Bending sheet metal has a significant impact on various industries since it is capable of being exploited for a broad range of activities. It is a critical component when it comes to the production of complex and delicate articles like automotive components or architectural components and interior decorations. By exploring the fashion in which a particular sheet metal bending machine works, the article presents the reader with an opportunity to grasp everything from its applications to the operating techniques. This article is directed towards demystifying the operation and real-world applications of sheet bending machines. So be prepared to acquire new knowledge irrespective of whether manufacturing is your area of expertise or you are simple inquisitive. Discover the essential tools, materials and knowledge which are useful for streamlining this critical operation.

Understanding the Bending Machine

What is a Bending Machine?

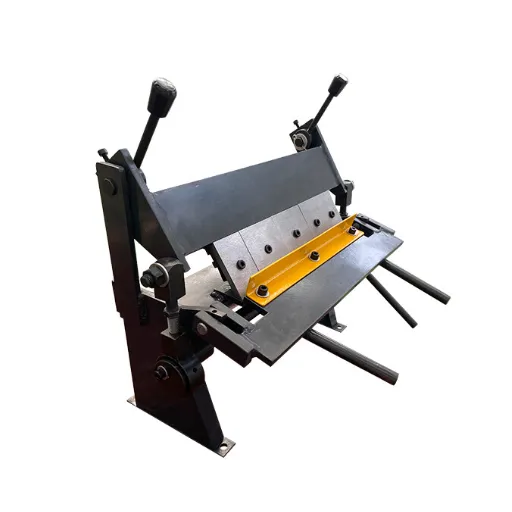

Metal bending machines are critical manufacturing equipment defined by their ability to shape the metal or metal sheet through the application of force. It is extremely important because clamping the work piece is necessary in order to press it and use it. In the automotive, construction, and aerospace sectors, metal construction for various sectors demands a well-defined shape and a precisely formed material. To fabricate from steel to aluminum, this requires a metal bending machine which is a must. The metal sheet requires a certain level of strength, so using stronger assists is valuable.

One of the most well-known characteristics of a metal bending machine is the ability to offer clean and precise bends constantly. The equipment is very helpful, as it is able to serve various metal thicknesses depending on the type of bending machine. It simplifies the process of developing both simple and complex outlines. Metal bending machines also carry a variety of functionalities like hydraulic and manual as well as CNC (computer numerical control).

Key Point:

The metal is bent through the press, hence the machine is able to take in and process much more, unlike before, when the process was extremely difficult if a metal sheet was thicker than a certain thickness. Steel forms steel press brakes. Eco steel has and carries out extensive capabilities that normal machinery can not achieve as opposed to steel sheets.

How Does a Bending Machine Work?

A press brake is used to apply a controlled force to metal sheets in order to shape them into the desired form. This is basically how a bending machine works. When the machine gets started, a punch clamps the sheet and a die is then used to press it, which causes a metal sheet to bend at a specific angle. Besides the angle, the accuracy of the process is defined by machine settings, such as the maximum possible force and the position of the materials.

Bending Methods:

- Air Bending: No need to close the entire length of the metal, allowing for steep angle bending

- Bottoming: Requires complete closure with the die for uniform and stiff bends

- Coining: Outstanding precision through permanent structural changes using larger force

With the implementation of modern devices, using technologies such as CNC (computer numerical control) systems, the entire operation and accuracy are significantly boosted. For instance, these new devices are capable of programming the exact design requirements to be met by the bending machine, which further ensures that they are made correctly, and helps to minimize any kind of mistake that can be made during the operation. In making the outlined requirements, the use of bending machines drastically assists in saving time and enables a manufacturer to produce consistently shaped components.

Key Components of a Bending Machine

| Component | Function |

|---|---|

| Frame/Bed | Structural component providing support and anchor for other features |

| Bending Die | Determines repetitive patterns like angles and bends (U and V stems) |

| Punch | Pushes workpiece onto bending die to create final shape |

| Control System | Programs instructions for accuracy, repeatability, and customization |

The punch is not the only feature that aids in bending work; the control system of the machine is as equally crucial. It is in the control system where the operator programs all the instructions necessary for their task. The control guarantees great accuracy and repeatability and eliminates repetition and reduction of returns. The control system of the new machines is usually digital or the screen is touch enabled. This ensures that the machine is really easy to operate and it also allows for much more customization in the operation of the machine. All these features together make sure the machine works with speed, precision, reliability, and very little human error.

Types of Bending Machines

Hydraulic Bending Machines

Hydraulic Bending machines have the function to operate by hydraulic system that operate with the hydraulic system that generate a high amount of pressure, which indeed can be used in the bending of steels and aluminium. A new feature has been added which allows utility in bending steels and other heavy products which include aluminium. Most especially construction of equipment and automotive which require bending precise equipment whose precision is maximally repeatable.

Advantages of Hydraulic Bending Machines:

- Massive mechanical power output

- Outstanding precision and high-level control

- Easy to use with intuitive control systems

- Low maintenance requirements

- Durable construction for heavy usage

Another key advantage of hydraulic bending machines is the comparatively lesser need for maintenance. These machines are very tough and can take heavy usage for a long time without any mechanical failure. This is very good news for companies that do not want to spend much on bending devices. So, in comparison with the other bending devices, the maintenance of hydraulic bending machines is very low.

CNC Sheet Metal Bending Machines

CNC sheet metal bending machines in the advanced technology of today’s world, are designed to give the maximum output with an automated process. the keyhighlight of this machineis the sheet metal which allows accuracies to be on a greater scale with less maintance given. so it can be accurate and consistent with the correct design or pattern and highly effective.

CNC Machine Benefits:

- Complex Operations: Excels at intricate bending patterns without detailed manual instructions

- Time & Effort Saving: Highly effective and scalable operations

- Flexibility: Configurable for various components, materials, and thicknesses

- Error Reduction: Lowers errors to insignificant levels

Pipe Bending Machines

Pipe bending machines are highly useful in various industries due to the ease they provide in pipe and tubing manipulation. They can bend pipes into the shape that is required without compromising the durability of the pipe. This can be used especially in niches such as aerospace, car manufacturing and house construction.

| Machine Type | Best For | Features |

|---|---|---|

| Manual | Smaller projects | Low cost, easy transport |

| CNC | Complex, large requirements | Advanced bends, outstanding precision |

Pipe bending machines have the added benefit of improving efficiency and aiding in manual labour. They help meet project deadlines efficiently without compromising on the quality. Most importantly, companies are able to meet orders that have specific requirements of custom shaped products such as the automotive industry. Nowadays, pipe bending machines are able to handle different shapes of materials thus making manufacturing procedures flexible. During the selection process of a pipe bending machine, specific needs of the project and capabilities need to be assessed for proper operations.

The Bending Process Explained

Step-by-Step Overview of the Bending Process

- Loading and Machining: Material selection and preparation happen first and then the material is loaded into the bending machine. Securing the material in place is very important. While loading, exact positioning, alignment and even material orientation can avoid deformations.

- Setting and Machining: First analyse the radius then select brush holding device, counter-holding device and brush material.

- Check and Set: Upon completion of the bending process, the bend angle, radius, and quality are closely verified. It is at this stage that the minor changes are altered even when they are barely noticeable. Finally, the product is aligned with the project requirements.

Transforming Raw Materials into Sheet Metal Components

The fabrication of sheet metal components requires a rigorous process to ensure precision and quality. Initially, the material that is to be used, typically aluminum, steel, or even copper, is selected with respect to the project it’s designed for, taking its physical strength, flexibility, as well as corrosion into account. The quality of the project depends on the project’s requirements.

This is immediately followed by the shaping of the raw material, which involves cutting, bending, and the use of various cutting and bending techniques to achieve the desired designs. Depending upon the finish and the desired accuracy, shapes can be laser cut, waterjet cut, or sheared. Press brakes are used to achieve accurate angles and dimensions, which helps in reducing the errors in further machining of the components, effectively achieving the industry standard in terms of the components.

In addition, to improve the characteristics of the components, post machining procedures such as heat treatment for metal strengthening and further finishing processes like painting, coating, and polishing are conducted, and adherence to refine finishes and good quality control allows the company to meet the needs of the project in the section. The final transformed sheet components are produced and can be utilized in numerous applications.

Precision and Accuracy in Bending

To appropriately bend sheet metal, one requires a thorough understanding and well controlled tools, processes, and materials. A formal and properly executed bending process is one where one performs careful calculations and regulated adjustments that allow for proper formation of the material within the correct tolerances without losing its structural integrity. Integral to modern sheet metal bending technology is a suite of advanced machines and tools that, when operated by trained personnel, will churn out component after component, all of which will be nearly identical and within tolerances.

Critical Factors for Accuracy:

- Material type, thickness, and grain direction

- Understanding material behavior under stress

- Proper implementation of testing techniques

- Use of CAD simulations for problem prevention

It is crucial to have control measures in place to check and maintain the accuracy of the established bending processes. Checks, when carried out before and after the bending is performed, make use of quality measures to ensure that the work is of required specifications. For reliable examination of the accuracy of the bends, especially when relevant to the design, modern quality control equipment, which include laser scanners for checking the angles of the bends, and electronic angle sensors for accurate measurements should be used. This ensures the highest level of compliance with functional requirements, apart from quality measures with meets the necessary standards for specialized projects.

Applications of Sheet Metal Bending Machines

Uses in the Automotive Industry

Without sheet metal bending machines, the automotive industry would struggle to produce the components necessary to build vehicles today. Chassis, brackets, and panel reinforcements are examples of parts that require a high level of precision and durability and have a significant impact on the functionality and performance of vehicles. The safety and reliability of vehicles would be compromised if these machines did not guarantee the sameness and exactness needed in mass production.

Automotive Applications:

- Compact Cars: Stringent bending for exhaust systems and fuel lines

- Body Panels: Smooth curves and precise angles for hoods, doors, and rooflines

- Structural Components: Chassis and reinforcement brackets for safety

Smooth curves and precise angles that cars are made with, for instance, hoods and doors. In today, modern cars have looks that are meant for its function. The ability to function in looks and structure is modern car outlines. These are the reasons cars need doors, hoods, and roof lines with precise angles, which, in addition, are there for the car to function and, at the same time, offer modern looks—marks of the car panels.

Applications in Construction

Construction projects rely on the use of a bending machine for the reshaping and modification of steel, aluminium, and other materials. Basically, its primary function is to bend materials into specific shapes and angles, depending on the design specifications. To achieve this, a force has to be applied to the material which is securely held, and bending is around the predetermined die. The application of this machine is very critical as it allows for very precise bending to match the desired aspect of various materials, for instance, beams and brackets.

Before a material under processing is bent, the process starts by placement of the material on the bending machine. The machine engages the designed clamps or holders that keep the material in place, and the bend is achieved on the application of pressure. The degree of force, the amount, and the type of die in use determine how the material is bent. The pressure can be set, and in some advanced bending formers allow for programmable control, and, in cases of complex designs, even the set up is allowed.

The construction of modern projects has integrated these machines as an essential tool. Bending machines form the basic construction units, such as custom metal frames, supports, and strengtheners. Their main application is the provision of accuracy and consistent production and waste reduction, coupled together with cutting down the work force, making them indispensable in both structure and architectural design projects. Modern construction machine helps a lot in maintaining the design and modern construction structure’s introduced and modern reinforcement designs.

Manufacturing and Industrial Applications

Bending machines work by bending materials, generally metals, into different shapes by applying a controlled level of precise force. Usually, the material rests between a punch and die with the punch forcing it down through the die to produce the bend. Control systems, be they mechanical, hydraulic, or electric, ensure a high level of precision and control the force. To prevent undesired outcomes, the control system is carefully set up. Damage is minimized by optimizing the process.

The setup begins with a selection of the target pin angle, a type of bending, and the support features to be used, in the event of a bend. Then, the system allows the operator to use the material and takes the machine to the defined pressure based on the program. The erector machines come with automatic correction, which is essential in the completion of complex bends, with only very shallow depth adjustments. Time is saved through the use of machines, as one can work with the assurance of reliability and traceability.

The use of bending machines has proven to be significant and important in various industries such as metal industries, automotive, construction, and aerospace. The processing of high-quality materials in bulk usually results in high errors such as high scrap levels. The machines are therefore necessary in reducing the high-volume physical bending operations, as they offer high precision and are faster as compared to the manual machines. The up-to-date bending machines are now capable of meeting the high precision bending requirements.

Maintaining Your Bending Machine

Tips for Improving Bending Machine Efficiency

1. Regular Maintenance

Inspect all moving parts and check all components and fasteners for tightness, providing lubrication, and performing all cleaning tasks. This will help you avoid problems in the future. By cleaning and inspecting the machine in a proactive way, you can make sure that in the near future, you will not face problems that will affect the efficiency of the machine.

2. Correct Tooling

Please transfer to an appropriate tool before the actual bending operation. Using uncalibrated tools that are worn-out will not only cause machine and material damage, but also poor bending and the inability of the machine to carry out the bending operations. Position the tools using appropriate jigs and ensure that they are adequately secured before running the machine.

3. Training the Operator

Make sure that operators are acquired skills on the bending machine. Skilled operators can help reduce the risk of errors and wear, thus helping to avoid any undue strain to the machine. Quarterly or bi-annual training, as well as updates to the latest operations standards, can greatly improve the level of productivity and performance.

Common Maintenance Practices

Standard Cleaning and Inspection

The pedal press must be kept clean at all costs if it is to function properly and to survive. Dust, assorted material, and oil-agents must be removed from the pedals, since their ill-advised use can lead to damages or malfunctions. Clamps, dies, and hydraulic systems need to checked regularly for early signs of failure. Repairs must be done in time to avoid further expenses.

Proper Lubrication and Calibration

The machine must be checked and lubricated at least thrice a year to prevent wear of its moving parts. The lubracant to be used must be the one that is recommended by the manufacturer. It is vital to ensure the machine undergoes lubrication as it is set to proper standards to guarantee correct operation. As such, checks and calibration should be removed from daily operations to an annually, to get the obsession of the machine.

Hydraulic System Monitoring

If a hydraulic system is equipped with a machine, always make sure to check the condition of oil, filters, and any obvious signs of damage. Following manufacturer’s recommendations and replacing the oil regularly allows the system to maintain the required performance levels and it prevents any major breakdowns.

The right maintenance is aimed at making a press machine serve a long time, increases safety, and securely enables an intended set of benchmarks. Consistent observation of the mentioned practices results in machine serving with less breakdowns and higher credibility.

Extending the Lifespan of Your Bending Machine

Consistent and careful operation, plus periodic maintenance are required to keep your bending machine in service for a while set. Have your machine checked for damage or wear and tear frequently. Simple problems can be addressed if caught early and simple problems and nipped in the bud. Fix all the simple things as the checks also touch the hydraulic systems, the electrical circuits, and the moving parts. Reduce the risk of damage to the machine by keeping the area clean.

Furthermore, always make sure that you use your device with its maximum capability, and ensure anything is kept above the minimum pressure. Ensure you observe the guidelines like not exceeding the specified capacities with weights. The machine should be maintained within the acceptable range to guarantee the maximum acceptable performance of the machine.

In addition, it is essential to let the authorized service technicians to service the machine. It is recommended to do the basic maintenance of the machine; the basic service practices can enhance and elong the life and efficiency of the machine in the long run. Basic service combined with scheduled service of this machine can reduce the operational time.

References

-

The Basic Guide to Bending Machine – Explains how pipe-bending machines use hydraulic, electric servo, or pneumatic pressure to bend materials.

-

Bending machine (manufacturing) – Wikipedia – Provides an overview of bending machines, their purpose, and the process of creating bends using tools.

-

What is a bending machine and how does it work? – Describes the working mechanism of bending machines, including the clamping and pressure application process.

-

The Basic Guide to Sheet Metal Bending Machine – Focuses on the principles of sheet metal bending machines and the role of adjustable parameters.

Frequently Asked Questions (FAQ)

Q: What is a bending machine and how does it work?

A: To put it very simple, a bending machine is a mechanical device that is used in the shaping of metal (mostly in industrial settings). Bending is a common process of manipulating materials to meet the requirements of the designer. By stirring the metal a desired the machine can be set and it deforms at a given degree and with a desired carpentry. The machine is used to manipulate different types of metal & different sheet and tubes can be bent with the help of different set of tools and using varied techniques.

Q: What are the different types of bending machines?

A: There are different categories of bending machines such as CNC bending machine, hydraulic press, manual bending presses, hydraulic tube bending machine, hydraulic plate bending machine, pinch roll bending machine, hydraulic double column bending machine, and other metal bending machines. Each bending machine is used for specific bending purposes. Bending radius and the materials which can be bent are some of the factors which are essential to look into while selecting the machine.

Q: How do CNC bending machines operate?

A: CNC machines are automated bending machines. By using pieces of plastics, hands, and metals, CNC bending builders create geometric shapes of specific sizes. Shape of cutting metal can be programmed to a machine using instructions that a machine understands. Materials made by this method are usually more precise and have more variance in production. CNC machines use computers for further revision on metal specifics and allow tighter tolerances, as well as the efficiency required for other manufacturing tasks.

Q: What is the function of a bending tool in the bending process?

A: The fundamental element of a bending machine, bending tools, reshapes metal parts during the bending process. Changeable tools widely in the metal industry help with different bending radii and bend angles, making sure the material is angled as required.

Q: Can a bending machine be utilized in different bending tasks?

A: With a certain adjusting, most machines do to some point two or more bending angles or radii that includes sheet metal folding, tube bending and panel bending. They can work done easily in tandem on all work pieces pending the type of machine and tools.

Q: Why is the speed of a sheet metal bending machine important?

A: Bending speed plays a direct role in the quality of the produced metal. The portion of the speed that is customisable speeds up the machine when the setting permit to metal can be more problem in the speed a machine is capturing. A machine that carries out slow bends ensures that the metal accuracy is taken care of.

Q: How do hydraulic cylinders work in a bending machine?

A: The featured in a host of bending machines offer necessary bending force. The cylinders make the work of the machine possible since they convert the hydraulic pressure to bending metal through the mechanical force. They make the machine possible to bend at different radii and angles.

Q: Which materials are generally utilized in a bending machine?

A: The machines are built to cater for bending of metals where the primary materials used are steel, aluminium and copper. These are commonly used in the manufacturing industries as metals are normally bent to meet specific requirements.

Q: How do you initiate a bending machine?

A: Initiating a metal bending work requires the operators to position the metals in the machine. After parameters, such as angle and speed, are set, one may turn on the power to enable bending. Loose or unsecured metals should not be fed; in addition, the bending tooling kit should be double checked for damages.