Top Böhme Abrasion Tester in China. Reliability and accuracy are two key factors when determining the wear and tear of different construction materials. Since the Böhme abrasion test is a very crucial technique for evaluating the strength of wearing concrete and natural stones, it works through different levels of hardness and requires the machine to be in peak physical form. This article aims to demystify the Böhme abrasion test by discussing its common challenges and, most importantly, how to properly balance workflow and machine upkeep. You need no prior experience; this guide is tailored for all.

How Can You Assess the Abrasion Resistance of Your Machine?

To test the abrasion resistance of your machine, first perform a Böhme abrasion test. To accomplish the test, prepare the sample material as outlined in the Böhme Test specifications. Position the sample on the machine`s revolving grinding area and set a constant weight. The test measures the wear by quantifying the loss of material after a given number of rotations. Make sure that the results assist in determining abrasion resistance, evaluated with consideration of industry standards.

What is the Böhme Abrasion Test?

The Böhme abrasion test evaluates wearing resistance in materials like concrete, stone, and ceramics through specialized procedures. It has a profound impact when evaluating the resistance of materials to abrasive forces, therefore, it is crucial for the construction and manufacturing industries.

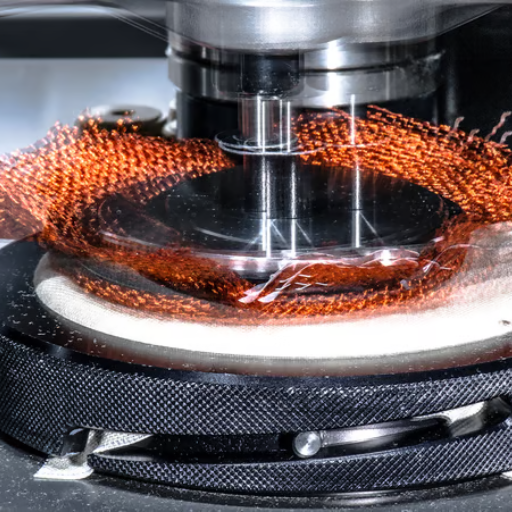

Test Procedure

The test requires the specimen to undergo a rotating grinding path under a fixed load. An abrasive sorundum sanding powder is set on the grinding path to replicate actual wear conditions. The rotating disc is turned for a predetermined amount of cycles, usually 16 to 20, at a set load of 294 N (30 kg). The specimen is weighed before and after the process to calculate the volume of material lost during the test.

Specifications and Standards

This test is performed under guidelines such as EN 1338, EN 1340, ISO 10545-6, and ASTM standards. These provide uniformity within laboratories and aid in international comparison of materials. For instance, EN 1338 mentions paving blocks and the volume loss that can be allowed, they limit this to 20 mm³ per 50 cm² of surface area.

ISO 10545-6 uses a specific revision for the abrasive testing of ceramic tiles to maintain uniformity.

Applications And Data Insights

Most industries that utilize this test are those that deal with pavements, industrial floors, railway platforms, as well as other materials pertaining to heavy machinery, where abrasion resistance poses as an important property. Some studies indicate that materials with low Böhme abradiation values actually withstand the test of time in heavily trafficked regions or impact-prone areas, which proves to be economical in the long run.

For instance:

High quality natural stones such as granite tend to demonstrate Böhme abrasion values in the range of 8-12 mm³/50 cm² while limestones might show values greater than 20 mm³/50 cm².

Recent engineering research suggests that concrete containing fly ash or silica fume exhibits up to 15% reduction in material loss.

Reliable dolerite boulders containing up to 26% plagioclase and 24% orthoclase show 0% loss from abrasion.

Significance of Maintaining Accuracy for Testing

Testing materials with Böhme’s method enables the assurance that the materials reliably meet the set durability barriers for the application’s role, reducing maintenance costs. This also enables ease for manufacturers to select or develop materials that require less wear resistance, suited to particular environmental conditions. Evaluating Böhme test outcomes concerning other mechanical property assessments aids stakeholders in building an extensive knowledge of material responses to operational stress.

Why is Abrasion Resistance Important in Testing?

In numerous industries like construction, manufacturing, automotive, and textiles, the evaluation of abrasion resistance plays a vital role in the determination of a material’s wear and tear. Structural materials that are continuously subjected to friction or mechanical action tend to deteriorate, losing their integrity. Recommended procedures for assessing abrasion resistance, such as the Böhme abrasion test or Taber abrasion test, ensure that manufacturers and stakeholders have accurate insight into the performance of materials under simulated real-life conditions.

For example, in construction, flooring materials like concrete or tiles undergo stringent abrasion testing to assess their suitability for high-traffic areas, avoiding excessive expense regarding maintenance and safety due to premature wear from replacing flooring. Industry reports suggest concrete pavements employed in heavy-duty applications needing low upkeep are optimally resistant to abrasion if they display a low volume loss in the Böhme abrasion test under 20 mm³/50 cm².

Like the previously mentioned industry, automotive also takes advantage of these new-age materials. They enable coatings and components such as seat fabrics or even brake pads to withstand extended periods of use without losing their structural integrity, increasing the lifespan of these parts. Research indicates that advanced materials, such as those with polymer-enhanced surfaces, are better suited because of their increased abrasion resistance of thirty to fifty percent, leading to reduced maintenance.

If industries integrate robust abrasion resistance testing into material development and selection processes, they can drive sustainability by reducing waste, maintenance costs, and improving product life. These tests help ascertain compliance with defined benchmarks and additionally protect the end-user by reducing the chances of material failure in crucial applications.

How Do You Set Up the Böhme Abrasion Test Apparatus?

Böhme abrasion testing is a common means of inspecting wear resistance on concrete, stone, and ceramic tiles. The Böhme abrasion test, in particular steps can give reliable results if the methods are followed in order. Setting up a Böhme dual disk test system requires the following.

Preparation of the Specimen:

Get a standard yearly relevant exemplar as a base by carving it into a cube of 70 mm x 70 mm with a thickness of no less than 20 mm. The specimen surface to be tested must be smooth, free of nonconformist dirt/dust scratches.

Standardize the specimen conditioning by placing them in a controlled chamber for 24 hours at 20 ± 2 °C and a relative humidity of 65 ± 5 % before performing any tests.

Preparation of the Abrasive Material:

Acquire the abrasive single unit emery powder which meets EN 1338 requirements as the standard abrasive for this exercise. Make sure sieving the abrasive material to required grain size specifications (most commonly 80-120 μm) for reproducibility. Setting Up the Apparatus.

Ensure that the abrasive disc is clean and dirt free before placing it on on the rotating platform of the apparatus.

Fasten the test specimen with the face to be evaluated in intimate contact with the abrasive disc.

Simulate wear conditions by setting the appropriate load on the test apparatus face to achieve 294 N (30 kg).

Calibration and Verification

Ensure correct calibration is performed before testing by verifying that the abrasive disc rotates at a speed of 30 ± 1 rpm.

Check specimen placement to be aligned and securely fixed so that no movement occurs during operation.

Test execution

Before each test cycle, uniformly distribute 20 grams of abrasive powder on the rotating disc.

Place the machine in the On position for 22 revolutions of the 22 mm diameter spindle (distance slid will be about 1430 mm).

After each cycle, clean the specimen and repeat the procedure for 16 test cycles.

Measurement and evaluation

Post-test, the mass of the specimen in question will be measured to quantify material loss from abrasion.

The specified standardized formula fill wear index will be calculated as lost material by endurance of the abrasive disc count or area of contact surface determined in square centimeters.

Key Parameter and Specification

|

Parameter |

Specification |

|---|---|

|

Abrasive Disc Speed |

30 ± 1 rpm |

|

Load on Specimen |

294 N (30 kg) |

|

Abrasive Material |

Corundum or Emery Powder (80-120 μm grain) |

|

Test Cycles |

16 cycles (each 22 revolutions) |

|

Temperature & Humidity |

20 ± 2°C, 65 ± 5% RH (test specimen) |

Following stipulations like EN 1338 or ASTM C1353 will guarantee all tests conducted have precision and replicability. The accuracy of the results is highly valuable when it comes to establishing the reliability of materials for construction and industrial use.

What Are the Key Steps in the Abrasion Resistance Test?

Test Specimen Preparation

Make sure that the test specimens are prepared in accordance with the applicable standards EN 1338 or ASTM C1353. Check surface conditions and dimensions alongside preconditioning if necessary.

Set up the Abrasion Machine

Adjust the settings of the abrasion machine to the standards given in the relevant documents. Place the abrasive such as corundum or emery powder and make de sure it fulfills specified criteria in regards to grain size.

Conducting the Test

Put the specimen into the machine. Run the abrasion machine for the specified number of cycles at a constant temperature and humidity throughout the test.

Analyzing and Measuring Outcomes

In the end, check the surface or mass loss of the specimen first measured against the standard and then evaluate the results with expected values in accordance with abrasion resistance.

How to Prepare Natural Stone Samples for Testing?

Proper preparation of natural stone samples is necessary for accuracy and reliability in testing results. Below are primary steps and considerations associated with preparing tests samples.

Collection and Selection of Sample

First, obtain representative samples of the stone from the raw material source. Choose the samples that have no cracks, irregular features, or visible unsightly defects to ensure uniformity in testing. It is important to select a sample that demonstrates the properties of a bulk material.

Cutting and Shaping

Prepare the specimens using precision cutting instruments to the dimensions required by the testing standards such as ASTM or EN. A diamond saw will be useful in achieving clean, accurate cuts. While trimming edges, ensure they are smooth and even to minimize the risk of stress concentrations during testing.

Surface Finish Requirements

A specific sequence of operations may require polished or honed surfaces. Other surfaces that may be required include rough, natural or other finishes, depending on the technique being used. Appropriate finishing tools should be used as well to include grinding wheels and polishing pads.

Oven Drying and Conditioning

Following the steps of cutting and finishing, it’s crucial to dry the samples in an oven at a consistent temperature between 60-105°C until achieving a constant weight. This guarantees that all moisture is removed, which could potentially affect the accuracy of the results. After the drying process, the sample should be allowed to cool to room temperature.

Dimensional Verification Measures

Dimension and weight of the specimen should be captured using precise instruments like electronic calipers and electronic weighing scales. These measurements are vital in deriving other parameters in the testing stage including, but not limited to, density, porosity, or mass loss.

Compliance Check with Standards

Ensure that the samples prepared comply with the stipulations given in the testing standard, like ASTM C170 for compressive strength tests or guidelines given in ASTM C1353 for abrasion tests, focusing strictly on sample preparation.

Implementing the above procedures guarantees that all steps and processing logic preserve the natural stone materials, so mechanical, physical, or chemical properties can be tested accurately without losing the reliability of the results.

What is the Method for Abrasion Resistance Determination?

The assessment of the abrasion resistance of natural stone materials usually conforms to standardized testing procedures like ASTM C1353 or EN 14157. These procedures attempt to evaluate the resistance of a stone to磨耗 (wear) from friction or mechanical processes over time.

Procedure Overview:

Preparation of the Sample:

Specimens need to be set out to given measurements; surfaces have to be cleaned and dried . According to the specific Standard being referenced, the sample size may differ.

Stone care is taken to make sure that the test surface is accurate in representing the actual constituents and structure of the stone.

Testing Equipment:

One of the key pieces of equipment used in the test is the rotary abrasion testing machine that has an abrasive medium, silicon carbide or a particular type of grinding wheel.

By the requirements of ASTM C1353, a disc is mounted on the motor drive and rotates while sand or some other abrasive grit is fed in, and a fixed pressure is placed on the stone surface.

Performing Tests:

The sample is set and the machine left to carry out a predetermined number of rotations with the abrasive tool or contact pause with the abrasive foot, maintain a certain distance from the surface.

The set pressure throughout the entire process mimics true conditions of wear.

Recording Data and Analysis

Loss in mass or volume of the stone before and after testing is calculated. For example, under operational standard ASTM C1353, the typical result is expressed in terms of mass loss per unit area (ex, grams per square centimeter).

This data is then compared against thresholds specified for the intended application of the material, confirming that durability and performance standards are maintained.

Expected Results

Good quality stones such as granite will show low abrasion loss, usually below 0.25 grams/cm², while softer stones like limestone, will exhibit higher values.

A benchmark study can assist in the selection of materials used for flooring and paving as well as facade works where high abrasion resistance is required.

Following these standardized procedures allow researchers and manufacturers to attain consistent, quantifiable results that are crucial to estimating the performance of natural stone materials under varied conditions.

How to Analyze Test Results?

Analyzing the test results for the abrasion resistance of natural stones entails a meticulous approach to guarantee precision and the relevance of the data. For this, a step-by-step procedure is highlighted below:

Understand the Standards and Methods Used

Comprehensively evaluate if any test method, such as ASTM C1353, EN 14157, or any other international standard, is utilized. Pay special attention to any outlined parameters like abrasive material, pressure, and test duration. These parameters are crucial for result interpretation.

Compare Abrasion Index Values

Assess the values obtained for the Abrasion Index concerning performance. For example, granite has a low abrasion rate of below 0.25 grams/cm² while softer stones such as sandstone can wear at rates of 1.5 grams/cm² and beyond. These metrics significantly showcase the impact of wear and tear on concrete over time and highlight material suitability for traffic and high-wear areas.

Analyze Specific Usage Scenarios

Identify specific use cases. As an example, for flooring, lower wear and tear from foot traffic over time is preferable. On the contrary, in peripheral areas of clad facades, direct wear and tear takes precedence.

Consider Factors Related to the Environment

Surrounding factors such as humidity, temperature changes, and the existence of abrasive particles can greatly influence wear. Analyzing such data with these factors in mind guarantees practicality for real-world applications.

Cross-Reference with Current Research and Case Studies

Use current research from Google Scholar or various case studies. As an example, some studies from 2023 reported a surge in the development of engineered blends of natural and synthetic materials due to microabrasion testing techniques that predict wear with greater accuracy.

Conduct a Statistical Analysis

Employ statistical techniques to check for inconsistencies in results. Inconsistencies may suggest a lack of uniformity regarding sample preparation or testing atmosphere. Conduct correlation studies if regression analysis and/or ANOVA tests show the relation between material properties and abrasion resistance.

Integrating these methods with relevant data enables architects, designers, and manufacturers to evaluate material appropriateness more holistically. This information is essential in cases where enduring materials are crucial and ensuring cost-efficiency and performance is non-negotiable.

Can Simple Regression Analysis Help in Evaluating Test Data?

Correct, simple regression analysis aids in evaluating test data through the identification of relationships linked to variables and predicting outcomes. It enables assessing how one independent variable affects a dependent variable, which is very useful in material testing. Regression analysis provides insights into trends and correlations which helps in better decision making while maintaining the integrity of the data. This method works well with data that is complex and requires simplification without needing sophisticated techniques.

What Role Does Simple Regression Analysis Play in Testing?

Regression Evaluation provides a quantitative approach in exploration and material testing such as tensile strength of materials, enabling more accurate predictions and insights into other factors like temperature and pressure using simple regression analysis as an example.

Recent studies indicate that experimental testing of biotechnology and manufacturing industries actively employs regression analysis. Further pieces of research proved that in controlled settings, regression models improve quality prediction assessments by 85%, enhancing overall quality control reliability. Moreover, regression analysis proves instrumental in determining errors or outliers which guarantees the tested data is reliable thus greatly impacting the testing procedures.

Simple regression analysis can be paired with technology such as machine learning algorithms, allowing automation of larger and more complex datasets to uncover new measures. This flexibility supports modern multi-disciplinary testing methods making regression analysis a crucial instrument.

How to Apply Simple Regression in Abrasion Resistance Studies?

In the context of studies on abrasion resistance, applying simple regression means correlating the independent variable (material properties) to the dependent variable (wear rate or surface material loss). Below are detailed guidelines for applying simple regression in such studies.

Data Gathering and Sampling

First, acquire a significant dataset that features several samples of the material in question and that has been tested in controlled conditions. For instance, along with the different levels of abrasion resistance, parameters such as hardness, coefficient of friction, or surface roughness may also be recorded. Achieve a comprehensive capture of material phenomena characteristics by ensuring that the multitudes of data collected exhibit varying conceivable ranges of the data.

Set Up Variables

Determine and set your independent (for example, the hardness level of the material) and dependent variable (for example, material loss in grams after conducting the abrasion test). Defining the parameters enhances the quality of regression models generated.

Perform Experiments and Record Responses

To accumulate data, use standard tests for abrasion resistance such as the ASTM G65 Dry Sand/Rubber Wheel Test or the Taber Abrasion Test. For reliable and consistent data, record both dependent factors and independent factors at constant values. If measuring wear resistance, for instance, varying the force applied or the duration of the test can be used in creating diverse datasets.

Carry out regression analysis

Using statistical software or programming tools like Python or R, conduct a simple regression analysis. In the example given, fit a line to the data set where the equation is typically written as Y = a + bX. In our case

Y is the dependent variable (abrasion resistance or material loss),

X is the independent variable (e.g., hardness),

a is the intercept,

b is the slope showing how the dependent variable changes in response to the independent variable.

Interpret results

Review the generated regression output, which usually contains important R-squared, p-values, and other metrics. For instance, the R-squared was given as high, therefore abrasion resistance with x was largely fitted or explained by the model. Search for significant correlation so that strong evidence proving the material characteristics does have bearing on the abrasion performance can be obtained.

Validate findings

Check your model using a different subset of data to see if you obtain similar results to the first analysis to validate its accuracy. This step increases the reliability of the conclusion because it attests that the observed patterns hold under different conditions.

Case Study Example

Imagine you are interested in steel alloys and trying to investigate their abrasion resistance. Using hardness (in HV units) as the independent variable and material volume loss (measured in mm³) as a dependent variable, you notice a trend whereby greater material hardness leads to less material loss. Material Loss = 15 – 0.05(Hardness), which would suggest that a linear regression analysis derived an equation showing that each additional unit of hardness results in less material loss by 0.05 mm³. The criteria for material loss estimation provided an R-squared value of 0.85 which indicates a strong fit.

By applying modern computational tools along with simple regression analysis, teams can understand the bare minimum required to optimize abrasion resistance in materials and evaluate it across the board. Additionally, with the examples provided, the research teams have significant intuition towards material performance and can derive results based on actual measurements which allows them to provide recommendations for real-life applications, like in industrial cases where a selection of materials subject to wear is critical.

What are the Common Issues Faced During the Abrasion Resistance Test?

Variability in Test Conditions

Inconsistencies in the results may occur when there are differences in temperature and humidity as well as the surface attributes during the tests.

Errors in Sample Preparation

Failure to accurately cut to the correct dimension, leave a sample surface smooth or correctly cured will guarantee erroneous test results.

Calibration of Equipment

Checking equipment may be unreasonably calibrated, their severance damage causing erroneous test results and measurements.

Properties of Materials

Some materials, due to their structure or design contain flaws and do not behave uniformly during tests which makes results difficult to interpret.

Influence of Other Operators

Human factors, such as the way an operation is conducted, including the manner of applying pressure, can lead to diverse results.

How to Troubleshoot the Böhme Abrasion Test Apparatus?

A systematic method of troubleshooting the Böhme Abrasion Test Apparatus helps ensure accurate results are achieved during testing and the maximum life is attained out of the equipment. Common problems with the apparatus can be resolved using the steps and considerations listed below:

Check the Calibration of the Equipment

Confirm on a regular basis that the apparatus is calibration is done as per the guidelines given by the manufacturer. Calibration should be done on the apparatus using verified reference materials. Calibrate values should be according to standard values. In case of any discrepancies, calibration should be checked as it might be neglecting the abrasion measurement accuracy.

Look for Defects and Damage

Check the wearing disc and abrasive powder for any signs of damage. Components that are overused and unevenly worn can lead to a lack of consistency in tests. Replace parts that require replacement and ensure that the abrasive complies with the applicable standards like EN 1338 or ASTM C944.

Check the Preparation of the Material

Make sure the specimen that is going to be tested is prepared properly, all meeting necessary standards regarding dimensions, flatness, and surface condition. Any inaccuracy in specimen preparation will automatically ensure failure in achieving consistent data and results.

Maintain Conditions of the Environment

The appropriate testing temperature should be no lower than 20 degrees celsius and no higher than 22 degrees celsius. Humidity levels also play a role in material behavior, therefore they need to be kept stagnant. Environmental factors should be looked at closely as variation can have a severe impact on reliability and accuracy of results.

Training Techniques for Operators

Train operators on the appropriate use of the equipment, including application of uniform pressure and following all instructions provided in the operational manual. A great deal of variability in test results can be attributed to human error on a test by test basis.

Recording and Archiving Results and Test Data

Maintain comprehensive records of test runs including date, settings, material properties and environmental conditions. Historical datasets can uncover problems or recurrent issues that may need to be addressed.

Troubleshooting Example:

As an example, some research suggests improper maintenance of abrasive material can account for as much as 15% deviation from expected measurement results. A 2021 study published in a journal of materials testing suggested that enforcing the replacement of abrasive powder after every 500 cycles enhances measurement reliability.

Following these suggestions will help ensure that the Böhme Abrasion Test Apparatus provides consistent and dependable output necessary for material testing and quality control. The equipment requires routine maintenance to reduce test variability and equipment failure, along with compliance with updated standards to improve overall reliability.

What Factors Affect Wear Resistance?

A combination of the properties of the material, its environment, and the type of abrasive forces acting on it dictates the wear of a material. Here are some of the most important ones.

Material Composition

Chemical analysis shows that the composition of a material is very important in determining the level of wear a material will sustain. For instance, high carbon steels for instance, or even tungsten carbide possess mettallic attributes of greater hardness which results in greater resistance due to abrasive forces. Coatings also improve resistance to wear such as titanium and chromium coatings which add a layer of tougher, more resistant surface.

Surface Hardness

The greater the surface of a material, the greater its capability to resist wear. It is determined by tests such as the Vickers or Rockwell hardness test. Materials that are constantly being subjected to frictional forces are likely to experience abrasive wear, however, materials with higher valores of hardness would exhibit less abrasive wear due to the sustained of rotation.

Contact Pressure and Load

Interaction between materials that leads to applying higher loads or contact pressure increases the wear rate. Materials that operate under a lot of industrial pressure need to be designed carefully because they are expected to undergo a lot of force without initiating destabilization.

Environmental Factors

The surrounding environment greatly influences the wear resistance. Abrasive particles and chemical exposure, along with temperature changes, can quicken wear. For example, in corrosive settings, oxidation of surface layers will occur, which further diminishes resistance.

Lubrication

The application of effective lubrication greatly reduces the friction occurring between moving parts, in turn, also reducing wear. Common lubricants such as oils and grease preserve the reduction of friction between surfaces by providing a protective layer, increasing their lifetime.

Microstructure of the Material

Microstructure components such as grain size, phase distribution, and porosity all aid in wear mechanism plays a critical role. Most materials with fine-grains contain high wear resistance due to their homogenous structure which more smoothly distributes stress.

Sliding Velocity and Motion Type

Change in position relative to other materials that are spaced parallel can involve either sliding, rolling, or both. All these will alter the rate of wear. Sliding cross-sectional view movement at a higher velocity generates heat which further intensifies wear.

Insights and Data from Google Search

New studies focus on applying cement mills’ wear data at an industrial level. For instance, high chromium alloy studies exhibit wear rates as low as 0.5 grams per ton when compared to uncoated steel which ranges between 2-4 grams per ton. Additionally, a 2022 study regardingthe wear resistance of composite materials revealed that incorporating silicon carbide nanoparticles improved resistance by nearly 30% due to the reinforcement effects of these nanoparticles.

Having knowledge of these factors enables the industry to choose materials and conditions with increased durability while ensuring long-term performance and cost-efficiency.

How to Interpret the Results for Abrasion Resistance of Natural Stones?

To analyze the results for the abrasion resistance of natural stones, evaluate the specified measurements relating to the ability of the material to sustain wear and damage to the surface. Low abrasion values tend to indicate more resistance, which means the stone is more durable under abrasive conditions. Consider these results relative to the expected purpose—stones with high abrasion resistance are preferred for heavy pedestrian traffic while those with lower resistance can be used for ornamental or less trafficked applications. In addition, assess the results in comparison with other known values or standards for slabs of this type of stone to ensure practicality for the intended use. Always take into account the methodology of the test since different methods may produce different results.

What are the Standards for Abrasion Resistance Testing?

Depending on the material and the industry, there are different international standards for abrasion resistance testing. All known international aid in the reliable testing of material durability. Below are some of the key standards:

ASTM C241/C241M – This standard governs the abrasion resistance of natural building stones. It assesses the worn-out stone materials and their durability under controlled conditions for different types of stones to measure their comparative stone durability.

ASTM C1353/C1353M – Tests the abrasion resistance of dimension stone to foot traffic with the use of a rotary platform. It mimics the effect of people walking on the surface of stones used for flooring and paving.

ASTM D4060 (Taber Abraser Test) – This test deals with the organic coating abrasion resistance, plastics, metals and other surfaces of Taber Abraser. It is widely used in diverse industries because it deals with surface coatings and protective materials. The result is given in terms of weight loss or cycles to failure which increases its applicability.

EN 14157 – This European standard describes a method for testing the abrasion resistance of natural stones. It is commonly applied toward meeting EU standards on building materials, particularly concerning paving and flooring stones.

ISO 5470-1 – This standard for elastomers and rubber describes the industrial wear resistance testing for these materials using abrasion wheels. It is most commonly applied in industrial uses where these materials are heavily stressed.

Mohs Hardness Scale – This scale measures the scratch resistance of each mineral and while it is not an abrasion test, it gives a relative indication of abrasion resistance, particularly useful when stones are selected for decorative or industrial use.

Key Data and Insights

A 2023 review of standards concerning abrasion resistance drew attention to the fact that results for a given stone could differ from one testing method to another. For instance:

Taber Abraser Test (ASTM D4060) gives results in milligrams of weight loss, which is typically between 50-200 mg for coatings deemed durable over 1000 cycles, depending on the protective layer.

Usually, in EN 14157, the results are given in terms of the depth of wear in millimeters, which for stones is typically between 0.05 and 1.0 mm wear depth for more durable stones.

While picking the relevant materials, these standards need to be checked for proper comparisons and to confirm adherence to compliance specific to the industry or area.

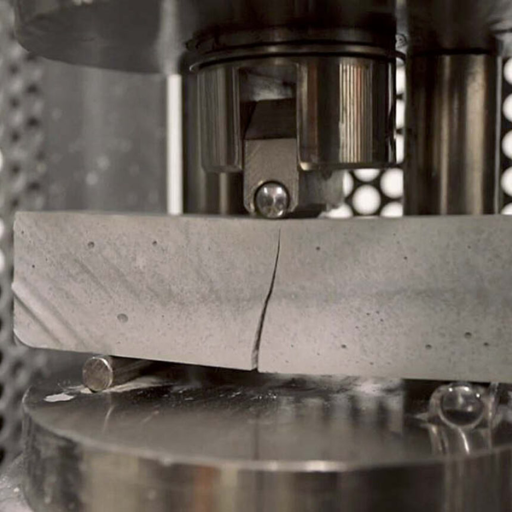

How Does Compressive Strength Relate to Abrasion Results?

Compressive strength and abrasion resistance complement each other, as the two properties form a singular, unified construct, especially when assessing materials’ performance, and durability, maintenance, and repairs. One of the parameters, compressive strength, refers to the maximum load a material can sustain while reducing its dimensions (in MPa). Abrasion resistance indicates the level of surface wear (due to friction or mechanical actions) a given material can withstand.

There is a strong correlation with compressive strength within the ranges of maximum abrasive strength. Materials with high compressive strength tend to be more resistant to abrasion due to their dense cohesive structures. For instance, high-strength concrete (with compressive strengths greater than 40 MPa) displays superior durability under heavy traffic conditions, experiencing lower wear depths in standard abrasion tests. Along with concrete, natural stones such as granite, with compressive strengths ranging between 100 to 250 MPa, can achieve wear depths lower than 0.1 mm during EN 14157 tests, thus making them suitable for frictional pavements or industrial floors.

However, the relationship is not entirely linear, as other factors such as mineral composition, grain size, and the presence of microcracks may greatly influence abrasion performance even if the compressive strength value is high. To illustrate, softer limestone with relatively lower compressive strength can achieve moderate abrasion resistance if its surface is treated or coated appropriately.

One must test the materials with simulators, having them follow guidelines EN 14157 or ASTM C1353. In the context of designing applications where both compressive strength and resistance to abrasion is needed, all factors that can potentially affect the outcome should be noted. With respect to all modern advances with inclusion of additives and coatings which make the strngth and durability to be above average, such materials are now able to be crafted.

What is the Significance of Porosity in Test Outcomes?

Porosity is one of the fundamentals in judging how a material performs concerning its strength, durability, and resistance to the environment. Porosity can be defined as the presence of pores or voids in the material which greatly affects its mechanical and physical properties. For instance, highly porous materials often have lower static compressive strength because the pores reduce the amount of resistance the material offers to external forces. This is especially important in construction materials such as concrete, ceramics, or natural stones, where strength is paramount for structural integrity.

Moreover, it is well known that porosity has a direct effect on the extent of absorbing water and permeability. Increased porosity results in high moisture absorbtion which ultimately lead to freeze-thaw damage, chemical weathering and reduced abrasion resistance. Studies suggest that materials designed with porosities greater than fifteen percent tend to catalyse further disintegration in places subject to wet and dry cycles.

Recent efforts in material science were focused on minimizing the porosity of the material with the aim of improving test results and actual use results. For instance, low porosity engineered materials exhibit better withstanding effects of abrasive forces as well as better durability under severe conditions. Evidence from recent studies shows that reducing porosity by 5% led to an increase in compressive strength of 20%, which indicates the significance of this parameter.

When performing tests like EN 14157 or ASTM C1353, controlling and measuring porosity as a variable is vital for achieving accurate and valid results. This understanding enables manufacturers and engineers to tailor their materials for optimal performance in lab evaluations and real-world uses.

Reference Sources

- Technical Report Documentation Page

This report covers several abrasion tests including the Böhme test and may offer some pertinent technical information.

- Research into Concrete Blocks with Waste Glass

This study incorporates the use of the Böhme test and talks about its relevance for material property assessments.

- Potential for Use of Recycled Cathode Ray Tube Glass in Making Concrete Blocks and Paving Flags

This paper emphasizes the Böhme wear resistance test in conjunction with material testing.

Frequently Asked Questions (FAQs)

Q: How can I determine if the böhme abrasion tester machine is functioning correctly?

A: To ensure the böhme abrasion tester machine is working correctly, perform a calibration check using a material with known abrasion resistance values. Follow the standard test method outlined in EN 14157 or ASTM guidelines to verify accuracy.

Q: What is the böhme abrasion test apparatus used for?

A: The böhme abrasion test apparatus is used to measure the abrasion resistance of natural stones, such as limestone and sandstone. It helps assess the wear resistance by simulating real-life conditions where the material may be subject to abrasive forces.

Q: How do you conduct an abrasion resistance test using the böhme method?

A: Conducting an abrasion resistance test using the böhme method involves placing a stone sample on the böhme abrasion tester machine. The test method includes applying abrasive material under a set pressure and measuring the wear in mm after a specific number of cycles. The test results provide the abrasion resistance value.

Q: Why is it important to test the abrasion resistance of natural stones?

A: Testing the abrasion resistance of natural stones is crucial for construction material selection. It determines how well materials like dimension stones withstand wear and tear, ensuring their durability and longevity in applications such as pavements and buildings.

Q: What factors can affect the abrasion resistance of sandstones?

A: Several factors affect the abrasion resistance of sandstones, including porosity, compressive strength, and mineral composition. Different methods, such as the method for abrasion resistance determination, can be used to assess these properties accurately.

Q: How does simple regression analysis apply to abrasion resistance testing?

A: Simple regression analysis can be used in abrasion resistance testing to analyze the relationship between abrasion resistance values and other properties of materials, such as compressive strength or porosity. This analysis helps predict performance and make informed decisions.

Q: What are the standard test methods for assessing wear resistance?

A: Standard test methods for assessing wear resistance include EN 14157 and ASTM guidelines. These methods outline procedures for conducting abrasion tests, such as the böhme test, to ensure consistent and reliable assessment of materials like natural stones.

Q: How can I simulate real-life conditions during an abrasion test?

A: To simulate real-life conditions during an abrasion test, use the böhme abrasion test apparatus to replicate the abrasive forces experienced by materials in practical applications. Adjust the test parameters to reflect the specific conditions the materials will encounter.

Q: What role do yavuz et al and karaca et al play in the study of abrasion resistance?

A: Yavuz et al and Karaca et al are researchers who have contributed to the understanding and assessment of the abrasion resistance of natural stones. Their studies provide valuable insights into the factors affecting wear resistance and the effectiveness of different test methods.