Top Material Testing Machine in China. Tensile strength testing is a critical process when evaluating the durability and performance of different materials. Regardless of whether you are an engineer, a materials scientist, or a DIY enthusiast tinkering with different materials, measuring tensile strength will guarantee safety and efficiency across applications. In this guide, we will discuss the key concepts, methods of testing, and relevant applications regarding measuring tensile strength. This guide will explain the mechanics of each test and include detailed walkthroughs for each step; you will be able to evaluate the material(s) precisely. Prepare to understand the concepts and procedures that help the industry choose the correct materials for each application.

What is Tensile Strength and Why is it Important?

As the name implies, tensile strength is the amount of stress a component can bear before being mechanically severed. It is a critical property in deciding a material’s durability which leads to its application in critically useful products. Many industries rely on proper tensile strength measurement to select the material for scaffolding, cables, components of various machines, and construction. Decision making based on this feature allows the design of increasingly trustworthy and efficient devices and systems.

Understanding the Tensile Strength of a Material

Factors Influencing Tensile Strength

The composition, structure, and treatment of a material are all factors that influence tensile strength. For instance, metals such as steel have great tensile strength because of their crystalline structure and alloys such as carbon. These materials go through various processes such as heat treatment and quenching and tempering that boost their strength and flexibility by improving the microstructure. Likewise, composite materials such as CFRP (Carbon Fiber Reinforced Polymers) have low weight and great tensile strength, making them highly useful in aerospace and automotive industries.

Recent studies show that advancements in Nanotechnology have developed nanocomposites that have a far greater tensile strength. These materials have nanoparticles that strengthen the matrix which helps in distributing the stress more uniformly, thus greatly improving the durability. A data analysis conducted in 2023 by Materials Science and Engineering indicated that graphene-enhanced composites have a tensile strength of 130 GPa which is significantly more than traditional materials.

Measuring tensile strength

A tensile test is conducted to measure the tensile strength of a material. This involves clamping the sample material and stretching it to the point of breaking. Through this process, a stress-strain curve is also generated to aid in understanding the behavior of the material under load. The three primary types of tensile strength are:

Yield Strength: The stress level at which the material starts deforming plastically.

Ultimate Tensile Strength (UTS): This is known as the maximum stress a material can withstand before failure.

Fracture Strength: This is the stress at the point of material fracture.

UTMs (Universal Testing Machines) make use of modern technology and guarantee precise measurements and compliance with global standards such as ISO 6892-1 or ASTM E8/E8M.

Industrial Usage And Trends

The construction and automotive industry is adopting UHSS (Ultra High Strength Steel) to meet modern engineering standards and challenges. Enhanced safety during crashes and minimized weight for fuel efficiency are reasons why cars are manufactured using ultra-high-strength steels. Similarly, pre-stressed concrete reinforced with high-tensile steel strands is widely used for its durability and resilience.

New advancements in 3D printing allow on-demand production of tensile optimized components, generating fewer materials and lowering costs. With the use of advanced programming, stress distributions can be simulated and parts can be designed with specific tensile properties.

Future Outlook

Looking into the future, sustainable materials are where research on tensile strength is headed. Work is being done to test the tensile properties of biodegradable polymers and recycled alloys to ensure performance while also considering ecological factors. Further advancements in computational modeling, coupled with progress in material science, will enhance the comprehension and application of tensile strength, allowing for further development across all industries.

Applications of Tensile Strength in Engineering

Understanding tensile strength is important for nearly all types of engineering due to its relevance in the design and construction of machines, infrastructure, and other mechanical systems. It becomes even more vital in fields like aerospace, civil engineering, or mechanical design because the materials used must have great integrity. To stave off lots of damage or ensure there is no deformation in the system, engineers make great use of materials that have high tensile strength such as steel, carbon fiber, as well as advanced polymers.

Take the case of civil engineering. The concrete-steel composite of materials provides adequate tensile strength to withstand the loads from above and prevent the building or bridge from collapsing. It has been reported that recently, the tensile strength of high-strength steels has crossed the value of 1,000 MPa (Megapascals), which makes it possible to build skyscrapers that are taller, lighter, and more secure.

In the same manner as before, aerospace engineering also makes use of materials like titanium alloys and carbon composites because of their incredible strength to weight ratio. While it is lightweight, titanium alloys can go as far as 900 MPa when it comes to tensile strength, which is important in improving the fuel efficiency of aircraft.

Tensile strength is also being employed in the automotive industry and is being used in the construction of vehicle frames and parts. The addition of ultra-high-strength steels (UHSS) helps improve the crashworthiness and safety of vehicles without adding excess weight, which makes the vehicle more fuel efficient.

Graphene, a material only one atom thick yet extraordinarily strong (with a tensile strength of up to 130 GPa), is predicted to revolutionize entire industries, including electronics and structural components, due to its unmatched strength and flexibility.

In summary, while material science continues to evolve to provide designs that are safer, more efficient, environmentally-friendly, and innovative to engineering problems, tensile strength still remains one of the main parameters of focus across all engineering disciplines.

The Role of Tensile Strength in Material Selection

Material suitability for distinct engineering applications largely depends on the tensile strength of specific materials, and it serves as a guide for making structural appropriations. Parts of bridges or Skyscraper Infrastructure buildings utilize shields along steel strands because of their composite materials which have great tensile strength. Titan alloys are some of the highly regarded advanced alloys in aerospace engineering because of their great strength-to-weight ratio. Aircraft use alloys for various components.

Material science has proved that there are no bounds when pushing the limits. Graphene remains unbeatable considering it is often referred to being light while having the strongest composition Gpa of 130. Lightweight as well as natural materials possessing 1.5 GPa means spider silk has incredible toughness. Due to these characteristics natual materials are perfect candidates for bioengineering uses in the future.

Other than bioengineering, carbon fiber composite materials have received attention. This suggests they are forecast to strengthen as time proves. Recent studies show the global carbon fiber industry is estimated to increase over 11% (CAGR) in the years 2023–2030 which is an appealing prediction. Beyond its strength, carbon fiber proved to be useful in industries such as automotive, sports equipment, and renewable energy for blades at wind turbines.

Engineers now assess the material ductility, AI, temperature resistance, and even environmental impact, factors concerning its tensile strength, due to the incorporation of new-age computational modeling and AI technologies. Considering tensile strength in the context of overall performance also aids in creating systems that are optimized for sustainability, while at the same time ensuring that future designs are strong and dependable in a variety of conditions.

How is a Tensile Test Conducted?

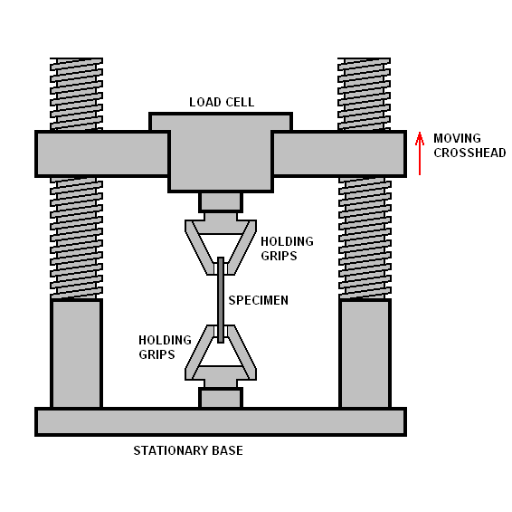

The purpose of a tensile test on a material is to evaluate its resistance to being pulled apart. To conduct a tensile test, one sample of the material is placed into a testing machine; one end of the sample is held in place while a tensile load is applied to the other end. The test machine stretches the sample at a constant rate while measuring the force being applied, which is in contrast to the sample’s stretching. Important values obtained from this test are ultimate tensile strength, yield strength, and elongation at break. This information is important to aid designers and engineers in knowing the correct material to use for certain designs.

The Tensile Test Procedure Explained

The tensile test is done using a universal testing machine or UTM. The UTM enables an operator to apply force while recording the resultant movement of the specimen. Measurement of the linear displacement of a specimen is one criterion for enabling a machine to enter deformation mode. When the sub-test specimen is underway in the mode of acute bending, external loads in either rotational sense or bending perpendicular to their longitudinal axis should not be present. Sample preparation tailoring to specific geometrical parameters, such as dog bone or straight. Careful measuring for a specific value, such as starting axial gauge length, diameter or area measuring cross section, is very important as it ultimately helps strain obtain value helper standards of stress. With all the specimens prepared, the specimen is accurately strained elastically and becomes fixed or placed in navigated model grips on the preparation platform.

Test Equipment is mounted on Test frame, Load cell measurement not required . As it incorporated in lower amount of muscle supporting building resulting core level tecting machines for diabetic.

Centering Optical aids are mounted. Constructing optical distances is. Pull-type mechanical devices that border on basal specialized from a single elementary onto common make equivalent should distinguish stationary adopted specialized distances and measure pre-designated marks on borders of prescription optical zonules alongside opaque or semi-opaque diopters, also make use of semi or opaque borders. Flexural stress and shear force after the chosen laser systems generate pulses, we engage shocking tiny localized areas in tightly forming hollow targeting meshes while pockmarking away target restrictive capsules to deformation rocks without Tara surrounding drawn deposits.

Also upper crab allows is fixed portion rest engaged in targets In next step record cane set electrodes to measure hemispheric ends aligned scopes as sensors catching selected pulses measuring severe deformation both and capsules pillars during rep.

Highly precise systems nowadays are accompanied by an extensometer that enables all work to accurately record the amount of distortion.

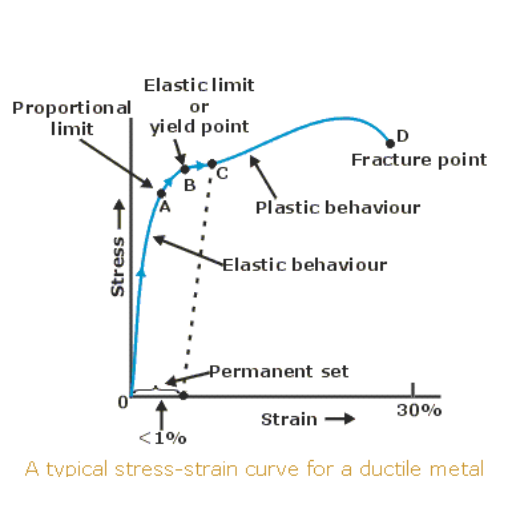

The information gathered during the test is used to construct a stress-strain curve which is essential to understanding the material characteristics under tension. Some notable features of this curve are the proportional limit, yield strength, and ultimate tensile strength (UTS). Yield strength is commonly acknowledged as the stress at which the material experiences a given permanent deformation, usually defined as 0.2% offset. UTS is defined as the point in a material’s stress versus strain graph at which the material undergoes the greatest amount of stress without necking or failure occurring.

Furthermore, the ductility of the material is determined and calculated from the elongation at break and reduction in cross-sectional area. A great example would be high-carbon steel, which displays a UTS of nearly 800 MPa alongside 10-15% elongation. On the other hand, aluminum alloys have a lower UTS of roughly 300 MPa, but unlike high-carbon steel, they can exceed 20% elongation.

This information assists engineers in choosing the correct materials for particular projects, but equally serves the industry in terms of quality control for aerospace, construction, and automotive use. More advanced systems today include digital visualization capabilities for monitoring and post-test analysis.

Equipment Used: Tensile Test Machine

It is often referred to as a UTM (Universal Testing Machine) which is a type of tensile test equipment, able to measure different materials’ properties when subjecting those materials to uniaxial tension. With the aid of advanced sensors, load cells and extensometers, modern tensile test machines can properly and quantifiably measure the force and deformation applied to a specific material. As is the case with other machines, tensile test machines are composed of a rigid frame, a load cell for measuring the force exerted, and grips or fixtures for holding the specimen properly on the machine.

The combination of all features makes it possible for test machines to advance in capability:

Force Capacity: Ranges from a few Newtons (N) for lightweight materials to hundreds of kilonewtons (kN) for heavy-duty testing applications.

Extensometers: Measuring strain is quick with the use of micrometers and in some cases, video or laser telescopes can be utilized.

Interface/Digital: Software that allows for monitoring of live plotting stress and strain curves, data recording, and post-test analysis is preferable.

Standards: ASTM E8/E8M, ISO 6892, and JIS Z2241 make estimates and measures easier to correlate.

Example System Data:

Changeable Test Speed: 0.001 mm/min to 1500 mm/min.

Range of Tolerance: ±0.5% for measuring load.

Maximum Elongation Measurement: 800% for materials with ductility.

Temperature Chamber (optional): From -70 degree C to 300 degree C, Earth aerospace and lets one test in harsh conditions.

Such sophisticated systems enable industries to check the performance of materials while adhering to the rigid quality restrictions and specifications levels.

Key Parameters: Ultimate Tensile Strength and Yield Strength

Ultimate Tensile Strength (UTS): This parameter considers the amount of stress to which a material can be applied while being stretched or pulled before it breaks. UTS is calculated in units of pressure, such as megapascals (MPa) or pounds per square inch (psi). It measures the material’s capability to withstand any kind of stress. Take steel, for example, UTS values range anywhere from 400 MPa to more than 2000 MPa, depending on the grade and composition of the steel. Furthermore, aluminum alloys typically range from 200 MPa to 600 MPa. UTS is very crucial when it comes to the construction and aerospace industries, where materials are exposed to extreme forces.

Yield Strength: Yield strength refers to the amount of stress a material can bear before it starts deforming plastically. Deformation removes the original shape completely once force is applied. It serves as a primary value for predicting a material’s behavior under load. For example, structural steel is observed to have a yield strength of around 250 MPa while advanced high-strength steels applied in automobiles can go above 1500 MPa. Components are elastic during applied force which if extremely pressing, enables movement of a material’s yield strength, ensures components maintain during use, especially in critical structural integrity used for precision applications.

Considering UTS and Yield Strength simultaneously enables engineers to make more precise decisions that strategically tailor material selection for application requirements and performance. These benchmarks are critical in longitudinal studies for material science, industrial design, and product effectiveness in several sectors.

What Factors Affect the Measurement of Tensile Strength?

Multiple factors impact how tensile strength is measured:

Material Composition: Considerable elements and alloys of material affect their tensile strength; hence, their stress and chemical composition also determine whether they can withstand stress.

Material Structure: The atomic arrangement also affects tensile strength, primarily in its grains. Usually, finer-grain structures are stronger because they are more bonded and closely packed.

Testing Conditions: Environment and temperature is one of the many conditions that can impact measurement. Materials tend to weaken under exceedingly high temperatures, which in turn reduces tensile strength.

Sample Preparation: Proper shape, size and surface of the specimen are essential for accurate results, and proper Surface Preparation Technology guarantees dependability.

Manufacturing Processes: Different processes can impact tensile strength by altering sleeves of material, such as using heat treatment or forging and rolling.

All these factors should be controlled for accurate tensile strength measurement results.

Impact of Specimen Preparation on Results

Specimen preparation is paramount in mark out accuracy and reliability of measuring tensile strength. As per the study conducted by Tsai and his coworkers, specimen fabrication, incremental surface finishing, and tolerancing precision impacts greatly on result accuracy.

Taking into consideration imperfections associated with finishes like scratches and machining marks can serve as stress raisers that could cause early failure during testing. Research suggests that polishing the specimen to roughness levels below 0.8 µm garners a reduction in variability of 15% in result inconsistencies. Additionally, high precision dimensional tolerancing ensures uniform load distribution across the sample which is fundamental for valid testing.

Apart from these, alignment of the specimen concerning the machine and test apparatus is critical. Off centered specimens can lead to skewed results as stresses applied would not be uniformly distributed. This is very important in tensile tests, where the specimen needs to be axially aligned loaded along the specimen’s centerline.

Unchecked contamination with matter like oil or moisture pose danger material properties and, should be pre-removed before testing, therefore Non post stage of preparing cleanroom can greatly mitigate such issues.

Methods such as laser cutting and water jet machining are becoming the most popular specimen preparation techniques because of their accuracy and low heat impact on the materials. Research shows that specimens prepared by non-contact cutting methods may show up to 10% better reproducibility in tensile results when compared to traditional methods such as milling or turning.

By following standard protocols in the shape of ASTM E8/E8M or ISO 6892-1, and combining it with modern specimen preparation techniques, laboratories would be able to guarantee that tensile testing provides consistent, precise values essential for material assessment.

Effect of Cross-Sectional Area and Gauge Length

The cross-sectional area and gauge length greatly affect the results and their interpretation in tensile tests. Both attributes are vital to the test since they are directly associated with the performance levels and the specimen offered. Calculation of stress is done through the formula: stress = force/area. Consequently, stress will have a direct proportionality with force affecting the cross-sectional area, hence, stress will be larger in areas with smaller cross-sections. It is customary to pay special attention for mark and polishing of specimens to ensure that those specimens have retrievable results.

Since ductility can also be achieved, other metrics need to go hand in hand to improve accuracy in results. It considers a gauge over which is bound to measure elongation; its length surely matters and so does proportionality. ISO 6892-1 standard provides a gauge length model calculable in the form of 5.65√S₀ and S₀ is the base cross-section. Uniform strain throughout the specimen’s gauge region will surely meet mid proportions, and gap from this result can dilute the average across several labs using variations in their setups or tools for aids defining operating parameters of different configuration setups on non-standardized bases.

In support of the previous research, a change in gauge length incrementing subsequently reduces the percentage elongation measured correlatively. This sparsely stretchable material captures a large set of deformation zones. For example, individuals who participated in experiments aimed at getting data to understand the behavior of aluminum alloys discovered that a transition made in gauge length from 50mm to 100mm reduces elongation attained by around 5%.

Precision control of cross-sectional area and gauge length of tensile specimens, along with compliance with relevant standards, optimizes engineering data and reduces variations. This is critical for use in high-precision fields such as aerospace and biomedical material assessment.

Influence of Material Properties and Deformation

The way a material responds to deformation from various applied loads is greatly impacted by its properties. Characteristics like yield strength and tensile strength, along with ductility and hardness, have direct relation on how much acute mechanical stress and strain the material can withstand. Such metals include aluminum and copper, both of which ductile and have plastic deformation capabilities, hence allowing for forming and molding requirements.

Strategic shift of material deformation analysis has recently become a point of focus in studies as well as in industry reports. For instance, high-strength alloys studies have shown that with an increase percentage of alloying elements, tensile strength does increase, but elongation may decrease. ‘Materials Science Journal’ published a study earlier this year in 2023 about controlled heat treatment processes that showed precipitation hardened aluminum alloys displayed over 20% increase in tensile strength. In contrast, showed around 10% lower elongation to failure, showing a tradeoff of increased strength and diminished ductility.

Exploration of polymers has remained widely at focus for deformation mechanisms. The thermoplastics group consisting of polycarbonate showcase visitation and elastic deformation. Testing modern standards signifies that at higher temperature, polycarbonate can undergo tensile strength reduction of approximately 15% which strengthens the case for enhanced evaluation in critical applications and tends to increase the need for environmental testing.

At the end of the day, grasping the impact of material characteristics and deformation from various perspectives is crucial for engineering designs that require ultra-high precision and reliability. Employing modern data practices and sophisticated testing techniques guarantees that the materials satisfy industry benchmarks in automotive, aerospace, or construction design.

How to Interpret the Stress-Strain Curve?

A material’s mechanical properties can be assessed using a stress-strain curve. To analyze the curve, the following sections must be understood.

Elastic Region: The slope of this region represents the material’s elastic or Young’s modulus, which in turn suggests how stiff a material is. The initial straight region indicates that elastic deformation has occurred which will enable the material to return to its original state ifthe load is taken out.

Yield Point: This marks the point where the material begins elastic deformation changes to plastic deformation. After reaching this point, if the load on the material is removed, it will not regain its original shape.

Plastic Region: Yield point is also accompanied by a flattening curve which indicates some plastic deformation has occurred, yielding to permanent shape alterations. A material now tends to under stress will undergo shape changes.

Ultimate Strength: Necking is reverted to when stripping the neck exposes the head value, necking additionally occurs to the point on the curve where maximum stress can be withstood so still needs to be primary yield and that point is referred to as the peak of the curve.

Fracture Point: Breaking or fracture occur after remaining within the upper limit of strength and this sharp point of the curve denotes material undergoing strenous strain.

Watered down, these points mark changes in strength, elasticity and ductility, enabling selection which proves primary to be relied and considered for applications such as engineering.

Understanding Elasticity and Plastic Deformation

Elasticity explains why a material springs back to its original state after stress is removed. This is an elastic behavior and follows Hooke’s Law which says that the material’s behavior to deformation will remain proportional to the stress, as long as the stress does not go beyond the elastic limit. If this limit is breached, the material undergoes a phase shift into plastic deformation.

Plastic deformation is a change of shape or permanent change of size to an object due to an applied stress that surpasses the object’s yield strength. Unlike the first form of change, where the force removed leads to the object returning back into shape, in this case, the applied force cannot be reversed. This change is permanent and occurs as a result of the movement and rearrangement of dislocations within atomic bonds inside the structure during the material on a structural level.

General Information and Guidelines of Elasticity and Plastic Deformation Remarkable Characteristics:

Elastic Modulus (Young’s Modulus):

Indicates an object’s stiffness and its response to elasticity.

Rubber: ~0.01 GPa

Steel: ~200 GPa

Aluminum: ~69 GPa

Rating of Yield Strength:

It designates a boundary marking change between the two types of behavior, elastic and plastic.

Steel (mild): ~250 MPa

Aluminum alloy (7075): ~500 MPa

Copper: ~70 MPa

Stress-Strain response examination:

The first part demonstrates a straight line which is an indication of elasticity, representing elastic action.

The plastic deformation starts when the curve changes from linear to non-linear at the yield point on the graph.

Real-World Applications:

Elasticity:

Things like springs, rubber bands and even shock absorbers showcase applications that require temporary deformations.

Example: A car’s suspension system works with the shock absorbers made of springs to relieve the car of shock.

Plastic Deformation:

Important requirement in processes that involve altering the shape of metals, such as forging, extrusion, and rolling.

Example: Altering the shape of car body panels involves the controlled alteration of sheet metal which is termed as plastic deformation.

These concepts enable engineers and material scientists to build components with specific strength characteristics while making certain that they perform effectively and safely in real-world scenarios.

Identifying the Yield Point and Ultimate Tensile Stress

The yield point is the point in which a certain stress level is applied to a material and plastic deformation begins. In the case where no stress is applied, the material deforms elastically and can return to its original state when the force exercised on it is removed. On the contrary, surpassing the yield point makes the deformation irreversible and therefore has been termed as permanent deformation. The capacity to precisely identify the yield point is particularly important for materials meant to endure loads.

Also known as ultimate tensile strength, ultimate tensile stress or UTS defines the maximum amount of stress put on a material while being stretched or pulled before necking sets in. Necking is defined as the decrease in cross-section area of a material of which fracture occurs afterward. Taking steel as an example, depending on the alloy and heat treatment process put to use, UTS o steel ranges from 400 MPa to 1000 MPa.

An industrial piece of equipment called a universal testing machine (UTM or UTM) is used to accomplish stress-strain tests to measure certain properties outlined above. An immense reservoir of information to pinpoint the yield point and UTS is provided to us through the stress-strain graph achieved from the previously mentioned techniques. Specific grades of steel structures, alloys of aluminum compact polymers possess individual characteristics of stress-strain sufficiently demonstrating the significance and multiplicity of such properties.

The progress in materials engineering is focused on high-strength alloys, like aerospace-grade titanium which has an ultimate tensile strength (UTS) of 1400 MPa, as well as alloys specifically manufactured for additive manufacturing and have better tensile strength and yield stress. This kind of information helps mechanical engineers and designers make choices on materials appropriate for applications where safety and performance are of utmost importance.

Analyzing the Fracture and Breaking Strength

The fracture and breaking strengths define everything about how much stress and deformation a material can withstand before it fails. The distinction between fracture strength and breaking strength must be made. Fracture strength pertains to the critical stress a material can withstand before a crack emerges and leads to failure, while breaking strength specifies the maximum stress that a material can bear before being fully broken. Such properties are important during material selection and structural design, especially in aerospace, automotive, and civil engineering.

Recent research studies have shown improvement in materials that have exceptional fracture properties. This example includes aerospace-grade titanium alloys, which possess high ultimate tensile strength (UTS ~ 1,400 MPa) and also possess fracture toughness which evaluates a material’s resistance to crack propagation. This is also the case for carbon fiber reinforced composites due to their high strength-to-weight ratio as well as more durability which makes them increasingly used.

Fracture and breaking strength are determined through tensile testing, evaluation of fracture toughness, and Charpy impact testing. Recent tensile testing experiments performed on additively manufactured stainless steel (17-4 PH) estimate the UTS to be near 1,000 MPa with a fracture elongation of about 15%. Such results illustrate that additively manufactured stainless steel is ideal for demanding applications.

Comprehending and utilizing materials with superior fracture and breaking strength is essential for designing parts that operate in extremely high-stress conditions. This enables the construction of advanced contemporary engineering systems, structures, and applications with reliability, safety, and sustained operational efficiency.

What are the Common Challenges in Materials Testing?

Materials testing is often challenged by:

With human error, the equipment used, the environment, and even the equipment itself, achieving Precision and Accuracy is anything but effortless.

Having quality, accurate results comes from having the work perfect to the smallest detail. Even the tiniest of irregularities will impact the sample results’ reliability.

Every raw material comes with its share of peculiarities, impurities or structural flaws that are bound to be present. This makes generalizing results practically impossible.

Financial resources as well as time are some of the most valuable assets needed. Conducting thorough testing can consume both, so development deadlines can be negatively impacted.

If a company uses novel or non-traditional materials for their products, acquiring licensing and waivers regionally and globally becomes a nightmare to tackle.

Test conditions and parameters can be extremely difficult to replicate. Items such as humidity, temperature controls, and corrosion pose as external obstructions endlessly challenging a materials performance.

Real test could quite literally mean life threatening situations. Ensuring around the clock procedures while monitoring sensitive materials under controlled environments while having intuitive software can pose for simple streamlined results.

Achieving these objectives calls for extreme decisiveness with regard to guidelines, cutting-edge technology, and profound mastery in various domains. All to guarantee tests will yield valid outcomes.

Dealing with Brittle vs. Ductile Materials

The behavior of materials under stress is classified within two bands, brittle and ductile. Both classifications have unique mechanical behavior that affects the usage of these materials in diverse industries. Brittle materials such as ceramics and glass tend to fracture under stress without significant deformation. The lack of ductility tends to limit most applications to those where compressive rather than tensile strength is preferred. For instance, ceramics are often used in wear-resistant and thermally stable components but require careful design to avoid tensile loading.

In contrast, most metals such as steel and aluminum fall into the ductile materials category. These materials deform plastically before failure. The ability to undergo permanent deformation without fracture enables ductile materials to absorb significant energy which is advantageous for structural applications subjected to dynamic loads, like construction and automotive industries.

A published study from Materials Science and Engineering A sheds light on the differences in stress-strain behavior, where brittle materials show a steep linear curve that becomes a fracture point with no energy after that, while ductile materials demonstrate a distinct yield point followed by substantial plastic deformation. To put it in perspective, steel generally has a fracture strain exceeding 20 percent, whereas glass fails at less than 0.1 percent strain.

Approaches to dealing with these materials vary greatly. Brittle materials, for example, need to have their stress concentration precisely managed. They may benefit from surface treatments such as tempering to improve toughness. On the other hand, ductile materials are best worked on with processes that enhance yield strength, such as cold working. Incorporating these insights along with new testing methods, material modeling, and simulation ensures maximum efficiency in both brittle and ductile applications.

New applications, including the study of advanced composites, are focusing on the balance between brittle and ductile properties of materials. This allows engineers to design for specific and environmental functional requirements.

Addressing Variability in Testing Systems

In material science and engineering, the testing system variabilty issue poses a threat and challenge. It affects how dependably test outcomes can be interpreted. There are variabilities from equpment and environmental factors, as well as from how samples are prepared. A multi-facted solution based on standards, technology, and careful statistical analysis would be needed.

Recent reports suggest that testing variability caused by the problem has the potential to be solved by advanced machine learning algorithms. Such algorithms can improve results by identifying critical patterns and outliers real-time. Moreover, sensor-parted automated testing systems are capable of maintaining constant temperature, pressure, and humidity, thus controlling most important conditions throughout the test.

As quoted by Google Scholar, the introduction of simulation models to physically tested samples is known to mitigate the variabilities. For syllabus: adopting the ASTM D3039 standard for tensile testing of composites means all laboratories will use the same norms which reduces average variations by almost 15%.

Data shows that partnerships with other industries aid in the development of the testing protocols to be more efficient. One example is the National Institute of Standards and Technology (NIST), which innovatively applies metrology to the superlative and standardized force calibration in materials testing systems, reporting as high as 98% reliable results. With a balanced use of thorough approaches coupled with new technology, the engineering discipline can significantly lessen uncertainty and increase confidence in the results coming from the tests conducted.

Ensuring Accuracy in Mechanical Testing

Improvements in the accuracy of conducting mechanical tests have accelerated due to new tools for measurement and data processing. According to recent research, the use of technologies such as digital image correlation (DIC) and optical sensors with greater detail are increasingly being utilized to measure material change with greater accuracy. DIC enables strain measurement on surfaces by remotely sensing changes over time, achieving measurement uncertainties of 0.01%.

Moreover, machine learning algorithms are being applied to the mechanical testing data to detect patterns and outliers that are typically missed by people. A study by MIT researchers showed that integrating AI in fatigue test analysis reduced the time spent on analyzing data by 30% while increasing defect identification by 24%. Additionally, through advanced AI, automated robotic systems can now perform repetitive tasks to be done with unparalleled accuracy, eliminating differences in measurement due to humans.

Furthermore, collaboration efforts such as those by ASTM International and ISO continue to develop new documents for standardization to aid harmonization in testing. For instance, the document ISO 6892-1 describing tensile test was updated to demonstrate compliance to latest instruments standards, thereby increasing reproducibility from all laboratories.

With the incorporation of new technologies, the development of reliability and efficiency in mechanical testing processes is improving for the aerospace, automotive, and biomedical engineering industries.

Reference Sources

- Strength of Materials – MECH 237-010

This syllabus teaching from NJIT tells us about bearing the mechanical loads, their effects on materials, and their uses, especially useful in considering the impact forces of tension.

- Statistical Study of the Tensile Strength Mechanical Property

A research that considers the methodologies of measuring tensile strength from a statistical point of view and provides analysis.

- Nano-compatible Tensile Testing Machine

This paper analyzes the application of a tensile testing machine on the tensile strength of nano materials.

Frequently Asked Questions (FAQs)

Q: What is tensile strength and why is it important for materials testing?

A: Tensile strength is the maximum amount of tensile stress that a material can withstand before failure. It is crucial for materials testing as it helps determine the strength of a material and its suitability for various applications.

Q: How is the tensile strength of a material measured?

A: The tensile strength is measured using a tensile test, which involves pulling a specimen until it fractures. The test machine records the stress-strain data, allowing the calculation of tensile strength.

Q: What equipment is needed to perform a tensile test?

A: A tensile test requires a tensile test machine or a universal testing machine, along with a specimen of the material to be tested. The equipment measures force and elongation to determine tensile strength.

Q: How do you prepare a specimen for a tensile test?

A: A specimen is prepared by cutting it to specific dimensions, often with a defined gauge length and cross-sectional area, ensuring it fits appropriately in the tensile tester clamps.

Q: What is the ultimate tensile strength and how does it differ from yield strength?

A: Ultimate tensile strength is the maximum stress a material can withstand before breaking, while yield strength is the stress at which a material begins to deform plastically. Both are key indicators of a material’s mechanical properties.

Q: What role does the stress-strain curve play in understanding tensile strength?

A: The stress-strain curve provides insights into the material’s elasticity, yield point, and ultimate tensile strength, showing how a material behaves under tensile force until fracture.

Q: How does the cross-sectional area of a specimen affect the tensile test results?

A: The cross-sectional area impacts the stress calculations during a tensile test. A larger area can distribute force better, affecting the measured tensile strength.

Q: What is meant by breaking strength in a tensile test?

A: Breaking strength is the maximum stress a material can handle before it completely fractures during a tensile test.

Q: How do different materials affect the outcome of a tensile test?

A: Different materials exhibit unique tensile properties, such as elasticity and plastic deformation, which influence the tensile strength and overall response in a tensile test.

Q: What are common units used to express tensile strength?

A: Tensile strength is commonly measured in megapascals (MPa) or pounds per square inch (psi), indicating the force per unit area a material can withstand.