Selecting the right geotextile test equipment is a critical step for ensuring the quality and performance of geosynthetic materials in various engineering applications. Whether you’re involved in construction, environmental protection, or roadway development, the accuracy and reliability of your testing processes can directly impact the success of your projects. This guide is designed to help you confidently make an informed decision by breaking down key factors such as testing standards, equipment functionality, and specific use cases. By the end of this article, you’ll understand how to align your testing equipment with your operational requirements, ensuring compliance, efficiency, and superior results.

What Is a Geotextile and Why Is Testing Important?

Geotextiles are permeable fabrics used in construction and engineering projects to enhance soil stability, provide erosion control, and improve drainage. They are typically made from synthetic materials such as polyester or polypropylene, designed to perform specific functions like separation, filtration, reinforcement, and protection in infrastructure projects. Testing geotextiles is crucial to ensure they meet performance standards and project-specific requirements. Proper testing verifies durability, strength, permeability, and resistance to environmental factors, allowing engineers to select materials that provide long-term reliability and sustainability.

Understanding Geotextiles and Their Applications

Geotextiles serve as indispensable components in civil engineering, contributing to the structural integrity and efficiency of numerous projects. According to recent data, their applications span a wide range, including road construction, erosion control, drainage systems, landfills, and soil stabilization. By enhancing soil’s natural properties and distributing loads more effectively, geotextiles significantly reduce the risk of structural failures.

Emerging trends emphasize the integration of advanced geotextile materials with smart technologies. For instance, sensors embedded in geotextiles can now aid in monitoring structural conditions, such as stress or moisture levels in real-time, offering critical data for predictive maintenance. This innovation not only optimizes cost-efficiency but also enhances the safety and sustainability of infrastructure projects. With advancements like these, the versatility and utility of geotextiles continue to expand, underscoring their importance in modern engineering solutions.

The Role of Testing in Ensuring Geotextile Quality

Testing plays a crucial role in guaranteeing the performance and reliability of geotextiles. Standards and methodologies have been established to evaluate their critical properties, ensuring they meet required specifications for various applications. Key technical parameters tested include:

- Tensile Strength: This assesses the geotextile’s ability to withstand applied stress without tearing or deforming, typically measured in kN/m.

- Elongation at Break: Evaluates the material’s flexibility and ability to stretch before failure, expressed as a percentage.

- Permeability/Water Flow Rate: Measures the rate of water passing through the geotextile under specific hydraulic conditions, reported in liters per second per square meter (l/s/m²).

- Puncture Resistance: Ensures resistance to penetration by sharp objects, which is critical for applications in harsh environments, commonly assessed in kilonewtons (kN).

- UV Resistance: Determines the geotextile’s durability when exposed to prolonged sunlight, ensuring longevity under outdoor conditions.

- Aperture Size/Opening Size (O90): Relevant for filtration applications, this ensures appropriate particle retention while allowing water flow, typically expressed in microns (µm).

By rigorously testing these parameters, manufacturers and engineers can validate the suitability of geotextiles for specific engineering applications, ensuring optimal functionality, durability, and alignment with project standards.

Common Issues Addressed by Geotextile Testing

From my perspective, geotextile testing addresses several key issues critical to their performance in engineering applications. First, it helps mitigate soil erosion by ensuring proper filtration and drainage properties, which rely on parameters like permeability (k-value) and aperture size (O90). Second, testing assists in evaluating tensile strength and puncture resistance, crucial for withstanding load-bearing and mechanical stresses, often expressed through parameters such as ultimate tensile strength (ASTM D4595) and CBR puncture resistance. Lastly, geotextile testing resolves concerns with product longevity by examining UV resistance, ensuring durability in outdoor installations. Each of these factors allows geotextiles to perform effectively in controlling sediment, reinforcing soils, and managing water flow in construction environments.

How to Choose the Right Test Machine for Geotextiles

Key Considerations for Selecting a Test Machine

Choosing the appropriate test machine for geotextiles requires a systematic evaluation based on the material properties, testing standards, and intended application. Start by identifying the specific test requirements, such as tensile strength, puncture resistance, or permeability, and ensure the machine complies with standardized methods like ASTM or ISO. Assess the load capacity and measurement accuracy of the machine to ensure precise readings, particularly for high-strength geotextiles. Additionally, consider the versatility and modularity of the equipment, as this may allow for multiple test configurations in a single setup, optimizing efficiency. Finally, prioritize durability and ease of operation, factoring in maintenance requirements to ensure long-term reliability in demanding testing environments.

Types of Test Machines for Geotextile Evaluation

The primary types of test machines for geotextile evaluation include tensile testing machines, puncture testing systems, permeability testers, and abrasion resistance instruments.

|

Test Machine Type |

Key Function |

Primary Parameter |

Usage Context |

|---|---|---|---|

|

Tensile Tester |

Measures strength |

Load (kN) |

Tension analysis |

|

Puncture Tester |

Assesses durability |

Force (N) |

Penetration tests |

|

Permeability Tester |

Evaluates flow rate |

Flow (mm/s) |

Drainage studies |

|

Abrasion Tester |

Tests resistance |

Cycles (#) |

Wear performance |

This table encapsulates the critical types of geotextile testing machines, highlighting their functions, parameters for measurement, and typical applications. Each of these machines is designed to address specific geotextile performance metrics essential for ensuring quality and standards compliance.

Factors to Consider When Selecting a Test Machine

- Material Compatibility – Ensure the test machine is compatible with the geotextile material being analyzed, as different textiles may require unique testing methods or equipment specifications.

- Measurement Precision – Select a machine that offers high accuracy and repeatability in measurements to ensure reliable test results and compliance with industry standards.

- Test Parameters – Identify the specific parameters that need to be evaluated (e.g., tensile strength, permeability, abrasion resistance) and confirm that the machine supports these tests.

- Standards Compliance – Verify that the test machine adheres to relevant international and regional testing standards, such as ASTM or ISO, for consistent benchmarking.

- Operational Efficiency – Consider the ease of operation, automation capabilities, and maintenance requirements to reduce downtime and maximize productivity.

Comparing Tensile and Other Testing Methods

Tensile testing, along with compression, bending, shear, hardness, and impact tests, represents the primary mechanical testing methods used to assess material properties and performance.

|

Parameter |

Tensile |

Compression |

Bending |

Shear |

Hardness |

Impact |

|---|---|---|---|---|---|---|

|

Force Type |

Pulling |

Pushing |

Flexing |

Sliding |

Indentation |

Sudden Blow |

|

Main Goal |

Strength |

Resistance |

Flexural |

Shear Res. |

Surface Res. |

Toughness |

|

Key Outcome |

Tensile Str. |

Comp. Str. |

Bend Str. |

Shear Str. |

Hardness Val. |

Energy Abs. |

|

Test Output |

Stress-Strain |

Load-Deform. |

Stress @ Fail |

Shear Force |

Hardness # |

Impact Val. |

|

Use Cases |

Metals, Pol. |

Concrete, Met. |

Beams, Plast. |

Bearings |

Coatings |

Safety Ma. |

What are the Key Geotextile Test Standards and Methods?

Geotextile testing adheres to numerous international standards to ensure precision, reliability, and uniformity in material evaluation. Key standards include ASTM International (e.g., ASTM D4595 for tensile properties of geotextiles), ISO standards (e.g., ISO 10319 for wide-width tensile tests), and EN standards specific to Europe. Common methods involve tensile strength testing, puncture resistance (ASTM D4833), water permeability (ASTM D4491), and filtration characteristics (ISO 12956). These testing protocols assess critical performance parameters such as durability, permeability, and mechanical strength, ensuring geotextiles meet design and regulatory requirements for construction, drainage, and erosion control applications.

Overview of ASTM and ISO Standards

Both ASTM and ISO standards represent globally recognized frameworks for ensuring the quality, safety, and performance of materials, including geotextiles. ASTM (American Society for Testing and Materials) develops standards primarily focused on test methods and specifications for materials used in engineering and construction, such as ASTM D4439 for geosynthetics terminology and ASTM D4595 for tensile testing of geotextiles. On the other hand, ISO (International Organization for Standardization) takes a broader international approach, with standards like ISO 10318 for geosynthetics definitions and ISO 12956 for filtration opening size determination.

These standards not only ensure reliability during product development but also facilitate international trade and compliance with regulatory frameworks. For example, ASTM’s detailed guidelines for mechanical and hydraulic property testing are essential for ensuring product strength under various load conditions, while ISO standards emphasize global interoperability by aligning specifications across countries. Understanding the integration of ASTM and ISO standards allows engineers and designers to adopt best practices, leveraging a harmonized approach to achieve consistency and sustainability in their projects.

Recent advancements have highlighted the increasing convergence of these two organizations in areas such as sustainability metrics and digital transformation of standards, reflecting the growing importance of cohesive global solutions in material engineering.

Importance of Test Standards in Geotextile Testing

Standardized testing in geotextile engineering is critical to ensuring material quality, performance, and suitability for specific applications. Test standards provide a uniform framework for evaluating key properties of geotextiles, such as tensile strength, elongation, permeability, and puncture resistance. For instance, ASTM D4595 is widely used to measure tensile properties, while ASTM D4491 quantifies water permeability. Similarly, static puncture resistance can be assessed using ISO 12236. These parameters are essential for determining a geotextile’s performance under real-world conditions, such as its ability to reinforce soil, provide drainage, or protect against erosion. Adopting harmonized test standards also ensures repeatability, facilitates comparability across manufacturers, and supports international project requirements, ultimately enhancing reliability and efficiency in civil engineering applications.

Specific Test Methods for Different Geotextile Applications

When examining specific test methods for geotextile applications, I focus on their primary functions such as filtration, separation, reinforcement, and erosion control. To evaluate these properties, several standardized tests are employed. For filtration and drainage, permeability testing measures water flow under various hydraulic conditions, ensuring the geotextile can maintain soil stability while allowing water to pass. Tensile strength tests, such as ASTM D4595 or ASTM D5035, are used for reinforcement applications to determine the material’s ability to withstand loads. Abrasion resistance testing and puncture resistance tests, like ASTM D4833, are vital for geotextiles used in erosion control or areas exposed to harsh environmental conditions. These standardized methods ensure rigorous evaluation, aligning with diverse project specifications and performance demands.

How to Evaluate Tensile and Other Strength Properties of Geotextiles

Key Testing Methods for Evaluating Geotextile Strength Properties

When evaluating the tensile strength and other mechanical properties of geotextiles, adherence to standardized testing methods is critical for consistent and reliable results. Specifically, tensile strength can be assessed through ASTM D4595 for wide-width strip tests or ASTM D5035 for strip tests, both aimed at determining the geotextile’s load-bearing capacity under tension. These tests simulate in-field stresses and offer detailed parameters for design considerations.

For abrasion resistance, ASTM D3884 is often utilized to measure material durability when subjected to repetitive surface wear, which is crucial for geotextiles exposed to prolonged environmental stressors. Puncture resistance, tested via ASTM D4833, evaluates a geotextile’s ability to prevent penetration by sharp objects, a vital property for erosion control or subsurface protection applications.

By employing these targeted methods alongside project-specific analysis, engineers can ensure the geotextile performs effectively under anticipated operational conditions.

Understanding Tensile Strength in Geotextiles

Tensile strength in geotextiles is a critical property that determines the material’s ability to resist tension forces without breaking or deforming. This strength is typically measured using standardized test methods like ASTM D4595 or ASTM D5035, which assess the geotextile’s response to uniaxial or biaxial tension. Tensile strength is essential in applications such as soil stabilization, road construction, and reinforcement, where the geotextile must distribute loads and maintain structural integrity under stress.

Factors influencing tensile strength include the polymer type, manufacturing process (woven or nonwoven), fiber orientation, and environmental exposure conditions such as UV radiation and chemical degradation. Woven geotextiles generally exhibit higher tensile strength compared to nonwoven varieties due to their interlaced fiber structure, making them suitable for high-strength applications. Understanding the ultimate tensile strength and the stress-strain behavior of the geotextile allows engineers to select the most appropriate material for specific projects, ensuring long-term performance and reliability in demanding conditions.

Methods to Measure Elongation and Durability

To assess elongation and durability, we rely on standardized testing methods that provide quantifiable and repeatable results. For elongation, tensile tests are performed according to technical standards such as ASTM D4595 or ISO 10319, which measure the maximum strain a geotextile can endure under uniaxial tension. Parameters include maximum elongation (typically reported as a percentage) and tensile strength at break.

For durability, tests focus on resistance to environmental factors such as UV exposure, abrasion, and chemical degradation. UV resistance is typically measured using ASTM D4355, where geotextile samples are exposed to simulated sunlight to track retained tensile strength over time. Abrasion resistance tests, like ASTM D4886, evaluate material integrity under repeated mechanical forces. Additionally, chemical resistance tests determine the ability of the fabric to retain its properties after exposure to varying pH levels or aggressive chemicals.

These methods ensure that the chosen material meets the design requirements and can maintain functionality under anticipated environmental and operational conditions.

Assessing Puncture Resistance and Grab Test Results

Puncture resistance tests, such as ASTM D4833, are essential for determining a material’s ability to withstand penetration by sharp or pointed objects. These tests simulate the mechanical stresses a fabric might experience during handling, installation, or operational use. The results are typically measured in terms of the force required to puncture the material, providing a quantitative assessment of its durability under specific conditions. Materials with high puncture resistance are preferred in applications where mechanical damage is a significant risk.

The Grab Test, standardized by ASTM D5034, evaluates the tensile strength of a fabric by applying a uniaxial force until rupture occurs. This test provides insight into the fabric’s ultimate strength and elongation properties, both critical for ensuring load-bearing capabilities. By complementing puncture resistance with grab test data, engineers obtain a comprehensive understanding of material performance, helping to select fabrics that meet stringent application requirements. Together, these two assessments ensure that the material can endure mechanical forces encountered during its lifecycle, guaranteeing reliability and safety.

What Equipment is Needed for Comprehensive Geotextile Test Analysis?

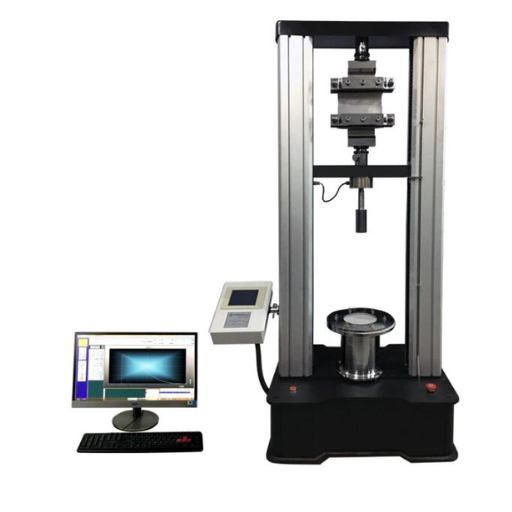

To conduct a comprehensive geotextile test analysis, several pieces of specialized equipment are required. A tensile testing machine is essential for measuring the strength and elongation of the material. A puncture resistance tester evaluates the fabric’s capacity to withstand pointed or sharp objects. For permeability and flow rate assessments, a water permeability testing apparatus is necessary. Additionally, grab test equipment is used to simulate real-world mechanical forces on the geotextile. Other essential tools include a thickness gauge for measuring material dimensions and a wide-width strip testing machine for evaluating tensile properties across larger samples. This combination of equipment ensures precise, reliable measurements for determining material performance under diverse conditions.

Essential Test Equipment for Geotextile Analysis

When conducting geotextile analysis, the correct testing equipment is critical to ensure accurate material performance evaluations. Key apparatuses include tensile testing machines, such as wide-width strip or grab test machines, for assessing strength and elongation properties under mechanical stress. Additionally, burst test devices are utilized to evaluate the material’s resistance to punctures and localized failure under pressure. Permeability testing equipment, like permittivity or transmissivity testers, measures fluid flow through geotextiles, crucial for drainage applications. Thickness gauges are vital for determining material dimensions, as thickness impacts mechanical and hydraulic performance. Finally, abrasion resistance test systems assess durability in conditions simulating long-term wear and tear. Employing this comprehensive array of tools allows for a thorough assessment of a geotextile’s suitability for its intended function.

The Role of Universal Testing Machine in Geotextile Testing

- Tensile Strength Testing: The Universal Testing Machine (UTM) is used to measure the tensile strength of geotextiles, ensuring the material can withstand the mechanical forces it will face during installation and operation.

- Elongation Measurement: UTMs evaluate the elongation properties of geotextiles under stress, which is critical for determining their flexibility and capacity to accommodate ground movements.

- Puncture Resistance Testing: By applying controlled stress, the UTM assesses a geotextile’s resistance to punctures, which is essential for its performance in applications involving sharp or uneven surfaces.

- Seam Strength Evaluation: UTMs measure the strength of seams in sewn geotextile materials, which is necessary to ensure durability and structural integrity when seaming is required.

- Creep Behavior Analysis: Over extended periods, the UTM can simulate long-term loading conditions to analyze the creep behavior of geotextiles, providing insight into their deformation characteristics under constant stress.

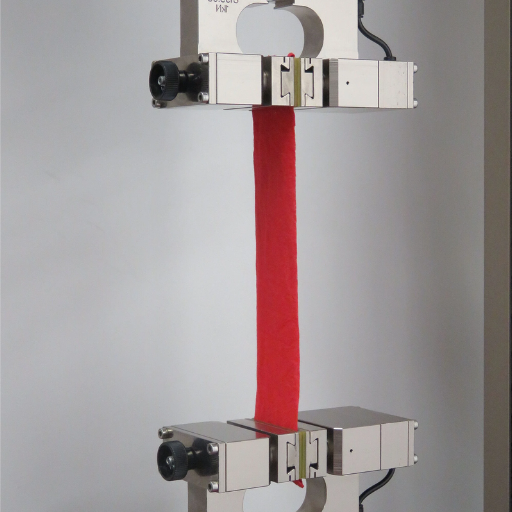

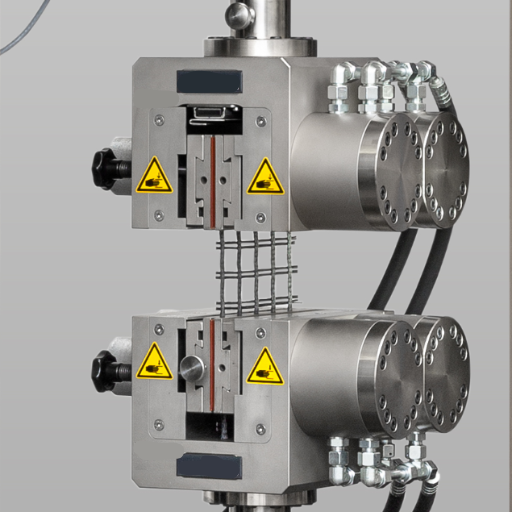

Ensuring Proper Fixture and Grip Usage

To ensure accurate results while testing geotextile materials, it is crucial to select and use the appropriate fixtures and grips. I focus on choosing fixtures designed specifically for geotextile testing, as they prevent slippage or distortion during tensile and puncture tests. Additionally, I verify that the grips firmly secure the material without causing premature damage or altering its properties, which could compromise the data integrity. Regular calibration of fixtures and grips is also part of my process to ensure consistency and reliability across different testing conditions. This attention to detail helps achieve precise and reproducible results in alignment with industry standards.

Reference Sources

-

TestResources – Geotextile Testing: Provides details on universal test machines and tensile testers for geotextiles.

-

Paramount Instruments – Geotextile Testing Instruments: A manufacturer and supplier of geotextile test instruments.

-

TestResources – Geotextile Grab Test Equipment: Discusses ASTM D4632 grab test methods for geotextile fabrics.

-

ASTM D4595 Standard Test Method: Covers tensile property testing standards for geotextiles.

-

Top Test Fixtures in China

Frequently Asked Questions (FAQs)

Q: What factors should I consider when selecting geotextile test equipment?

A: When selecting geotextile test equipment, consider properties such as tensile strength, puncture resistance of geotextiles, and the specific geotextile material you are working with. Additionally, take into account the type of test specimen, whether it involves elastic woven fabrics or nonwoven geotextiles, and the testing needs related to geosynthetics, drainage, and filtration applications.

Q: How do I find the right geotextile tester for my needs?

A: To find the right geotextile tester, evaluate the range of materials you will be testing, such as geomembranes, geogrids, and geocells. Consider the machine that suits your specific requirements, including the ability to conduct tests like strip tensile, trapezoidal tear, and puncture resistance tests.

Q: What types of tests are commonly used to determine the properties of geotextiles?

A: Common tests used to determine the properties of geotextiles include the strip tensile test, trapezoidal tear test, and tests for puncture forces. These tests help assess the tensile strength, tear resistance, and puncture resistance of geotextiles and geosynthetics.

Q: Why is it important to choose the right test specimen size?

A: Choosing the right test specimen size, such as 25.4 mm or 50.8 mm, is crucial for obtaining accurate results. The size affects how the specimen interacts with the testing equipment, ensuring that the measurements reflect the true properties of the geotextile material.

Q: How does the surface of the geotextile affect testing outcomes?

A: The surface of the geotextile can influence testing outcomes, especially in tests involving clamp mechanisms. A smooth surface might require different clamping techniques compared to a textured surface to prevent slippage and ensure consistent results.

Q: Is it possible to use geotextile test equipment on various materials?

A: Almost all geotextile test equipment can be used on geomembranes, geogrids, and even geosynthetic clay liners. Just make sure that the specific material attributes and dimensions of the specimens are align with the equipment.

Q: What is the impact of yarn on geotextile testing?

A: Yarn has a bearing on the overall attributes of geotextiles, and therefore its strength is essential. Used testing equipment may also test yarn to evaluate its tensile strength, especially for geotextiles in restraining components and other performance applications.

Q: How do I ensure my geotextile test equipment meets my testing needs?

A: To ensure your geotextile test equipment meets your testing needs, consider the specific geotechnical applications you are addressing, such as drainage or reinforcement. Look for equipment with the capability to test the relevant properties and handle the required specimen sizes and types.

Q: What is the significance of selecting test equipment used in contact with clay liners?

A: Selecting test equipment used in contact with clay liners is significant because it helps assess the compatibility and effectiveness of geosynthetic clay liners, ensuring they perform well in preventing leakage and enhancing stability in construction projects.