Testing your universal testing machine (UTM) as a part of routine machine maintenance ensures reliability of your results in material testing. These machines play a critical role in determining several mechanical properties of materials and thus, are important for quality control, research, and development of novel products. Regardless, even the top-tier machines may face issues due to lack of calibration, aging, inconsistent machine operations, etc. knowing how an uncalibrated testing machine can lead to extensive errors and monetary loss in a company’s finances, this article will provide you the required actionable knowledge to take steps to ensure precision and accuracy in test results.

What’s a Universal Testing Machine and How Does it Work?

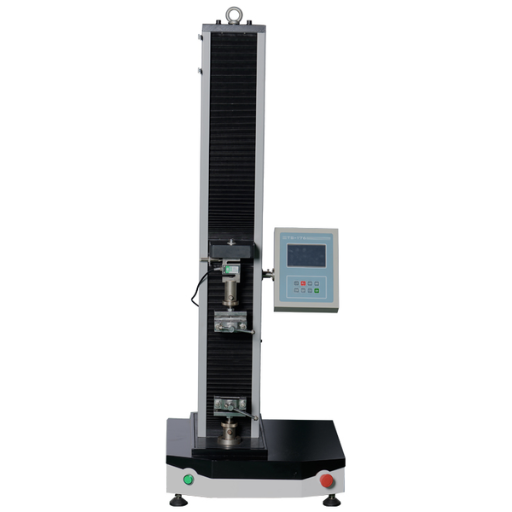

A UTM (Universal Testing Machine) is a mechanical apparatus used for the testing of the physical characteristics of a given material. A UTM performs standardized tensile, compressive, and bending load tests to find out the strength and elasticity values along with some other important material properties. A UTM exerts a force on a specimen and records its response which includes load and displacement information. A UTM consists of two primary parts: a structure or load frame that supports the specimen and applies force to it, and a control measurement system that records the relevant data. Engineers and researchers depend on the results from such tests for material optimization and product development, regulatory compliance, and other complex engineering tasks.

Understanding the Tensile Test Process

Like in any other type of welding test, tensile testing has multiple predefined steps which help in obtaining consistent and accurate results. To start, the operator must insert a sample which has been prepared in advance, usually machined to some standard shape into the grips of the tensile testing equipment. The sample undergoes a uniaxial force that ramps up steadily which the machine applies while the load cell records the force being applied and an extensometer tracks the elongation of the sample.

The test captures important parameters such as ultimate tensile strength (UTS), yield strength, elongation at break, and modulus of elasticity. Test accuracy can be affected by temperature variability or misalignment, so control systems that limit these factors are essential. Automated systems equipped with high precision sensors, real-time data acquisition programs, and automated control systems provide reliability and precision for more advanced accuracy, which enhances the dependability of the engineered materials for critical use.

Components of a Universal Tensile Machine

|

Component |

Description |

Key Parameters |

|---|---|---|

|

Load Frame |

The main structure holding the testing setup. |

Capacity, rigidity, size |

|

Crosshead |

Moves to apply load to the specimen. |

Speed range, precision, positioning |

|

Load Cell |

Measures the force applied to the specimen. |

Accuracy, capacity, sensitivity |

|

Grips and Fixtures |

Hold the specimen during testing. |

Type, size, material compatibility |

|

Actuator |

Drives the crosshead for applying load. |

Stroke length, force control, speed |

|

Extensometer |

Measures strain on the specimen. |

Gauge length, accuracy, range |

|

Controller |

Operates and monitors testing parameters. |

Control mode, interface, data rate |

|

Software |

Manages data and provides analysis tools. |

Compatibility, features, user-friendly |

|

Safety Mechanisms |

Ensures safe machine operation. |

Emergency stop, limit switches |

|

Data Acquisition System |

Captures and processes test data. |

Sampling rate, resolution, storage |

Role of Load Cells in Testing

Instrument and mechanical test systems use load cells as vital components. They act as precise sensors providing measurement of force or load for the test performed. These devices measure force by the applied strain gauge technology where small deformation changes the electrical resistance. Today’s load cells are very sensitive and consistent, often within ±0.03% of the precision claim.

Also, for delicate specimens such as delicate load cells, they can be scaled to millinewtons in weight. For industrial-grade applications, they can also be scaled up to several megatonnes. Moreover, load cells are constructed robustly to withstand harsh environmental factors, including but not limited to, fluctuations in temperature, vibrations, and mechanical fatigue, as well as other wear and tear. This environment fortitude ensures their performance long term. For advanced and real-time data, integrating load cells with sophisticated data acquisition systems provides instant access to high sampling rates and detailed force-displacement curves. All of this data is crucial for material characterization, safety assessments, and performance validation. Using such equipment adds to the scientific accuracy of the testing processes and follows international guidelines such as ASTM and ISO.

How to Perform a Tensile Test on a Universal Testing Machine?

- Prepare the Sample

Verify that the specimen follows the shape and requirements as per the defined standards like ASTM D638 for plastics or ASTM E8/E8M for metals. Look for any defects or irregularities in the sample.

- Set Up the Machine

UTM deems that all parameters necessary for the test must be set. Proper grips and fixtures should be used to fasten the sample in order to measure proper strain.

- Input Test Parameters

As per the written standard, enter necessary values into the control system of the machine such as strain rate, max load, and others.

- Mount the Specimen

Position the test specimen into the grips of the machine ensuring it is aligned accurately to avoid excessive bending, or skewed forces throughout the test process.

- Run the Test

Begin the machine, allowing it to start applying tension to the specimen. The machine will load the specimen continuously and record the required data until the sample breaks.

- Analyze Results

Analyze the data including the stress-strain curve to extract important material properties like tensile strength, yield strength, and elongation at break while verifying standard compliance.

- Report Findings

Bring all measurements and observations, including relevant standards, and compile the test results into a cohesive document that outlines all critical findings in detail.

Setting Up the Tensile Testing Machine

Follow these guidelines to accurately and reliably perform the tensile test procedures:

- Machine Inspection

Before setting up the machine, check for abnormalities or damage to the components such as load cells, grips, and the crosshead movement. Also, check if all components are working accurately within the manufacturer’s specifications. If not, that could lead to inaccuracies during the test.

- Calibration

As for the strain, calibrate load cell and displacement sensors according to governing body standards, like ASTM E4 for force/ load Cell Calibration and ASTM E83 for strain gauge Calibration. Proper compliance with international testing protocols is mandatory for minimal errors during machine calibration in the steps above.

- Sample Preparation and Alignment

Prepare test specimens to the required tolerances and dimensions as per applicable standards, which in the case of metallic materials is ASTM E8. Ensure the specimen is secured and placed within the grips of the machine. Vertically and axially alignment would aid in reducing any bending moments caused during the test to achieve uniform load distribution.

- Selection of Testing Parameters

Set control steps of the machine software such as strain rate, gauge length, and maximum load capacity according to the relevant testing standard. Fitting these parameters together enables the test to be performed in controlled conditions, ensuring meaningful data is fetched as an outcome.

- Safety Checks

Check that all safety functions, like limit switches and emergency stop devices, are working properly. Brief relevant personnel on the testing procedures to minimize potential risks and ensure that the clean room is clear of extraneous items.

After these steps are done, the tensile testing machine can be operated at any time, and its outputs can be used with confidence for the material property analysis.

Understanding Test Parameters for Accurate Results

Tensile testing accuracy should not just focus on the test equipment, but accuracy factors as well. Some of the factors include the rate of load application, size of gauge length, shape of the specimen, and other measured material properties. External factors such as temperature and humidity also greatly affect how a material behaves, thus need to be kept constant. Equipment should also be regularly maintained and calibrated against ASTM or ISO benchmarks to ensure measurement accuracy. Configuring these factors makes the results of the tensile testing reproducible and consistent regardless of the number of trials, and scientifically reliable evaluations of the material as a whole.

How to Calibrate a Universal Testing Machine?

The Universal Testing Machine (UTM) calibration requires a combination of thorough but simple steps in order to guarantee precision:

- Refer to Calibration Standards

Utilize international standards such as ASTM E4 or ISO 7500-1 for guidance during the calibration procedure.

- Inspect the Machine and Components

Examine all external as well as internal components to the UTM device to ensure there is no damage , including but not limited to load cells, grips, and the frame.

- Verify Load Cell Accuracy

Check the accuracy of the load cell against known weight standards using calibrated weight devices such as load calibration units equipped with precision weights or proving rings. The displayed values must match the actual known weights.

- Check and Adjust Alignment

Evaluate the alignment of the machine’s loading platens and grips; correct as required. Misalignment of these components can lead to skewed results of the tests conducted.

- Calibrate Displacement Measurement

Assess the accuracy of crosshead displacement through checking with calibrated gauges or rulers, making necessary adjustments.

- Document Results

Capture all calibration data including discrepancies from the standard and adjustments made. Issue a calibration report to document compliance with standards.

- Schedule Regular Maintenance

Set limits accompanied by the manufacturer or governing standards to maintain long-term accuracy.

Following these procedures guarantees that the UTM will provide accurate and reliable results in all test scenarios involving the equipment.

Importance of Calibration in Testing

Calibration consists of testing processes performed on measurement systems, for example, Universal Testing Machines, to confirm that they are working within certain acceptable limits and indentations. In the absence of sufficiency in calibration, the data collection done risks yielding inaccuracies and misinterpretations, deeming non-compliance to industry standards within the collected data. Precision and repeatable and reproducible results are factors that need focusing especially within normal conditions.

Aerospace industries and medical device manufacturing have acknowledged the effects of non-sufficiency in calibration on deviations that compromise product integrity, overall industry safety, and quality assurance. Organizations like ASTM and ISO stipulate that to align with restricted compliances, there is need to have documented processes of sufficiency calibrations performed. There is also AI-based monitoring that along with digital tools aids in tracking calibration intervals, detecting drift in performance of equipment corroborating to operational strict requirements sufficiency striving for excellence.

Common Calibration Issues and Solutions

- Drift in Equipment Accuracy

Drift is when an instrument’s measurements gradually deviate from accuracy over time because of any wear and tear, environmental factors, or internal component aging. An instrument’s drift can be corrected by following the manufacturer’s recommendations and adhering to industry standards, which suggests preset intervals for recalibration. Now, more sophisticated systems are using AI-powered technologies to monitor drift tendencies and notify users prior to any significant deviation in accuracy.

- Environmental Influences on Calibration

Calibration processes conducted in varying temperatures, humidity, and vibration may not be uniform in precision. For example, in metrology, even slight temperature deviations may yield expansion or contraction of reference materials, affecting results. These concerns may be corrected through climate-controlled environments, vibration isolation tables, or ensuring stable conditions during the calibration procedures.

- Incorrect Reference Standards Usage

Another significant aspect that contributes to cascading inaccuracy is the lack of calibration and untraceable reference standards within the calibration process. Such inaccuracy may be avoided through certified traceable standards from NIST or equivalent organizations which guarantee the measurements are in line with global standards. Handling and usage training of certified standards also needs to be reinforced.

- Lack of Clear Documentation

Lack of thorough documentation for calibration tasks may lead to non-compliance issues and inefficient business operations. Automated logging features within digital tracking systems improve documentation reliability, while blockchain-capable systems provide audit-ready documentation trails.

Businesses can trust their calibrated devices and reap operational and compliance accuracy rewards when these challenges are mitigated with preemptive action.

What are the Common Issues with Testing Equipment?

- Calibration Drift

As a result of the calibration drift phenomenon, testing equipment loses measurement accuracy over a period of time. For any device, regular calibration is a prerequisite to ensure accuracy.

- Wear and Tear

Continuous use can lead to a deterioration in performance, reliability, or an impact in some mechanical or electrical component parts.

- Environmental Factors

Some temperature, humidity, or dust exposure can impact sensitive systems within testing equipment.

- Improper Maintenance

Skipping scheduled maintenance or applying improper cleaning techniques may cause the equipment to malfunction or reduce the lifespan of the device.

- Operator Errors

Using no operator training, as well as inadequate training procedures, leads to either wrong setup and usage which changes measurement results for the worse.

With proper attention to these aspects, organizations will be able to achieve repeatable and reliable accuracy with their testing equipment.

Identifying Mechanical Problems in a UTM

The malfunctioning Mechanical Wear and Alignment Issues as well as Part Failures are the possible causes of a Universal Testing Machine (UTM). These put strain onto the load cell, cross head and gripping mechanisms. Also, load cells that measure forces also have the possibility of malfunctioning. They can be off-calibrated, requiring replacement, which results in expensive repairs. The gripping mechanism is also a source of errors. If a clamp mechanism is deemed faulty, it can lead either to no tightening force being engaged and can alter either the forces required to break parts in the machine. There are different approaches to eliminating errors from such factors. Controlling schedules for the inspection of moving mechanical parts, governance of lubricants used on sliding parts of machines and checking position allowances as well as alignment angles all help to eliminate wear. Using sophisticated instrumentation such as specialized tools that measure vibrations or see the heat patterns of an object can protect machines in sudden failure of test accuracy and reliability.

How to Troubleshoot Tensile Testing Machines

Following a specified system when resolving issues with a tensile testing machine, step-by-step, is important for identifying and fixing problems adequately. Below are some of the most common operational problems and their solutions:

- Irregular Force Measurement

Load cells and the system components can impact machine accuracy when improperly calibrated or damaged. Confirm calibration with standards, and if the machine is uncalibrated, recalibrate it. Also check the load cells for damages and remove masks. Damage replacement should be done if inconsistencies continue.

- Gripping or Slippage Problems

The grips should always maintain a firm grasp on an object to avoid slippage that would bias the results. For the sample provided, the grips should remain clean with no debris to avoid wear. Moreover, offer sample retention through textured grips that improve their grasping efficiency.

- Machine Alignment Errors

Components positioned inappropriately and unevenly could cause permanent damage by creating internal non-isotropic geometric shapes therefore, impacting the precision of the test results adversely. Detailed alignment checks should be performed where the crosshead, load cell, and grips case fixed in a specific stance but rotate around a different axis. Use laser tools or clamps with threaded rods for accurate rotational alignment.

- Software or Data Logging Faults

Errors that occur unprompted while capturing data by the instrument can be software-related and cause loss of information. Data loss can be avoided when the testing software is updated to its latest version, validating system parameters, and configuration would guarantee appropriate working conditions after checking compatibility. If the printer does not print, diagnostics should be run for proper assistance.

- Hydraulic or Motor Malfunctions

Check machines that are hydraulic-based for hydraulic fluids, leaks, or contamination. To avoid losing performance, replace rotary motors driven by hydraulics at their prescribed frequency. For electric motors, look for unusual sounds or vibrations as they may indicate overheated bearings or misalignment. Looking after and maintaining these components is critical.

The proper steps will ensure that accuracy and dependability are preserved for prolonged periods, as tensile testing machines will always be accurate with frequent calibration and maintenance.

When to Seek Professional Help

Standard Operating Procedures (SOP) frameworks tend to recommend those reports which remain unresolved post an extensive troubleshooting routine, such as maintenance workflows, to require subject matter experts with specialized knowledge. For instance, load cell inaccuracy necessitates calibration from certified technicians. Software errors that lie outside the boundaries of simple manual adjustments also warrant reaching out to equipment manufacturers for diagnostics.

Some high-degree failure like broken motors or frames falling out of alignment require subject-matter expertise immediately so that operator safety, along with functionality, isn’t put at risk. Routine examinations by specialists are crucial for compliance with industry regulations such as ASTM, or ISO, especially in critical sectors where precision matters and need sharp bi-annual or annual recalibration and checks. They can also pinpoint concealed damage that could hinder reliability and machine efficiency from a precision engineering perspective.

What Testing Standards are Applicable to Universal Testing Machines?

Universal Testing Machines (UTMs) are usually checked against standards set by ASTM, ISO, and EN. For instance, ASTM E4 outlines Calibration and Verification practices for force-measuring systems, which are aimed at testing accuracy and precision in measurement quantifications. For measurement accuracy, ISO 7500-1 also deals with the calibration and classification of UTMs used for materials testing, establishing rules and requirements for force measurement. Other supporting standards such as ASTM E8 for tensile testing of metals, and ISO 6892 provide test methods which ensures the reliability and reproducibility of the data collected. Compliance to the outlined standards is vital for maintaining compliance and obtaining valid, industry-accepted results.

Understanding ASTM Standards for tensile tests

ASTM standards do not only serve as benchmarks; providing a framework for defining the boundaries within which a material can be reliably tested under tensile stress is equally important. One such benchmark is ASTM E8/E8M which arguably has the most comprehensive E standards dedicated to metallic materials. Like many other standards, ASTM E8 sets forth specimen preparation, dimensional tolerances, and procedural steps associated with the tensile testing which includes stringent control on the strain rate, gripping technique, and post-test calculation of important mechanical properties including the yield strength, ultimate tensile strength, and percent elongation.

Like any other field, the materials industry has made strides towards precision in its environments and equipment. For example, in ASTM E2658 appendices are provided which describe the evaluation of strain measurement systems used with extensometers ensuring high precision accuracy for elongation data. The more rigorously defined standards are complemented by innovations in testing instrumentation, such as with the incorporation of modern digital extensometers and automated testing systems. Compliance with ASTM standards provides uniformity across laboratories which makes reliable evaluations and comparisons possible for materials tested in different conditions and their applicability across multiple scenarios.

ISO Standards: What You Need to Know

The International Organization for Standardization (ISO) is responsible for creating international standards which streamline innovation, safety, efficiency, and quality for various industries. Compliance with these standards ensure that both customer and regulatory expectations are satisfactorily addressed. In the domain of material testing, some iso standards such as ISO 6892 for metallic materials and ISO 527 for plastics set forth rigorous standards for tensile testing and determining the tensile properties of various materials.

Critical changes have been instituted to conform to ISO benchmarks to contemporary industrial needs. Take, for example, the enhancements made to ISO 6892-1 which now allows for control of strain rates, thereby increasing the accuracy and repeatability of tensile test outputs. In the same manner, ISO affirmed the need for accuracy in testing environments, equipped with proper calibration tools that reduce measurable error. These industries range from aerospace, automotive, and construction to electronics, undersetting optimum benchmarks of iso standards.

Any corporation failing to implement these iso benchmarks not only risks their reputation but the business is cut off from other markets as access becomes impossible. With these benchmarks set, now there is no ambiguity in the information and thorough innovation and confidence can be warranted all along the supply chain.

How to Assess the Results of a Tensile Test?

As part of the evaluation of the tensile test results, it is important to review the stress-strain curve which is generated in parallel to carrying out the test. Important parameters to evaluate are:

- Ultimate Tensile Strength (UTS): The stress a material sustains results in failure or fracture under tension which is identified as the peak of the curve.

- Yield Strength: It is the stress at which an engineering material undergoes permanent deformation. It is normally defined using a certain offset approach (for example: 0.2% off).

- Elongation at Break: Indication of ductility is measured by percentage increase in length of the material at fracture point.

- Modulus of Elasticity: It is measured as the slope of the linear part of the curve concerning stiffness of the material.

Results should always be compared to pre-defined benchmarks such as material criteria, industry standards or competitor analysis in order to evaluate competitiveness for performance capabilities.

Interpreting Tensile Strength and Elongation Data

In understanding the values of tensile strength and elongation, one must always remember how these aspects relate to the considered material’s uses and their performance under loads of stresses. The tensile strength gives one a reflection of the amount of force which may safely be applied on the material without failing. This is very important in the case of structures, load bearing members and also designs which are safety critical. This is complemented by elongation at break which indicates ductility which is the ability of a material to plastic deform prior to fracture. A higher elongation value is generally good since not only will the material will become more flexible, but it will be more suitable in terms of a device that undergoes deformation without breakage, for example, in cases of energy absorption, impact resistance and so on.

Studying these properties together allows balancing between strength and ductility to be noted. Take, for example, materials that have very high tensile strength; such materials usually have low elongation which leads to brittleness that can result in failure when subjected to static loads. On the other hand, materials that have high elongation may lack the stiffness required in some engineering tasks. Also, temperature, strain rate, and certain environmental conditions may change the mechanical attributes of the material; these influencing factors also need to be reasoned. Materials can also need to be measured against a set standard or benchmark to ensure that they meet the expected requirements. These example scenarios largely apply to the aerospace, automotive, and construction industries where accurate mechanical performance is needed.

Understanding Deformation and Yield Strength

When subjected to force or stress, material undergoes changes in size or shape, in turn losing its original form. The change can be sub-categorized into two; elastic and plastic deformation. An example of elastic deformation is when stress is removed, and the material returns to its initial form. Plastic is permanent, meaning the material has crossed its elastic limit.

The yield strength or yield point is one of the most important mechanical characteristics of materials. Yield point is known as the yield stress or yield strength of a material is quantitatively measured yield point that indicates the point officially recognized by the International Workshop on Measuring the Yield Point of Materials as the tension step is completed. This yield strength happens on the material when you put stress on it, removing it will cause the material to return back in its original state. The standard means of yield strength determination involves tensile testing where a specimen is subjected to uniaxial loading until rupture or substantial deformation occurs. The yielding point is located at the transition point where elastic deformation disappears and permanent deformation begins. On the aforementioned test, the bottle caps are subjected to failure under controlled strain rates.

Research made in material science has been done in areas such as grains, impurities, temperature, strain hardening, and how they affect yield strength gives us more sophisticated insights. For example, with regard the Hall-Petch relation, smaller grains especially below certain temperatures enhance yield strength whereas higher temperatures tend to lower it because of increased dislocation energy. Industry-grade super computers and modeling alongside physical testing make it possible to estimate and refine yield performance, which stimulate development of high-strength alloys and composites for crucial purposes.

Reference Sources

-

Development, Validation, and Implementation of Universal Testing Machine: The modular design allows for easy upgrades, and the results were validated against standard UTMs.

-

Remanufacturing Aided Upgrading of UTMs through Sustainability Assessment Modeling: Identified components suitable for remanufacturing and upgrading, emphasizing the need for enhanced social and management viability.

-

Micro Universal Testing Machine System for Material Property Measurement: The system is cost-effective, meets UTM standards, and is suitable for microstructure analysis.

Frequently Asked Questions (FAQs)

Q: How can I determine if my universal testing machine is suitable for compression tests?

A: To check if your universal testing machine is suitable for compression tests, verify that it is equipped with appropriate compression fixtures and a load cell that can handle the expected forces. Additionally, consult the machine’s specifications to ensure it meets the requirements for testing the specific materials you will be using.

Q: What maintenance should be performed on a hydraulic universal testing machine?

A: Regular maintenance on a hydraulic universal testing machine should include checking hydraulic fluid levels, inspecting seals and hoses for leaks, and ensuring that all moving parts are lubricated. It’s also essential to calibrate the machine periodically to maintain accuracy in tension and compression tests.

Q: How do I perform adhesion testing using a universal testing machine?

A: Adhesion testing can be performed using a universal testing machine by applying a specific test method for tensile properties. Prepare the sample according to ASTM D412 standards, mount it in the tester, and gradually apply tension until failure occurs. The results will indicate the adhesion strength of the materials.

Q: What is the role of extensometers in material testing?

A: Extensometers are used in material testing to measure the elongation and tensile properties of a sample during a tension test. They provide precise measurements of strain, helping to analyze the material’s behavior under load, which is crucial for understanding its mechanical properties.

Q: Can a universal testing machine be used for testing metals and plastics?

A: Yes, a universal testing machine can be used for testing different materials such as metals and plastics. It is versatile and can perform various tests including tensile, compressive, and flexural tests, making it suitable for a wide range of materials and applications.

Q: What types of tests can be performed with a material testing machine?

A: A material testing machine can perform a variety of tests including tensile tests, compression tests, shear tests, torsion tests, and flexural tests. Each test is designed to assess specific properties of the material under different loading conditions.

Q: How do I know if my tester is calibrated correctly for tensile and compressive tests?

A: To ensure your tester is calibrated correctly, you should perform routine calibration checks using certified calibration weights or standards. Additionally, you can compare the test results with known values from standard test methods to verify accuracy.

Q: What should I do if my universal tensile testing machine shows inconsistent results?

A: If your universal tensile testing machine shows inconsistent results, check for potential issues such as misalignment, worn components, or calibration errors. It may also be beneficial to review the testing procedure and ensure that all environmental factors, such as temperature and humidity, are controlled.

Q: Are there specific test methods I should follow for rubber o-ring testing?

A: Yes, for rubber o-ring testing, it is essential to follow specific test methods such as ASTM D412, which outlines the procedures for testing the tensile and elongation properties of rubber materials. Adhering to these standards ensures reliable and consistent test results.