Top Impact Testing Machine in China. Impact testing is essential for crafting an understanding of the endurance and security of various materials, products, and even the human body system. Ranging from industrial uses, such as the Charpy test which gauges material toughness, to concussion safeguards testing in athletes and other individuals who engage in high-impact activities, these tests reshape our assessment paradigms in regards to the consequences instigated due to sudden force impact. This article explores the testing realm of impacts, how it’s shaped through history, its methodologies, and its relevance in crucial sectors like manufacturing, healthcare, and sports. Be it the construction of injury-safe structures by engineers or the intricate assessments of brain injuries conducted by medical professionals, this guide will unveil the importance of impact tests and their protective features on our inventions and lives.

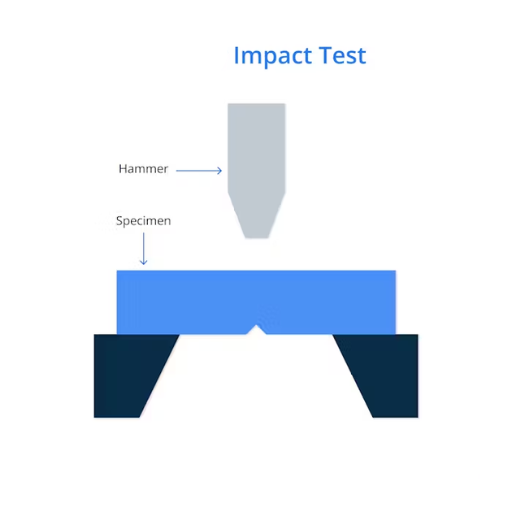

What is an Impact Test and Why is it Important?

An impact test is useful for determining how well a material can endure sudden force or shock. It plays a vital role in assessing the durability, resilience, and safety of various applications. The simulations performed in these tests help uncover material and product flaws that could lead to failure, safety, and quality issues. Products designed for the construction, automotive, and healthcare sectors depend heavily on impact testing. A failure can lead to loss of life and great risk which are some of the tests’ most gruesome results.

The Basics of Impact Testing

Impact testing tests the limits of a material’s resistance to damage when sudden forces or shocks are applied to it. It simulates real-world senerios. The energy that is absorbed before a sample material breaks is measured using standard method such as Charpy and Izod tests. Knowing the amount of energy and its absorption rate helps researchers understand if the material is tough enough for the task it is designed for.

Charpy Test-Based Impact Testing Impacts

Charpy Test

Notched samples are struck with pendulum hammers while measuring the enery absorbed during fractures in the test, Charpy Impact Test. This technique is predominantly used for evaluating the embrittlement of metals and polymers with high strain rates.

Izod Impact Test

This test like Charpy also uses swing pendulums placed vertically. It is widely applied on polymers, composites as well as other non metallic materials.

Drop Weight Test

A sample is tested by dropping a specific weight on it, and the deformation or fracture that occurs is observed. It models the impacts of heavy objects in real life. This method is essential for automotive and construction industries where impacts are recurrent.

Recent Changes in Impact Evaluation Studies

As per the recent breakthroughs in impact testing protocols, other technologies such as simulation methods, and especially Finite Element Analysis (FEA), are now integrated. FEA enables modeling to substitute physical tests and experiments in the labs which cut down testing timelines and optimize designs through simulations. Moreover, emerging sensors and high-speed cameras are improving the quality of the information captured in the tests, which enables understanding of how materials respond to impacts in a much refined manner.

Data Analysis

An ISO study revealed that titanium alloys as one of the hardest materials perform Charpy tests at over 40 joules while brittle ceramics tend to fail below 5 joules.

The material requirements for drop-weight impact tests, pertaining to automotive safety designs, has shifted to 100 joules, significantly improving the durability during crashes.

Polymers strengthened at the nano-level and of nano-structure tend to use traditional materials polymers for energy absorption and outperform the latter by up to sixty percent, greatly benefiting aerospace and healthcare industries.

Impact testing is an ever-increasing traditional science through modern technologies, making sure materials and components are subjected to rigorous safety and performance evaluations. This testing fuels innovation towards more advanced industries and develops structures and devices that are safer and stronger.

Understanding Impact Resistance of Materials

Impact resistance means the capacity of a material to endure harsh, sudden impacts without breaking or failing. This is important in fields like automobile construction and sporting goods, where safety and reliability are extremely important. Some key components influence impact resistance:

Material Composition

Composed materials directly influence the magnitude of energy that can be absorbed or dissipated. For example, commonplace metals like titanium and high-tensile steel display remarkable impact resistance because of their dense atomic structures. Also, composites such as carbon fiber are, relatively speaking, stronger and lighter.

Microstructure

Grain size and phase distribution in the microstructure of a material impacts its impact resistance. Usually, finer grain structures increase toughness. To enhance and customize microstructure for designated purposes, advanced techniques like heat treatment and alloying are employed.

Temperature Dependency

The ability of a material to sustain stress under impact is modifier due to temperature conditions. For example, rubber is flexible and impact resistant in cold temperatures; however, some brittle materials could be more prone to shattering.

Current Data and Advancements

Exciting developments in recent years Graphene-reinforced composites have shown 200%, improvement in the energy absorption when compared to conventional polymers according to research conducted in the year 2023. Other advancements in the field include metallic glass alloys which exhibit much greater impact resistance and are applied in high speed machinery and electronics.

So-called “impact resistance” is being accurately predicted these days by engineers using AI-powered software simulations. As an example, predictive modeling methods have reduced the need for physical testing of impactful resistances by almost 40%, streamlining the speed of prototyping and production cycles.

Testing Methods

Charpy and Izod impact tests are not only some of the oldest, but also the most accessible methods of testing impact resistance. They consist of a notched sample being struck by a pendulum to determine the energy absorbed by the sample when it fractures. Among many other things, high speed 3D imaging enables researchers to dynamically assess the mechanics of fracturing materials in greater detail than ever.

Innovation in impact resistance is being pursued across the world, supporting various industries in more advanced technologies.

The Role of Impact Test Results in Material Selection

Impact test results are significant for assessing the suitability of materials for specific applications, particularly for those requiring safety as a priority. The tests determine the impact an immaterial may have in absorbing an energy burst in the middle of an engineering structure. It is for this particular reason that high-strength composites and steel alloys are frequently utilized in tough, enduring automotive and aerospace industry applications. Quoted data sheds light on a study put forward by Materials Today, which reveals a strong correlation between greater Charpy impact values and energy absorption, thus emphasizing the need for safety materials composites.

Modern material selection protocols have transformed with schematic simulations aimed at both analyzing the impact of a material and conducting experimental impact tests in the field. The introduction of software aimed at generating viscoelastic and stress-strain under impact simulation relieves the industrial sectors from the burdensome workloads that require field tests. The fundamental aim of implementing this method is to improve performance and lower purchasing expenses, as well as innovation and resource waste across almost all sectors. Also, it has been observed that impact-resistant materials which can be recycled, are being greatly preferred. A case in point can be certain grades of thermoplastic polymers, which are claimed to be eco-friendly through their secondary goals to polycarbonate impact strength.

These findings shape the work of product designers, but are particularly important in regard to meeting legal requirements for construction, transportation, and utility fields that have strict safety policies. With safety and performance requirements, impact testing in conjunction with data modeling ensures these industries are able to advance these standards.

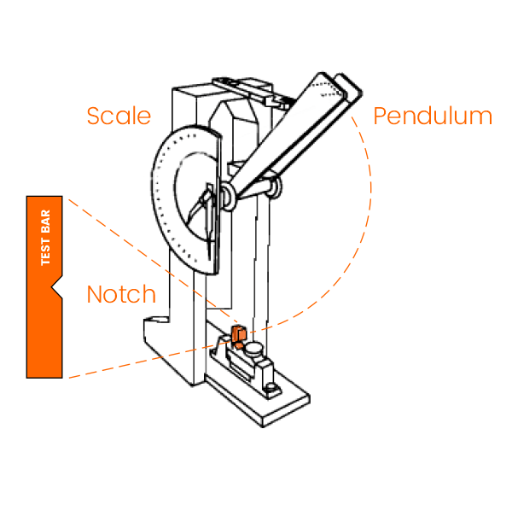

How Does a Charpy Impact Test Work?

A Charpy impact test measures the energy absorption capacity of a material during fracture. A standard specimen with a notch cut into it is placed horizontally on supports in the test machine. A pendulum hammer is released to hit the notch on the specimen, thereby breaking it. The energy that goes into the specimen undergoing the pendulum swing is determined by the difference in initial and final heights of the pendulum swing. This value determines the material’s toughness and the specimen’s ability to resist impact forces under certain conditions.

The Test Method and Setup

The test method ensures that results are reproducible by following a set procedure and using a given device or tool associated with a specific measuring standard, in this case, E23 and ISO 148 Standards. For a cornerstone specimen to be accurate for testing, its edge width needs specific measuring or rounding, in most cases, nominal values set by these standards. The toughness, particularly the fracture toughness of a material, is evaluated by setting a stress concentration notch geometry of a particular depth and angle.

One example of such a device is a unitized pendulum impact tester. All samples, which are usually in rectangular slab form, are attached horizontally between the arms of the machine, thus being in a swinging frame. The pendulum’s pendulum arm is set at a certain height and locked so that it releases at this height. In such position, it’s guaranteed to have exact energy set before strike. The sample is released at a set rod in notch position and the dropped angle. The sample’s energy floats in the way captured by the dial measuring pendulum movement up. The difference between normal and below the average measured range indicates the amount of energy consumed during the break, which allowed the sample dial to move. This absorbed energy is read on the machine’s dials and sometimes electronically.

Joule absorption values of high-strength steel are between 150 and 350, varying with the material’s composition, temperature, and surface treatments. In contrast, more brittle materials, like cast iron, have lower energy absorption values, which generally fall between 10 and 50 Joules. Modern testing has added temperature chambers to assess material toughness at sub-zero or elevated temperatures, simulating real-world applications.

Comparing Charpy and Izod Testing Techniques

Both the Charpy and Izod tests are standard methods of determining the impact toughness of a material. Both these methods have similarities such as the use of a pendulum to measure the energy required to fracture a material, but they differ in sample placement, notch cutting direction, and other specific areas of focus.

Cutting Direction of Notch and Sample Positioning

Charpy Test: The specimen is placed horizontally with the notch facing away from the impact point. The notch is struck so that the sample breaks when the pendulum hits the opposite side of the notch.

Izod Test: The specimen is positioned vertically, and the notch is oriented toward the swinging pendulum. The side to receive the impact sits on the notched side.

Energy Absorption Measurement

As with most tests, both tests quantify the amount of energy the material absorbs during fracture and this is usually given in Joules (J). But, the Charpy test is typical with giving results in a wider range of energy, which is beneficial to material comparison under different condition tests, hence comparison between multiple materials.

Sample Data:

Charpy Test Data for a mild steel specimen: 150-350 J (depends on temperature and treatment).

Izod Test Data for a mild steel specimen: Slightly lower than the charpy test, 120-300J is the general measurement.

Shocks and impacts are integral when it comes to conducting tests on structures and materials. The following are some of the most prominent applications:

Charpy Test: Bridges, pipelines and buildings use structural engineering and vast materials that encompass a wide range of dynamic loads alongside being subjected to impacts, even brittle fractures. Carrpy test charpy test can extensively evaluate the impact of such events.

Izod Test: This test is more popular in the case of plastics and polymers. It’s mainly used for inspection purposes, but has some applications in picking materials for designing or manufacturing.

Temperature Sensitivity

Practically speaking, both testing methods have been developed over testing ranges extending to anything beyond the thermometer. An example is the sub-zero ductile to brittle transition temperature ranges that contain safe zones for steel and pipelines without arctic dangers: ductile-to-brittle steel transition temperatures. At elevated temperatures, several aerospace materials also require extensive testing with thermal stress.

Knowing the fundamental differences between the charpy and izod tests gives an advantage to engineers and researchers when it comes to sophisticated selection guaranteeing optimized warrantied performance under realistic conditions.

Interpreting Energy Absorbed and Fracture Patterns

The impact test on a material’s surface measures the energy absorption, which directly indicates the material’s toughness. In both the Charpy and Izod tests, this energy is measured in joules or foot pounds and reveals the material’s resistance to fractures under rapidly changing loads. Materials that can absorb higher energies without breaking are considered tough, whereas materials that cannot absorb high energy and fail suddenly are brittle.

Another important parameter to study the behavior of materials are the fracture surfaces as they can reveal a lot of information. A ductile fracture shows considerable plastic deformation, having a very rough surface, commonly called an energy fracture as such materials require high energy to break. Smooth and shiny fractures with little to no energy absorption, referred to as brittle fractures, signify sudden breakage and are the opposite of ductile fractures.

Metallographic studies document the dependency of temperature on fracture features. For example, low carbon steels exhibit ductile to brittle transitions at critical temperatures with approximate mid-range testing yielding critical values. Recent investigations suggest that toughened stainless steel and titanium alloy cryogenic materials exhibit superior toughness above and below the operating temperatures, thus making them suitable for aerospace and cryogenic operations. Fracture mechanics with improved monitored and predictive analysis models has also advanced further, enabling infrastructure and component lifecycle cost assessments based on mechanistic, data-driven fracturing algorithms.

Exploring Different Types of Impact Test

Under sudden impacts, impact tests are a critical procedure for determining the strength and durability of materials. Oftentimes, the most well-known types of impact tests entail:

Charpy Impact Test: Assess how much energy a material can absorb during and after impact by using a notched specimen which is hit with a pendulum.

Izod Impact Test: The same as the Charpy test, but a specimen is put in a vertical position and struck on one of the vertical ends of the specimen to analyze notch toughness issues.

Drop Weight Test: Used for analysis of pipeline materials, this procedure involves dropping a weighted object on the specimen to analyze the specimen’s resistance to impact.

Instrumented Impact Test: This test measures impact, force, and displacement of material through advanced sensors that enable real-time measurement.

These tests are specially designed to comprehend a material’s properties and aid in predicting how it will perform in practical scenarios.

Understanding the Pendulum Impact Testers

Pendulum impact testers are popular tools that evaluate material impact resistance and toughness. The testers work by releasing a pendulum from a specific height so that it hits the specimen under test. Measurements are decisive on its impact properties alongside the energy absorbed by material through fracture or deformation.

Modern impact testers come with pendulums that include more advanced features and technologies. Test versatility across industries is ensured by both Charpy and Izod testing standards. Examples of these advanced features include: Automated specimen positioning, precise and repeatable testing with high digital display resolution, and clear specimen identification. The machines usually have broad energy ranges tailored for polymers, metals, composites, ceramics, and other complex materials. Integration of high-speed data acquisition systems within the machines captures real-time data, including material force, energy and deformation, enhancing understanding of its behavior.

Innovations like chambers regulated concerning temperature for materials exposed to extreme environments have greatly improved real world applications. Other improvements include high-capacity testers that accommodate industrial-grade materials exceeding 750 Joules of impact energy. Furthermore, several models have software features that allow for uncomplicated data analysis and reporting, greatly streamlining the process.

Mechanical pendulum impact testers play a key role in the quality guarantee processes, product design cycles, and material science researches. Historically, these testers have been utilized by the automotive and aerospace industries as well as civil engineering companies whose constructions require substantial reliable materials.

The Drop Weight Testing Method

The drop weight testing method is a popular procedure for determining the impact resistance of materials within set parameters. This method consists of raising a weight to a predefined height and then releasing it so that it drops onto the material that is to be tested. The force applied to the material and its accompanying effects, like deformation or fracture, are also recorded. This is accepted practice for researchers and manufacturers who want to determine if their materials are sufficiently durable and reliable.

Modern automated drop weight testers make it possible to calculate specific energy metrics, examine intricate fracture patterns, and stress distribution details, which greatly increases data accuracy. Modern drop weight testers incorporate high-speed cameras and sensors that monitor the material’s reactions in real-time. It has been found that composites, polymers, and occasionally alloys are some of the frequently tested materials in different sectors like construction, packaging, and sports equipment through the use of this method.

Recent publications indicate that drop weight testers are capable of delivering impact energies between a few Joules and several kilojoules. This depends on the configuration and the needs of the industry. With this range, researchers are able to simulate conditions from minor impacts to severe loads. In the automotive industry, for instance, this method is used to evaluate the crashworthiness of panels while in aerospace, it assesses critical components like turbine blades.

The boundaries of innovation in material science are ever expanding with the use of the drop weight method in science and engineering. When advanced instrumentation and thorough testing standards are applied to this method it ensures targeted results across numerous domains.

How do impact testing machines work?

Machines that perform impact tests check how much a specimen can absorb under an instantaneous force by applying controlled force or weight to it. A common procedure is to hold the specimen firmly within a vice and strike it with a pendulum or drop weight. The engineering skills, integrated with physics and material manipulation, allow measuring the specimen’s toughness and durability by capturing energy absorbed during impact. This allows a conclusion upon the material’s ultimate resiliency to trauma. These machines are built around the principles of rigid conditions, designed to achieve correct and precise answers.

Components and functioning of pendulum impact testers

Pendulum impact testers are made with careful craftsmanship to evaluate material toughness. Below is a list of critical parts of the machine and their functions.

Pendulum Arm: The pendulum arm is the principal part of the device that gives the controlled impact. It is usually made from high-strength steel to guarantee consistent force application. Different weights of pendulum are also provided to suit the various standards of tests and types of materials used.

Specimen Holder (Anvil): This fixture restrains the test specimen to enable the impact to be precisely aimed on the intended target. The holder is designed to immobilze the specimen so that thrust will take place only on the area that the specimen was intended to be marked.

Striker (Impact Blade): This part is attached to the pendulum arm, is the part that directly strikes the the specimen. The size and shape of the striker may differ depending on the test, whether it be Charpy or Izod.

Scale or Digital Display Unit: The older pendulum impact testers used a calibrated energy scale, while more contemporary machines have digital sensors and display units that record. Energetically, the amount of energy that the material can absorb will be out in Joules (J) after being impacted.

Base Frame: A sturdy base frame is required in order to support the whole apparatus whilst minimizing vibrations and maintaining alignment during testing. The material of the base ensures that there is no instability, which is crucial for repeatable outcomes.

Safety Enclosure: Safety enclosures are now fitted on modern pendulum impact testers in order to ensure that operators are not exposed to danger from uncontrolled debris or shards fragments which could come from a failed specimen test.

Enhanced precision and efficiency is gained with advanced models. This is achieved through automated test setups, data collection via sensors, as well as software for real-time analysis of tests performed.

Operating Procedures for Pendulum Impact Testers

The following procedures are done in operating pendulum impact testers:

Preparing the Test Sample: A specimen that is to be tested is shaped into a rectangular bar or circular rod with standardized dimensions such as E23 for Charpy impact tests.

Inserting the Specimen: The specimen is placed on the holder or anvil. Notably, for Charpy tests, the notch has to be facing the impact direction in order to replicate certain stress conditions.

Activating the Pendulum: The pendulum is set to a specific height which is predetermined. This height determines a certain value of potential energy. When the pendulum is let go, it swings downward, gaining kinetic energy while being pulled down by the force of gravity.

Impact and Fracture: The strike of the pendulum on the specimen at the notch allows it to absorb energy and eventually fracture. The amount of energy absorbed depends on the material’s composition, toughness, and structure.

Measurement and Analysis: During the testing of the specimen, the energy absorbed by the material is stored in a scale or digital system. This information is important for assessing the material’s capacity to endure sudden forces.

Data and New Adjustments

Varying the Energy Measurement of Devices: The majority of pendulum-type impact testers could measure energy absorption between 1 Joule and 750 Joules, which serves well in testing metals, polymers, and composites.

Modern Testers: New Testers add software like LabView or custom systems for real-time observation, statistical evaluation, and generating reports on the test’s outcomes.

Altered Environmental Conditions: Some devices enable testing under different temperatures of extremes due to built-in cooling or heating chambers; this information is essential in determining how the material would behave in various operational conditions.

In summary, pendulum impact testers are essential in material science, construction, automotive and aerospace industries as they help engineers select the most suitable materials that need safety and operational performance in critical applications.

The role of testing machines in determining material strength

As technology progresses, testing machines become more efficient at evaluating material strength and the safety, reliability, and performance of products across different sectors. These machines are used to replicate real-life scenarios, allowing engineers to study how materials behave and their limits when subjected to stress. Modern testing machines currently come outfitted with precision sensors, automated controls, and data analysis systems that provide accurate results.

Commonly practiced around the world is tensile testing, a procedure that measures a material’s tensile strength, elongation, and modulus of elasticity. Today’s standards dictate that these machines can apply forces anywhere from a few newtons to hundreds of kilonewtons, meaning they are built for everything from fragile fibers to tough metal alloys. Other testing machines, like compression and flexural testing machines, evaluate how materials perform when placed under crushing loads or bending forces. This is important in construction and structural engineering.

Some recent statistics state that the global market for material testing machines is set to exceed 6 \% in CAGR growth rate from 2023 to 2030, primarily fueled by demand from the aerospace and automotive industries. These industries incorporate advanced testing to polish low-weight materials like carbon composites and high-strength alloys which are mandatory for safety and performance.

Moreover, innovations such as non-destructive testing (NDT) techniques are transforming how materials are evaluated. Ultrasonic testing and x-ray computed tomography are examples of advanced techniques that help engineers find internal defects without harming the material, which is time and cost effective. Together with automated data analysis, these technologies make quicker decisions possible, which enhances quality assurance.

In the end, testing machines offer valuable information regarding the response of materials to different magnitudes of force, temperature, and other environmental factors. This sets further upper limits for engineers when determining which materials best serve their intended applications to guarantee safety, efficiency, and durability at the same time.

What Equipment is Used in Impact Testing Machines?

The tools used for impact testing machines comprise a pendulum, hammer, and an anvil, which are used to apply force on a given test material. The materials are put through sequential tests to check if they can withstand real-world impacts while examining the level of achievable energy absorption or resistance to fractures. Often, the measuring instruments, such as sensors and data appraisal systems, are incorporated into the machines so that test results are accurately captured and can be analyzed later.

The Role of Instruments and Testing Machines

The modern impact testing machines, as well as their instruments, have a great importance in material science, quality assurance, and engineering works. In modern machines, precision measuring is critical for assuring the material’s operative capability under stress conditions, and integrating modern technology is an absolute necessity. Precision measuring devices such as high-resolution sensors, digital data acquisition systems, and others are capable of monitoring force, displacement, and energy absorption surely and unreservedly during the test.

To provide further data for thorough analysis, fracture behavior may be recorded, and these videos are time-lapsed in real time, so additional data for intricate analysis in real time can be added. The 2023 industry review states that the impact testing systems that are highly automated underwent an 18% increase in demand single-handedly from the aerospace, automotive, and construction industries. All of them are chartered by ASTM E23 or ISO 148 on Charpy impact test compliance, telling us that substantial control on material evaluation is global.

Precision in impact testing surpasses geometry due to the amalgamation of traditional hardware components like pendulums and anvils together with sophisticated software for automated data processing and analysis, unlock new heights of efficacy. This not only fortifies the reliability of materials, but also helps in the infallible innovations of engineering design and product safety.

Standards and Guidelines: ASTM and ISO

Two important organizations in the world are the American Society for Testing and Materials (ASTM) and ISO (International Organization for Standardization). These organizations have set up guidelines and standards to provide the necessary prerequisites in areas such as consistency, safety, and quality in different industries. The USA has industry standards for a diverse collection of systems, materials, and services, like metal, construction goods and plastic known as ASTM. Whereas, ISO focuses on developing international agreements on inter-industry product compatibility, efficiency and safety.

ASTM standards are known to provide detailed framework guidelines in form of charpy impact tests, for example E23 which aligns with ISO 148. Calibration of the equipment, along with setting the limits of test specimens is given equal importance among both standards to maintain worldwide uniformity. Research data suggests that following these guidelines mitigates experimentation variability up to 20% leading to consistency in engineering results.

Furthermore, modern developments in digital technology have integrated sophisticated tools like automated testing software and digital calibration systems into these standards. For instance, quality management systems certified to ISO 9001 often utilize ASTM testing guidelines to check material integrity within manufacturing processes, illustrating the cross-influence of these systems. This integration approach promotes high standards while further advancing design innovation and sustainability.

Following the ASTM and ISO standards enables industries to embrace modern technology while guaranteeing international consistency in engineering and product safety practices.

Reference Sources

- Mechanical Testing – Behrend Labs, Penn State University

Discuss pendulum and vertical drop impact testers and their use in studying material behavior under rapid loading.

- Charpy Impact Machine Verification Program – NIST

Discusses the details of the Charpy impact test, particularly striking a specimen with a pendulum and the process of measuring the energy absorbed.

- IMPACT TESTS AND FRACTURE TOUGHNESS – OSTI

Covers the mechanics of impact testing, including fracture energies and various equipment used.

Frequently Asked Questions (FAQs)

Q: What is an impact test and why is it important?

A: An impact test is a method used to evaluate the ability of a material to resist sudden forces or shocks. It is important because it helps determine the impact resistance of materials, which is crucial in applications where materials are subject to collision or impact, such as in sports equipment and automotive industries.

Q: How does a concussion test relate to impact testing?

A: A concussion test, often used in sports medicine, is a type of assessment used to evaluate cognitive function post-impact. While it differs from material impact testing, both are concerned with the effects of sudden forces, albeit on different subjects—one on materials and the other on human cognition.

Q: What is a baseline test in the context of impact testing?

A: A baseline test in impact testing refers to an initial assessment that establishes a reference point for comparing future tests. In sports medicine, a baseline test, such as post-concussion assessment and cognitive testing, helps determine an athlete’s normal brain function for comparison if a concussion is suspected.

Q: What are the different types of impact test methods?

A: The main types of impact test methods include the Charpy impact test, Izod impact testing, and drop weight testing. Each method uses different instruments and setups to measure the energy absorbed by a material during fracture or deformation.

Q: What is the Charpy impact test and how does it work?

A: The Charpy impact test is a method used to determine the impact resistance of materials. In this test method, a notched sample is struck by a pendulum, and the energy absorbed during fracture is measured. This test helps assess the material’s toughness and ability to resist impact applications.

Q: How does drop weight testing differ from other impact tests?

A: Drop weight testing involves dropping a weight from a known height onto a specimen to evaluate its impact resistance. Unlike the pendulum-based Charpy and Izod tests, drop weight testing directly measures the force of impact and the subsequent deformation or fracture of the material.

Q: What is the role of a pendulum in impact testing?

A: In impact testing, a pendulum is used as an instrument to apply a controlled amount of energy to a material sample. Pendulum impact testers are key components in both the Charpy and Izod test methods, where they swing to strike a notched specimen, measuring the energy absorbed during fracture.

Q: How do impact testing machines measure energy absorbed?

A: Impact testing machines measure the energy absorbed by calculating the difference in the pendulum’s potential energy before and after impacting the sample. The amount of energy absorbed indicates the material’s toughness and ability to resist impact.

Q: What is the significance of the notch in impact tests?

A: The notch in impact tests, such as the Charpy and Izod tests, serves to create a stress concentration point that encourages fracture. This allows for a consistent and measurable way to assess the material’s impact resistance and behavior under stress.

Q: How are impact test results used in sports medicine?

A: In sports medicine, impact test results, such as those from concussion tests, are used to assess an athlete’s cognitive function after an impact. These results guide decisions on when it is safe for an athlete to return to play, aiming to prevent further injury and ensure proper recovery.