From strength and ductility to elasticity, tensile testing is a basic step in material property characterization. Whether you’re an experienced professional or just making your first steps in material testing, one prerequisite will always be the mastery of operating a tensile test machine in order to derive correct data from a test. This blog post introduces the basic elements of tensile testing, with more focus on the testing machine and method, while also offering best practices for obtaining accurate measurements. By its conclusion, you should have understood how tensile testing is done and the reason why it plays a vital role in evaluating the activity of materials in several industries.

Introduction to the Tensile Test

Definition of a Tensile Test

Tensile testing refers to the study of the test in which a specimen is placed under tension to study the response of materials to the actual condition. Controlled forces are applied to a specimen until it breaks; the test determines properties like tensile strength, elongation, and modulus of elasticity. These properties give a clear understanding of the application of a material under real-working conditions, mainly in construction, automotive, and aerospace industries.

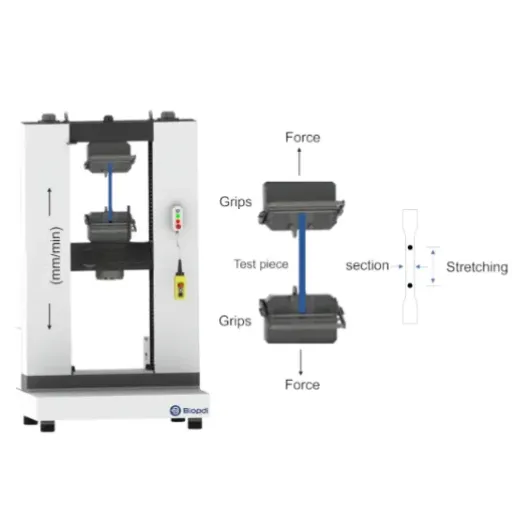

Tensile testing machines are the basic apparatus on which such tests are performed. It consists of a requisite frame for loading, grips which hold the specimen in place, and a load cell which records the force applied. Stretching the material at an established rate prevents test conditions from varying, thereby providing very exact results. Data is collected throughout the process, analyzed afterward to depict the mechanical behavior of materials, including resistance to tensile force and deformation inflicted upon it prior to failure.

In the testing tensile results are so indispensable in selecting materials and quality control. Engineers and manufacturers use these results to decide whether a material should be used for a particular application or meets the standards of its industry. These tests also go toward creating safer and better-working products with knowledge of the exact strength limits of the materials, thereby ensuring reliability and durability in different applications.

Purpose and Importance of Tensile Testing

Tensile testing machines play an important role in establishing accurately the mechanical properties of materials. In these machines, a controlled tensile load is applied to the material sample, stretching it to the point of fracture. This gives the test wire tensile values of maximum stress, elongation, and modulus of elasticity, which are very important in the determination of the performance of materials under stress. By studying these performances, engineers come to realize more clearly about the capabilities and limitations of the material.

Key Benefits of Tensile Testing Machines:

- Ensure adherence to industry standards and regulations

- Verify material specifications for safety, reliability, and performance

- Support quality control in manufacturing processes

- Enable material development and innovation

This machine serves purposes other than testing for data collection. It ensures a level of adherence to industry standards and regulations. The materials were tested on these machines by manufacturers to ascertain their specifications in regard to safety, reliability, and performance. Tensile testing machines are used in industries such as construction, aerospace, automotive, and manufacturing in industries where materials have to be strong and durable. They act as the backbone in ensuring that the products manufactured are of the highest quality and are useful.

In addition to this, tensile testing machines have an important function in the development and innovation of materials. Researchers perform tests on the new materials with the intent of modifying their properties for a given use. For example, the testing may determine whether a material is fit for lightweight structures or heavytrain work. This inclination will promote technologies and product designs that will provide safer, efficient, and modern solutions in different areas.

Applications in Various Industries

Aerospace Industry

Tensile testing stands for determining composites and other alloys that comply with demanding safety standards and are durable. Engineers endeavor to build components that can withstand extreme conditions such as severe pressure changes and high temperatures.

Construction Industry

These machines are employed for testing and checking the strength and reliability of materials such as steel, concrete, and polymers. These materials are subjected to tests relative to a heavy load and environmental stressors, thus harnessing the safety of structures and infrastructure.

Automotive Industry

Tensile testing is performed to analyze the materials that are being used to produce a vehicle. Metals, plastics, and other materials are tested for strength, elasticity, and impact resistance to make vehicles light weight for fuel efficiency and strong for safety.

Tensile Testing Equipment

Tensile Testing Machines

Tensile testing machines, or universal testing machines, are those precious instruments that check the tensile mechanical properties of materials. They analyze characteristics such as tensile strength, elongation, and elasticity, thus providing crucial data on material selection, quality control, and product development. By putting a material piece under constantly controlled tension, the machine provides clear insight into how the material will react when various loads are applied to it, thus assuring safety and reliability in several applications.

Key Components of Tensile Testing Machines:

- Load Frame: Holds the specimen firmly during testing

- Load Cells: Measure the force being applied on the sample very accurately

- Extensometers: Record deformation and elongation accurately

- Digital Interface: Allows for automated testing procedures and analysis of results

These are the reply machines for industries like automotive, construction, aerospace, and manufacturing. These machines make sure that lightweight and durable materials are developed for better performance and to meet the standards of the industry. These tensile testing machines provide reproducible and reliable test results whether working with metals, plastics, textiles, or composites, making them an indispensable tool in advancing material science and engineering.

Grips and Fixtures

Grips and fixtures form an indispensable part of a tensile testing machine owing to their task to keep the test specimen during the procedure and to allow accurate and precise results. Such components shall have to be chosen carefully according to the materials to be tested, the shape of the specimen, and the kind of testing to be done. Properly selected grips and fixtures will not only act against any slippage of the specimen but, at the same time, do not cause any localized damage, which can alter the verification results.

| Grip Type | Best For | Characteristics |

|---|---|---|

| Wedge Grips | Metal testing | Strong clamping force, reliable for rigid materials |

| Pneumatic Grips | Soft/flexible materials | Gentle clamping for textiles and plastics |

| Compression Plates | Compression testing | Specialized for compression force applications |

| Bending Fixtures | Flexural testing | Designed for bend and flexural strength tests |

Choosing the right grips and fixtures is very important if one is to obtain reliable outcomes under reproducible circumstances. Some of the factors to be looked at in the selection process would be grip capacity, clamping surface, and mechanical properties of the material. By designing grips and fixtures in accordance with the specimen and test conditions, tensile testing machines provide an accurate characterization of relevant material properties such as tensile strength, elongation, and modulus of elasticity, hence advancing in material performance and behavior.

Sample Preparation Tools

Sample preparation is regarded as a vital step for tensile testing in order to minimize inconsistent outcomes. An improper sample would prevent the tensile testing machine from properly displaying the material properties under controlled conditions. It becomes important to make sure specimens conform to standardized dimensions and shapes to curb variability and improve test outcome reproducibility.

Cutting Equipment

Shape materials to specific test specimen sizes and geometries

Polishing Equipment

Provide smooth surface finish and remove imperfections

Precision Measurement

Check dimensional compliance with testing standards

The best preparation of samples will aid tensile testing to extract relevant material information about strength, elasticity, and ductility. Such knowledge is very important for product design, manufacturing, and quality assurance, where knowledge of material behavior under stress is crucial. Perhaps the most valuable contribution of sample preparation is to the overall success and accuracy of tensile testing.

How to Perform a Tensile Test

Step-by-Step Testing Procedure Using a Tensile Testing Machine

- Prepare the Sample: Carefully select and prepare the material sample for dimensional requirements, if necessary, and keep tensile testing standards in mind. Ensure the sample is free of defects or irregularities that may influence the test results’ accuracy. The most usual forms are dog bone and rectangular cross-sections.

- Set Up the Tensile Testing Machine: Calibrate the tensile testing machine first, to guarantee accurate measurements. Forcing the specimen into the grips of the machine, it should be aligned so as not to induce bending or twisting in the course of testing. Set the parameters required by the test-specimen including gauge length, crosshead speed, and load requirement into the control system of the machine.

- Conduct the Test: Start the machine and subject the specimen to tensile force in a controlled manner. The tensile testing machine elongates the specimen until it yields. Monitor on the software system or disturb display; the key data such as the stress, strain, and elongation levels are recorded in the form of stress-strain curves, providing detailed information on the mechanical properties of the tested materials.

- Analyze the Results: Interpret the data at the end of a test to evaluate the ultimate tensile strength, yield strength, and elongation at break properties of the specimens. Use the stress-strain curve to identify elastic and plastic deformation regions in the material. These results are very useful in describing the behavior of the material under tension and its suitability for different applications.

- Document Findings: Summarize all testing data and record everything, such as environmental conditions, sample dimensions, and test parameters. This will ensure that with sufficient documentation, there will always be a traceable source that can serve for quality control or further analysis.

An adherence to these procedures will prove to be the backbone of accurate and reliable determinations for engineers to base their decisions on with regard to material performances and applications.

Setting Up the Sample

During tensile testing, it is important to have the material specimen prepared and mounted as per requirements to provide a true and reliable result. Choose a specimen that meets the body’s dimensional and geometric requirements according to a present standardized testing method, e.g., ASTM or ISO. From the factors influencing testing are material type, thickness, and shape of the specimen being tested, which must be compatible with the tensile testing machine set.

After the specimen is ready for testing, securely mount it within the grips or fixtures of the testing machine. The specimen should be properly aligned to prevent any misloading and uneven distribution of stresses during testing. The proper alignment ensures premature failure is avoided and that the applied force is evenly shared among the length of the specimen. Double-check that the grips are tightened just right: tight enough to hold the sample in place but not tight enough as to cause any sort of deformation or damage to the sample within the grasping area.

Set all conditions of testing, including loading rate, gauge length, and test environment, as per the test selected. These conditions shall then be entered into the testing machine, ensuring consistency with the existing material properties and testing objectives. Lastly, check the calibration of the machine to ensure its accurate working. Set up the sample in the right way, and along with the testing conditions, the data regarding the tensile strength of the material, elongation, and other mechanical properties retrieved shall be reliable.

Understanding Tensile Properties

Tensile Strength and Yield Strength

Tensile Strength

Tensile strength denotes the greatest stress that can be imposed on a material while stretching or pulling it before breaking. It shows how much force a material can bear without failure, therefore being an essential property in designing objects subjected to pulling forces. Measures of tensile strength are force per area, i.e., megapascals (MPa) or pounds per square inch (psi).

Yield Strength

Yield strength, in contrast, is the stress at which the material appears to deform plastically. Before this particular stress value, the material behaves elastically, where it can return to its original shape upon release of the applied load. Once this stress value is exceeded, the material permanently changes under stress.

The tensile testing machine is fundamental in determining the tensile strength and the yield strength. The machine performs controlled, steadily increasing tensile force on the specimen while monitoring the stress and strain in the specimen. This data are plotted on a stress-strain curve from which an engineer can determine the exact yield strength and ultimate tensile strength of the material. These values serve as an important parameter in study, selection, and application of materials in quality control and for structures.

Ultimate Tensile Strength

Ultimate tensile strength (UTS) is the maximum stress or force that can be imposed upon the material while it is being stretched up to the point of breaking. Of course, it is one of the important properties tested in a tensile test. It gives engineers an idea of how the material behaves under stress and is utilized in designing components that need to bear high loads without failing.

UTS is defined as force per unit area and is thus measured in Pascals (Pa), pounds per square inch, and so forth. Directly measuring the ultimate tensile strength of a material involves first clamping the specimen under the grips of a tensile testing machine. The machine then slowly applies the tensile load until the rupture point is reached. The forces applied and deformations undergone by the material are recorded to create the stress-strain curve on the basis of the two variables. The concerned point at the peak of the curve is called ultimate tensile strength, where engineers may judge and compare materials for their applications.

The knowledge of ultimate tensile strength of materials is very much required in engineering fields like construction, aeronautics, and manufacturing. It is always ensured that the materials selected can safely bear the expected loads and can reliably perform in service to minimize chances of failure. This data is used by engineers to develop products and structures that are both safe and efficient, ensuring good performance and durability throughout the lifespan.

Modulus of Elasticity

Essentially, a tensile testing machine is used to understand whatever mechanical aspect a material exhibits under tension and, mainly, in strength, ductility, and elasticity. The machine operates by subjecting the test material to a stretching force in controlled magnitude until either deformation or fracture occurs. Data are then recorded with time; these include the applied force and extension of the material, which engineers apply toward understanding material behavior under stress.

Components of a Tensile Testing Machine:

- Load Frame: Setup that supports the specimen and applies tensile force

- Grips/Fixtures: Hold the specimen to prevent slippage during testing

- Force Measuring System: Combined with digital software for accurate data storage

These are graphed as stress-strain curves, which are used to analyze and determine the yield strength, ultimate tensile strength, and modulus of elasticity. Tensile testing machines find utility in a host of industries, such as automotive, building, aerospace, and manufacturing. They help to ensure that materials comply with safety and quality standards so that they are less prone to structural failure. Engineers can obtain accurate, reproducible data under standardized conditions that directly allow for the design and manufacture of efficient and high-quality products.

Avoiding Common Mistakes

Challenges in Tensile Testing

Specimen Preparation Issues

Test specimens that are not prepared as per the required standards or in the required dimensions will therefore give varying or inaccurate results. Specimens must be free of defects, have uniform shape, and be cut to exact specifications.

Misalignment Problems

Misalignment of the test specimen may create extra stress points or uneven tension, thereby producing wrong data. Operators should properly mount the specimen and do regular calibration of the testing equipment.

Environmental Factors

Temperature, humidity, or external vibrations can change test results. A material could behave very differently at extreme temperatures, so testing should be done in controlled environmental conditions.

Best Practices for Accurate Results

Key Best Practices:

- Regular Calibration: Proper calibration and maintenance of tensile testing machines are essential in securing precise measuring operation. Calibration must take place periodically so that the machine remains accurate and reliable.

- Controlled Environment: Operating the tensile testing machine under controlled environmental conditions is crucial. Maintain unchanging temperature and humidity levels throughout testing.

- Standardized Procedures: Follow proper sample preparation procedures and standardized testing requirements. Specimens must be devoid of defects and conform to standard requirements.

The testing of machine calibrations should confirm industry standards and permitted guidelines so that a temptation for distortion of the results might be minimised. For instance, a bit too much heat or cold could sometimes induce a change in the property of a material and would thus yield an inconsistent or outright inaccurate result. The manifestation of an environment ensures that the tests can be compared with each other concerning the repeats.

Operators themselves ought to follow safety measures and standardized working procedures in order to realize reliable date and reduce hazards during testing.

Examples of Common Errors

- Improper Sample Preparation: One of the most common mistakes that can be observed during tensile testing is improper sample preparation. If samples are improperly cut or possess some surface defects, then they will give inaccurate or inconsistent results. The standard samples must have acceptable dimensions and shapes prescribed by the relevant standards so that the reliability of the testing procedure is ensured.

- Incorrect Machine Calibration: Calibration errors in the tensile testing machine would produce gross variation in test results. If the equipment has not been calibrated as specified by the manufacturer or by industry standards, then such measurements taken do not truly describe the characteristics of the test material. Hence, regular calibration and maintenance of the machine should be done to maintain its accuracy.

- Misalignment of Specimens: Another common problem results when a specimen is not placed correctly in the grips of the machine. Due to misalignment, the stress distribution during testing is not uniform. Hence, the specimen either fails prematurely or gives erroneous results. Proper orientation of the sample is, therefore, required to avoid these errors.

By addressing these common errors, operators can carry out tensile testing in a more consistent and accurate manner and provide trustworthy data for material evaluation.

Frequently Asked Questions (FAQ)

What is a tensile test?

A tensile test is the name given to a mechanical test in which a test specimen is subjected to a tensile force until it breaks. The tensile strength, yield strength, and elongation provide vital data for understanding the tensile behavior of the material.

How do you perform a tensile test?

In order to perform a tensile test, first, a tensile test specimen must be prepared according to the standards. The specimen is then fixed into the tensile testing machine that pulls with a controlled velocity until the specimen fails. In the process, data consisting of applied force and good distance changes are recorded.

What instruments are used in tensile strength testing?

The basic equipment involved in tensile strength testing is a tensile testing machine into which two grips are mounted to hold the specimen. An extensometer is attached to record the change in length during the test. For data reduction, testing software may be used.

What are the types of tensile tests?

The tensile tests may be classified mainly as uniaxial tensile tests which study the response of a material when it is subjected to tension in one direction only. Others may include dynamic tensile tests and creep tests that monitor the material behavior under varied conditions.

What is the ultimate tensile strength?

The ultimate tensile strength is the load carrying capacity of a material under tension right before the failure. It is an important parameter tested during tensile strength testing, which essentially defines the ability of a material to hold a load before breaking.

What is the importance of the yield strength of the material?

Yielding point is when plastic deformation begins in the material. Engineers find it important to know the yield strength so that they can adequately assess safe loading conditions of a material utilized in structures and components.

How does an extensometer operate in a tensile test?

An extensometer is a device used in tensile tests to measure the change in length of a specimen as tensile loading is applied to it. The device provides direct measurements on elongation from which engineering strain is computed and stresses are analyzed on the stress-strain curve.

What happens when a tensile specimen yields?

When a tensile specimen breaks, it indicates that the material has reached its ultimate tensile strength. The testing system records the major strength properties of the material at failure, and the obtained data is used to further evaluate the strength and durability of materials and the relevant tensile properties.

References

- NextGen Material Testing – How to Perform a Tensile Test

A step-by-step guide on performing tensile stress tests, including setup and procedure. - Zeiss – Tensile Test: Technology & Industrial Application

An overview of tensile testing, its purpose, and how it evaluates material strength and deformation. - Victor Testing Machine – Tensile Test Procedures

Detailed instructions on conducting tensile tests, including equipment setup and material considerations.