In considering material performance and durability, ultimate tensile strength (UTS) governs the discussion. This mechanical property indicates how much stress a material can be subjected to before it fractures, thereby indicating how reliable a material is for one application or another. From wonders of engineering to everyday objects, tensile strength must be appropriately assessed so that safety, efficacy, and creation can be assured. Here, we will go through the deeper workings of this ultimate tensile strength, alongside the basics of stress and material strengths, and why comprehensive testing is so pivotal. This will be an in-depth road map for seasoned engineers, avid students, or just whoever is eager to learn about materials science and view what makes something worthy of pressure. Prepare to explore the concept of structural integrity and its importance in a practical sense.

Introduction to Ultimate Tensile Strength

Definition of Ultimate Tensile Strength

Ultimate Tensile Strength for a material refers to the maximum tensile stress it can sustain prior to failure or fracture. It is expressed as force per unit area, typically in megapascals (MPa) or pounds per square inch (psi). The characteristic is especially utilized in appraising the mechanical behavior of a material in scenarios in which the material will be imposed with considerable pulling or stretcher forces.

To allow the UTS to be determined, the material is considered to be subjected to a tensile test in which the amount of tensile force is gradually increased until the product faces a fracture. The force under which the material broke was recorded and then divided by the cross-sectional area of the sample to give the computer UTS value. This value goes into considerations for the strength and durability of the material, being critical to an engineer when selecting an appropriate material in construction, manufacturing, or aircraft design.

From an engineer’s point of view, this knowledge of UTS is vital as it has dire consequences in safety, workability, and life. A low tensile strength in any material can bring about equipment failure, accidents, or huge expenses in repairs. Materials with a known UTS can guarantee with certainty that the materials chosen will withstand the loads and stresses expected to be applied in their actual applications, thereby ensuring the structural integrity and reliability of the structures or the application under consideration.

Significance in Material Science and Engineering

Since material science and engineering deal with the characterization and utilization of materials, ultimate tensile strength (UTS) becomes equally important there. For any given application, UTS is deemed to choose a material that is permitted to undergo operational loads without actual failure or excessive deformation; in other words, it strongly guards the interests of scientists and engineers to produce safe and reliable structures or machines and systems.

UTS is also significant in terms of material designing and innovation. When the tensile strengths of conventional materials are evaluated, such an evaluation would pinpoint the inadequacies, thereby leading to the development of new materials with higher strength properties. These advancements find application in such industries as aerospace, construction, and automotive, where the utmost need is safety and performance.

Besides, UTS also takes the lead in setting particular quality control procedures while manufacturing is being carried out. Checking materials for their tensile strengths and comparing the results with the established limits does ensure uniform standardization of production and assists by signalling any weak points or defects in the materials before the same can be accepted for use. This cuts losses due to failures and lengthens the life period of the end product and its reliability. Considered in this way, ultimate tensile strength is not merely a mere capacity parameter of a material but rather, is the basis of development and reliability in engineering.

Overview of Tensile Test Procedures

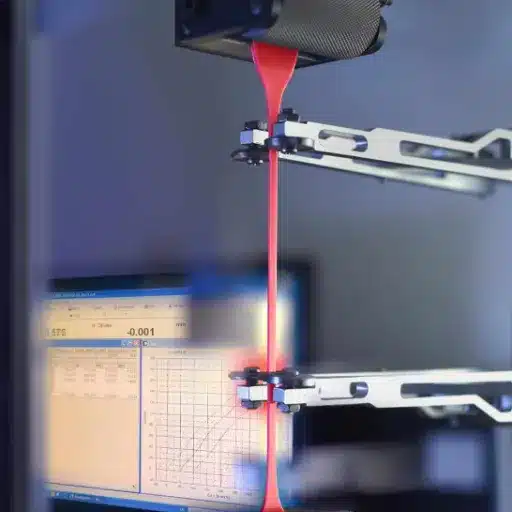

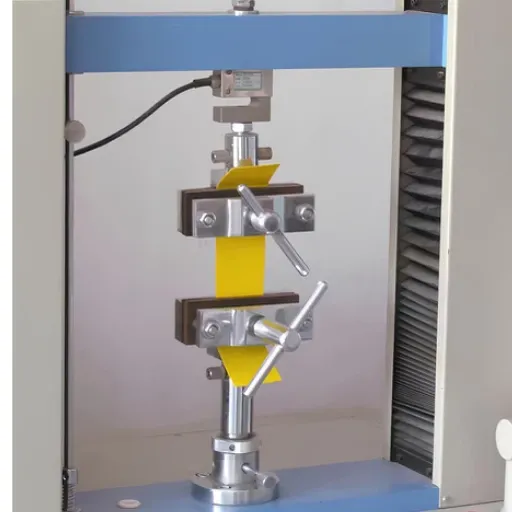

Tensile testing is a fundamental procedure carried out to determine the mechanical properties exhibited by a subject material under tension. The procedure consists mainly of fixing a sample material into a tensile testing machine, wherein a pulling force is gradually applied until the subject material either moves or breaks. Measuring and recording final properties-an ultimate tensile strength, yield strength, elongation, and modulus of elasticity-are the primary objective.

This testing usually follows the steps for accuracy and consistency. The specimen is first prepared to standard dimensions and shape according to codes of practice, such as ASTM or ISO. Thereafter, the sample is secured between grips or clamps provided in the machine so that the force of application remains uniform. After securing the specimen, the testing machine then begins to apply the tensile load at a controlled and slow rate, and at the same time, various sensors record the response of the specimen. Stress and strain data are recorded while testing and used later to draw the stress-strain curve, which is quite useful in understanding the behavior of the material.

Engineers, by analyzing the test data, judge the suitability of such materials for pertinent applications and predict their working conditions. Such tests serve the purpose of quality control and also help foster newer developments in materials, giving impetus to their improvement. This testing procedure is used extensively in construction, automotive, and aerospace domains, ensuring the long life and reliability of components.

Understanding Ultimate Tensile Strength

The Concept of Tensile Stress

Tensile stress is the pulling force on a material used to stretch it. It is defined as the force applied per unit area of the material. Mathematically, tensile stress is considered as the applied force divided by the cross-sectional area of the material, with its unit often being in Pascals (Pa).

The material elongates in the direction of the applied force whenever the material is subjected to tensile stress. Such a material is behaving elastically when under lower stress; that is, once the force is removed, the material regains its original dimensions. However, when the stress exceeds the elastic limit, the material deforms irreversibly or may fracture.

Understanding the concept of tensile stress is essential in engineering design to find out the mechanical character of materials in order to properly design them for particular applications. An understanding of tensile stress will allow engineers to work toward guaranteeing safe and durable structures and components in construction, automotive, aerospace, and other industries.

Different Types of Tensile Strengths

Tensile strength is the measure of the resistance offered by any material to being broken under tension. It is generally divided into three main types corresponding to the different stages of material response to stress.

Yield Strength:

Yield strength refers to the level of stress at which a material starts to deform plastically; it cannot come back to the original shape when the stress is removed. In most applications, it is essential that the material does not change its shape under the given load.

Ultimate Tensile Strength (UTS):

The value of ultimate tensile strength is the greatest amount of tensile stress that a material can withstand before it starts to fail. This value corresponds to the stress at which the material commences necking, in which localized diminution in cross-sectional area occurs. The UTS is one of the important values in ascertaining for an undertaking the resistance of material in respect of its application.

Fracture Strength:

This is the maximum stress that occurs at the breaking point of a material and signifies the ultimate limit of the tensile property of the material. The fracture strength is usually lesser than the ultimate tensile strength since, as failure is initiated, the material is weakened at the site of stress concentration.

Thus, gaining insight into these three varieties of tensile strengths is highly useful in the determination of the most appropriate material for specific engineering applications to certify safety, efficiency, and durability of structural design and components.

Importance of Yield Strength in Context

Yield strength is considered a very important factor in materials engineering, as it describes the largest stress that can be applied on a material without causing permanent deformation. Its consideration is significant for an engineer who intends to maintain the shape of the material and prevent failure in dimensionally accurate applications.

The importance of the yield strength also arises in the design of load-bearing frameworks and machinery. It sets the criteria for safe use of materials in actual working conditions. Engineers look at operating stresses and compare them to the yield strength so that they can choose materials that will withstand the anticipated loads, thereby making structural design safer and more durable.

If yield strength is not rationally considered, the structures and components are bound to deform thereby rendering them ineffective or even leading to disastrous failure. So, the yield strength makes sure that the material can withstand all the stresses required from it at a stage where design optimization can be carried out by balancing strength with cost and efficiency. Hence, the yield strength is paramount in construction, automotive, aerospace, infrastructure, etc.

Calculating Ultimate Tensile Strength

Step-by-Step Guide to Calculate Ultimate Tensile Stress

1. Getting the Basics Right:

UTS is the acronym for ultimate tensile stress. It is calculated by dividing the maximum load a specimen can sustain before failure with its original cross-sectional area. This measurement gives an indication of a material’s tensile strength.

2. Conduct the Test:

A tensile test is performed on a specimen of the material under test. A universal testing machine applies tension gradually and records maximum force, F_max, at failure. A standard method should be followed for correct and consistent results.

3. Apply the Formula:

The UTS is calculated using the formula UTS = F_max /A where F_max is the maximum tensile force recorded, and A is the original cross-sectional area of the specimen. For instance, if the maximum force is 50 kN and the cross-sectional area is 25 mm², then UTS = 50,000 N / 25 mm² = 2,000 N / mm² or 2 GPa.

These steps guide engineers in ascertaining the ultimate tensile stress of materials to ensure their optimum usage in architecture, aerospace, or automotive industry. Accurate UTS values thus act as a landmark for material selection and guarantee safety and performance.

Tensile Strength Formula Explained

Tensile strength, often known as the Ultimate Tensile Strength (UTS), is calculated with the simple formula:

UTS = Maximum Force (N) / Cross Sectional Area (mm²)

Two values are, therefore, required in specifying this formula-the maximum force a material can withstand before it finally breaks and the initial cross-sectional area of the specimen being subjected to the test. The UTS comes as a denominator where the maximum force is divided by the area giving a precise value indicating the capability of the material resisting tension.

For example, if one were to say that the maximum force recorded was 60 kN and the cross-section is 30 mm², then through the formula, it yields UTS = 60,000 N / 30 mm² = 2,000 N / mm² or 2 GPa. Such quantitative details enable engineers to classify materials and evaluate areas where materials could be best suited.

Knowledge of tensile strength guarantees structural integrity of design, be it in construction, aerospace, or automotive manufacturering. Being a universal formula, it leaves no room for guesswork and provides metrics that are consistent and reliable in guaranteeing performance and safety.

Formula for Calculating Yield Strength

The formula for calculating yield strength is:

Yield Strength σy = Yield Load / Cross Sectional Area

- Yield Load is the maximum load a material can take up for which it can undergo permanent deformation.

- Cross-Sectional Area is the initial area over which the value of yield load acts.

Yield strength is an important parameter of a material because it distinguishes between elastic, that is, a temporary deformation behavior, and plastic behavior, that is, a permanent deformation. This assures that the material can undertake the required working stresses without failing or finally damaged.

Once the yield strength is precisely calculated, engineers and designers select the materials that are considered safe and will ensure structural integrity. Other vital applications are the construction of bridges, airplane parts, and machine parts, where unexpected material failures can bring about life-threatening situations. Therefore, calculating the yield strength enables these professionals to design structures that can sustain applied stresses in life.

Common Pitfalls in Calculating UTS

Common Mistakes to Avoid

❌ Incorrect Sample Preparation

One such commonly overlooked mistake in the calculation of Ultimate Tensile Strength is the failure to carry out correct sample preparation. Any irregularity, such as surface defects or incorrect dimensions, can cause unreliable results. For a meaningful test, samples must be prepared according to accepted standards and must be free of any defects that could affect strength measurements.

❌ Faulty Equipment Calibration

Another typical error is the faulty calibration of the apparatus used for testing. Calibration provides an accurate reading of stress and strain during tensile testing. Any outdated or ill-conditioned apparatus will cause errors in readings and thus the determined value of UTS. The apparatus for tensile testing should be calibrated and maintained periodically to avoid such inaccuracies.

❌ Misinterpretation of Stress-Strain Curves

Finally, in the misinterpretation of stress-strain curves lies another cause of erroneous UTS determination. Analysts do not identify either the time or the point of maximum stress just as clocks strike failure. Training in proper curve interpretation and data analysis with precise tools can avoid these problems. UTS calculations become reliable and accurate with the application of these practices.

Tips for Accurate Measurements

✅ Quality Instrument Selection

The most important factor toward measurement accuracy involves proper choice of an instrument that is of good quality and well-calibrated. Calibration is always done against a traceable standard to maintain the tool’s accuracy since a small drift in its calibration will contribute drastically to the variations in the results. The instruments should also be stored properly according to the manufacturer’s recommendations. Improper handling or storage might build up wear or damage, which eventually will register as incorrect observations.

✅ Environmental Control

Keep in mind environmental influences such as temperature, humidity, and vibration, which might affect the readings. As the best practice, hold measurements in controlled environments if at all possible to prevent those interferences, while if measurements need to be taken in a variable environment, allow the instruments to adjust to the condition before use.

✅ Standardized Methods

Lastly, the standardized measurement methods for specific measurement applications must be followed. Recording and data analysis procedures must be unambiguous to ensure no discrepancies. Assuring that these measurement procedures are taught consistently to all technicians, with ongoing reviews to make certain that all adhere to the recommended standards, will improve accuracy and repeatability of measurements.

Importance of Proper Testing Conditions

Proper testing conditions are of utmost relevance to the contrary for results that are accurate, reliable, and reproducible. Temperature and humidity exaggerate environmental effects; any kind of lighting will influence testing and must be controlled so that testing always remains consistent. For example, due to inappropriate temperature conditions, there could be variations in the material properties, thus jeopardizing the assessment itself. Such environmental conditions will not be considered if it is ensured that a stable environment is ensured and if the focus and attention of the subject are on the matter under testing.

Secondly, instrument calibration plays a very important role in test correctness. Instruments should be calibrated from time to time, depending on precision, thus avoiding erroneous results. With no adequate calibration procedures, measurements vary spatially and temporally, existing as an illusion of actual condition or property. Regular checks and calibration of equipment with respect to time will help eliminate erroneous results and add to the reliability status of the testing system.

Finally, it is the standardization of test codes and practices that governs the production of repeats and resume standards, thereby ensuring uniform and acceptable test conditions and applied methods. Standards should specify the sampling, sample preparation, sample handling, curing procedures, and data recording procedures for a particular type of testing. Undertaking testing to specifications ensures that testing scenarios are uniform-the results may be compared within the same testing facility or even from one place to another. Proper training of personnel undertaking these tests will reduce human errors and thus ultimately help in making the collected data valid and reliable.

Real-World Applications of Ultimate Tensile Strength

Use in Manufacturing Industries

Considering manufacturing industries, ultimate tensile strength is a very important property because it dictates the maximum amount of stress that can be endured by a material just before it breaks apart. It is widely used in deciding over materials to be used for building machines and buildings as well as for everyday items. UTS actually helps the manufacturer decide on the materials that will be reliable and safe against expected loads and conditions so that the finished product meets the standards of durability and integrity.

In the automotive industry, for example, UTS is necessary when designing vehicle components such as the frame, bolts, and suspension systems that need to withstand large forces during operation. In the construction industry, steel and concrete are chosen and tested for tensile strength to guarantee that these materials would stand mechanical stresses from load-bearing or environmental acts. This indicator streamlines the decision-making process involved in balancing optimal performance against safety.

UTS testing is also essential in innovative activity, as it gives engineers means to develop and arrange a variety of materials that have increased strength and resistance. The design of lightweight yet strong materials, such as some alloys or composites, is considered under the umbrella of UTS to weigh strength against function. This, therefore, gives direct impetus to industries that are looking for better and sustainable answers.

Importance in Aerospace Engineering

UTS being a very high-performance measurement in aerospace engineering maintains a safety constant. Aerospace components experience harsh working conditions: high stresses, large fluctuations in temperature, sudden loads, etc. The determination of UTS should ensure that materials used in these parts could resist extreme environments posed with failure of the component, thereby ensuring functionality and safety in operation.

UTS is a very important factor affecting material selection in aerospace engineering. The demand of aerospace engineering chair requires materials that are lightweight and very strong. UTS testing helps engineers to identify materials of sufficient strength so that materials such as high-strength alloys and composites can be entertained to provide aircrafts and spacecrafts with maximum performance without any compromise in safety.

UTS testing also acts as a stimulus to an innovative design. In an attempt to overcome the limitations posed by the present-day materials or to enforce materials that could sustain even greater stresses for not more weight, engineers use the information from tests on UTS and are able to consequently keep the aerospace engineering abreast with technological developments for producing safer, faster, and more efficient vehicles that meet ever-changing demand of the industry.

Applications in Construction and Civil Engineering

Material strength plays a crucial role in construction and civil engineering, insofar as safety and structural integrity are considered. In other words, materials such as steel, concrete, and composites are subjected to UTS tests to check that they can sustain the loads or stresses carried by buildings, bridges, or other infrastructures. Depending on UTS, all engineers are able to determine and specify materials according to respective utilization, thus ensuring greater longevity and good performance.

For instance, construction of tall buildings entails the use of high-strength steels with a definite UTS rating capable of supporting exceptionally large vertical loads with a degree of flexibility that is much required to stand against environmental forces such as wind or seismic motions. Similarly, concrete containing steel rebar is designed for tensile stresses to ensure stability in foundations, beams, and columns.

UTS testing also allows for testing new materials like high-performance concrete or fiber-reinforced polymers. These materials, which provide improved strength with very little additional weight, make projects stronger and hence better with respect to efficiency and cost. Using accurate UTS data, engineers create safer and greener structures that evolve with society’s changing needs.

Frequently Asked Questions (FAQ)

❓ What is ultimate tensile strength?

A bigger way of stating ultimate tensile strength is the greatest stress that a material can withstand when being extended or pulled and just prior to rupture. It is, so to speak, the greatest strength of a material. Tensile strength is determined based on the maximum tensile stresses that a material can repel before it actually fractures.

❓ How do you calculate ultimate tensile strength?

The ultimate tensile strength is equal to the maximum load applied to the specimen divided by the original cross-sectional area of the specimen. UTS=F/A, where F is the maximum load, and A is the original cross-section.

❓ What is the difference between yield strength and tensile strength?

Yield strength is the stress at which a material begins to undergo plastic deformation, while tensile strength is the maximum stress a material can bear before failure. That is why yield strength is an indicator of permanent deformation, whereas tensile strength is the maximum stress that can be applied.

❓ Why is it important to know tensile strength of material?

It is crucial to know the tensile strength of a material when engineers and designers choose materials for construction and related works. It helps to assure that materials withstand anticipated loads without failing so that strength requirements and safety standards are met.

❓ What does the stress-strain graph show concerning tensile strengths?

A stress-strain graph shows a visual representation of the behavior of a material under stress. It is a graphical representation of applied stress versus resulting strain. The maximum peak of the graph would be the ultimate tensile stress, thus indicating the maximum stress which the material can withstand before failure.

❓ How does hardness relate to ultimate tensile strength?

A material’s hardness indicates its resistance to deformation and is often correlated to tensile strength. Thus, a material with high hardness usually has high tensile strength and can resist applied loads better without suffering plastic deformation.

❓ What is the role of cross section in the calculation of tensile strength?

The cross section of the test specimen is useful in the calculation of tensile strength because it influences the amount of stress applied on the material. A specimen with a larger cross section would have a smaller stress value for the same load applied, which in turn affects the ultimate tensile strength and its calculation.

❓ What type of materials generally have a high ultimate tensile strength?

Some materials generally having high ultimate tensile strength include carbon steels and some other alloys. These materials are usually selected in areas that require high strength and wear resistance, whereby they can absorb super loads before failure.

❓ What characteristics can change the value of tensile strength of a substance?

The ultimate tensile strength of one material can be altered by numbers of factors like composition, methods of production, temperature, and presence of defects, etc. By considering all such elements, one is able to gain insight into the strength of a material and check the suitability of a material to the particular use for which it is intended.