the maximum stress it withstands is recorded as the tensile strength. This test helps assess the quality of plastic by determining its ability to withstand pulling forces.

Q: What is the melt flow test and why is it important?

A: The melt flow test measures the viscosity of a thermoplastic material by determining the rate at which it flows through a specific orifice under controlled conditions. This test is important for assessing the processing behavior and quality control of plastic materials.

Q: How do you assess the hardness of plastic?

A: The hardness of plastic is assessed using a hardness testing machine, which applies a specific force to the sample of the plastic. The resistance to indentation provides a measure of the material’s hardness, which is crucial for applications requiring durability.

Q: Why is quality control essential in plastic manufacturing?

A: Quality control is essential in plastic manufacturing to ensure that the plastic products meet industry standards and specifications. It helps in identifying defects, evaluating the properties of plastics, and ensuring the reliability and safety of products, especially in critical applications like food packaging and medical devices.

Q: What role does polymer testing play in plastic recycling?

A: Polymer testing plays a crucial role in plastic recycling by evaluating the quality and properties of recycled materials. This ensures that recycled plastics maintain their integrity and performance for reuse in new products, supporting sustainability and reducing waste.

Q: How is the quality of plastic films tested?

A: The quality of plastic films is tested through various methods, including puncture resistance, permeability tests, and tensile testing. These tests assess the film’s strength, barrier properties, and durability, which are important for applications like packaging material.

Q: What are the standard test methods for evaluating plastic materials?

A: Standard test methods for evaluating plastic materials include ASTM and ISO testing procedures. These standardized tests ensure consistency and reliability in measuring properties like tensile strength, hardness, melt flow, and impact resistance across different types of plastic.

Q: How do testing procedures vary for different types of plastic?

A: Testing procedures vary for different types of plastic based on their properties and intended applications. For example, polyethylene might undergo different tests compared to a thermoplastic polymer, focusing on specific attributes like flexibility, permeability, and temperature resistance.

Q: Can you provide case studies on successful plastic quality assurance?

A: Case studies on successful plastic quality assurance often highlight the use of thorough testing techniques and quality control measures. These studies can demonstrate how specific testing methods and procedures have improved the quality and performance of plastic products, ensuring compliance with safety and industry standards.