Footwear is more than just a basic necessity; it is a critical component of performance, safety, and comfort in our daily lives. Whether it’s a pair of running shoes designed for high-impact endurance, industrial boots engineered for hazardous work environments, or casual sneakers offering all-day comfort, the importance of rigorous footwear testing cannot be overstated. This article delves into the science and precision behind mastering footwear testing. We will explore the methodologies, technologies, and standards employed to ensure that every shoe not only meets but exceeds safety and performance expectations. By understanding these fundamentals, manufacturers and industry professionals can deliver products that inspire confidence with every step. Prepare to uncover the intricate processes that determine whether footwear is ready for real-world challenges.

What Is Footwear Testing and Why Is It Important?

Footwear testing is a systematic process used to evaluate the safety, durability, comfort, and performance of shoes under various conditions. It ensures that footwear meets established industry standards and regulations, providing consumers with reliable and functional products. This testing is critical to identify potential weaknesses, such as insufficient traction, inadequate material strength, or poor fit, which could lead to discomfort or injury. By addressing these factors, footwear testing upholds product quality, promotes customer satisfaction, and enhances overall safety.

Understanding the Basics of Footwear Testing Methods

Key Footwear Testing Methods

Footwear testing methods are designed to evaluate critical attributes such as durability, comfort, safety, and performance under various conditions. The primary testing processes include mechanical testing, material analysis, and functional assessments. Mechanical testing measures factors such as tensile strength, abrasion resistance, and flexibility to ensure the materials can withstand real-world usage. Material analysis focuses on the chemical composition of the footwear to identify potential hazards, such as harmful substances or environmental toxins. Functional assessments replicate specific movements like walking, running, or pivoting, ensuring the footwear performs as intended during athletic or everyday activities. These methods not only verify compliance with industry standards but also support manufacturers in optimizing product design for enhanced consumer safety and satisfaction.

The Role of Footwear Testing in the Footwear Industry

- Ensuring Material Quality

Rigorous testing evaluates the durability, flexibility, and strength of materials used in footwear production to ensure they meet the required standards and provide reliable performance.

- Compliance with Safety Standards

Footwear testing ensures adherence to industry safety regulations and international compliance requirements, safeguarding consumers from potential hazards.

- Performance Optimization

Tests replicate real-world conditions to evaluate design and functionality, helping manufacturers refine products for better longevity, comfort, and usability.

- Consumer Protection

By identifying harmful chemicals, allergens, or other unsafe materials, testing ensures that footwear is safe for all users, reducing health risks.

- Sustainability Verification

Testing can confirm the eco-friendliness of materials and manufacturing processes, fostering sustainable practices within the industry.

How Testing Ensures Quality and Safety in Footwear Products

As a professional in the footwear industry, I ensure quality and safety by rigorously testing materials, designs, and final products. Material testing evaluates durability, flexibility, and resistance to external factors such as moisture or abrasion. Design testing focuses on biomechanics, ensuring ergonomic fit and comfort while minimizing injury risks. Additionally, we enforce compliance with industry regulations by identifying potentially hazardous chemicals or allergens to protect consumers’ health. Sustainability is another key aspect—our processes verify eco-friendly materials and production methods, supporting a more sustainable future for footwear manufacturing. Through these measures, we deliver products that meet both safety standards and consumer expectations.

How to Conduct Slip Resistance Testing for Footwear

Slip resistance testing for footwear involves a series of precise and standardized procedures to evaluate the shoe’s performance on various surfaces under controlled conditions. The following steps outline the key stages of the process:

- Selection of Testing Standards: Choose the appropriate testing method, such as ASTM F2913 or EN ISO 13287, to ensure compliance with industry requirements.

- Preparation of Samples: Obtain footwear samples representative of production and condition the items as per the specified standards to avoid discrepancies during testing.

- Surface and Lubricant Selection: Utilize standard testing surfaces (e.g., dry, wet, or oily tiles) to replicate realistic conditions. Apply appropriate lubricants, such as water or oil, if specified by the testing method.

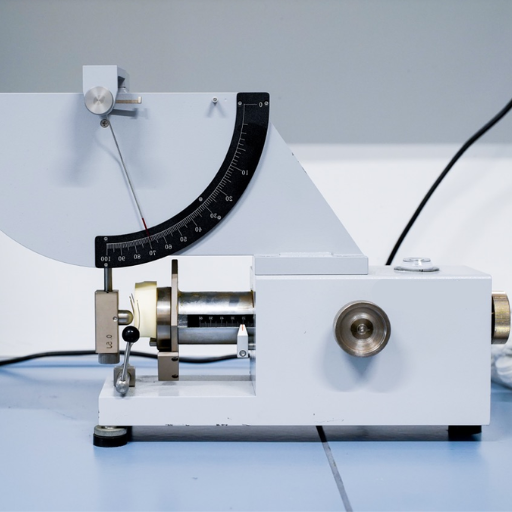

- Testing Equipment Calibration: Ensure the testing apparatus, like the slip resistance tester, is calibrated and operating within the parameters outlined by the standard.

- Measurement of Friction Coefficients: Conduct tests by placing the footwear sole in contact with the testing surface and measuring the dynamic and static coefficients of friction under defined load and motion conditions.

- Data Reporting and Analysis: Record results, including friction coefficients, surface conditions, and test variables. Evaluate results against the defined pass/fail criteria to determine performance adequacy.

By following these steps, manufacturers and testing facilities can accurately assess and document the slip resistance properties of footwear, effectively ensuring safety and compliance.

What is a Resistance Test and How is it Performed?

A resistance test is a systematic procedure designed to measure an object’s ability to withstand specific forces, environmental conditions, or other external stressors. It is widely employed in industries such as manufacturing, construction, and consumer safety to ensure products meet both functional and regulatory standards. Resistance tests can focus on various parameters, including but not limited to mechanical strength, heat resistance, chemical corrosion resistance, and slip resistance, depending on the application.

The process typically involves subjecting the test specimen to well-defined conditions that replicate real-world usage or extreme scenarios. For instance, in a slip resistance test for footwear, the sole material is tested on standardized surfaces under controlled environmental conditions with specified forces and angles to evaluate its frictional properties. Advanced instruments are used to record critical data points, such as the coefficient of friction, wear patterns, and deformation.

Performance results from resistance tests are analyzed against established industry benchmarks or pass/fail criteria derived from regulatory standards. Such tests enable manufacturers to identify areas for product improvement and provide end-users with reliable, safe, and durable solutions. Regular inclusion of updated testing methodologies informed by modern data, such as advancements sourced from global databases and research, ensures that resistance testing remains accurate, effective, and relevant in evolving markets.

Exploring the Coefficient of Friction in Slip Resistance Testing

The coefficient of friction (COF) plays a critical role in evaluating slip resistance, providing quantitative data essential for assessing surface safety. COF is a dimensionless value that quantifies the force required to move one surface over another relative to the force pressing them together. This measurement is categorized into static COF, the resistance before movement begins, and dynamic COF, the resistance during motion.

Slip resistance testing, often performed using standardized protocols such as ASTM (American Society for Testing and Materials) or ISO guidelines, incorporates COF metrics to gauge surface safety under specific conditions. For instance, varying environmental factors, like wet or oily surfaces, significantly impact COF values. Thresholds such as a static COF of 0.5 or higher are commonly cited in safety standards, although requirements may vary by industry and application.

Modern instruments, including tribometers and pendulum testers, are integral to precise COF measurement, offering high repeatability and sensitivity to surface texture and condition. These tools align results with globally recognized benchmarks, allowing stakeholders to ensure compliance and mitigate risks effectively. By accurately interpreting COF data, industries can enhance product design, reduce workplace accidents, and uphold safety in public and commercial spaces.

Choosing the Right Testing Machine for Accurate Results

When selecting a testing machine for accurate COF measurement, I focus on devices that provide precision, reliability, and compliance with industry standards. Key parameters to consider include the force range, resolution, and test speed. For example, a machine should offer a force range suitable for your material type (e.g., 0.1 N to 50 N for most applications), a resolution of at least 0.01 N for detailed analysis, and a controllable test speed from 1 mm/min to 500 mm/min to accommodate various testing scenarios. Additionally, compatibility with ASTM D1894 or ISO 8295 standards ensures data alignment with global requirements. These factors collectively help in achieving consistent and reproducible results tailored to specific operational needs.

What Are the Key Durability Tests for Footwear?

Durability testing for footwear involves a series of standardized procedures designed to evaluate a product’s ability to withstand prolonged usage under different conditions. Key tests include:

- Flex Testing – Assesses the flexibility and resistance of the shoe’s sole and upper materials to repeated bending, simulating walking or running motions.

- Abrasion Resistance Testing – Determines the shoe’s ability to endure friction and wear, primarily focusing on outsole and upper materials.

- Tear Strength Testing – Measures the force required to tear the material, ensuring the shoe retains structural integrity under stress.

- Compression and Impact Testing – Evaluates the midsole and toecap’s performance under compression and impact forces, which is crucial for safety footwear.

- Waterproofing or Hydrolysis Testing – Examines the shoe’s resistance to water penetration and material degradation due to moisture exposure over time.

- Bond Strength Testing – Tests the adhesion between different shoe components, such as the outsole and midsole, to prevent separation during use.

These tests collectively ensure that footwear meets quality standards and performs reliably across diverse conditions.

Understanding the Abrasion Test and Its Impact on Outsoles

The abrasion test is a critical evaluation designed to measure the durability of outsole materials when subjected to friction and wear. This process typically involves standardized testing methods such as the DIN Abrasion or ASTM G105, where the outsole material is subjected to controlled abrasive forces. The test determines weight loss or volume loss, which directly correlates to the material’s resistance to wear.

High abrasion resistance is vital for outsoles, as it ensures long-lasting performance under repeated contact with rough or uneven surfaces. Materials with better abrasion resistance help maintain traction, structural integrity, and overall functionality, reducing the likelihood of premature failure. Test results are essential for manufacturers to refine material formulations and ensure compliance with industry standards, particularly for footwear designed for demanding uses like work boots, sports shoes, or hiking footwear. This makes the abrasion test an indispensable tool in quality assurance and product development processes.

How to Simulate Real-World Conditions in Durability Tests

To accurately simulate real-world conditions in durability tests, I focus on replicating the specific environmental and usage factors that the product will encounter. This involves selecting appropriate testing parameters such as pressure, temperature, moisture, and abrasion that mimic the actual stresses endured during regular use. For example, I might use temperature cycling chambers to simulate extreme heat or cold variations or employ mechanical abrasion testers to replicate repeated surface wear.

Additionally, I incorporate real-life usage scenarios wherever possible, such as conducting field tests to gather data on performance over time. Using industry standards like ASTM or ISO guidelines ensures the simulated conditions remain consistent, reliable, and verifiable. By combining laboratory simulations and real-life testing, I can effectively predict the product’s longevity and functionality under practical conditions. This comprehensive approach ensures dependable results that guide enhancements in material and design quality.

The Importance of Abrasion Resistance in Children’s Footwear

Abrasion resistance is a critical factor when evaluating the quality and durability of children’s footwear. Given the high levels of physical activity children engage in, including running, jumping, and frequent contact with abrasive surfaces, the materials used in their shoes must endure prolonged wear without significant degradation. Ensuring sufficient abrasion resistance helps maintain the structural integrity, comfort, and appearance of the footwear, thereby prolonging its lifespan.

From a technical perspective, abrasion resistance can be measured using standardized testing methods, such as ISO 4649 or ASTM D3884. These tests simulate the wear experienced under actual usage conditions by assessing material loss over defined cycles under specified loads and friction levels. For children’s footwear, the outsole abrasion resistance should ideally display a maximum volume loss value of ≤150 mm³ under testing conditions, ensuring that the material can withstand repeated stress while maintaining functional performance.

Additionally, the upper materials should meet adequate scuff resistance standards to prevent rapid aesthetic deterioration, with tolerable wear parameters defined based on specific fabric or leather grades. By prioritizing and adhering to these technical benchmarks, manufacturers can design footwear that ensures both longevity and protection for young users.

Why is Water Resistance Crucial in Footwear Testing?

Water resistance is a critical parameter in footwear testing because it directly impacts the durability, functionality, and user comfort of the product. Footwear exposed to moisture without adequate resistance can degrade more rapidly, leading to compromised structural integrity and reduced lifespan. Additionally, insufficient water resistance can result in discomfort for the wearer, as moisture penetration affects thermal insulation and increases the likelihood of blisters or infections. Testing for water resistance ensures that the footwear meets standard performance criteria for various environmental conditions, maintaining quality and reliability across diverse usage scenarios.

Methods to Evaluate Water Resistance in Testing of Footwear

To evaluate water resistance in footwear, we employ a combination of standardized laboratory methods and practical testing procedures designed to simulate real-world environmental conditions.

- Static Water Penetration Test

This test involves placing the footwear in water to a specified depth and observing if water penetration occurs after a designated time period. The resistance is determined based on the duration the footwear remains impermeable. Common parameters include immersion depth (e.g., 20-50 mm) and testing period (e.g., 2-4 hours).

- Dynamic Water Resistance Test (Flexing Test)

During this test, footwear is subjected to repeated flexing while partially submerged in water to mimic walking motions in wet conditions. The focus here is on assessing how seams and materials perform under repetitive stress. Typical parameters include a flexing cycle count (e.g., 200,000 cycles) and water immersion depth (e.g., 30 mm).

- Hydrostatic Pressure Test

This method applies water pressure to the material or footwear to evaluate the threshold at which water begins to permeate. It measures the maximum pressure level materials can resist before failure. Parameters may include water pressure increments (e.g., 1-10 psi) and material thickness.

- Spray Test

Specifically designed for assessing upper materials, a spray test evaluates water repellency by exposing footwear to simulated rain conditions. The degree of wetness is graded based on standardized visual scales, such as ISO 4920.

By utilizing these methods and monitoring associated technical parameters, we ensure the footwear achieves optimal water resistance, aligning with both industry standards and user expectations for durability and comfort in adverse conditions.

Impact of Water Resistance on Safety and Performance

Water resistance directly influences both safety and performance by enhancing the usability and reliability of footwear in challenging environments. A high level of water resistance prevents water ingress, which reduces the risk of blisters, skin irritation, or infections caused by prolonged exposure to moisture. From a technical perspective, materials with a water penetration resistance greater than 8000 mm under hydrostatic pressure (measured per ISO 811) are deemed highly effective for waterproofing.

On the performance side, water-resistant footwear ensures durability, maintaining material integrity under repeated wet-dry cycles and reducing degradation caused by swelling, cracking, or chemical wear. Key technical factors include the retention of tensile strength (at least 90% of baseline per ASTM D5034), along with minimal weight increase after submersion tests, typically less than 15% based on standardized conditions. These parameters provide a quantifiable framework for evaluating water resistance and its critical impact on safety and performance.

What Does Laboratory Testing Involve in the Footwear Industry?

Laboratory testing in the footwear industry involves a series of controlled evaluations aimed at assessing material properties, durability, and overall performance under simulated real-world conditions. Key tests include tensile strength testing, abrasion resistance, and water resistance, all conducted following established standards such as ASTM or ISO protocols. Additionally, environmental and chemical exposure tests are performed to ensure longevity and compliance with safety regulations. These procedures provide manufacturers with critical data to improve product design, validate quality, and meet industry-specific requirements.

The Process of Lab Testing and Its Benefits

- Quality Assurance: Lab testing ensures products meet predefined quality standards, reducing the risk of defects and maintaining customer satisfaction.

- Regulatory Compliance: It helps manufacturers adhere to industry and governmental regulations, avoiding potential legal or financial repercussions.

- Safety Validation: Rigorous testing identifies potential hazards, ensuring the safety of end users and reducing liability concerns.

- Performance Optimization: Testing provides critical insights into product performance under various conditions, enabling iterative improvements and robust design.

- Market Competitiveness: Products that undergo and pass comprehensive testing gain a competitive edge by showcasing reliability and durability to consumers and stakeholders.

How Testing of Footwear in Labs Enhances Safety Testing

Laboratory testing of footwear plays a vital role in enhancing the safety and reliability of products by identifying performance metrics and ensuring compliance with safety standards. Key technical parameters involved in testing include:

- Slip Resistance (Coefficient of Friction): Determines the sole’s grip on different surfaces to prevent slip-related injuries. Testing is conducted using standardized testing devices under variable conditions such as wet or oily surfaces.

- Impact Resistance: Measures the footwear’s ability to withstand sudden impact forces to ensure proper protection for toes and other vulnerable areas. This is particularly critical for industrial or safety footwear.

- Abrasion Resistance: Assesses the durability of outsole materials through frictional wear simulations, ensuring longevity under demanding conditions.

- Flex Resistance: Evaluates the integrity of the outsole and upper materials under repetitive bending to ensure they do not crack, tear, or lose structural integrity over time.

- Waterproofing and Permeability: Tests the footwear’s resistance to water penetration and its ability to maintain breathability, protecting the wearer under various environmental conditions.

- Chemical and Thermal Resistance: Ensures the materials used in the footwear can withstand exposure to harmful chemicals or extreme temperatures without degradation, essential for specialized footwear.

By rigorously testing these parameters in controlled laboratory environments, manufacturers can proactively address potential hazards, reduce risks, and deliver safer, more reliable footwear to the market.

The Range of Tests Conducted in Footwear Lab Testing

Footwear lab testing encompasses a diverse range of assessments designed to evaluate the performance, durability, and safety of footwear under various conditions. Key tests include:

- Abrasion Resistance Testing: Measures the ability of outsole and upper materials to withstand wear and friction over time, ensuring long-term durability in different environments.

- Slip Resistance Testing: Determines the coefficient of friction on various surfaces to reduce the risk of slips or falls, critical for workplace and athletic footwear.

- Flex and Fatigue Testing: Assesses the flexibility and endurance of materials when subjected to repeated bending or stress, simulating real-world usage.

- Impact and Compression Testing: Evaluates the structural strength of safety footwear to withstand impacts or heavy loads, ensuring foot protection in hazardous settings.

- Waterproofness Testing: Checks the footwear’s ability to resist water penetration, maintaining comfort and functionality in wet conditions.

- Thermal Insulation and Conductivity Testing: Measures how well the footwear insulates against extreme temperatures or transfers heat, offering comfort in challenging climates.

- Chemical Resistance Testing: Verifies the material’s resilience when exposed to harmful chemicals, ensuring safety in industrial applications.

These precise and methodical tests enable manufacturers to meet international quality standards, comply with regulatory requirements, and enhance consumer satisfaction by delivering high-performing footwear designed for specific purposes.

Reference Sources

-

Intertek – Footwear Testing Services: Offers comprehensive footwear testing, inspection, and quality assurance services.

-

QIMA – Footwear Testing: Provides laboratory testing for various footwear products to ensure compliance and performance standards.

-

SATRA – Footwear Testing, Research, and Consultancy: Specializes in footwear testing with advanced facilities like climate chambers and water resistance testing.

-

MTS Global – Footwear Testing Guide & Requirements: Covers compliance with US and international regulations, along with physical and performance testing.

-

Top Footwear Testing Machine in China

Frequently Asked Questions (FAQs)

Q: What is the importance of performance testing in footwear?

A: Performance testing plays a vital role in ensuring that footwear meets both performance and safety standards. It helps identify any potential safety issues, assesses the durability of footwear materials, and ensures that the shoes provide the necessary support and comfort to the wearer’s feet.

Q: How do footwear manufacturers ensure the safety of safety shoes?

A: Footwear manufacturers conduct various types of testing, including measurement tests and resistance tests, to ensure that safety shoes meet international standards. These tests determine the shoe’s ability to protect against impact, penetration, and other hazards, ensuring the safety of the wearer’s feet.

Q: What types of performance testing are conducted on a range of footwear?

A: Performance testing for a range of footwear includes tests for durability, comfort, slip resistance, and impact protection. Each test assesses specific footwear components, such as the shoe upper, heel, and sole, under standard room conditions to ensure they meet quality control requirements.

Q: How is the shoe size and fit evaluated in footwear testing?

A: Testing includes evaluating the shoe last to ensure the correct shoe size and fit. This involves assessing the design and shape of the shoe to accommodate different foot shapes and sizes, ensuring comfort and preventing any potential safety issues.

Q: What role does temperature and humidity play in footwear testing?

A: Temperature and humidity are crucial factors in footwear testing as they can affect the performance and longevity of footwear materials. Tests are often conducted under controlled conditions to simulate real-life environments and ensure the manufacturability and longevity of the footwear.

Q: Why is the heel an important focus in footwear testing?

A: The heel is a critical component of footwear as it directly impacts the wearer’s posture, balance, and comfort. Testing determines the resistance of the heel to wear and tear, ensuring it provides the necessary support and stability across different types of footwear.

Q: How does a test report contribute to quality control in footwear manufacturing?

A: A test report provides detailed results of all conducted tests, helping manufacturers identify any deficiencies in footwear components. This ensures that any issues are addressed before the footwear reaches consumers, maintaining high standards of quality control.

Q: What international standards are typically used in footwear testing?

A: Footwear testing often adheres to international standards such as ISO and ASTM, which provide guidelines for testing procedures and performance criteria. These standards ensure consistency and reliability in assessing the performance and safety of footwear across different regions.

Q: How does testing ensure the manufacturability and longevity of footwear?

A: Testing evaluates the durability and performance of various footwear materials and components, ensuring they can withstand typical wear and tear. This assessment helps in designing footwear that not only meets performance requirements but also has a longer lifespan, making it more cost-effective for both manufacturers and consumers.