Color fastness is a very important parameter to assess for all types of footwear, especially when evaluating its use and market demand. It is equally important with leather, synthetics or fabrics that colors should not only be bright, but also color transfer/fading resistant. This article aims to describe in detail the measurement of the color fastness of shoes with friction color fastness testing machines. This equipment is invaluable to footwear manufacturers, QC departments, and other experts as it allows testing for color stability against friction. Keep reading for the detailed description, major requirements and recommendations, as well as the analysis for consistency and objectivity in test analysis reliability.

What is Color Fastness in Footwear?

Fastness of color in footwear means the durability of hue with exposure to wear traction, humidity, and light. It shows performance on fading, bleeding, or being transferred with wear and exposure to different conditions. To sustain attractive appearance and functional integrity of the footwear as well as consumer value, upholding stringent standards on fastness is imperative.

Understanding Colour Fastness and Its Importance

As with everything in textile processing, color fastness is influenced by several critical factors that include the type of dye applied on the cloth, the material that is being used and the conditions under which the material will be used. With most synthetic dyes, their fastness varies with the constituents and degrees of bonding in the dye. Moreover, the substrate material is also very important, for example, woven fabrics made of natural fibers such as cotton may have different fastness than those made from polyester. Prolonged exposure to UV radiation, high-stayed temperatures and repeated wetting and drying can greatly accelerate fading or bleeding instead of normal wear and tear.

Color fastness under these factors is measured and classified using advanced testing techniques like ISO or AATCC tests. These tests measure color change from washing, rubbing, perspiration, and light exposure, helping manufacturers maintain high standards of quality. Modifying these factors increases product life, meets industry and consumer demand, and improves trust in the end-user experience.

Types of Color Fastness Tests for Footwear

- Color Fastness to Washing

This test replicates the washing processes footwear undergo over time in order to evaluate their materials’ resistance to fading and bleeding. It includes assessing the material finishing fabrics after a standardized washing cycle to ensure performance criteria. For precise evaluation of washing fastness, advanced techniques like ISO 105-C06 are commonly applied.

- Color Fastness to Rubbing (Crocking)

This test evaluates the dry and wet rubbing of materials used in dyeing or pigmentation. Dry and wet tests AATCC 8 or ISO 105-X12 are all widely accepted to facilitate the analysis. This ensures that products retain their elegance while staining other materials as little as possible.

- Color Fastness to Light

For testing color fastness to light, materials are exposed to simulated sunlight. This test replicates long periods of UV exposure, usually using a controlled light source. ISO 105-B02 is commonly used, giving manufacturers useful data on possible color degradation over time which is critical for outdoor footwear exposed to intense sunlight.

- Color Fastness to Perspiration

Considering that shoes often come in contact with moisture and sweat, this test evaluates shoes for staining and color change under acidic and alkaline perspiration. Standards like ISO 105-E04 provide critical benchmarks to analyze performance, assuring satisfaction and durability in everyday usage.

These footwear tests help manufacturers create eye-pleasing and long-lasting standards-compliant footwear. Maximizing material and dyeing methods provides multi-purpose footwear in diverse consumer-friendly settings.

How Dye Affects Color Fastness

For shoes, the types of dyes used are categorized as reactive, vat, direct, and acid dyes. Each have their differences balancing color fastness and performance. For example, reactive dyes create covalent bonds with fibers which increases resistance to washes, but may be weaker to long-term light exposure. Conversely, vat dyes have exceptional light and wet fastness as they are insoluble and exist in a reduced form which deeply binds to the substrate.

In most cases, a dye’s effectiveness is defined by its chemical affinity to a material, the material’s pH and temperature during dyeing, and the dyeing process itself. In the textile processes, it will be noticed that processing fiber reactive dyes at slightly alkaline pHs (around 10 to 11) yield higher dye sorption, which means better retention of the color through washes. Strength and permanence of coloration using dyes require intertwinning of dye molecules to the fibers, which allows them to form strong bonds that resist various stresses of pulling, rubbing, or chemical washing.

How Does a Friction Color Fastness Tester Work?

Any friction color fastness tester works by testing the resistance of color of a fabric to rubbing abrasion. This apparatus applies a standardized rubbing motion to the fabric either wet or dry, at a constant pressure and speed. The extent of color transfer onto the test fabric, normally a white cotton cloth, is visually assessed as well as quantitatively analyzed through grayscale comparison to determine the level of color fastness. This procedure guarantees uniformity and reliability in testing conditions, thus consistency regarding the fabric’s durability and performance based on the claims facilitated by daily exposure.

Components of a Color Fastness Tester

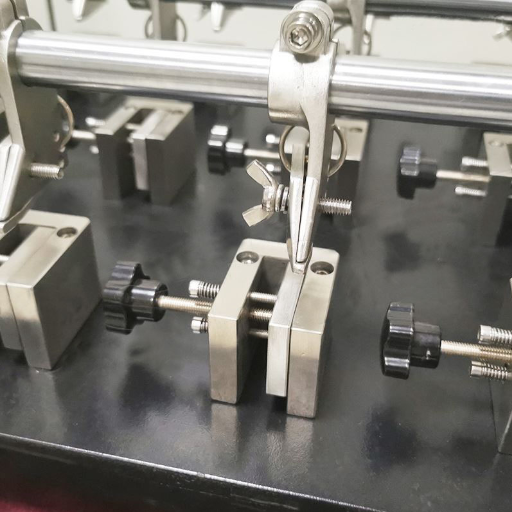

Each of the color fastness testers has several components which serve as the major parts of color fastness tester A and B and are crucial to the charge precision and consistency during the testing process:

- Test Rubbing Head: This Test Rubbing Head is the rubbing head of the color fastness tester. This part of the color fastness tester applies standard pressure or motion to the test fabric. . It is designed in a certain way to achieve desired results and offers both disconnect and wet testing in order to mimic external conditions.

- Clamping Mechanism: This part does not allow movement of the piece of fabric sample and the testing material during the step. This part does not allow sample or specimen tension slack which may lead to stretch of sample fabric and ruin accuracy of results.

- Control System: Today’s testers come with a digital interface or a programmable control system that permits the operator to define certain aspects like testing intervals, pressure, and rubbing cycles. This facilitates uniform and precise repetition of the tests.

- Weighed System: In color fastness testing, the application of controlled pressure is critical. There are specially designed adjustment weights or built-in load systems to create controlled conditions for the tests.

- Test Surface Materials: Specific high-quality cotton cloths and other similar surfaces are used to determine the degree of color transfer. These materials undergo rigid tests during manufacturing to ensure uniformity so that consistent results can be obtained for measuring staining or fading on the test fabric.

- Motion Assembly: Precise repetitive movements are created by advanced testers that include electric motors or automated systems. This enables the simulation of realistic wear patterns which improves the overall reliability of the testing procedure.

- Evaluation Tools: Measurements of staining, fading, or color changes can be physically quantified using calibrated grayscale cards or spectrophotometers, therefore, these instruments alongside measuring devices provide objective and standard inches for sharper precision while assessing.

Integrating these components and advanced technologies into modern color fastness testers enable them to cater to a multitude of testing requirements, thereby ensuring the reliability and durability of textiles engineered for diverse applications.

Operational Steps to Conduct a Fastness Test

- Sample Preparation: To start, cut fabric samples to the dimensions outlined in either ISO or AATCC standards. Appropriately document the sample labeling to ensure traceability throughout the testing stages. Also, confirm that no extraneous materials that could affect the test are present on the fabric.

- Conditioning: Place the samples into an environment with the stipulated temperature and humidity matching standard setting of 70°F (±2°F) and 65% (±4%) relative humidity. Conditioning is as important as sustaining the controlled environment, as in consistency to reproducibility for the testing process.

- Selection of Testing Medium: Prepare the testing medium for testable fastness properties like: washing, light, rubbing, or perspiration. For instance, for wash fastness, create a solution of detergent with the correct pour and pH balance.

- Test Setup: A launderometer serves for wash fastness testing while xenon arc lamps are employed for light fastness evaluation. The equipment needs to be calibrated as well before use to ensure accurate and reliable data collection.

- Test Execution: Execute the test by subjecting the samples to the focus stressor for the determined period under controlled settings. Make sure all monitored variables such as temperature, pressure and time adhere to the stipulated standard range.

- Post-Exposure Evaluation: After the test cycle is done, the samples along with any relevant control fabrics should be removed for both visual and instrumental examination. Use spectrophotometers and similar devices to assess color changes, stains, or fading for objective measurements of the tests.

- Data Recording and Interpretation: All observations and measurements should be recorded per protocol, including all noted discrepancies and calibrations. Evaluation can be done against established standards or bespoke customer criteria.

- Reporting: The compiled report must include the of all data as well as test conditions, equipment used, and any anomalies which were noted. Where applicable, props should be supplied with instruments deemed necessary as proofs to the claims.

Careful adherence to the outlined procedure enables accurate assessment and reproducibility of described findings, and ensures reliability of textiles for their intended use.

What is the Rubbing Color Fastness Test?

Assessing the color fastness of textiles focuses on the defect/issue of color bleeding due to friction rubbing. The color fastness assessment cloth is done for both dry and wet rubbing friction. A defined friction technique is employed while using specialized equipment to determine color rubbing on different types of textiles. After noting the sample of the fabric, interview it, rubbing it with various materials which will then analyze the degree of color change. Based on the assessment, a grade range from G1 up to G5 is analyzed based on a loss of color changing measurement against the Gray scale. According to the evaluation classification system, textile Sta G5 grade is considered to guard high durability and quality under different usage environments.

Overview of the Rubbing Color Fastness Test Method

A rotary rubbing test device or crockmetre does the same tasks as G5, G4, and G3 grade required levels. Standardized and replicable test assessments for measuring color fastness to rubbing should always be done using crockmeter, perspiration tester, washing machine, etc. Preparation of test sample fabrics or garments measuring 50mm x 140mm in the cross-sectional dimension range. The samples undergo structural fixation process. A white test rug is placed onto the sample so that its edges do not extend to the test drying indentation and the sample edge. Further, dependent on predetermined test specs, water is added the rubbing fingers attached to machine arms including dry, moist and wet levels. Stimuli condition increase to test sample rub arm will actively scour fabric in straight movements, rubbing sample cloth for specific number of cycles. As per the needs of the most industry rules, this number rounds up to ten cycles.

For wet rubbing, the white test cloth is soaked with distilled water and wrung out to a specific dampness level to maintain uniformity. The white test cloth is analyzed for color transfer after the rubbing procedure. The transferred color is assessed on a grayscale where Grade 1 denotes poor color fastness, and Grade 5 denotes excellent color fastness. This system of grading is quantitative and ensures objective assessment across various materials.

The textile quality control is further improved because modern changes to the equipment enable precision automation, batch processing, digital measurement, and more. These changes reduce operator variability, increase throughput, and enhance control for high-volume textiles. Moreover, certain variations of the method can provide specific material property tests to ensure the method is relevant to changes in the industry. The data collected from the tests is essential for manufacturers in optimizing the dyeing processes, selecting the right materials, and ensuring internationally accepted standards of quality are upheld.

Different Types of Rubbing Color Fastness Test

|

Type of Test |

Description |

Key Parameters |

|---|---|---|

|

Dry Rubbing Test |

Evaluates color transfer when dry. |

Pressure, strokes, material type |

|

Wet Rubbing Test |

Measures color transfer when wet. |

Pressure, moisture level, strokes |

|

Crockmeter Test |

Simulates abrasion for uniform testing. |

Crock cloth, rubbing cycles, speed |

|

Rotary Rubbing Test |

Uses rotating motion to measure transfer. |

Rotation speed, pressure, fabric type |

|

Uni-Directional Rubbing Test |

Tests in a single rubbing direction. |

Stroke length, pressure, cycles |

|

Multi-Directional Test |

Tests various rubbing directions. |

Angles, pressure, cycle count |

|

Manual Test |

Hand-rubbed for simplicity. |

Operator force, rubbing duration |

Interpreting Results from the Rubbing Color Fastness Tester

Rubbing color fastness test results evaluation involves complex test method data parameter assessments. Before assessing degree of color transfer, the rubbing consistency of cycles performed must also be evaluated. Properties evaluated include transfer of color from the uid to the substrate based on agreement of rubbing uniformity between several cycles, which are called stratified cycles. For quantitative assessment, the color transfer is quantified in a standardized gray scale for staining where five grades exist. Grade 1 indicates high color transfer while grade 5 denotes no color transfer.

The type of test performed (rotary, uni, multi-directional, etc.) also has an impact on the overall balance estimate, since the implemented force is pressure, number of cycles, and direction on the fabric, as impact. Multi-directional yields information about the behavior in terms of wear and tear with the combination of motions while unidirectional, looks at the behavior under stress a single direction path. In the interpretation of manual tests, the test variability has to be factored in, including differences such as the force applied and the time duration of application for consistency.

Higher order test procedures use spectral evaluation in measuring discrete color changes, ΔE values, pre-testing, and post-testing. Since fabrics are expected to meet certain endurance standards under actual working conditions, sustaining industry requirements on color fastness becomes imperative along with seamless handling of cross compliance metrics makes these values critical. The borders provided by industry standards become necessary to control evaluation and determine color fastness.

What Equipment is Used in Color Fastness Testing?

The evaluation of color fastness involves concentration and precision, and so specialized equipment is vital to achieving exact and reproducible outcomes. The most important equipment includes:

- Crockmeter – Assesses the movement of color in and out of a fabric by rubbing both in a dry and wet state.

- Xenon Arc Tester – Used for test lightfastness by imitating sunlight.

- Launderometer – Tests the fabric color change during washing in a controlled environment.

- Perspirometer – Simulates perspiration to study its effects on color.

- Spectrophotometer – Measures colors accurately and determinately, and also measures color differences from after testing to before testing (ΔE values).

These devices are indispensable for complying with the accepted international benchmarks for testing reliability measures and providing impartial evaluation of fabric quality.

Essential Test Equipment for Color Fastness

Investments in testing equipment have yielded more precise and efficient techniques for assessing color fastness. One example would be the digital crock meter for evaluating fabric’s resistance to abrasion or rubbing which does the work automatically. Unlike manual methods, this equipment applies constant pressure and a set movement pattern which reduces operator inconsistency. Another example is the weathering tester which uses modern xenon arc lamps to assess a fabric’s resistance to ultraviolet degradation by enduring prolonged simulated exposure to sunlight and other natural elements.

Spectrophotometers have also been improved by the addition of systems for high resolution imaging, as they are now more capable of discerning even the slightest changes in color. These imaging systems offer comprehensive visual and numerical information which assists in helping a detailed analysis. In addition, the new developments of AI based tools for data analytics in testing laboratories makes it possible to interpret ΔE values in real time, enabling instant delta evaluations along with future estimates, which makes it possible to implement quality control strategies ahead of time. These advancements respond to the market’s demand for greater productivity, better compliance with standards, and enhanced dependability on products.

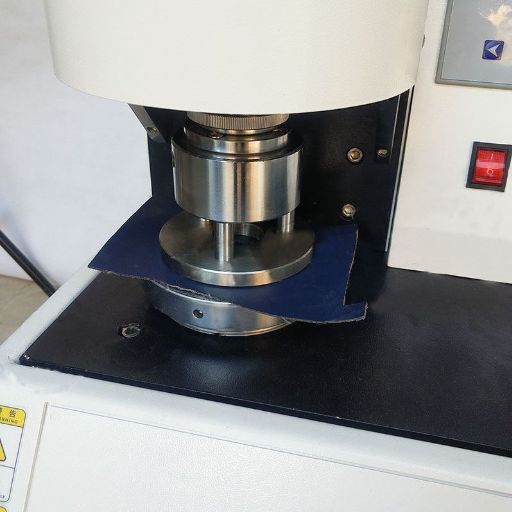

Using a Crockmeter for Testing

In the evaluation of the fabric quality, colorfastness to rubbing is one of the most important parameters and the crockmeter is one of the basic equipment needed to measure this parameter. It measures the dye transfer from the surface of a specimen to a standard test fabric using a defined mechanical rubbing process. The specimen to be tested is mounted on the crockmeter and subjected to a definite number of rubbing cycles either dry or wet, according to an established standard such as ASTM D5053 or ISO 105-X12.

Today’s crockmeters are equipped with sophisticated digital cycle counters, variable rubbing speeds, and automated pressure systems which guarantee exact and repeatable testing conditions. By controlling these factors, the device provides dependable and stable data which accurately forecasts the performance of textiles in practical scenarios. The information acquired from crockmeter evaluations is crucial in controlling product quality and helps manufacturers validate compliance with industry benchmarks to avert discoloration or dye bleeding released during end-use processes. This enhances product durability and reliability while ensuring customer satisfaction.

How to Ensure Accurate Color Fastness Test Results?

Following standardized protocols and stringent regulations concerning testing conditions is necessary for obtaining accurate color fastness test results. Make sure to use high-quality equipment that is calibrated regularly to avoid measurement errors. Make sure the test samples are clean and dry, and correctly represent the batch of the product. Consistency and reliability are critical, so comply with industry standards such as ISO or AATCC test methods. Just like consistency with a controlled environment aids focused testing without temperature, humidity, or light variables, rigorous documenting aids confirm accurate and reproducible results through meticulous reviews.

Factors Affecting Color Fastness Measurements

Along with repeatability, several different pivotal factors affect fastness measurements. The type of dye and its chemical composition is especially influential as different dyes can resist surges of light, washing, or even rubbing differently. Also, differing fibers are pivotal to fastness; natural fibers such as cotton or wool are different than synthetic fibers like polyester due to their absorbency and chemical structure.

Environmental factors are just as important. Changes in temperature, humidity, and Ultraviolet light (UV) exposure can result in discrepancies in colorfastness evaluation. For instance, lightfastness testing of light sensitive dyes exposed to high humidity may yield results faster than under normal conditions. Also, the type of color measurement used, whether automated visual spectrophotometers or manual visual assessment, has an impact on the accuracy of measurements. The precision of these evaluations are also determined by calibration of equipment and following strict test protocols like ISO 105 and AATCC standards.

Best Practices for Conducting a Fastness Test

- Standardize Testing Conditions

To improve reproducibility, temperature, humidity, and lighting for the testing need to be controlled. For example, humidity should comply with the ISO 139 range to avoid biases in test results.

- Calibrate Instruments Regularly

As with all measuring devices, spectrophotometers and light exposure devices, require proper checks against known values, so they can be meticulously recalibrated to ensure concordance with established standards. Such verifications reduce instrument differing.

- Adhere to Established Protocols

A recognized methodology should be adhered to, like AATCC TM61 for wash fastness, which cannot go without mention ISO 105-B02 and its lightfastness counterpart, to guarantee international benchmarking. They lay out detailed steps consigned pertaining to sample, exposure time, and evaluation criteria.

- Select Representative Samples

For instance, fabric samples need to be representative of the intended use of the material including dyed parts and any coatings or finishes that are designed to mask alterations to the material or its performance.

Following these best practices enables industries to obtain high precision and consistency in fastness testing, thus tailoring materials to their quality and performance requirements.

Reference Sources

-

“The Role of Friction in the Measurement of Slipperiness”: Explores friction mechanisms at the shoe-floor interface under different conditions (dry, liquid, solid). Focuses on defining test conditions for accurate slipperiness assessment.

-

“Slip Resistance Characteristics of Footwear Solings Assessed Using the SATRA Friction Tester”: Reviews the SATRA Friction Tester and its application in evaluating footwear soling materials. Discusses the relationship between soling material properties (like hardness) and friction. Highlights the importance of surface roughness and abrasion in slip resistance.

Frequently Asked Questions (FAQs)

Q: What is rub fastness in footwear testing?

A: Rub fastness refers to the ability of a material, such as leather or fabric, to withstand abrasion without significant color transfer when subjected to friction. It is an essential factor in determining the durability and quality of footwear.

Q: How does a rub fastness tester work?

A: A rub fastness tester is an industrial test and measurement equipment used to simulate wear and tear by applying controlled friction to a test piece. It measures the degree of color transfer from the footwear material to a dry or wet white cloth under specified testing conditions.

Q: What are the common conditions used to test rub fastness?

A: Common conditions used to test rub fastness include both dry and wet friction. Testing can be performed with a friction head that reciprocates against the footwear material, usually using a friction cloth to assess the level of color transfer.

Q: What is the significance of testing machine calibration in rub fastness testing?

A: Proper calibration of the testing machine is vital to ensure accurate and reliable results. An uncalibrated abrasion tester may yield inconsistent data, affecting the assessment of the color fastness of the fabric used in footwear.

Q: How is perspiration simulated during rub fastness testing?

A: Perspiration is typically simulated by using a special testing solution that mimics the composition of sweat. This allows for the evaluation of color fastness under wet friction conditions, which is crucial for footwear that may be exposed to moisture.

Q: Can a light fastness tester also be used for rub fastness testing?

A: While a light fastness tester is primarily designed to assess the resistance of materials to fading when exposed to light, it is not typically used for rub fastness testing. Each tester has its specific purpose and testing parameters.

Q: What role does the surface of the friction hammer play in rub fastness testing?

A: The surface of the friction hammer is critical as it creates the abrasion necessary to test the color fastness. The material and texture of the hammer can influence the results, making it important to use the correct specifications for accurate testing.

Q: How is the color fastness of the lining leather after friction assessed?

A: After conducting the friction test, the lining leather is examined for any visible color transfer to the test piece, usually a dry or wet white cloth. This helps determine the degree of color fastness and overall quality of the footwear.

Q: What factors can influence the rub fastness results?

A: Factors that can influence rub fastness results include the type of material being tested, the testing conditions (dry or wet), the pressure applied during testing, and the duration of the friction test. Each of these can affect the degree of color transfer observed.