Although the bend test is known as a mechanical operation, it serves as an intricate ‘border’ defining strength and flexibility, or ductility in a material. Construction, or manufacturing and engineering each have a distinct need to understand how a material behaves when force is applied to it, which is critical for the safety, reliability, and performance of structures and machines. In this blog post, I hope to take you with me as I uncover the concepts of the bend test and demonstrate its significance in many industries while revealing the hidden traits of materials that this test exposes. Prepare yourself as we explore a feat measuring a material’s yielding and breaking point, only to discover it’s a measure of resilience, flexibility, and the intelligence guiding decisions to be more informed. As we walk through the layers of this seemingly straightforward testing method, we will reveal its true nature and impact on the future of innovation and creation.

What is a Bend Test and Why is it Important?

A bend test is an impact test type that examines the flexibility, strength, and ductility (if any) of a specimen by flexural loading. A bend test provides information on how much a material can endure deformation before a fracture or complete break occurs. It is critical in assessing factors like suitability for design application, compliance with standards, discovering how a material could fail, and knowing the basic make-up of the material. To maintain safety, reliability, and quality of materials and goods, the construction, manufacturing, and aerospace industries pay particular attention to bend tests.

Understanding the Basics of the Bend Test

Principles Behind Bend Testing

Bend tests provide broad information about a material’s pliability, elasticity, and tensile strength, performed by using forces to bend the material until it breaks. It is usually performed in one of the three following ways:

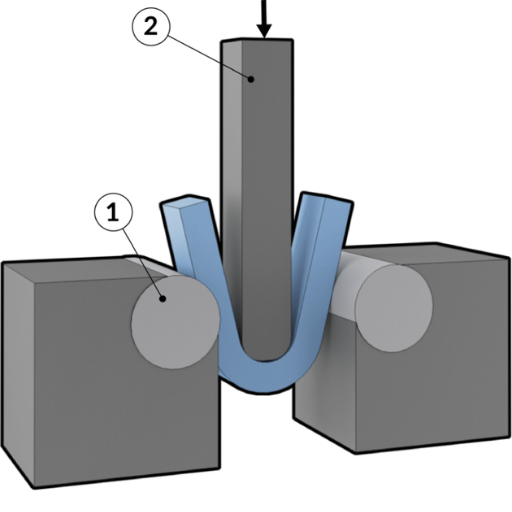

The Three-Point Bend Test measures flexural strength by applying a single load at the middle of a simply supported beam, giving information on how the material behaves under flexural stress.

The four-point bend test effectively reduces the concentration of stress around the center of the specimen by adding another loading point, which makes it useful for testing more brittle materials or larger specimens.

The Reverse Bend Test is the test for ductile materials as it permits copious cycles of bending without the onset of cracks and evaluates the ease of enduring bending cycles.

Key Parameters and Metrics

The performance of a bending test is measured through critical parameters such as the following:

Flexural Strength – Represents the point of stress the material fails to withstand.

Deflection – Represents the angle of arms concerning the vertical in which a flexible bar is pushed.

Elastic Limit – The threshold strain up to which the material will not deform permanently.

Applications and Example Data

Among other things, bend testing indicates material qualities essential to various industries. For example:

Bend testing reinforces bars made of steel used in construction to test the safety and flexibility principles they adhere to.

The aerospace sector employs light but tough composites like carbon fiber reinforced polymers which have undergone extensive reliability testing.

Example Data

About standards such as ASTM E290:

Steel employed in structures shows flexural strength within the range of 50,000 and 100,000 psi (depending on grade).

Carbon fiber composites, increasingly used in aerospace, tend to have flexural strengths greater than 350,000 psi.

Advancements in testing equipment widen the scope of what can be achieved with precise measurement, especially with the use of digital sensors and automated testing machines that assure reliability and repeatability. Moreover, bend testing has developed into an indispensable tool for assuring and enhancing quality and performance in various materials across numerous industries.

Key Objectives of Performing a Bend Test

The primary goals of a bend test are to assess a material’s response to stress and verify its usability within defined limits. Bend testing determines several critical characteristics, such as:

Flexural Strength

This measurement indicates the capacity of a section of a material to bear bending moments without fracturing. For example, aerospace grade carbon fiber composites have flexural strengths in excess of 350,000 psi, which indicate their remarkable durability and strength under stress.

Ductility Assessment

Bend tests facilitate evaluation of the amount of plastic deformation a component can tolerate before failure. Aluminum and steel are materials that characteristically show significant ductility, which is often important for many advanced engineering applications.

Manufacturing Process Quality Control

Routine bend tests are fundamental in industrial processes to ensure some degree of uniformity and steady repeatability of the properties of the materials produced. Failure of some of these tests reveals some defects like inadequate bonding in composites or microcracks in the metals, which can be rectified to maintain the level of the product’s integrity.

Elasticity Measurement

Bend testing determines the maximum deformation that an object can undergo without permanently changing its shape, which reveals how much a material can regain its initial shape when stress is taken out. Materials such as spring steel and rubber have good elasticity which makes them applicable in making springs and seals.

Fracture Toughness Analysis

The test measures the fracture resistance of materials by bending them to the point of failure, which is essential when developing safety-critical items such as bridges, aircraft, and pressure vessels.

Industry Standards Compliance

Bend tests are performed as part of compliance surveys with regulatory organizations such as ASTM and ISO. For instance, ASTM D790 covers flexural strength assessment of plastics, as a constituent of ensuring that materials meet set standards within an industry.

Recent Data Trends and Insights

According to new research, precision testing machines with digital strain gauges can flexibly strengthen measurements with accuracy up to 99.9%, enhancing dependability in aerospace and automotive industries.

The drive towards lighter materials has increased the use of composites like GFRP (Glass Fiber Reinforced Polymer) and CFRP (Carbon Fiber Reinforced Polymer) which all undergo extensive bend testing to validate compliance with designed structural standards.

AI enabled real-time analysis of test data allows instant identification of weak or inconsistent features which reduce material testing time significantly.

These are the objectives, and this is the expected outcome for bend testing in order for the engineering of materials to ensure safety, performance, and innovation in industrial applications.

Applications of Bend Tests in Industry

Bend tests are important in ensuring that the materials in different industries are safe, reliable, and perform adequately under different conditions. These tests are especially important in the automotive, construction, aerospace, and energy industries due to the severe consequences of material failure that pose threats to safety along with potential monetary losses.

1. Automotive Industry

Automotive manufacturers use bend tests extensively in assessing flexural, impact, and tensile properties of vehicle parts like the chassis, suspension, and brake systems. These components are expected to rest under extreme stress while in operation. Advanced steel and aluminum alloys in electric vehicles undergo extensive three point and four point bend tests to ensure compliance with deformation under load standards.

2. Construction Industry

Bend tests also serve as a basis for determining the strength of reinforced concrete, steel rebars, as well as structural composite panels. These tests make certain that all building codes and safety regulations are met. New high-strength polymer reinforcements in concrete have been verified through bend testing to provide a fifteen percent growth in structural load-bearing capacity, as cited by a 2023 industry report.

3. Aerospace Industry

The aerospace sector requires materials that can operate under extremely high pressures and temperatures. Comprehensive bend testing is conducted on carbon composites to check their withstand endurance for space re-entry pressures, structural integrity, and for flight scenarios. For instance, NASA tested advanced carbon composites extensively for the Artemis program’s advanced carbon composites endurance tests.

4. Energy Sector

Renewable energy technologies, like the solar panel mounts or wind turbines, often involve materials under continuously changing physical environmental forces. According to a recent study, conducting bend tests on the turbine blade composites used on the turbines worsened their operational efficiency by 20%, while reducing maintenance costs. Moreover, for the construction of pipelines, bend testing guarantees the material’s integrity when transporting oil, gas, or fluid across long distances under varying pressures.

Application of AI-driven simulation models and high-speed sensors and integrating them with bend tests enhances the precision in exposing weaknesses at the early stages of development. These applications underscore the decisive significance of bend test in shaping testing and proving the limit of materials and innovation.

How to Perform a Bend Test on Ductile Materials?

To carry out a bend test on ductile materials, do the following steps:

Prepare the Sample: This is very critical as the sample must be cut to specific measurements and shapes as per protocol, usually a flat or cylindrical specimen, based on test requirements.

Inspect the Testing Machine: Ensure that the bending machine or bending fixture you intend to use is properly calibrated with the capabilities of exerting controllable force on the sample.

Position the Sample: See that the specimen is positioned and secured appropriately on the support anvils or intended for all specified bending fixtures.

Apply the Force: Using a plunger or a bending tool, use adequate force towards the center of the sample until the desired amount of bending or fracture is reached.

Observer and Record Results: Take note of any cracks, deformations, or fractures present on the specimen. Also, record the amount of bending that is incurred, along with how the material reacts to load.

Always follow relevant industry standards, such as ASTM or ISO, for accurate and reliable results.

Preparing the Test Specimen for Accurate Results

Ensuring dependability and representativeness of results begins with the test specimen preparation. Eliminating variables through adequate specimen preparation enhances the specimen’s reliability. Below are the key steps with additional best practices for precise material testing:

Material Selection: Pick a specimen that adequately reflects the entire batch or the expected performance of the material. Uniformity of composition is critical for metals while composites require verification of consistent fiber distribution or layer alignment.

Dimensional Accuracy: The specimen, as stated in ASTM E290 or ISO 7438, must meet given length, width, and thickness tolerances (defined) at specific values. Claiming to meet standards requires utilizing calipers or micrometers to gauge the verified dimensions.

Surface Preparation: Other than measurement accuracy, surface finish has an impact on the results achieved, especially in bend and fatigue tests. Additionally, sharper edges and irregularities require smoothing of the contour, thus reducing stress risers that cause premature failures.

Moisture Control and Temperature: Factors such as temperature and moisture content can affect test results, particularly with wood, plastic, or composite materials. Prepare the specimen, based on the relevant standards, to ensure the intended use conditions are simulated. For example, recent findings suggest that 50% relative humidity and 23°C (73.4°F) benchmarks serve as standard reference points for many testing conditions.

Notches or Other Particulars (if Relevant): For impact or fracture toughness test, apply standardized notches with a precision notch cutter. It has been recently noted that the dimensions of the notches strongly influence fracture propagation, making precision indispensable.

Preparation for Specimen Cleaning: Oily, dirty, or other extraneous contaminants should be cleaned with appropriate solvents. Other recently developed methods show that ultrasonic cleaning is efficient for producing contamination-free specimens.

Following these guidelines for specimen preparation will greatly increase the dependability and accuracy of test results while meeting industry standards and gaining valuable insights into material performance.

Setting Up the Bend Test Machine

Following the steps outlined below guarantees the accuracy and reproducibility of outputs from the bend test machine.

Inspection of the Machine: The very first step in the process is a basic check of the components of the bend test machine. The rollers, supports, and bend fixtures which are considered critical parts necessitate a thorough check for any wear and tear. All parts that are damaged must be replaced before continuing with the process.

Machine Calibration: The load cell needs to be calibrated so that it meets standards set by either ASTM E290 or ISO 7438. Total Auxiliary Automated Equipment Total’s tools can be used to perform the calibration and guarantee that the bend test machine is working perfectly.

Selection of the Fixture: Confirm that the inline scales suit and work for the material, diameter of the specimen, and all bending radii that come with the preset requirements. The use of three-point and four-point bending setups is common for certain applications requiring more complicated geometry.

Clamping of Specimen: Clamps along with adjustable grips are the go-to tools to guarantee the Test Specimen is aligned horizontally, assumes the center, and does not move from the location onsite after it is positioned on the supports.Adjust Support Spans: Modify the spacing between the supports (span length) as per standard testing protocols or as tailored to project-specific requirements. Usually, this distance, for best results, is a function of the specimen thickness.

Set Testing Parameters:

Loading Rate: Set the machine’s required rate of loading, often given in mm of movement per minute. It is recommended, as per ASTM guidelines, to employ a constant rate of strain to meet standardization.

Bend Angle: For all materials that are to be bent to particular angles, load the target angle into the machine control system.

Verify Alignment: Ensure to confirm the alignment of the specimen alongside the machine parts to avoid tilted bends, imbalances, or misdirected forces throughout the test. These errors may generate significant damage to the specimen or misleading data on its performance.

(Optional) Perform a Trial Run: To ensure smooth functioning of the entire setup, a dry run using a dummy specimen made of the same beatable material facing industry challenges during the test can uncover many unsolvable problems.

Automation technologies, such as altitude monitoring systems that track measuring system movements during experiments, confirm precision tools, and modern alignment approaches, improve setup procedures multidisciplinary in modern robotic warfare with surprising accuracy and rapid precision. Analytics from the defense sector explains the presented technology alongside integrated cameras with data capturing systems, automating the setup and filming setup and still camera systems have cut offered time per setup from an estimated 15 to 25% without compromising issued measure error margin standards.

Executing the Test Method for Reliable Outcomes

Consistent and systematic precision is key to accomplishing objective accuracy and precision during evaluation. Start by confirming that all instruments are calibrated and within the bounds of the equipment’s specification. Calibration guarantees accuracy and limits the chances of imprecision that may affect the outcomes. In industrial and laboratory settings, calibration discrepancies account for approximately 20% of errors within test results, as highlighted in recent studies.

Furthermore, control and consistency must be maintained within the environment where the tests are performed. As is commonly known, temperature, vibration, or humidity are even more sensitive setups that may alter test outcomes. The American Society of Mechanical Engineers (ASME) places a strict 2% environmental conditioning threshold for optimum reliability. Monitoring these parameters through advanced environmental monitoring systems allows timely corrective measures to be taken before exposing test subjects to harmful conditions.

Equally important to other test methods is maintaining data integrity. Harnessing repeatability and human error with automated data acquisition systems lowers’ human error magnitudes. According to recent findings, data recorded by automated devices with advanced artificial intelligence (AI) algorithms tends to be 30% more accurate than manual recording. Besides scrutiny, real-time monitoring allows for flagging discrepancies during tests, which helps in troubleshooting at the earliest point possible.

In conclusion, perform the post-test analysis using integrated software that allows for complete reporting and visualization. MATLAB, analytics on Python, and other specialized tools can automate trend and outlier detection, enhancing result evaluation effortlessly over time. Adopting these strategies maintains optimal testing workflow while guaranteeing results that meet industry benchmarks.

What are the Different Types of Bend Tests?

Each criterion has a set of requirements that involves some kind of evaluation. Evaluation could be long and tedious, but remember, it is what helps us distinguish materials and gauge their reliability. Flexibility and ductility could easily be gauged using types of bend tests. More stress on material leads to flexibility or ductility tests being conducted, which include:

The U-bend test focuses on testing two major features of materials, ductility and resistance to fractures. While the free bend test looks at how easy a piece of material can bend without any helpful supporting forces.

The previous test mentioned does not require timely application of aid. Achieving this makes measuring elongation easy, thus fulfilling multiple requirements of stress evaluation.

Test include data collection from enduring tension. Sorting test while applying stress around helps examine suitability for required applications. It can be said that test are based off assessing different prospective outcomes.

Every singular test makes collecting constructive data all the easier, making health checks simple, authenticating the material in question.

The tests outlined above make deciding the eligibility and reliability of a given material effortless, making test stress evaluation sim… amazing!

Comparing 3-Point Bend and 4-Point Bend Tests

The 3-point and 4-point bend tests are two prevalent methods utilized to assess a material’s mechanical properties, specifically its flexural strength and stiffness. Both methods apply force to the material sample at two supports, but differ in the method of force application as well as force distribution.

3-Point Bend Test

Setup: The test applies force at the center of the specimen which is supported on both ends and only applies force at the middle.

Stress Distribution: All stress that is distributed in the specimen is at maximum registered under the load; this causes an unidirectional wave of concentrated stress which peaks at a part.

Pros: Wider applicability to brittle materials like ceramic and glass, where increased localized stress due to fracture is key.

Simplicity concerning calculation design models, minimal computation.

Cons: Concentration of stress often leads to fracture, causing strength to be overestimated.

4-Point Bend Test

Setup: The two force application points are between the supports, resulting in a wide region devoid of any stress in between the opposite loading points, termed the area of uniform stress.

Stress Distribution: Stress is not focused on a specific, narrow area. Instead is wider, therefore the concentration of stress is lower.

Applications: These materials are capable of withstanding high amounts of unrestricted tension while slowly giving in to fracture. This includes composites and polymers which require thorough analysis of areas devoid of stress.

Advantages:

Better depicts the real response of materials when subjected to bending stress.

Mitigates the effects of concentrated material defects.

Disadvantages:

Calls for greater effort regarding the configuration of the apparatus for testing.

Preparation and analysis are somewhat more laborious.

Key Differences in Performance Evaluation

|

Characteristic |

3-Point Bend Test |

4-Point Bend Test |

|---|---|---|

|

Stress Concentration |

Localized under central load |

Distributed between loading points |

|

Accuracy |

Lower for materials with flaws |

Higher due to uniform stress |

|

Setup Complexity |

Simpler |

More complex |

|

Application Suitability |

Brittle materials |

Ductile and composite materials |

Current Data and Trends

As per the study conducted regarding material testing standards in the year 2023, the 4-point bend test has gained popularity for use with advanced composites due to better simulation of real load distribution. It has also been pointed out that composites tested under 4-point bending differed in failure mode by 15-25% from 3-point tests, which, from a toughness perspective, provides more helpful information regarding fracture development and material degradation. The 3-point test, however, continues to dominate for ceramics and brittle metals because of the simplicity of its application and primary interest in critical region stress concentration determination.

Each method has their corresponding advantages and disadvantages. Because of this, engineers are able to adopt the appropriate testing method that will address the specific needs of the project or materials involved.

Exploring the Guided Bend Test and Its Applications

The industry of fabrication and welding commonly utilizes guided bend tests and assess ductility, soundness, and the quality of welded joints. From a mechanical perspective, this test checks the capability of controlled welds to bear deformation without cracking or fracturing, which is critical in applications where structural integrity is paramount. During the test, a certain section of the welded sample is bent about a predetermined radius and attempts to locate any flaws, lacking strength or insufficient fusion within the weld zone.

Guided bend tests are regularly identified as face bend tests, root bend tests, and side bend tests according to the part being concentrated in the weld. Face bend tests, for example, judge the external surface of the weld, while root bend tests judge the internals of the penetrating weld. Sid bend on the other parts of focus the entire joint and make sure there are no cracks or flaws throughout the cross section. The progress made in techniques for testing materials recently has improved the precision and consistency of the reproducibility of guided bend tests. Modern equipment has sensors and automation that feature modern testing tools, lower human interference, and provide useful information about the angles of bending, the force applied, and any defects present. Industry studies suggest the accuracy of the guided bend tests exceeds eighty-five percent with modern testing devices, making them essential for projects in aerospace, automotive, and construction industries.

In addition, there are other standards that are set for the test executions such as ASTM E190 and ISO 5173, which allows uniformity across different industries and laboratories. Following the set standards, allows engineers and quality assurance specialists to assert the welded elements beyond the stringent safety and performance boundaries.

With the design expectations shaped with real-world performance, the guided bend is the fundamental quality control measure.

Understanding Free Bend and Semi-Guided Bend Tests

Free Bend Test

The free bend test is one of the oldest techniques for assessing a material’s ductility and soundness, usually for metals or welded components. Like all bend tests, it is performed by exerting force on the specimen until it bends, without the aid of guides or fixtures that specify the angle to which the specimen must be bent. The test is performed using only one’s capability to deform the specimen under stress. When compared to other methods, free bend tests are inexpensive and direct, but are limited in flexibility, consistency, and precision because they do not use external frame guides which allows for more controlled bending.

One of the best selling points of free bend tests is that they can be done easily which is perfect for smaller shops and facilities. However, due to the absence of a mechanical framework, uniformity in the conditions of the test becomes difficult, thus leading to differences. This test is straightforward and does not need sophisticated equipment which makes it great for first impressions or evaluations where high precision is not required.

Semi-Guided Bend Test

As for the semi-guided bend tests, they offer more controlled testing conditions. In this case, a bending fixture is used to enhance control and implement proper bending of the sample such that adequate and uniform forces are employed for proper sample deformation. The application of some tools, like forming dies or rollers, makes it possible to manage the bend radius which enhances the comparative relationship of the material properties or the weld quality being tested.

This is very important in cases where reproducibility and precision are pivotal Semi-guided bend tests enable the precision required in replicating test conditions. The bend test method is popular with engineers and technologists in aviation and automotive sectors because of ability to predict performance of these components under real life conditions.

Consider a semi-guided bend test done on Grade 304 stainless steel specimens. The data obtained indicated uniform elongation and tensile strength with a 180-degree bending of a fixed radius. These results demonstrate the importance of compliance testing and guided quality assurance.

Free Bend and Semi-Guided Bend Tests

Both free bend and semi-guided bend tests are useful in their ways but choosing between the two is usually more based on the testing needs. The amount of precision needed, the type of material, and the prevailing standards of the industry on materials all guide the choices made. A Free bend test requires little time compared to a semi-guided bend test which is more detailed and standardized.

Through industry reports and studies, it has been noted that there is a shift toward more automated semi-guided bend test setups. These enable the removal of the operator’s error, improving the objectivity and repeatability of the tests. When engineers understand the intricacies of both methods, they can choose the right method to achieve thorough and precise results in evaluating material performance.

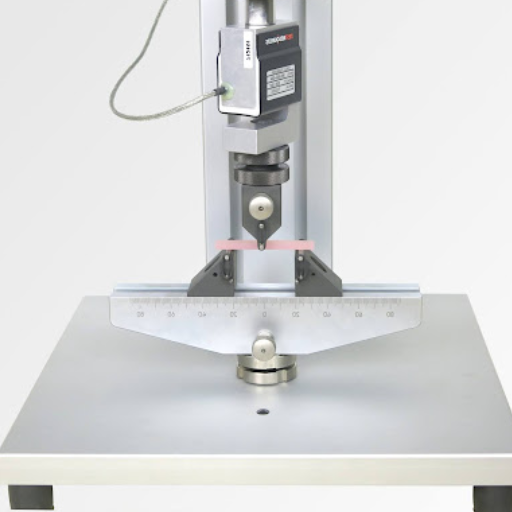

How Does a Bend Test Machine Work?

A bend test machine functions by exerting a calibrated force on a specimen until it bends and exhibits some degree of deformation. Generally, the process starts with controlling the specimen’s position by placing it in a clamp or lathe, applying a forward counteracting movement at a specific velocity through a plunger or roller, and applying a predetermined angle of attack. The machine records the amount of flexure the material undergoes along with values of its flexural strength, ductility, and tendencies to fracture. Such parameters define the material’s mechanical values along with other performance indicators for stress testing.

Components of a Bend Test Machine

Tell me more about some devices on the bend test machine.

A bend test machine comprises the following basic components with their respective functions:

1. Load Frame

Lasst but not least, The load frame is the machine’s main component structure. It gives the aid and support necessery to apply force for a test. Modern frames are manufactured from steel and aluminum alloys as these materials have a very high resistance for large loads and minimum deflection.

2. Loading Mechanism

The bending force is applied using a loading mechanism which can come in the form of a plunger, roller slu, or a motorized system. With these applications, the material is applied with force in the right angle, speed, and controlled pressure.

Advanced Machines are also capable of integrating motorized systems that can meticulously control the amount of force applied as well as the speed at which it’s applied.

3. Support Anvils

These devices keep the material to be bended stationary while executing the test. This can be tailored to particular specimens of sizes and shapes. An adjustable set of anvils made from hard materials like steel maintains their shape after many tests, increases their effectiveness.

4. Force Sensor

Every specimen has an appropriate force sensor made which makes sure to grab the correct load is applied for the specimen test. Of course, this sort of sensor must be complex enough to guarantee the accuracy of test results. Other systems that make use of capture sensors that have dynamic measuring capabilities use strain-gauge or piezoelectric force-responsive materials that change on the amount of force applied.

5. Systems for Measuring Displacement

This system captures the movement of the material as it bends, noting it against the exact deformation values. High accuracy and contactless measures use laser or digital encoders.

6. Software and Controller

Today’s bend test machines come with programmable controllers alongside associated software for automating tests and data collection. Such systems enable test parameter definition, monitoring test progression, and results analysis while testing in real time. Software extensions usually include functions for comprehensive report generation, data trend analysis, and visualization.

7. Safety Features

Bend test machines are fitted with protective shields, emergency stop buttons, and overload safety systems for operator and equipment safety. These features mitigate the risk of damage to the specimen, machine parts, and the operator in case of unforeseen circumstances.

8. Device for Clamping the Specimen

Clamping devices are designed to ensure stability while applying the bending forces to the test specimen. Uncontrolled movements have been minimized using adjustable clamps that fit various specimen sizes.

9. Heating Devices (Optional)

Other machines have built-in heaters to maintain specific testing temperatures for certain materials. These features help to create an environment of elevated temperatures, thereby checking the endurance of the material under thermal stress.

Recent Developments and Trends in Bend Test Machinery

Automation: Recent developments focus on fully automated systems to improve the consistency and effectiveness of the tests. Now, AI result interpretation tools are being used that require little to no human input for analysis.

High Strength Testing: Modern machinery accommodates the testing of ultra-high-strength materials like advanced composites and newer alloys.

Compact Designs: New models have been developed that are light and portable to meet the requirements of onsite material testing while maintaining functionality and precision.

Portability has been incorporated into these units without compromising their accuracy, enhancing versatility in various fields, including construction and aerospace. With the latest components and technological development, modern bend test machines guarantee precision, reliability, and versatility.

Operating the Universal Testing Machine

Operating a universal testing machine (UTM) requires adhering to systematic procedures. These steps ensure accurate, reproducible, and safe material testing. Below are the general guidelines and tips on using a UTM effectively:

Preparation and Setup:

Confirm that the machine is installed on a sturdy surface and is assembled according to the manufacturer’s guidelines. The machine must be calibrated before use.

For the chosen material and the type of test (e.g., tensile, compression, bending), select a matching load cell and grips/fixtures.

Standards for specimen dimensions issued by certifying bodies like ASTM International and ISO should be checked against the specimen. (e.g., ASTM D638 for polymers)

Specimen Positioning:

Material specimens must be adjusted within the grips or fixtures of the machine to ensure no misalignment would cause uneven distribution of forces that could be acted upon on the specimen. Specimens must be securely aligned.

The specimen must not move during the test. Permissible specimen motion must be available in the boundary conditions for free displacement.

Configuring parameters under specimen testing:

Using the computer integrated within the machine, set up the parameters necessary for the specific test being performed (e.g: test speed, preload, or targeted force/strain). Ensure machine-accurate readings by complying with test specifics.

A set of particulars unique to the material like gauge length and cross-section area geopolitical compliance to standards suffices for compliance with regulations consider per-test data precision.

After the specimen placement procedure is completed:

The machine may be activated. Based on the type of test, force or displacement will be applied, and the actuator will begin applying power or displacement.

Watch measurements like active strain, stress, and elongation progress on either the machine’s display or its software in real time.

Data Collection and Evaluation:

UTM software will indicate and record the measurement of significantly important yield strength, ultimate tensile strength, modulus of elasticity, and elongation at break.

Export detailed reports in CSV or PDF and analyze the results with sophisticated graphing software.

After Test Procedures:

Carefully detach the specimen from the machine; remember to analyze the fracture or failure modes for further insights.

Shut down the machine to cleanse the grips which may now sustain contaminants.

Current industry studies suggest that modern UTMs incorporate load cells configured to control forces with measurement accuracy of ±0.5% or better which strengthens reliability. For example, the study on tensile testing of structural steel (ASTM A36) demonstrated average yield strengths in the range of 250 MPa to 400 MPa that were consistent with expectations, reflecting the UTM’s reliability. In addition, contemporary models come equipped with AI reporting, technologies that ease the test execution.

UTM are universal testing machines applicable in any industry. They can effectively evaluate the material properties if advanced technology are used together with the structured guidelines through out the sessions along the engineering and research work.

What are the Test Standards for Bend Tests?

Standards are set relating to conducting bend tests to maintain uniformity and precision in determining the ductility and strength of a material. Two commonly cited documents are:

ASTM E290– This document describes the conducting of guided bend tests on metallic materials and contains specifications on specimen preparation, describes step by step the testing, and states the bend angles that are deemed acceptable.

ISO 7438– This international document describes the procedures for bend tests on metallic materials with particular emphasis on standardization of the measurement and the analysis of the results.

The documents guarantee consistency of the measurement as well as comparability of the tests that are done under the same conditions.

Overview of Standard Test Methods for Bending

Bending tests are pivotal for evaluating ductility, strength, and material traits for any type of stress, particularly for metals. They are important in construction, automotive, and aerospace industries to evaluate the quality and performance of construction materials. Recent developments and changes in methods of bending tests include use of more precise equipment along with updated standards to guarantee consistent and reliable results.

Key Changes:

Equipment Modernization

Modern bending test machines have new software and high-resolution sensors, enabling accurate measurement of bend angles, force application, and failure points in real-time. Digital data recording enhances precision, and analysis becomes simple and traceable.

Enhanced Material Testing Standards

ISO 7438 still serves as a critical international benchmark for the bend tests of metallic materials. Recent technical changes put greater emphasis on stricter control of specimen dimensions and controlling test environment factors before testing in order to minimize variability.

New in ASTM E290-22 are optional advanced methods for high-strength alloys and composites which impose additional strain and bend tolerances.

Wider Scope

Bending tests are now being adapted for multi-layered composites and 3D printed metals. These complex materials need changes in the amount of force, speed, and the application of stress in order to accurately assess the performance.

The most recent trends in the data are given as follows:

As per the latest reports from the industries:

The requirement related to the evaluation of high-yield strength metals has increased by twenty-five percent over the past three years due to their increased use in heavy-duty infrastructure spending.

Research indicates that the implementation of automated bending systems lowers the testing time by about forty percent, leading to increase in the laboratory productivity and throughput while maintaining accuracy.

Experimental work done using the updated protocols of ISO 7438 shows a 15% enhancement in repeatability for high-stressed materials.

These developments highlight the importance of being aware of the latest methodologies and technologies concerning bending test application and developments. They also point out the importance of international standards, ISO and ASTM compliance with regard to quality and testing outcome comparability.

Ensuring Compliance with Test Standards

Fulfilling test compliances like ISO 7438 and ASTM E290 is paramount in ensuring consistency, dependability, and integrity in executions of a bending test. These standards contain all-encompassing comprehensive processes regarding methodology, conditions of the tests, and how information is recorded for analyzing a material’s behavior under stress.

Research shows that modern technological advancements allow for the attainment of higher accuracy in laboratory testing through automated testing systems. Updated bending test machines, for instance, now contain digital sensors that measure deflection and stress of up to 0.01 mm. These more modern systems are programmed to produce detailed reports by ISO and ASTM standards, further increasing trustworthiness by minimizing human errors.

Moreover, the application of new calibration procedures has proven to raise compliance rates with the standard curves remarkably. Research indicates that compliance with recalibration frequencies as stipulated by ISO 7500-1 has, in some cases, increased system reliability by 20%. This not only ensures compliance but enables the swift detection and correction of equipment deviations before they breach the set non-compliance thresholds.

Furthermore, the use of modern data management tools improves tracing and documentation of test results. Such tools facilitate the storage, retrieval, and sharing of test information by ISO and ASTM standards. This compliance streamlines the processes of audits or third-party evaluations and improves transparency and reliability.

Equally important is keeping track of the updates to these standards. For example, the latest updates focus on the consideration of environmental factors like specific temperature and humidity maintenance for operational consistency during testing. If these practices are followed in conjunction with imposed guidelines, laboratories will be able to improve compliance practices while yielding accurate, high-quality results.

Role of Quality Control in Bend Testing

Bend testing accuracy requires attention to detail to maintain quality control as it relate to testing accuracy, precision, reliability, and overall credibility. Flexible bend testing is among the preferred methods of ductility testing due to its simplicity, yet it is equally demanding in quality control procedures. The maintenance of bend testing machines alongside strict observance of test standard operating procedures guarantees compliance with industry benchmarks, for instance, ASTM E290 or ISO 7438.

One key metric will be concerning equipment quality control through calibration checks and test machine calibrations. Use of properly calibrated equipment for measurement implies there will be fewer measurement errors such as in force or angle of bend measurement. Various literature, Wright (2000) as cited in Richards et al. (2013), shows sufficient frequency of machine calibrations considerably reduces testing error rates by 20% when compared to machines that are not consistently maintained and calibrated.

In the control stage, maintaining the cleaning policy for the test specimen and the specimen mounting surface should be implemented. Elevations in temperature and humidity can alter specimen surfaces, thus influencing the specimen surfaces. Research shows alterations in some specimens of almost 15% during changes to temperature, with test runtime tends to cause test data range consistency issues such as gathering incongruent results for elasticity or yield point data.

Recording and analyzing testing processes is equally important. Reporting of high quality, thorough, and complete detail scratch enables easier performance evaluation of trends and deviations from defined standards. Real-time monitoring of laboratory testing conditions using data acquisition systems permits tagging of pre-defined corrective action windows for immediate outlier identification.

Concerning modern industrial expectations, quality control has a marked impact on the accuracy and reliability of laboratories through the exacting attention to equipment accuracy, environmental consistency, procedure authenticity, and data monitoring during bend testing.

Reference Sources

- Estimating Deformation and Strain Responses During Circuit Board Bend Testing

This paper describes the procedures for achieving the targeted deformation and strain profiles during bend testing.

- Lowering Measurement Error in the Three

Point Bend Test Incorporating a Linear Gradient Correction Model – This thesis works on the refinement of the analyses related to three point bend tests by formulating a correction model.

- The Reverse Bending Test: An Indirect Technique of Bauschinger Effect Measurement in Metal Sheets

This work focuses on the reverse bend test as an approach to measuring material characteristics such as the Bauschinger effect.

Frequently Asked Questions (FAQs)

Q: What is a bend test and why is it important?

A: A bend test is a mechanical test used to determine the ductility and soundness of a material by subjecting it to bending stress. It is important because it helps evaluate the ability of a material to withstand bending forces without fracture, which is crucial for quality control and ensuring the material’s mechanical properties meet required standards.

Q: How do you perform a bend test using a bend test machine?

A: To perform a bend test using a bend test machine, the test specimen is placed on two supports and a bending force is applied at the midpoint or at multiple points, depending on the type of bend test. The machine applies a controlled bending load until the specimen fractures or deforms to a specified angle, allowing evaluation of its ductility and bend strength.

Q: What are the different types of bend tests?

A: The different types of bend tests include the 3-point bend test, 4-point bend test, free bend test, and guided bend test. Each type varies in how the bending force is applied and the support setup, affecting how the test evaluates the material’s resistance to bending and deformation.

Q: What is the difference between a 3-point bend and a 4-point bend test?

A: In a 3-point bend test, the bending force is applied at a single midpoint between two supports, creating a concentrated stress point. In a 4-point bend test, the force is applied at two points, providing a more even distribution of bending stress across the specimen. This allows for a more comprehensive assessment of the material’s bending behavior and fracture toughness.

Q: How does a bend test evaluate weld quality?

A: A bend test evaluates weld quality by testing the weld joint’s ability to withstand bending without defects such as cracks or incomplete fusion. This is often done using a weld bend test, where the test sample includes the weld area, ensuring the weld’s ductility and soundness meet the necessary standards.

Q: Why is specimen preparation crucial in performing a bend test?

A: Specimen preparation is crucial because the test specimen must have a uniform size, shape, and surface condition to ensure accurate and reliable results. Proper preparation helps eliminate variables that could affect the outcome, such as surface defects, which could lead to premature fracture or incorrect evaluation of the material’s bending strength and ductility.

Q: What standards are typically followed for conducting a bend test?

A: Bend tests typically follow specific test standards, such as ASTM or ISO, which provide guidelines on test procedures, specimen dimensions, and test setups. These standards ensure consistency and reliability in testing and allow results to be comparable across different laboratories and testing conditions.